Plaster mold dewaxing and roasting process

A roasting process, plaster mold technology, applied in the direction of manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of low energy consumption, many defects, etc., and achieve rapid dehydration, less internal defects, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

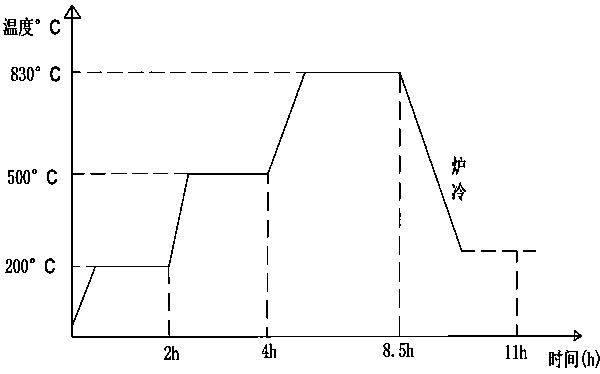

[0018] Embodiment 1: a kind of gypsum mold dewaxing roasting process, comprises the steps:

[0019] S1: put into the dewaxing roasting furnace after drying the gypsum mold containing wax fat;

[0020] S2: raising the temperature in the dewaxing roaster to 180°C-220°C and keeping it warm for two hours;

[0021] S3: After step S2, the temperature in the dewaxing roaster is further raised to 480°C-520°C, and the temperature is kept for two hours;

[0022] S4: heat up the dewaxing roaster after step S3, raise the temperature to 800°C-850°C, and keep the temperature for 4.5 hours;

[0023] S5: furnace cooling the dewaxed and roasted inner plaster mold after step S4.

[0024] In the above design, rapid dehydration, dewaxing and roasting of the gypsum mold can be achieved by quickly increasing and keeping the temperature in the dewaxing roasting in stages. The crystal water in the plaster mold can be gradually eliminated by holding the temperature at 180°C-220°C for two hours. 480 ...

Embodiment 2

[0028] Embodiment 2: a kind of gypsum mold dewaxing roasting process comprises the following steps:

[0029] S1: put into the dewaxing roasting furnace after drying the gypsum mold containing wax fat;

[0030] S2: raising the temperature in the dewaxing roaster to 200°C and keeping it warm for two hours;

[0031] S3: After step S2, the temperature in the dewaxing roaster is further raised to 480°C-520°C, and the temperature is kept for two hours;

[0032] S4: heat up the dewaxing roaster after step S3, raise the temperature to 800°C-850°C, and keep the temperature for 4.5 hours;

[0033] S5: furnace cooling the dewaxed and roasted inner plaster mold after step S4.

[0034] In the above design, the rapid dehydration, dewaxing and roasting of the plaster mold can be realized by rapidly increasing and maintaining the temperature in the dewaxing roasting. The water of crystallization in the plaster mold can be gradually eliminated by holding the temperature at 200°C for two hour...

Embodiment 3

[0035] Embodiment 3: a kind of gypsum mold dewaxing roasting process comprises the following steps:

[0036] S1: put into the dewaxing roasting furnace after drying the gypsum mold containing wax fat;

[0037] S2: raising the temperature in the dewaxing roaster to 180°C-220°C and keeping it warm for two hours;

[0038] S3: After step S2, the temperature in the dewaxing roaster is further raised to 500° C., and the temperature is kept for two hours;

[0039] S4: heat up the dewaxing roaster after step S3, raise the temperature to 800°C-850°C, and keep the temperature for 4.5 hours;

[0040] S5: furnace cooling the dewaxed and roasted inner plaster mold after step S4.

[0041] In the above design, the rapid dehydration, dewaxing and roasting of the plaster mold can be realized by rapidly increasing and keeping the temperature in the dewaxing roasting in stages. The crystal water in the plaster mold can be gradually eliminated by holding the temperature at 180°C-220°C for two h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com