FDM-3D printer external-connected color mixer

A FDM-3D, printer technology, applied in 3D object support structure, additive manufacturing, processing heating elements, etc., can solve problems such as unfavorable printers, and achieve the effect of saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

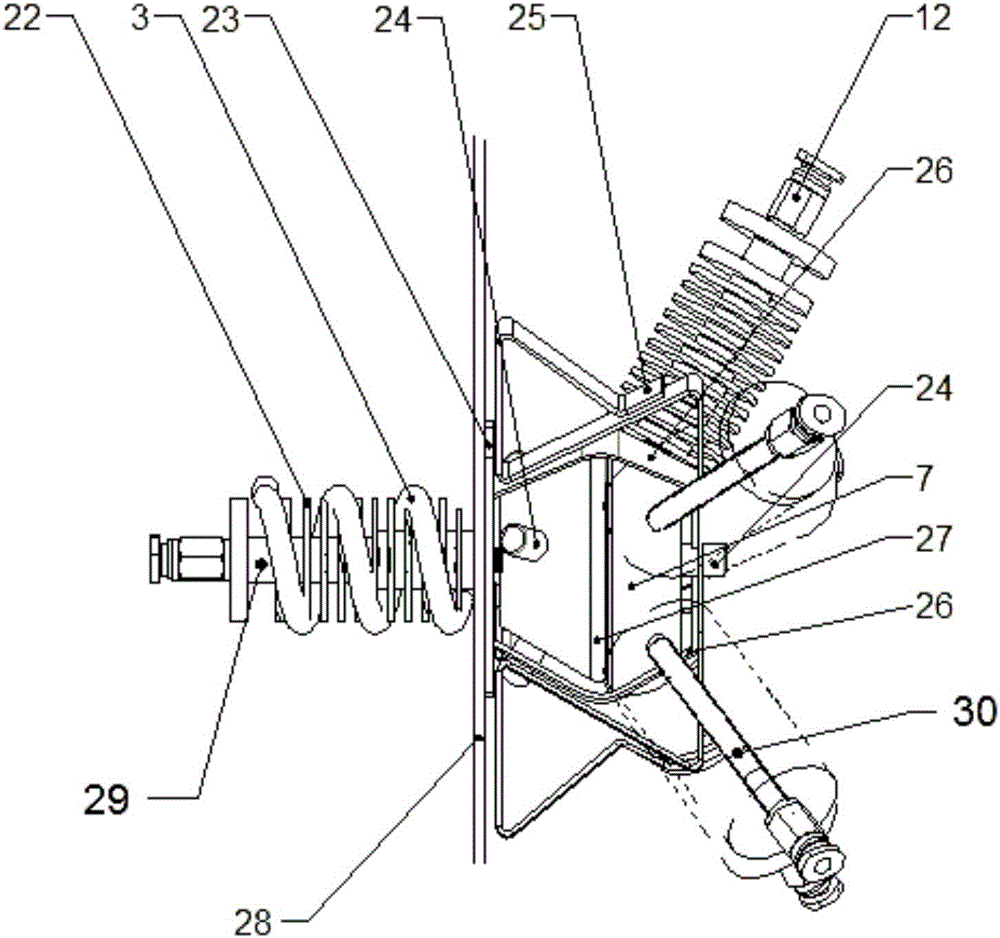

[0058] When mixing colors of PLA materials, the temperature at the center of the heating melting chamber 7 is controlled at 190-200° C., and the temperature at the inlet and outlet is less than 50° C. Among them, the red and blue wire feeding speeds are 20mm / s respectively. Other color wires stop wire feeding. Finally, a mixed-color purple is formed, and the silk output speed is 40mm / s.

Embodiment 2

[0060] When the ABS material is mixed, the central temperature of the heating and melting chamber 7 is controlled at 220-230° C., and the temperature of the inlet and outlet is 60-50° C. Among them, the red wire feeding speed is 20mm / s, and the yellow wire feeding speed is 10mm / s. Other color wires stop wire feeding. Finally, a mixed color reddish-orange is formed, and the wire output speed is 30mm / s.

Embodiment 3

[0062] When mixing colors of PA materials, the central temperature of the heating melting chamber 7 is controlled at 250-280°C, and the temperature at the inlet and outlet is 75-65°C. The yellow wire feeding speed is 30mm / s, the blue wire feeding speed is 20mm / s, and the black wire feeding speed is 10mm / s respectively. All the other color wire materials 15 stop wire feeding. Finally, a dark yellow-green mixed color is formed, and the silk output speed is 60mm / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com