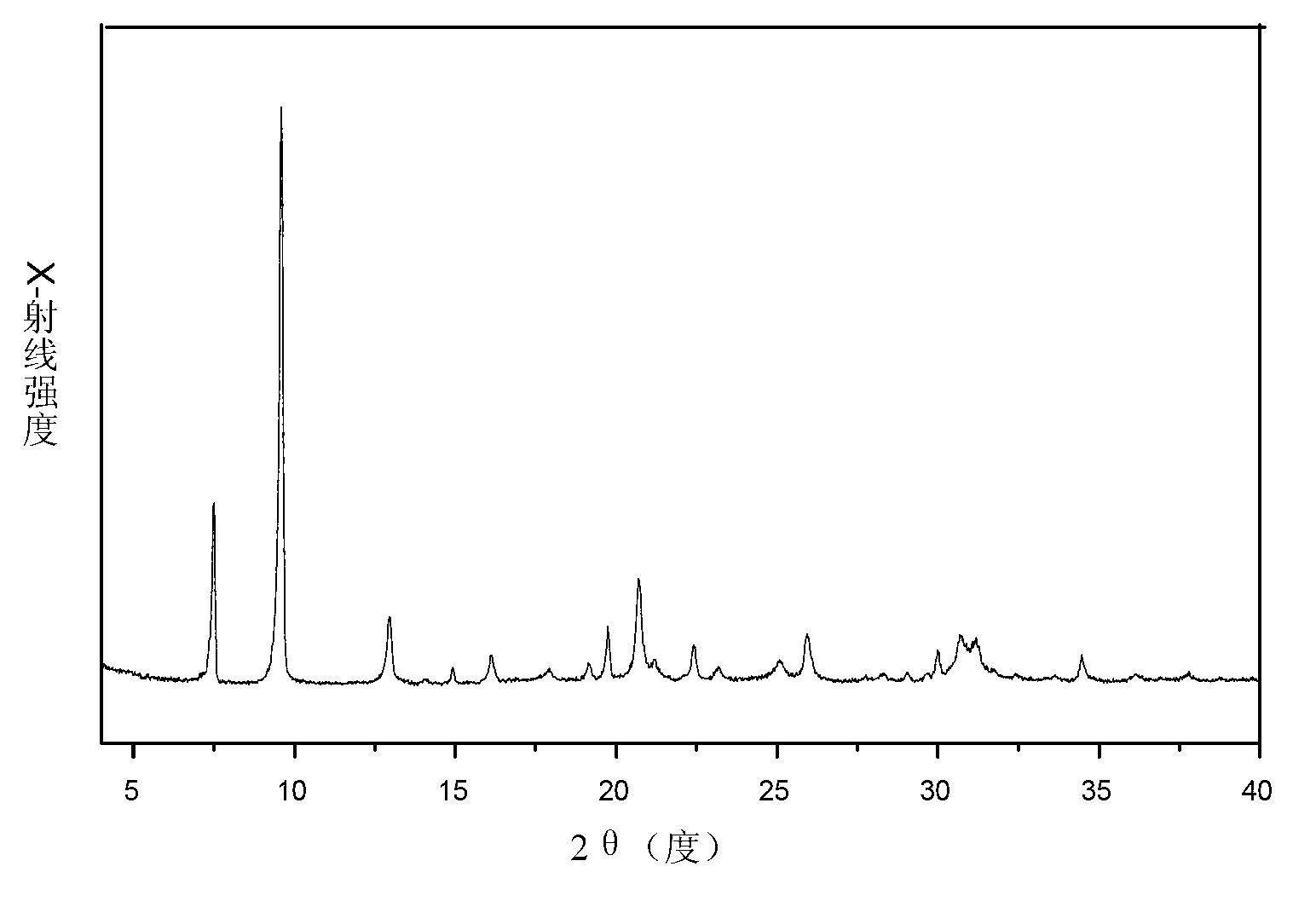

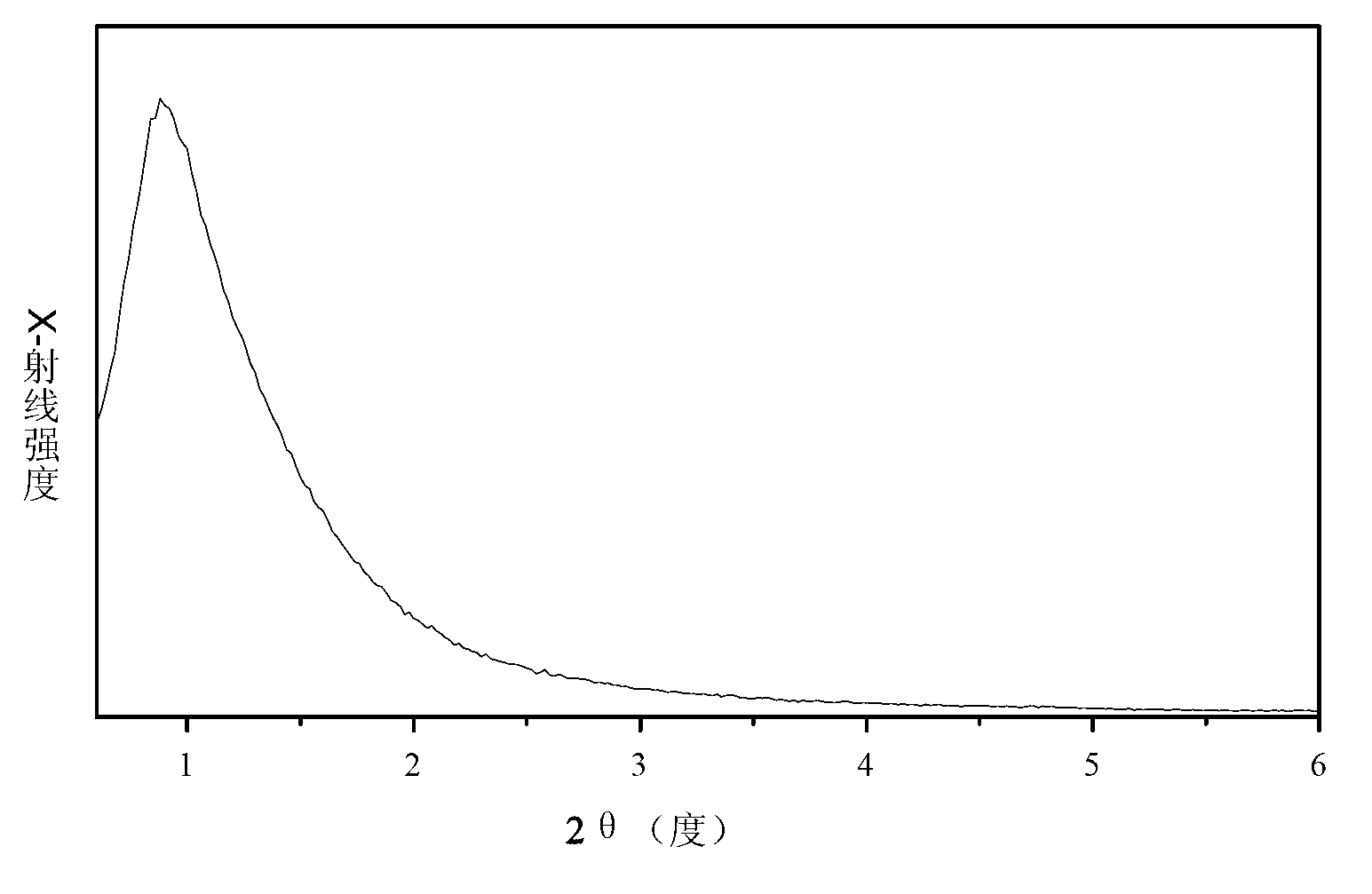

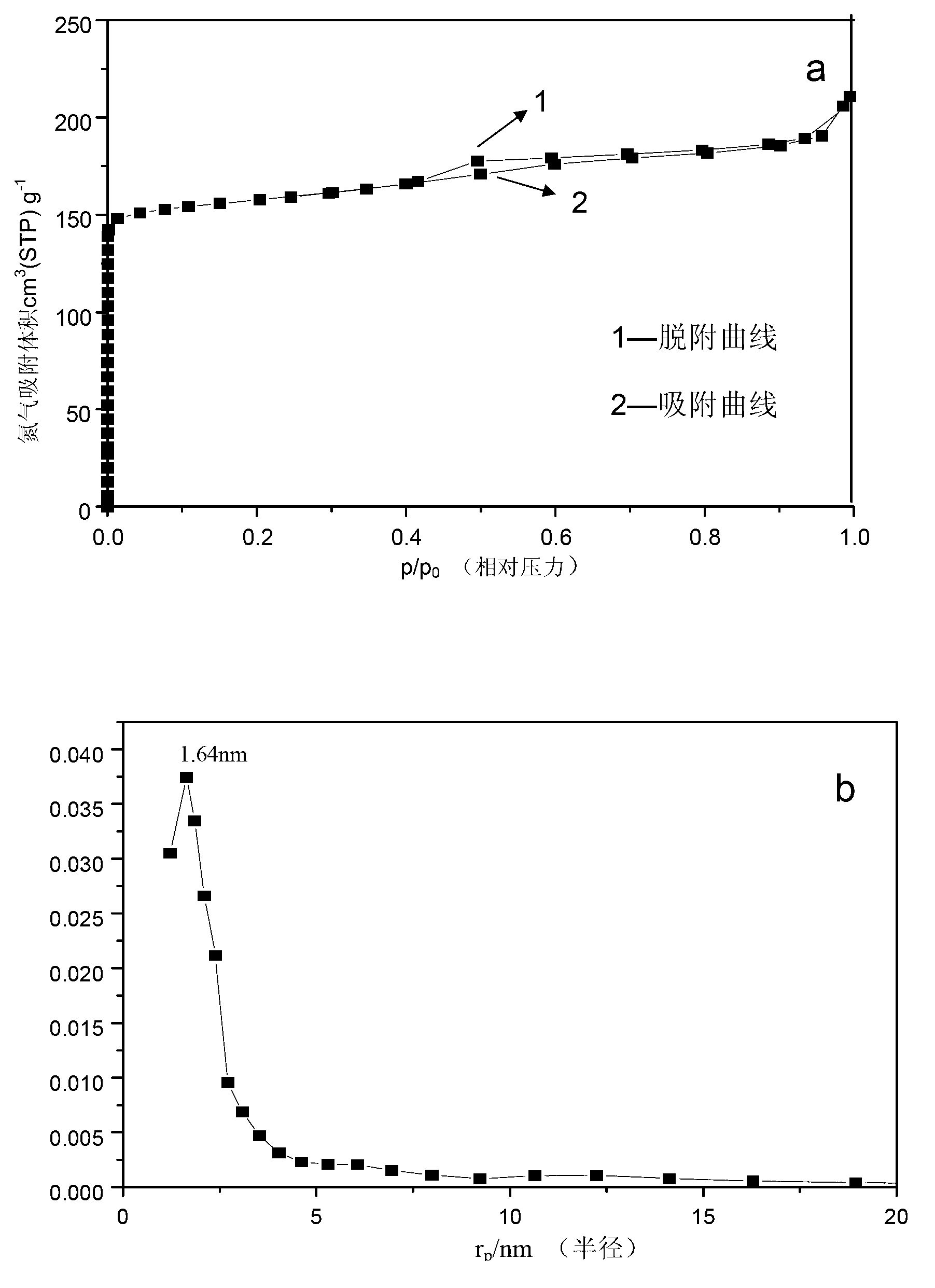

One-step preparation method for hydrogen type multistage pore molecular sieve with SAPO-5 and SAPO-34 symbiosis

A SAPO-34, SAPO-5 technology, applied in the field of inorganic hierarchical porous material preparation, can solve the problems of catalyst deactivation, blocked pores, diffusion, poor mass transfer performance, etc., to reduce costs and reduce steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 0.8g of ethyl silicate, 0.1g of STSAC, 20.2g of TEAOH (35% by mass), 8.2g of ground aluminum isopropoxide and 27.0g of deionized water to prepare white slurry liquid A;

[0028] (2) Mix 3.9g of phosphoric acid and 9.0g of deionized water and slowly add dropwise (1mL / min) into liquid A under vigorous stirring (stirring speed is 800r / min);

[0029] (3) Thoroughly stir to obtain uniformly dispersed precursor B, and the molar ratio of the obtained precursor at this time is: 1.0Al 2 o 3 : 1.0P 2 o 5 : 0.19SiO2 2 : 2.4TEAOH : 0.01STSAC : 100H 2 O, then put it into a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, and