Method for synthesizing monodisperse samarium-doped rare earth cerium oxide nanocrystal

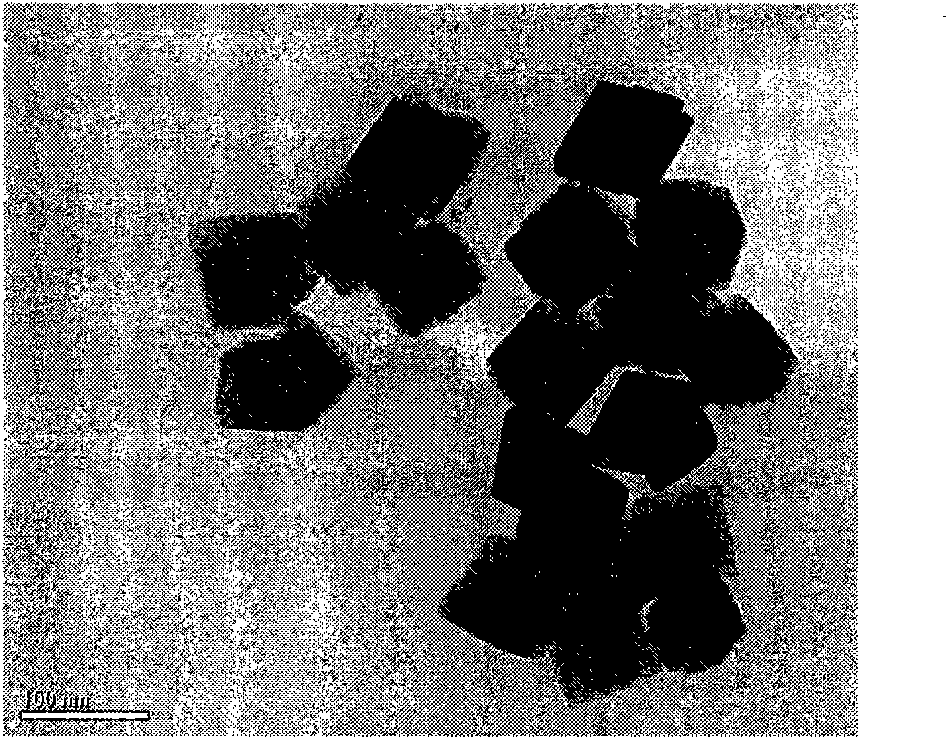

A technology of rare earth oxidation and monodispersity, applied in the direction of rare earth metal compounds, chemical instruments and methods, nanotechnology, etc., can solve the problems of grain agglomeration and adhesion, difficult control of size, grain coarsening, etc., and achieve highly uniform particle size , Precise composition and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

