Porous calcium silicate filter material for water treatment

A porous calcium silicate and water treatment technology, which is applied in the fields of application, filtration and separation, household appliances, etc., can solve the problems of high cost and affecting the promotion and use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

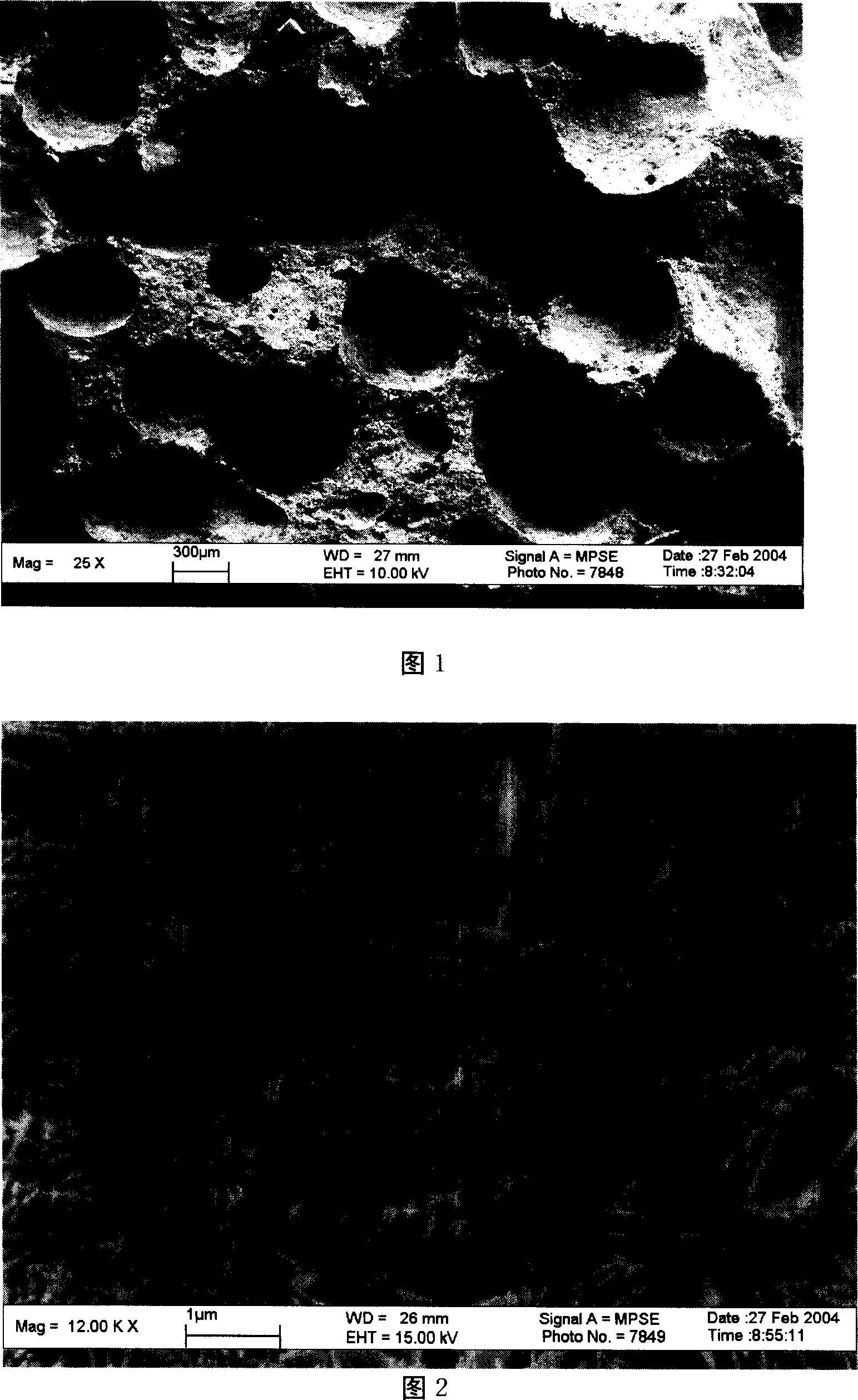

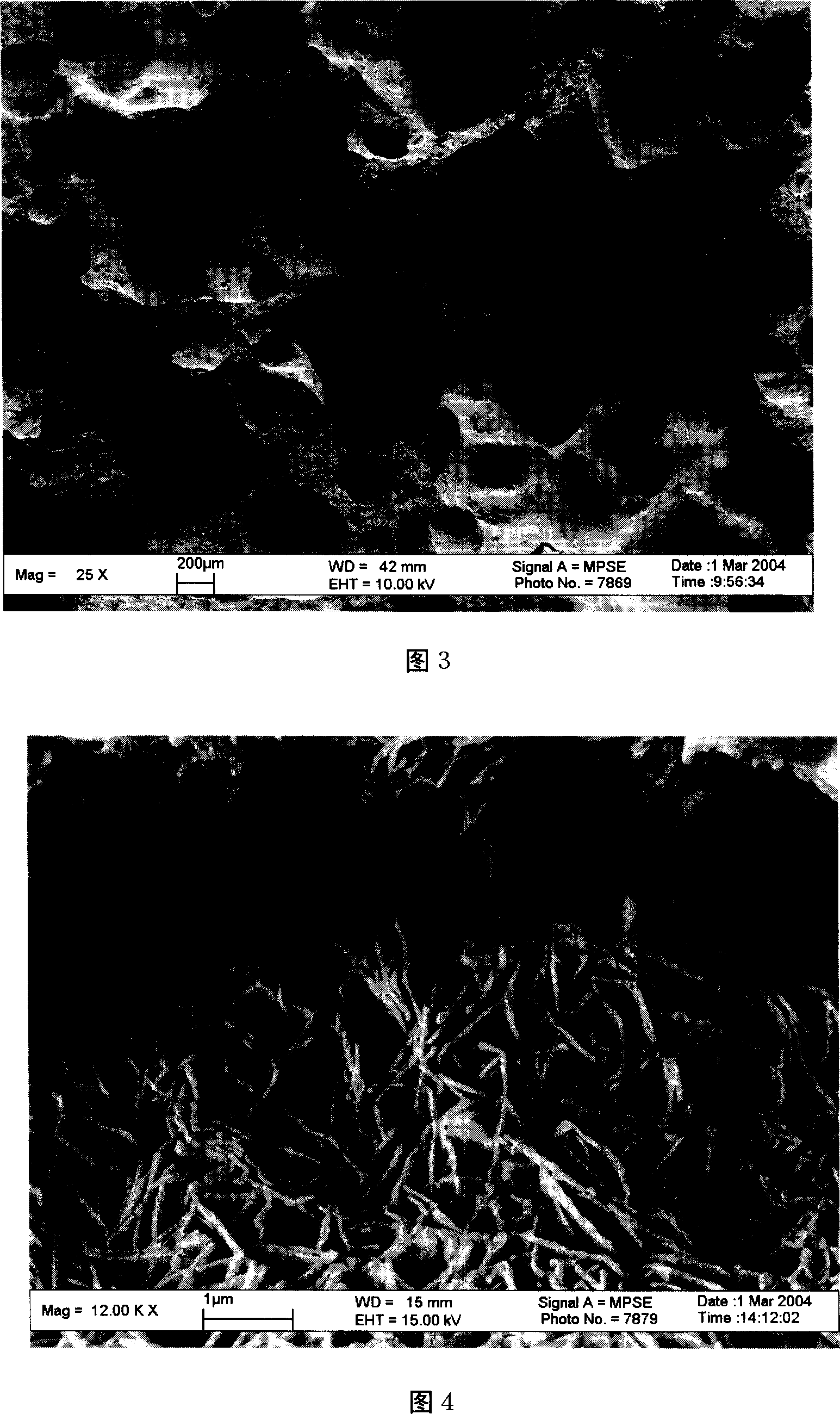

Image

Examples

Embodiment 1

[0018] Filter material formula is as follows (by weight):

[0019] Powdered Quartz (SiO 2 )--50

[0020] Ordinary Portland cement (label 425 or 425R)--10~26

[0021] Powdered calcium oxide (CaO)--5~26

[0022] Powdered gypsum (CaSO 4 )--5

[0023] Aluminum (Al) powder--0.15~0.22

[0024] water - appropriate amount

[0025] Powdered Quartz (SiO 2 ) can use domestic powdered thymite or weathered quartz, diatomaceous earth, etc.; calcium oxide (CaO) can also be Ca(OH) obtained by first dissolving quicklime with water 2 substitute.

[0026] a. Coagulation

[0027] powdered quartz (SiO 2 ), ordinary Portland cement (label 425 or 425R), gypsum (CaSO 4 ), calcium oxide (CaO) and aluminum (Al) powder mixing;

[0028] Add water and stir quickly and then pour it into the mold.

[0029] b. Steam foam curing

[0030] Move the mold and semi-finished products to a 60°C steamer for foaming, curing, and curing for about 8 hours.

[0031] c. High temperature and high pressure st...

Embodiment 2

[0043] Tests have shown that adding an appropriate amount of seed crystals to the formula can quickly crystallize Tobermorite and inhibit the formation of Xonotlite. The finished product has better filtration performance, and at the same time, it can be used for waste and save costs. Therefore, 1-5% by weight of seed crystals can be added into the formula.

[0044] After crushing the finished sawing scraps obtained in Example 1, use them as seed crystals. After adding 1 to 5% by weight of seed crystals in the formula, the tobermorite (Tobermorite) in the finished product increases by 3 to 6 %.

[0045] The method of adding crystal seeds to increase the proportion of tobermorite in the finished product is only effective for the formula with pyrymite as raw material, and the effect is not obvious or basically ineffective for the formula with weathered quartz or diatomite as raw material, but it can still reach The purpose of waste utilization and cost saving.

[0046] Compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com