Preparation method of CuCeSAPO-34 molecular sieve, product obtained therethrough, and use of product

A molecular sieve and deionized water technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of limiting the application of molecular sieves, affecting catalytic performance, and high synthesis cost, and achieving excellent catalytic activity, uniform morphology, and crystallization. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

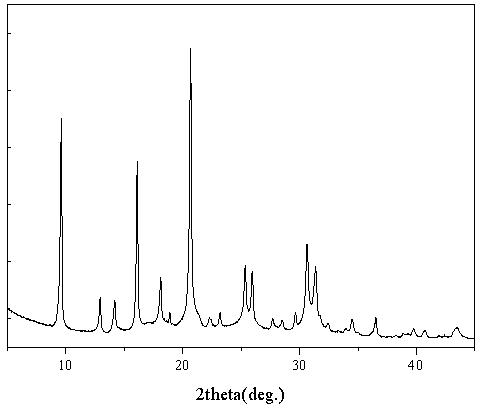

[0026] Such as Figure 1-4 Shown, the preparation method of CuCeSAPO-34 molecular sieve, using one-step hydrothermal synthesis method to prepare CuCeSAPO-34 molecular sieve and used for NH 3 - SCR reaction comprising the steps of:

[0027] Step 1. Add tetraethylammonium hydroxide into deionized water and stir. After the solution is evenly stirred, add aluminum isopropoxide until completely dissolved, then add orthophosphoric acid and ethyl orthosilicate, and then add cerium salt after mixing. After fully stirring, add copper salt and stir evenly to obtain a sol;

[0028] Step 2. Put the sol in step 1 into a hydrothermal reaction kettle for crystallization. After the crystallization reaction is completed, cool at room temperature, separate the solid crystalline product from the mother liquor, wash the solid crystalline product with deionized water until neutral, and dry 1. After roasting in the air, the desired CuCeSAPO-34 molecular sieve was obtained.

[0029] In this metho...

Embodiment 1

[0038] CuCeSAPO-34 molecular sieves prepared by one-step hydrothermal synthesis and used in NH 3 -SCR reaction, the preparation method of CuCeSAPO-34 molecular sieve, comprises the following steps:

[0039]Add 1.47g of tetraethylammonium hydroxide into 6.3g of deionized water and stir. After the solution is uniform, add 2.08g of aluminum isopropoxide until completely dissolved, then add 1.38g of orthophosphoric acid and 0.63g of ethyl orthosilicate, and wait After mixing, add 0.08g of cerium nitrate, after fully stirring, add 0.03g of copper acetate, then put the fully stirred sol into a hydrothermal reaction kettle for crystallization, then cool at room temperature, separate the solid crystalline product from the mother liquor, and wash until neutral , after drying in the air at 80°C, the molecular sieve powder was obtained, and the raw powder of the molecular sieve was calcined in the air at 550°C for 5 hours, and CuCeSAPO-34 molecular sieve catalyst was finally obtained.

...

Embodiment 2

[0042] The raw material feeding order and grinding time of preparing CuCeSAPO-34 molecular sieve are the same as embodiment 1, wherein, aluminum isopropoxide, orthophosphoric acid, ethyl orthosilicate, deionized water, tetraethylammonium hydroxide, copper salt, cerium salt The amount added should make each component A1 during the crystallization reaction 2 o 3 ,P 2 o 5 , SiO 2 、H 2 The molar ratio of O, TEAOH, copper salt, and cerium salt is 1:1.2:0.6:70:2:0.01:0. The fully stirred sol is put into a hydrothermal reaction kettle, crystallized at 170°C for 3d, and then After cooling, the solid crystalline product was separated from the mother liquor, washed until neutral, dried at 80°C, and calcined in air at 550°C for 5 hours to finally obtain CuCeSAPO-34 molecular sieve with an inorganic atom utilization rate of 85.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com