Preparation method of biological soil solidifier

A biological soil and curing agent technology, applied in the field of biological soil curing agent preparation, can solve the problems of poor soil porosity and permeability, low compressive strength, etc., and achieve the effect of improving soil strength and hardness and promoting sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

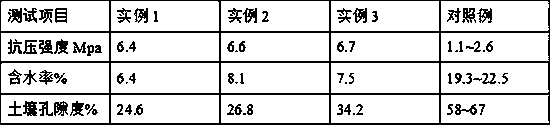

Examples

example 1

[0036] Bacteria: the freeze-dried powder of Bacillus pasteurianus and Bacillus subtilis used in the present invention.

[0037] Preparation of solid medium: by mass parts, get 6 parts of glucose, 15 parts of tryptone, 5 parts of yeast extract, (NH4) 2 HPO 4 0.2 parts, KH 2 PO 4 0.1 parts, MgSO 4 •7H 2 0.04 parts of O, 12 parts of NaCl, 10 parts of agar, 0.05 parts of phosphate buffer, 1000 parts of water, sterilized at 121°C for 20 minutes, pH 5.4.

[0038] Preparation of liquid medium: remove the agar components and keep the other components unchanged.

[0039] Preparation of catalytic enzyme fermentation medium: by mass parts, 0.5 parts of peptone, 10 parts of glucose, KH 2 PO 4 0.05 parts, Na 2 HPO 4 2 parts MgSO 4 •7H 2 0.02 parts of O, 5 parts of urea, pH 6.8, urea was sterilized under ultraviolet light for 30 minutes and then mixed.

[0040] Quartz sand pretreatment: use standard quartz sand (containing 99.7% quartz), uniform gradation (gradation coefficien...

example 2

[0047] Bacteria: the freeze-dried powder of Bacillus pasteurianus and Bacillus subtilis used in the present invention.

[0048] Preparation of solid medium: by mass parts, get 8 parts of glucose, 20 parts of tryptone, 10 parts of yeast extract, (NH4) 2 HPO 4 0.4 parts, KH 2 PO 4 0.4 parts, MgSO 4 •7H 2 0.1 part of O, 15 parts of NaCl, 20 parts of agar, 0.1 part of phosphate buffer, 1000 parts of water, sterilized at 121°C for 20 minutes, pH 5.8.

[0049] Preparation of liquid medium: remove the agar components and keep the other components unchanged.

[0050] Preparation of catalytic enzyme fermentation medium: by mass parts, 0.8 parts of peptone, 12 parts of glucose, KH 2 PO 4 0.1 parts, Na 2 HPO 4 5 parts, MgSO 4 •7H 2 0.05 parts of O, 10 parts of urea, pH 7.2, urea was sterilized under ultraviolet light for 30 minutes and then mixed.

[0051] Quartz sand pretreatment: use standard quartz sand (containing 99.7% quartz), uniform gradation (gradation coefficient ...

example 3

[0058] Bacteria: the freeze-dried powder of Bacillus pasteurianus and Bacillus subtilis used in the present invention.

[0059] Preparation of solid medium: by mass parts, get 7 parts of glucose, 17.5 parts of tryptone, 7.5 parts of yeast extract, (NH4) 2 HPO 4 0.3 parts, KH 2 PO 4 0.25 parts, MgSO 4 •7H 2 0.07 parts of O, 13.5 parts of NaCl, 15 parts of agar, 0.75 parts of phosphate buffer, 1000 parts of water, sterilized at 121°C for 20 minutes, pH 5.6.

[0060] Preparation of liquid medium: remove the agar components and keep the other components unchanged.

[0061] Preparation of catalytic enzyme fermentation medium: by mass parts, 0.65 parts of peptone, 11 parts of glucose, KH 2 PO 4 0.07 parts, Na 2 HPO 4 3.5 parts, MgSO 4 •7H 2 0.35 parts of O, 7.5 parts of urea, pH7, urea was sterilized under ultraviolet light for 30 minutes and then mixed.

[0062] Quartz sand pretreatment: use standard quartz sand (containing 99.7% quartz), uniform gradation (gradation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com