SAPO-34 (Silicoaluminophosphate-34) molecular sieve catalyst and application thereof to preparation of low-carbon olefin from methanol

A SAPO-34 and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of molecular sieve crystal size and morphology not uniform, long processing and synthesis time, expensive gel raw materials, etc., to achieve economical solvent consumption, clear morphology and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

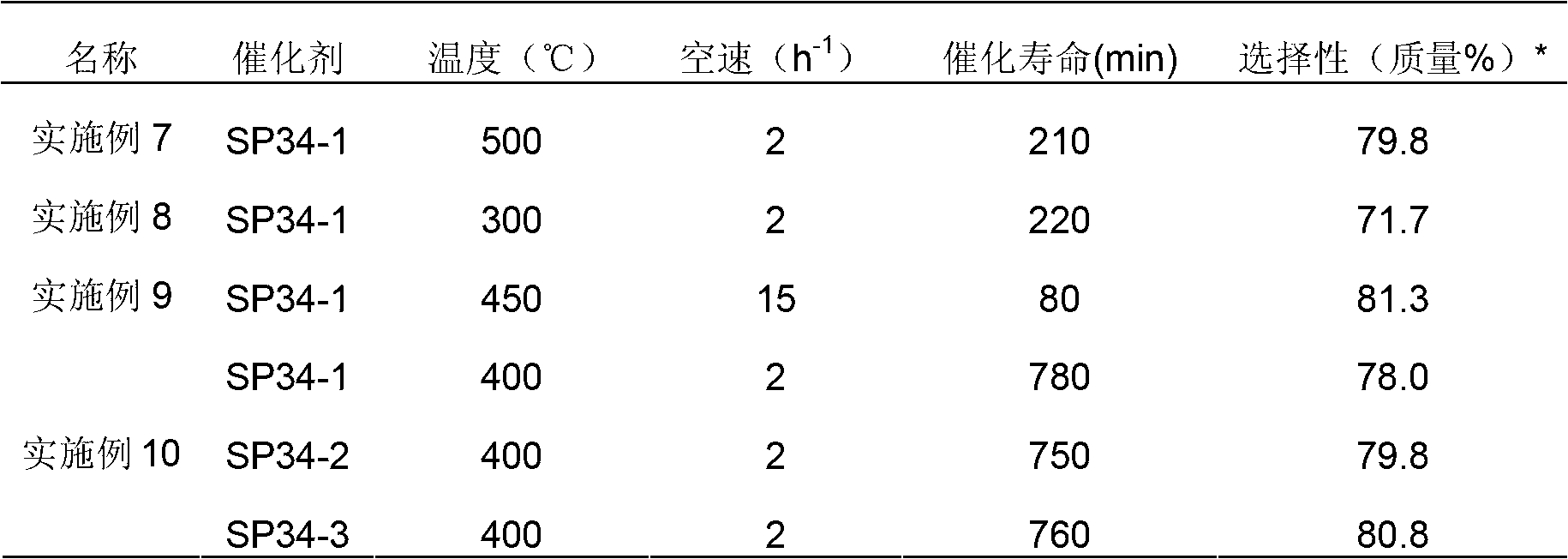

Examples

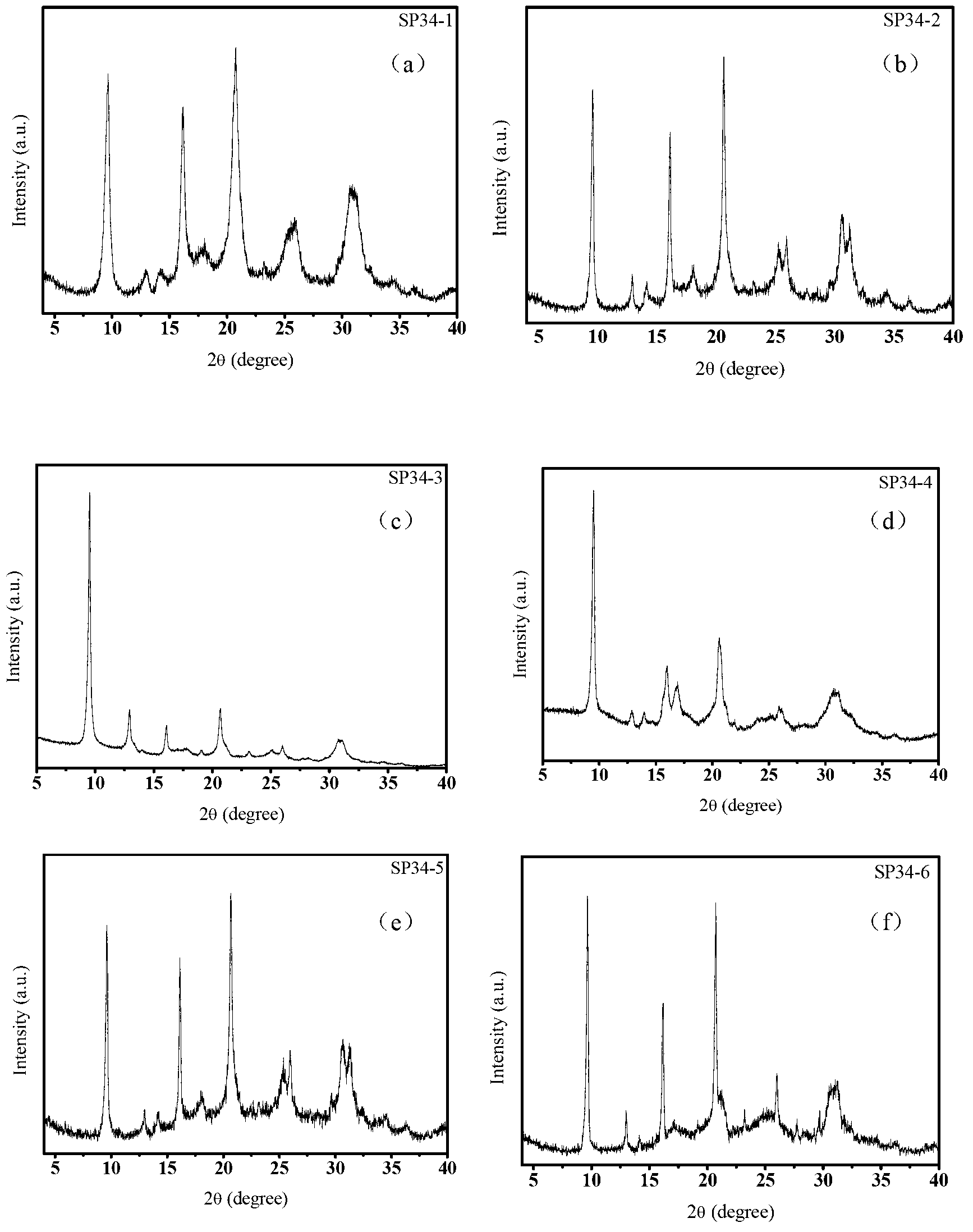

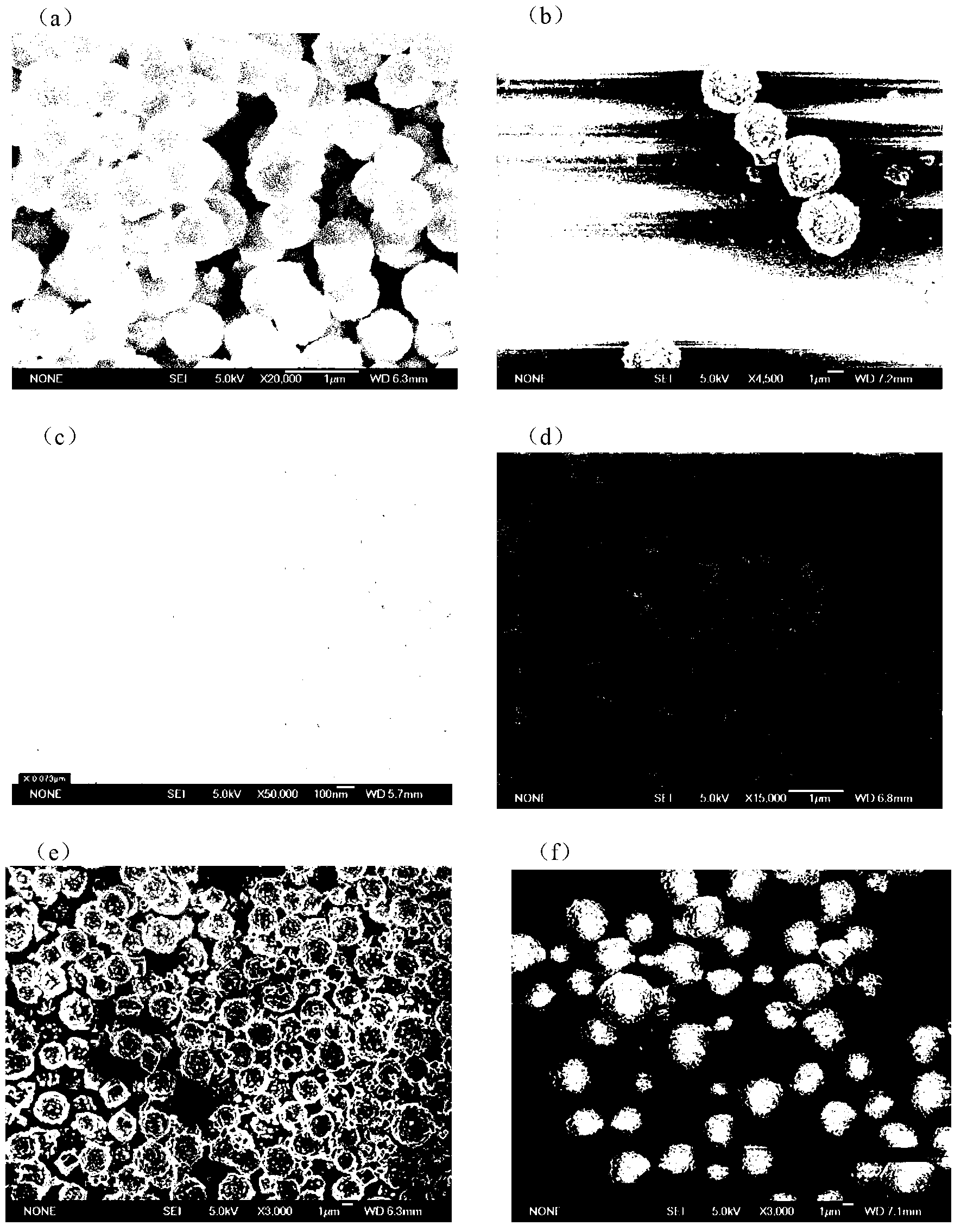

Embodiment 1

[0037] Mix and stir tetraethyl orthosilicate, aluminum isopropoxide, water, and tetraethylammonium hydroxide and treat at 20°C for 36 hours under autogenous pressure (closed container) to obtain a mixture; add phosphoric acid to the above mixture, Stirring treatment under autogenous pressure for 12 hours to obtain the initial gel mixture of SAPO-34 molecular sieve; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 3.5TEAOH:0.5 SiO 2 : 1.8P 2 o 5 :Al 2 o 3 : 150H 2O: Put the initial gel mixture into a microwave reactor, heat it up