Preparation method of Sn-beta molecular sieve nanocrystal

A nanocrystal and molecular sieve technology, applied in molecular sieves and alkali exchange compounds, nanotechnology, nanotechnology and other directions, can solve the problems of complex preparation and synthesis process, difficult to scale production, difficult waste water treatment, etc. Industrial production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method for Sn-beta molecular sieve nanocrystals, comprising the steps of:

[0027] (1) Mix 0.006~0.042g of tin tetrachloride and 4.21-20g of tetraethylammonium hydroxide with a mass fraction of 35% solution, stir at a stirring speed of 450~550r / min for 1~24h, and then Dry at 40-90°C for 120-720 minutes to prepare a mixed solution;

[0028] (2) After mixing the mixed solution with 1 to 5 g of white carbon black evenly, the mixture is prepared;

[0029] (3) Move the mixture into an open glass vessel, then transfer it to the lining of the hydrothermal reaction kettle, add 2-10ml deionized water to the lining of the hydrothermal reaction kettle, and prevent the water outside the glass vessel from entering the In a glass vessel; under steam-assisted conditions, after adjusting the hydrothermal reaction kettle to 100-200 ° C, the mixture is crystallized, and the crystallization time is 6-72 hours to obtain a crystalline product;

[0030] (4) Naturally cool the...