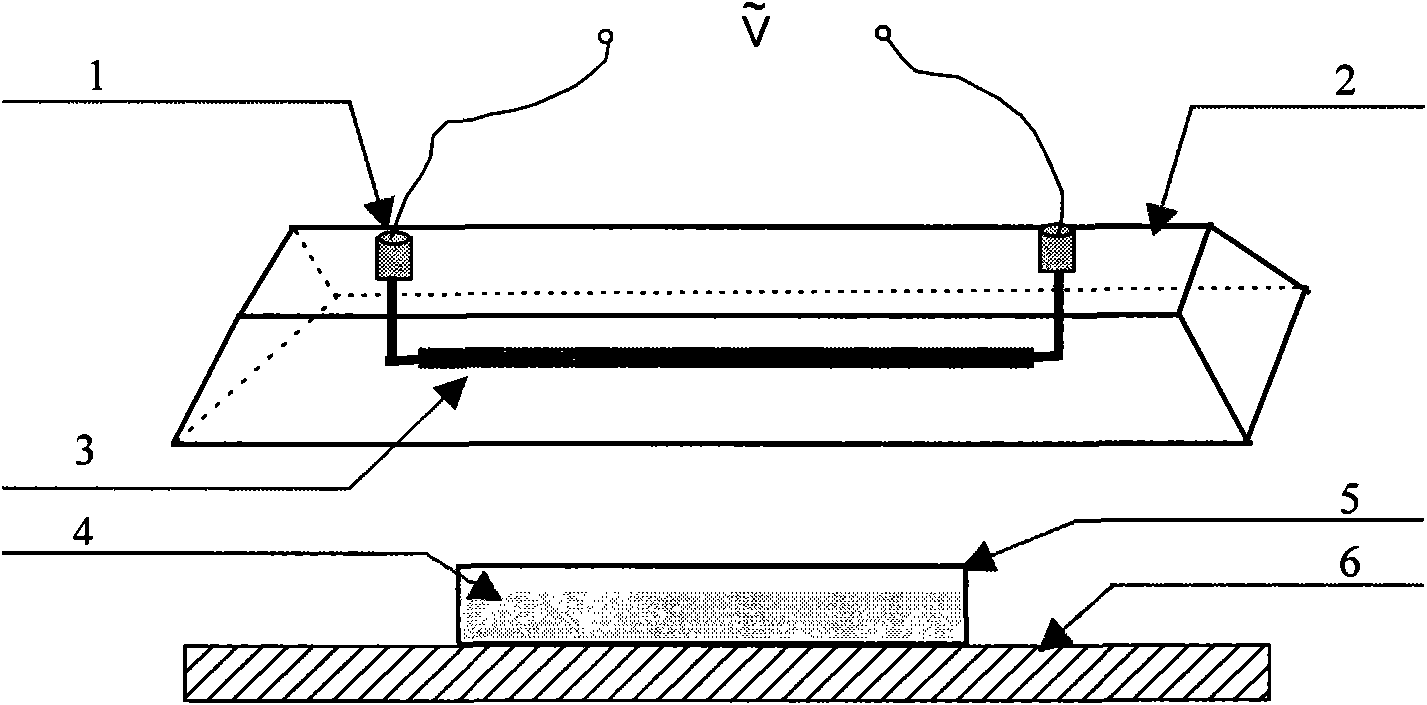

Method used

Image

Examples

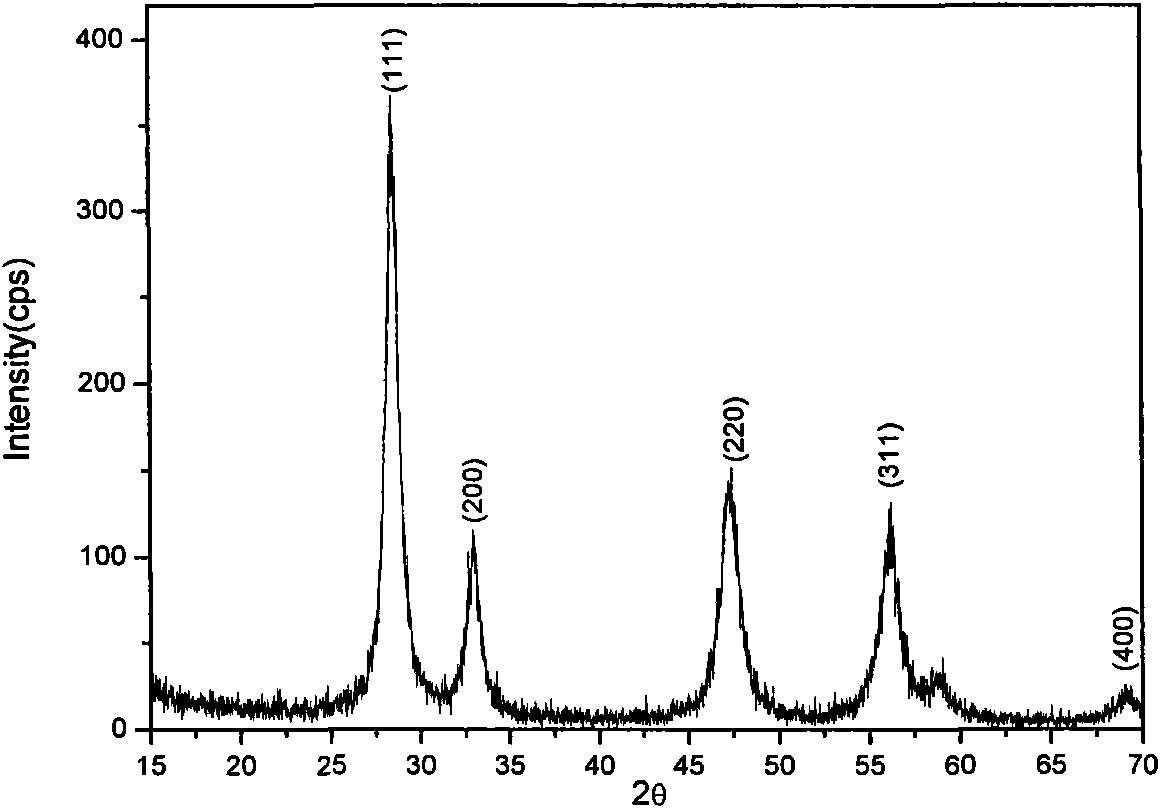

example 1

[0031] A. With soluble nitrate Ce(NO 3 ) 3 and Sm(NO 3 ) 3 As the starting material, according to samarium doped cerium oxide (Ce 0.8 SM 0.2 o 2-δ ) stoichiometric ratio, accurate preparation of aqueous solution ([Ce 3+ ]=0.40mol / L, [Sm 3+ ]=0.10mol / L), in the obtained aqueous solution, add urea by the ratio of the molar weight of precipitating agent urea (Ur) and the metal ion molar weight in the aqueous solution to be 1.5:1, namely Stir to dissolve to obtain an aqueous phase solution.

[0032] B. Measure n-octane (n-octane) 100.0ml as oil phase, take cetyltrimethylammonium bromide (CTAB) as surfactant [CTAB]=0.25mol / L, n-butanol (n -butanol) is a co-surfactant, and the amount of addition is 5: 1 according to the ratio of the amount of its substance to CTAB, and 8.0ml of the above-mentioned prepared aqueous phase solution containing metal ions and precipitant of a certain volume is added dropwise, that is, the oil phase The volume ratio to the aqueous phase is 12.5:...

example 2

[0036] A. With soluble nitrate Ce(NO 3 ) 3 and Sm(NO 3 ) 3 As the starting material, according to samarium doped cerium oxide (Ce 0.8 SM 0.2 o 2-δ ) stoichiometric ratio, accurate preparation of aqueous solution ([Ce 3+ ]=0.40mol / L, [Sm 3+ ]=0.10mol / L), in the obtained aqueous solution, add urea by the ratio of the molar quantity of precipitant urea (Ur) and the metal ion molar quantity in the aqueous solution to be 4.0:1, namely stirring and dissolving to obtain an aqueous phase solution;

[0037] B. Measure n-octane (n-octane) 100.0ml as oil phase, take cetyltrimethylammonium bromide (CTAB) as surfactant [CTAB]=0.50mol / L, n-butanol (n -butanol) is a co-surfactant, the amount of addition is 5: 1 according to the ratio of the amount of its substance to CTAB, and 10.0 ml of the above-mentioned prepared aqueous phase solution containing metal ions and precipitating agent of a certain volume is added dropwise, that is, the oil phase With a volume ratio of 10:1 to the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com