CuCe-SAPO-34 molecular sieve catalyst, as well as preparation method and use thereof

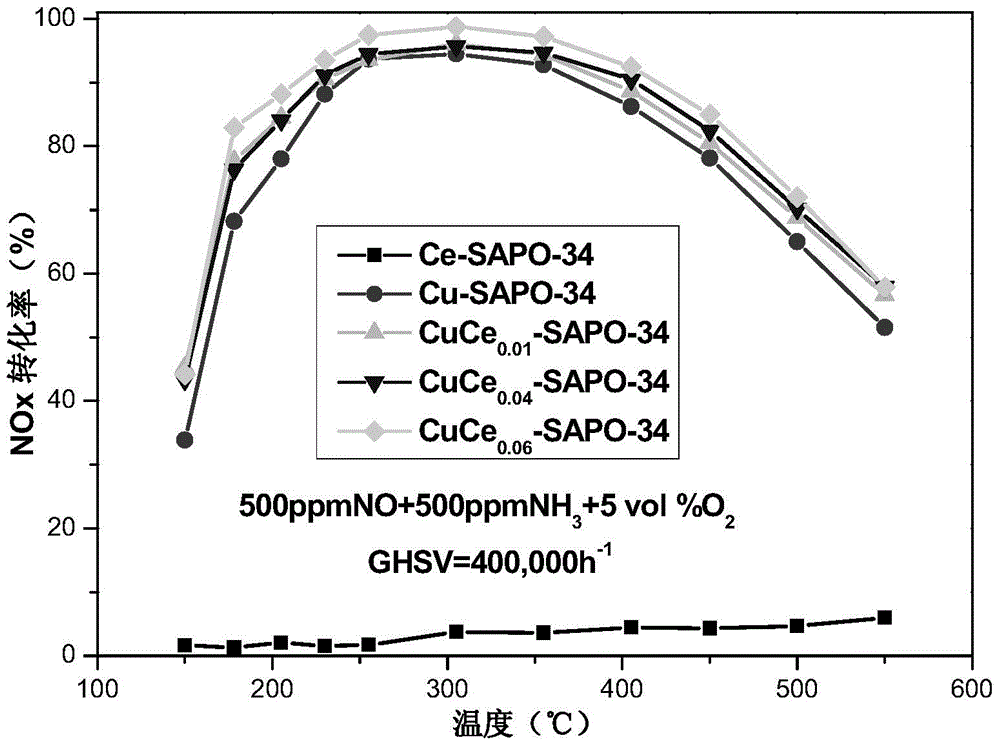

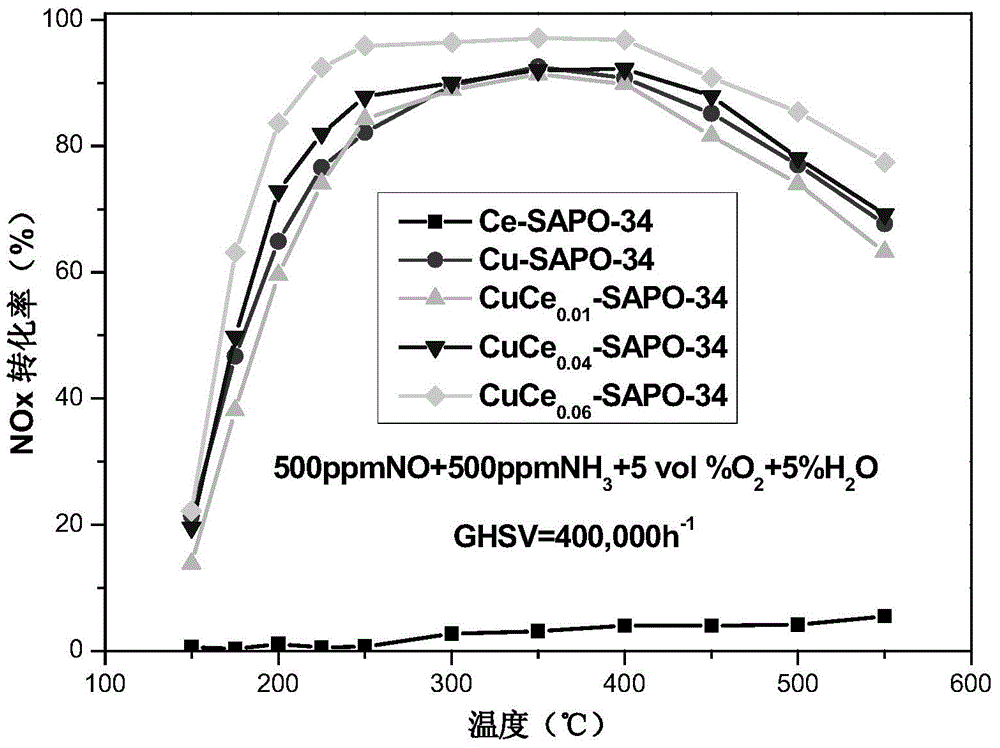

A technology of cuce-sapo-34 and molecular sieve, which is applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of not being able to meet the requirements of diesel vehicle exhaust NOx purification, low initial activity, etc., and achieve excellent catalytic activity and Effects of water resistance, reduction of adverse effects, and improvement of high-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

