Method for preparing small granulated SAPO-34 molecular sieve, product prepared through method, and use of product

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problem of large grain size and achieve high crystallinity and high catalytic performance of the product Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

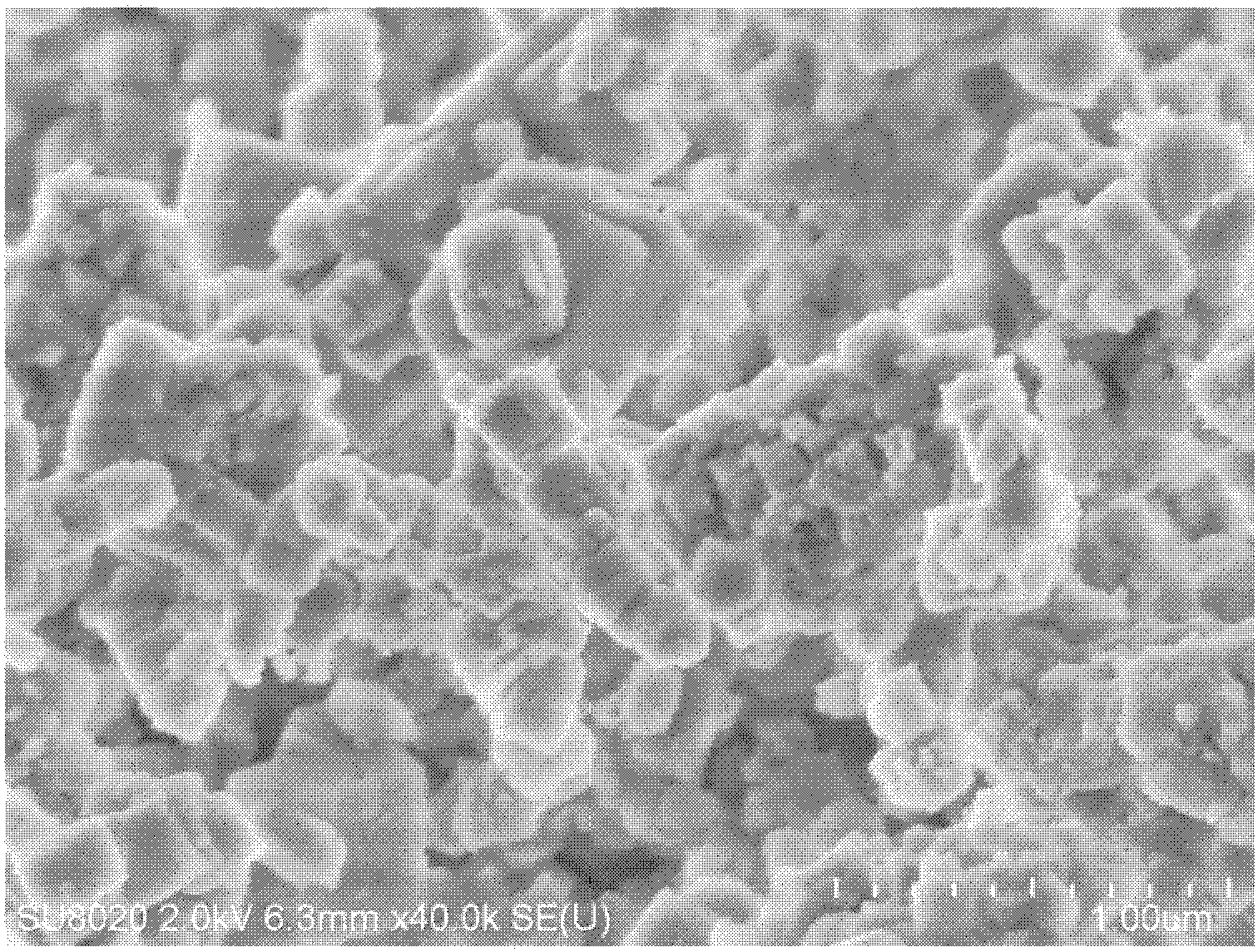

Image

Examples

Embodiment 1

[0071] Example 1: Preparation of SAPO-34 molecular sieve samples (a)~(f) as raw materials

[0072] As the raw material of SAPO molecular sieve, in addition to using SAPO-34 molecular sieve purchased from Zhengda Energy Materials (Dalian) Co., Ltd. (with a particle size ranging from 1 to 10 μm), the following SAPO-34 is also prepared by conventional hydrothermal crystallization method A sample of molecular sieve is used as a raw material.

