Photodiffusion-type flexible colored PVC (polyvinyl chloride) composition and application thereof

A technology of light diffusion and composition, applied in the field of polymer materials, can solve the application of soft color PVC without light diffusion, etc., and achieve the effects of low cost, simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

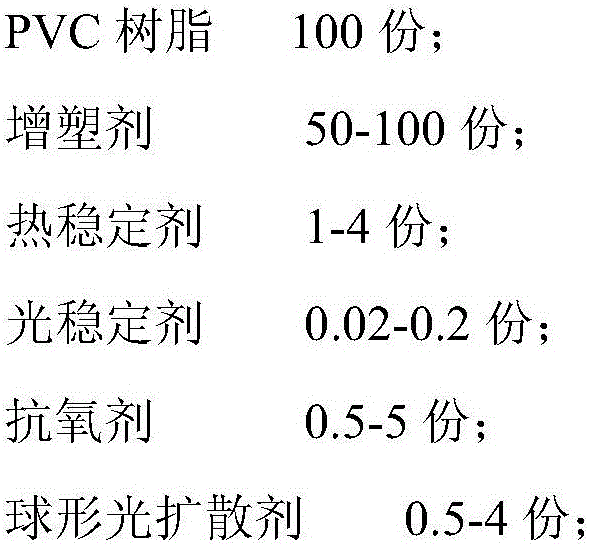

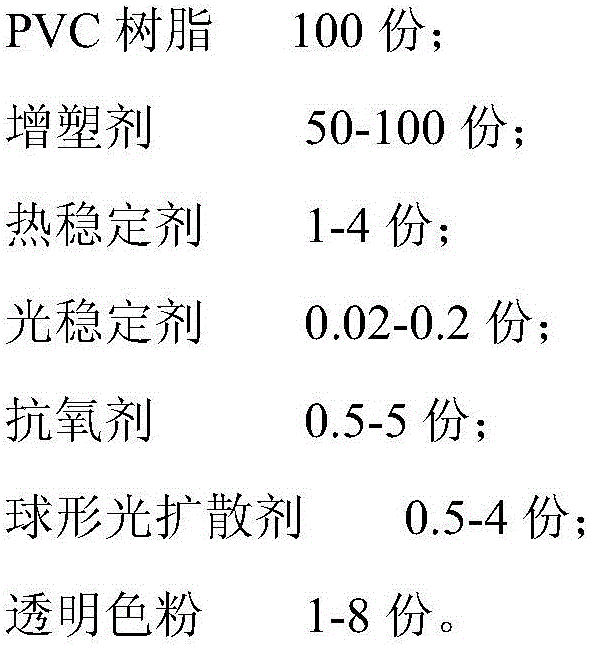

Method used

Image

Examples

Embodiment 1

[0024] Based on 100 parts by mass of PVC SG3 resin, 50 parts of dioctyl phthalate, 1 part of the compound of calcium zinc stabilizer and organic tin stabilizer, 0.02 part of fluorescent whitening agent, 5 parts of antioxidant 1010, spherical poly 1 part of silsesquioxane light diffusing agent and 1 part of transparent toner are dispersed and mixed uniformly in a high-speed stirring mixer, and a light-diffusing soft color PVC composition is produced by screw extrusion. When the composition is injection-molded into a film or strip with a thickness of 2 mm, it is soft, bright in color, can be bent arbitrarily, has a haze of 90 percent and a light transmittance of 83 percent.

Embodiment 2

[0026] 100 parts by mass of PVC SG3 resin, 100 parts of dioctyl phthalate, 4 parts of the compound of calcium zinc stabilizer and organic tin stabilizer, 0.2 part of optical brightener as light stabilizer, 0.5 part of antioxidant 1010 4 parts of cross-linked polymethyl methacrylate microsphere light diffusing agent, 5 parts of transparent toner, dispersed and mixed evenly in a high-speed stirring mixer, and extruded by a screw to produce a light-diffusing soft color PVC combination. When the composition is injection-molded into a film or rubber strip with a thickness of 2 mm, it is soft, bright in color, can be bent arbitrarily, has a haze of 93 percent and a light transmittance of 76 percent.

Embodiment 3

[0028] 100 parts by mass of PVC SG3 resin, 70 parts of dioctyl phthalate, 3 parts of calcium zinc stabilizer and organic tin stabilizer compound, 0.1 part of fluorescent whitening agent, 2 parts of antioxidant 1010, cross-linked 2 parts of polystyrene microsphere light diffusing agent and 5 parts of transparent toner are dispersed and mixed evenly in a high-speed stirring mixer, and extruded by a screw to produce a light-diffusion type soft color PVC composition. When the composition is injection-molded into a film or strip with a thickness of 2 mm, it is soft, bright in color, can be bent arbitrarily, has a haze of 92 percent and a light transmittance of 71 percent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com