under autogenous pressure, first crystallize at 85°C for 24 hours, and then crystallize at 200°C for 48 hours. After the crystallization is completed, the solid product After suction filtration, washing with deionized water until neutral, and drying in the air at 100°C for 1 day, 2.9 g of the original powder of microporou...

Embodiment 2

[0032] (1) Mix 0.8g of ethyl silicate, 0.1g of STSAC, 20.2g of TEAOH (35% by mass), 8.2g of ground aluminum isopropoxide and 27.0g of deionized water to prepare white slurry liquid A;

[0033] (2) Mix 3.9g of phosphoric acid and 9.0g of deionized water and slowly add dropwise (2mL / min) into liquid A under vigorous stirring (stirring speed is 600r / min);

[0034] (3) Thoroughly stir to obtain uniformly dispersed precursor B, and the molar ratio of the obtained precursor at this time is: 1.0Al 2 o 3 : 1.0P 2 o 5 : 0.19SiO2 2 : 2.4TEAOH : 0.01STSAC : 100H 2 O, then put it into a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, and crystallize it at 200°C for 72 hours under autogenous pressure. properties, dried in air at 80°C for 3 days to obtain 3.0 g of hydrogen-form SAPO-5 and SAPO-34 symbiotic microporous-mesoporous composite molecular sieve powder;

[0035](4) The original powder obtained in step (3) was roasted in the air at a heating rate o...

Embodiment 3

[0037] (1) Mix 0.8g of ethyl silicate, 0.1g of STSAC, 8.4g of TEAOH (35% by mass), 8.2g of ground aluminum isopropoxide and 16.8g of deionized water to prepare white slurry liquid A;

[0038] (2) Mix 2.4g of phosphoric acid and 8.4g of deionized water and slowly add dropwise (1mL / min) into liquid A under vigorous stirring (stirring speed is 900r / min);

[0039] (3) Thoroughly stir to obtain uniformly dispersed precursor B, and the molar ratio of the obtained precursor at this time is: 1.0Al 2 o 3 : 0.6P 2 o 5 : 0.19SiO2 2 : 1.0TEAOH: 0.01STSAC: 70H 2 O, then put it into a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, and crystallize it at 180°C for 120 hours under autogenous pressure. properties, dried in air at 100°C for 1 day to obtain 2.1 g of hydrogen-form SAPO-5 and SAPO-34 symbiotic microporous-mesoporous composite molecular sieve powder;

[0040] (4) The original powder obtained in step (3) was roasted in the air at a heating rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com