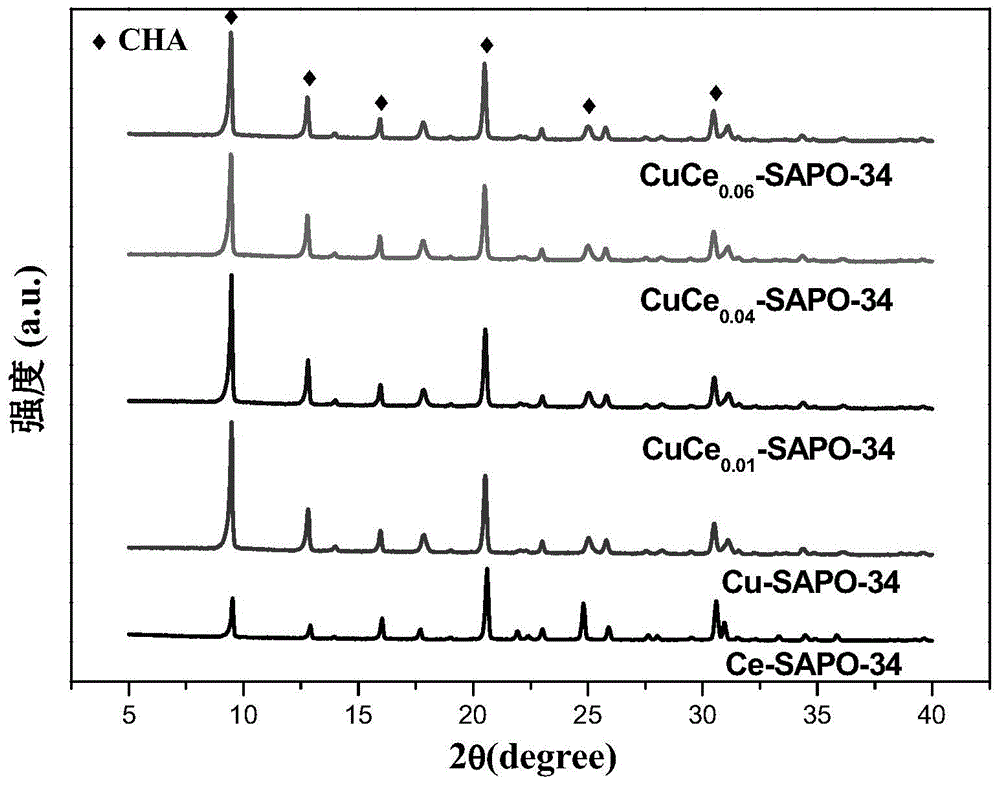

Method used

Image

Examples

Embodiment 1

[0038] Add pseudo-boehmite into deionized water and stir, then add orthophosphoric acid and fumed silica, add optional copper salt and tetraethylenepentamine after mixing, add optional cerium salt and n-propylamine after fully stirring ;

[0039] Put the fully stirred gel into a hydrothermal reaction kettle for crystallization at 180°C for 72 hours. After the crystallization reaction is completed, cool at room temperature, separate the solid crystalline product from the mother liquor, wash with deionized water until neutral, and dry at 100°C for 12 hours , and then calcined in air at a calcining temperature of 700° C., a heating rate of 1° C. / min during the calcining process, and a calcining time of 5 hours to obtain a molecular sieve catalyst.

[0040] Controlling the consumption of each reactant makes the reaction system have the following mass ratio relationship:

[0041] Among them, control AlOOH, H 3 PO 4 , SiO 2 、H 2 The molar ratios of O, copper salt, tetraethylene...

Embodiment 2

[0049] Control AlOOH, H 3 PO 4 , SiO 2 、H 2 The mol ratio of O, copper salt, tetraethylenepentamine, cerium salt and n-propylamine is 1:1:0.25:40:0.06:0.072:0.06:1.6, crystallization temperature is 150 ℃, all the other are identical with embodiment 1, the catalyst The performance evaluation is shown in the table below.

[0050]

Embodiment 3

[0052] Control AlOOH, H 3 PO 4 , SiO 2 、H 2 The mol ratio of O, copper salt, tetraethylenepentamine, cerium salt and n-propylamine is 1:1:0.25:40:0.06:0.072:0.06:1.6, crystallization temperature is 200 ℃, all the other are identical with embodiment 1, the catalyst The performance evaluation is shown in the table below.

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com