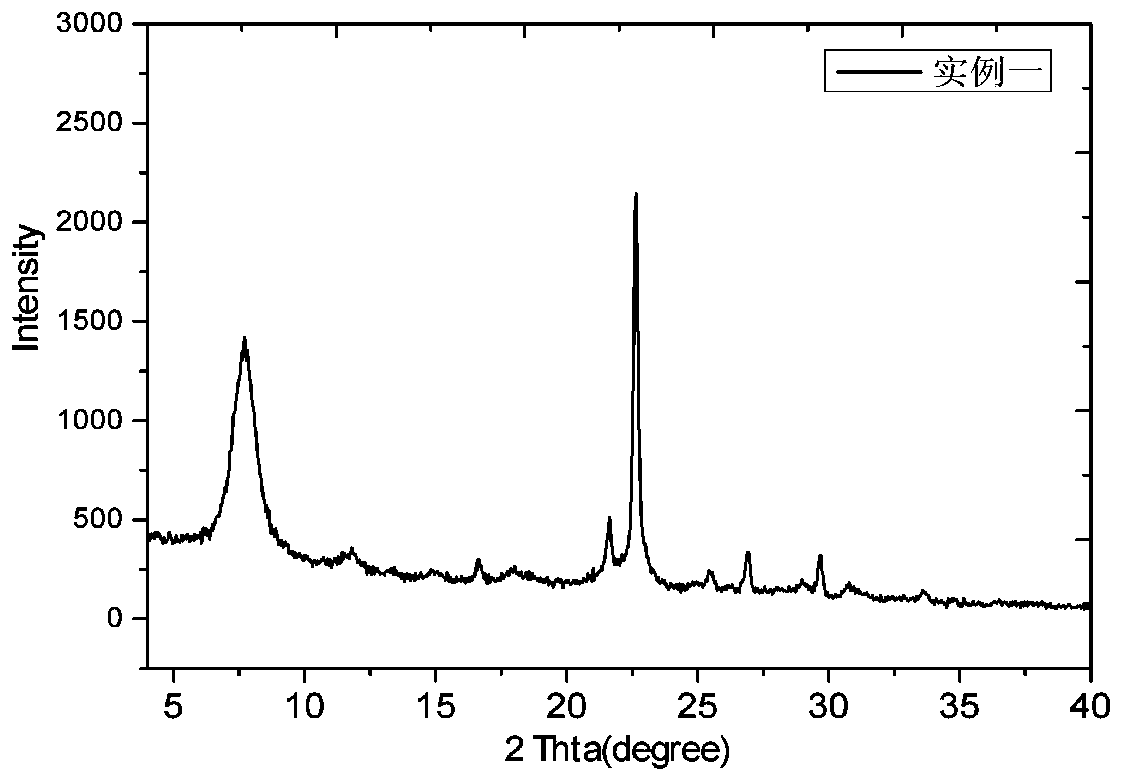

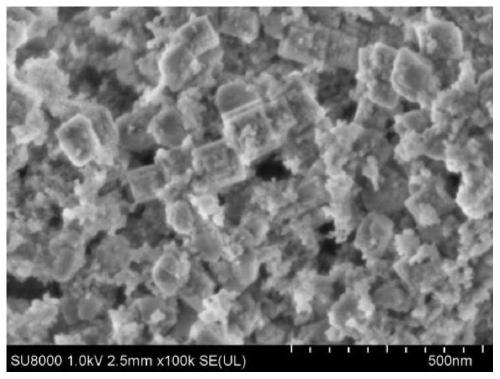

Embodiment 1

[0033] A preparation method for Sn-beta molecular sieve nanocrystals, comprising the steps of:

[0034] (1) Mix 0.021g of tin tetrachloride and 4.21g of tetraethylammonium hydroxide with a mass fraction of 35% solution, stir for 12h at a stirring speed of 500r / min, and then dry at 70°C for 120min to obtain mixture;

[0035] (2) After the white carbon black of mixing solution and 4.8g is mixed uniformly, make mixture;

[0036] (3) Move the mixture into an open glass vessel, then transfer it to the lining of the hydrothermal reaction kettle, add 2ml of deionized water to the lining of the hydrothermal reaction kettle, and prevent the water outside the glass vessel from entering the glass vessel Middle; under steam-assisted conditions, after adjusting the hydrothermal reactor to 160 ° C, the mixture was crystallized, and the crystallization time was 20 hours, and the crystallized product was obtained;

[0037] (4) Naturally cool the crystalline product to room temperature, then...

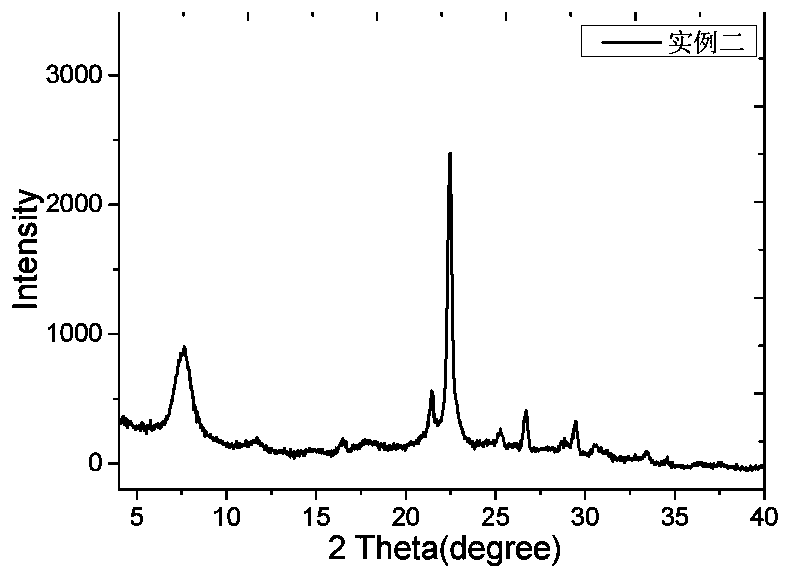

Embodiment 2

[0040] A preparation method for Sn-beta molecular sieve nanocrystals, comprising the steps of:

[0041] (1) Mix 0.042g of tin tetrachloride and 8.42g of tetraethylammonium hydroxide with a mass fraction of 35% solution, stir for 1h at a stirring speed of 450r / min, and then dry at 65°C for 180min to obtain mixture;

[0042] (2) After mixing the mixed solution with 5g of white carbon black, the mixture is prepared;

[0043] (3) Move the mixture into an open glass vessel, then transfer it to the lining of the hydrothermal reaction kettle, add 5ml of deionized water to the lining of the hydrothermal reaction kettle, and prevent the water outside the glass vessel from entering the glass vessel Middle; under steam-assisted conditions, after adjusting the hydrothermal reactor to 165 ° C, the mixture was crystallized, and the crystallization time was 26 hours, and the crystallized product was obtained;

[0044] (4) Naturally cool the crystalline product to room temperature, then was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com