to 160°C under a power of 1000 watts, and carry out constant temperature crystallization under autogenous pressure for 0.5 hours. Then, the solid product was separated by standing, washed with deionized water until neutral, and dried in the air at room temperature to obtain the original powder of SAPO-34 molecular sieve, which was roasted at 550°C for 6 hours to ...

Embodiment 2

[0040] Mix and stir tetraethyl orthosilicate, alumina, water, and tetraethylammonium hydroxide, and then treat it at 20°C under autogenous pressure for 36 hours to obtain a mixture; add phosphoric acid to the above mixture, and stir under autogenous pressure After 12 hours, the initial gel mixture of SAPO-34 molecular sieve was obtained; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system was 3.5TEAOH:0.5SiO 2 : 1.8P 2 o 5 :Al 2 o 3 : 150H 2 O: Put the obtained initial gel mixture into a polytetrafluoroethylene-lined stainless steel autoclave, statically place it in a 160°C oven (hydrothermal heating), and carry out constant temperature crystallization under autogenous pressure for 120 hours. Then, the solid product was separated by standing, washed neutral with deionized water, and dried in the air to obtain the original powder of SAPO-34 molecular sieve. The original powder was roasted at 550...

Embodiment 3

[0042] Mix and stir tetraethyl orthosilicate, aluminum isopropoxide, water, tetraethylammonium hydroxide and treat at 20°C for 36 hours under autogenous pressure to obtain a mixture; add phosphoric acid to the above mixture, under autogenous pressure Stir for 12 hours to obtain the initial gel mixture of SAPO-34 molecular sieve; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 3.5TEAOH:0.5SiO 2 : 1.8P 2 o 5 :Al 2 o 3 : 60H 2 O: Put the initial gel mixture into a microwave reactor, heat it to 180° C. under a power of 200 watts, and carry out constant temperature crystallization for 1 hour under autogenous pressure. Then, the solid product is centrifuged, washed with deionized water, and dried in the air at room temperature to obtain the original powder of SAPO-34 molecular sieve. The original powder is roasted at 550 ° C for 6 hours to remove the organic ammonium template to obtain SAPO -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com