Active sludge floatation thickening device and method for membrane biological reaction tank process

A membrane bioreactor and activated sludge technology, which is applied in dehydration/drying/thickened sludge treatment, etc., can solve the problems of high dependence on operation, high failure rate of automatic control system, and many operating points, so as to reduce the type and quantity of equipment , low self-control dependence, and reduced operating points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

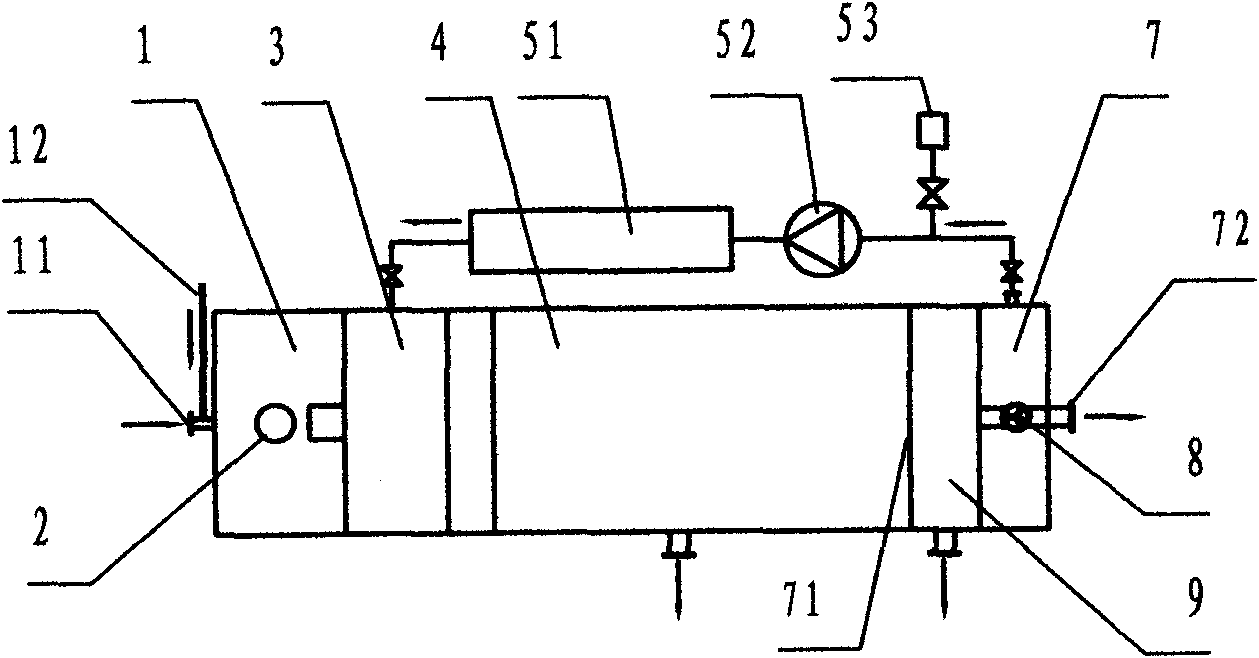

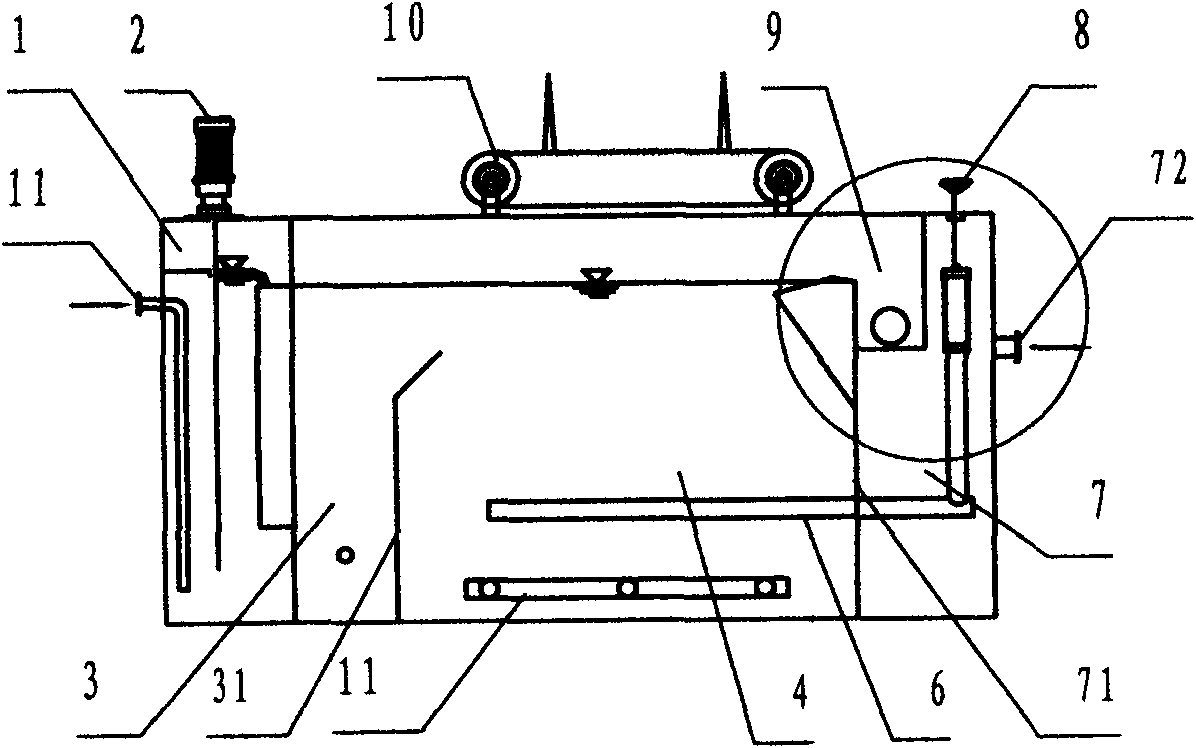

[0027] The present invention will be further described below in conjunction with accompanying drawings and examples: Example: Refer to accompanying drawings: A sewage treatment plant in this city has been transformed into the largest