[0073] Sample (a )

[0074] Add 132g pseudo-boehmite (Al) to the 2L hydrothermal crystallization synthesis kettle 2 O 3 Mass content 72%), 218.5g phosphoric acid (phosphoric acid mass content is 85%), 87g silica sol (SiO 2 Mass content 28%), 290g triethylamine and 740g water, stir evenly, then seal, heat up to 210°C with stirring, and crystallize for 24h. The solid product is separated by centrifugation (Hitachi high-speed centrifuge, centrifugal speed is 10,000 rpm), and the supernatant of the centrifugal separation is collected. The solid prod...

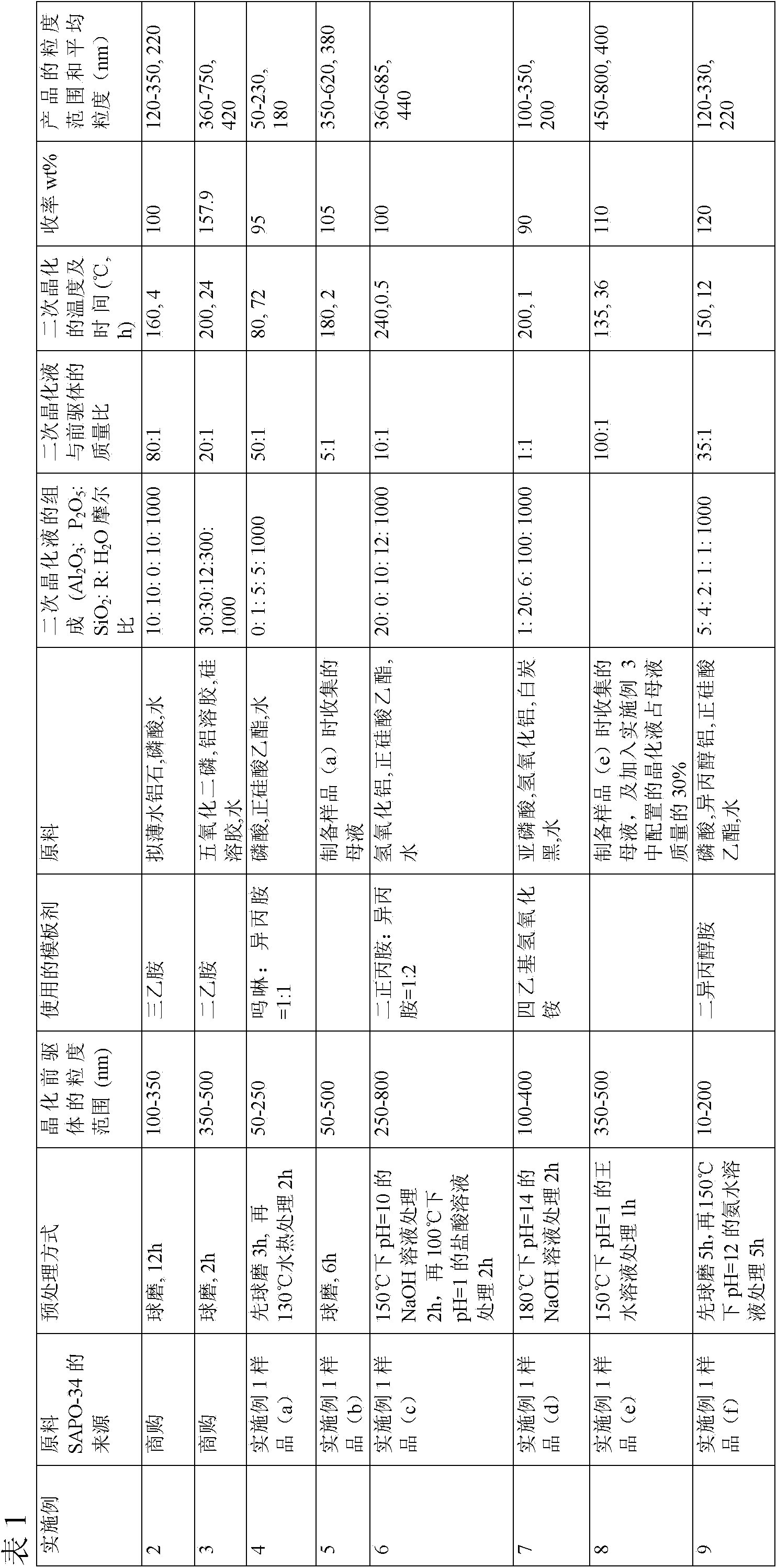

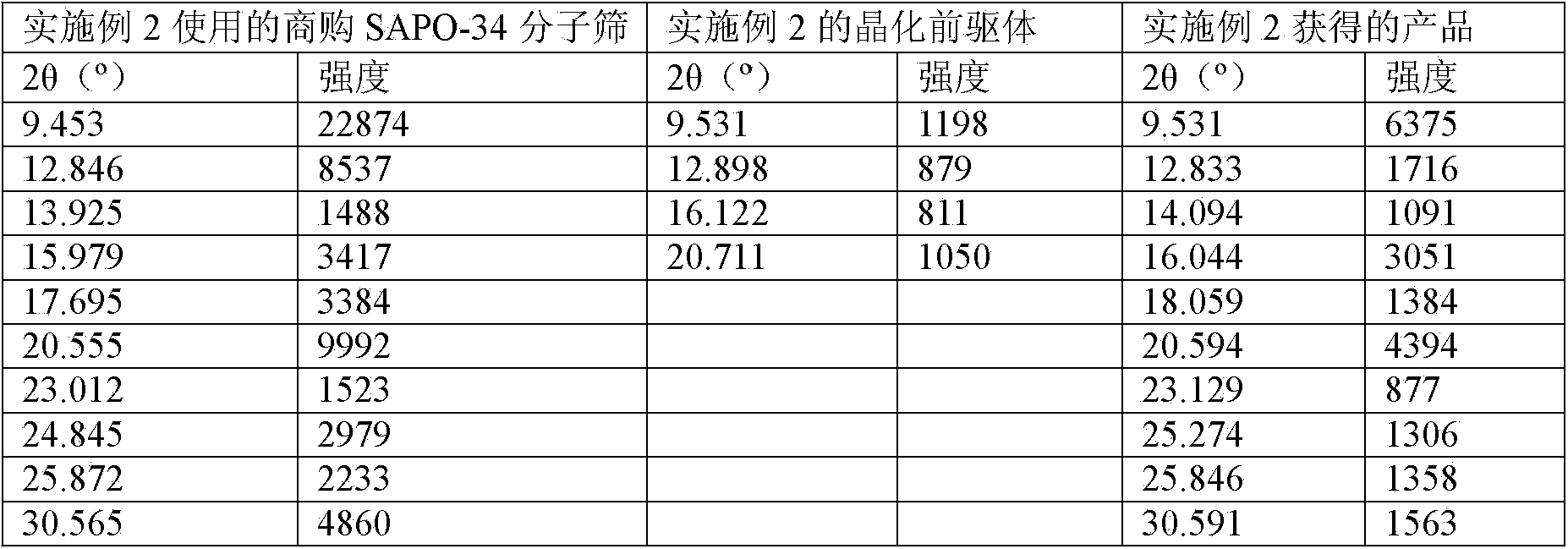

Embodiment 2~9

[0085] Examples 2-9: Preparation of small-crystalline SAPO-34 molecular sieve products

[0086] The commercially available SAPO-34 molecular sieve and the SAPO-34 molecular sieve samples (a) to (f) prepared in Example 1 were used as raw materials, respectively, and pretreated into 10-800 nm particles to obtain crystals with small particle size and low crystallinity. The precursor; then the organic amine template R and water and the optional silicon source, aluminum source and phosphorus source are mixed in a certain proportion to prepare a crystallization solution, or directly used to prepare the above samples (a) to (f) The collected mother liquor is used as the crystallization solution; the above-mentioned crystallization precursor and the crystallization solution are mixed in a certain ratio, and the second crystallization is performed at a certain temperature for a period of time; after centrifugal separation, washing with deionized water, and drying (120°C) In air), the SAPO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com