Preparation technology for water-soluble resveratrol particle, and product and application thereof

A technology of resveratrol and preparation process, which is applied to the preparation process of water-soluble resveratrol granules and their products and application fields, can solve the problems of low bioavailability in industrial applications and the like, and achieves improved bioavailability and solubility. , the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

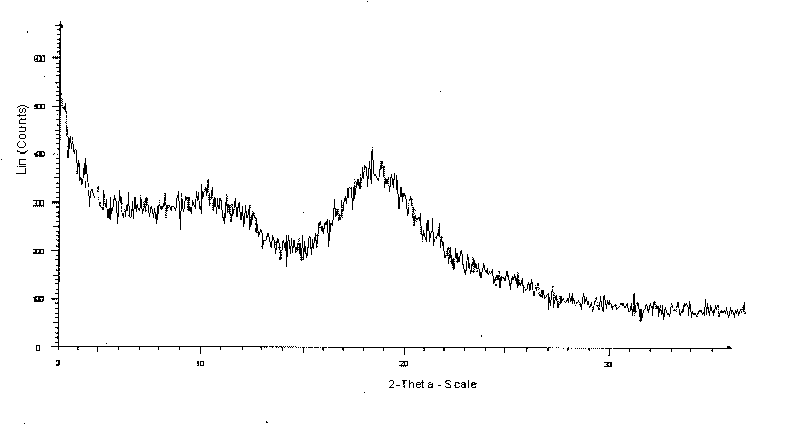

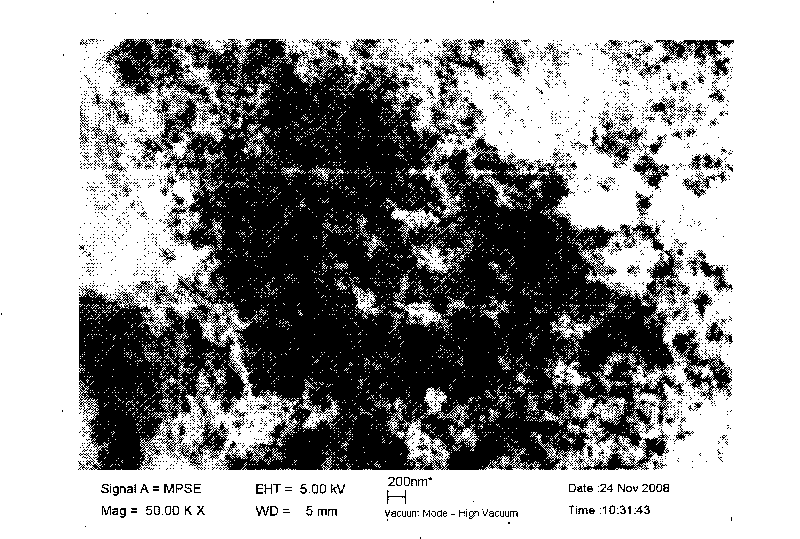

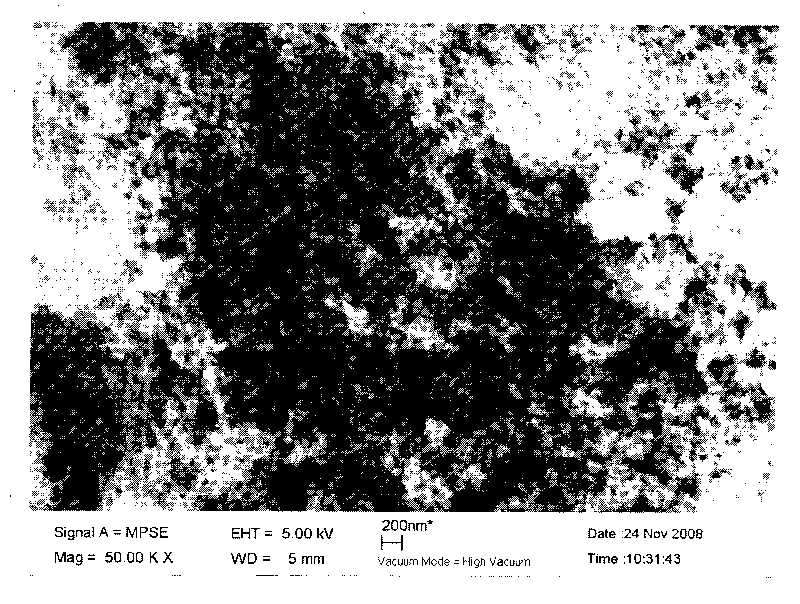

[0019] Embodiment 1: a kind of water-soluble resveratrol particle, its preparation method is as follows:

[0020] (1) Dissolve 0.26 g of resveratrol in 20 ml of absolute ethanol, add a small amount of stabilizer, and ultrasonically oscillate to dissolve into a light khaki transparent solution to obtain a drug sample solution;

[0021] (2) Install the supercritical fluid crystallization equipment and install a 1500um nozzle, set the supercritical fluid system, the pressure of the crystallization kettle is 120bar, the temperature is 35°C, and the flow rate is 10g / min. After the equipment is running stably, pass the high-efficiency liquid at 0.5ml / min The phase pump is pumped into the supercritical system at a constant speed. After the sample injection is completed, the residual liquid in the pipeline is washed with absolute ethanol, and the 2 After flushing with fluid for 20 minutes, adjust the pressure to atmospheric pressure, and naturally cool down to room temperature, and th...

Embodiment 2

[0024] Embodiment 2: a kind of water-soluble resveratrol particle, its preparation method is as follows:

[0025] (1) Dissolving 0.20 g of resveratrol in 20 ml of methanol, adding a small amount of stabilizer, ultrasonically oscillating and dissolving into a light khaki transparent solution to obtain a drug sample liquid;

[0026] (2) Install the supercritical fluid crystallization equipment and install a 1500um nozzle, set the supercritical fluid system, the pressure of the crystallization kettle is 120bar, the temperature is 41°C, and the flow rate is 15g / min. After the equipment is running stably, pass the high-efficiency liquid at 0.5ml / min The phase pump is pumped into the supercritical system at a constant speed. After the sample injection is completed, the residual liquid in the pipeline is washed with absolute ethanol, and the 2 After flushing with fluid for 20 minutes, adjust the pressure to atmospheric pressure, and naturally cool down to room temperature, and the ob...

Embodiment 3

[0029] Embodiment 3: a kind of water-soluble resveratrol particle, its preparation method is as follows:

[0030] (1) Dissolve 0.26 g of resveratrol in 20 ml of acetone, add a small amount of stabilizer, and ultrasonically oscillate to dissolve into a light khaki transparent solution to obtain a drug sample liquid;

[0031] (2) Install the supercritical fluid crystallization equipment and install a 400um nozzle, set the supercritical fluid system, the pressure of the crystallization kettle is 150bar, the temperature is 38°C, and the flow rate is 30g / min. After the equipment is running stably, pass the high-efficiency liquid at 0.5ml / min The phase pump is pumped into the supercritical system at a constant speed. After the sample injection is completed, the residual liquid in the pipeline is washed with absolute ethanol, and the 2 After flushing with fluid for 20 minutes, adjust the pressure to atmospheric pressure, and naturally cool down to room temperature, and the obtained p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com