municipal sewage treatment plant of membrane bioreactor process in China in 2008. However, through the existing sludge thickening process and drum thickening + belt dewatering integrated machine treatment in the factory, the mud cake moisture content of the remaining sludge can only be controlled at 82% to 88%, and cannot be reduced to below 80%, which increases the The cost of sludge transportation and disposal has become an urgent problem to be solved.

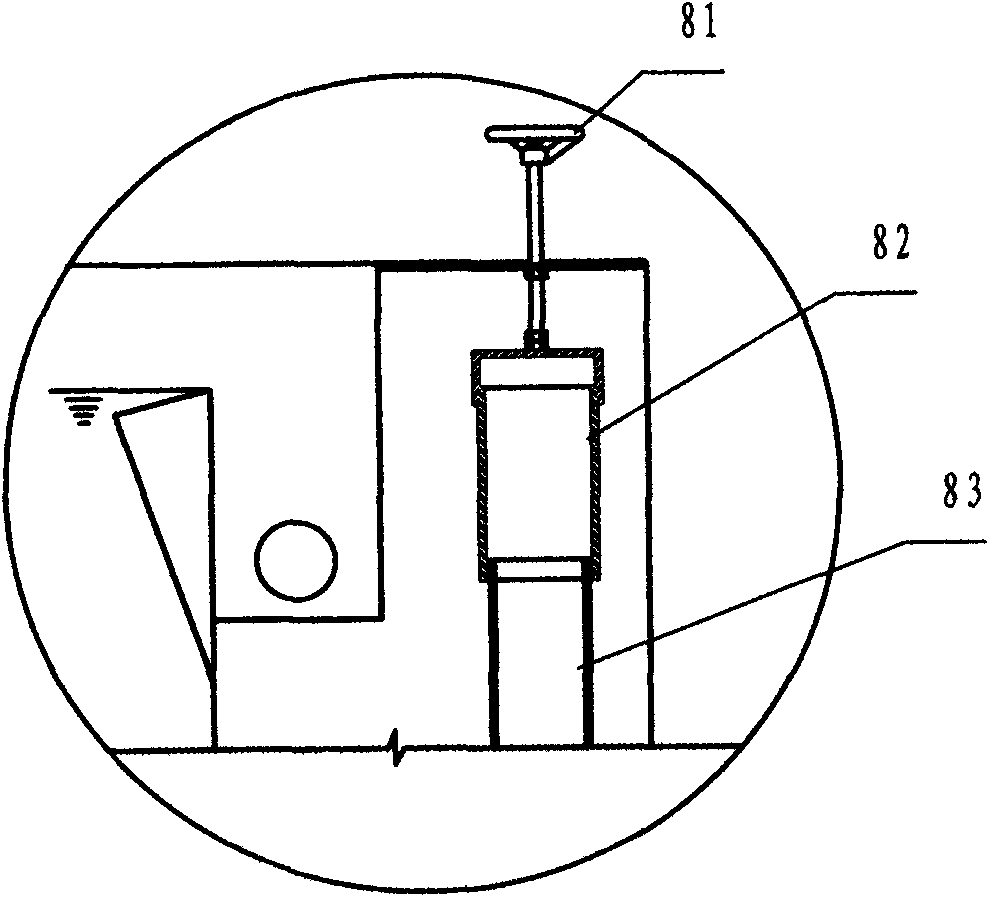

[0028]The present invention has been carried out in this factory, and the air flotation concentration device of the activated sludge of membrane bioreaction tank process is provided with integrated air flotation concentration tank, referring to accompanying drawing: be provided with flocculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com