Photosensitive acrylic AED resin and negative photoresist composition comprising same, and preparation method thereof

A technology of photosensitive acrylic and photoresist, applied in the field of photosensitive acrylic AED resin, negative photoresist composition, the preparation of the composition, can solve the problem of poor adhesion, uneven film thickness, The problem of low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

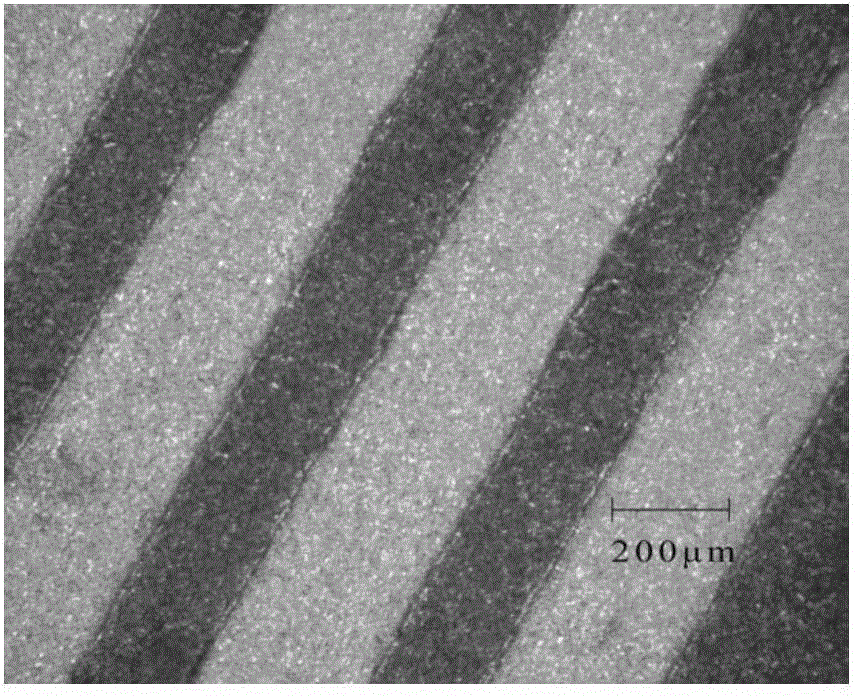

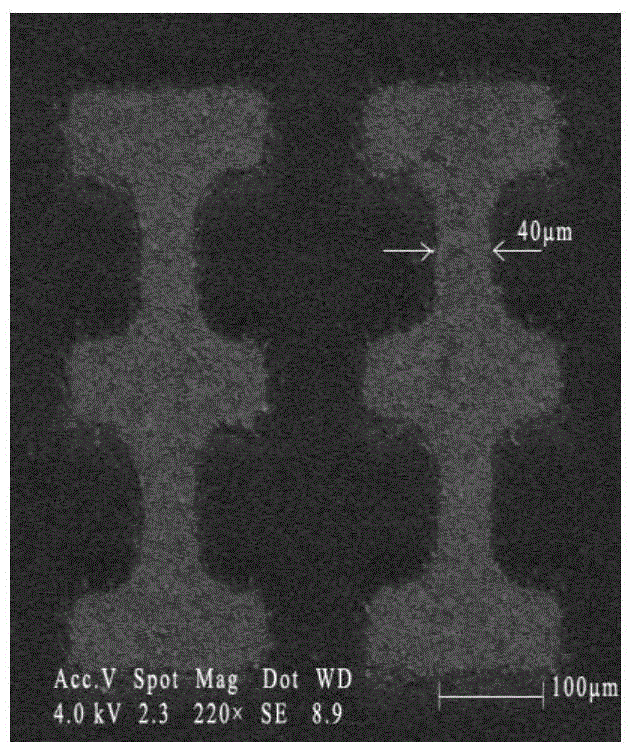

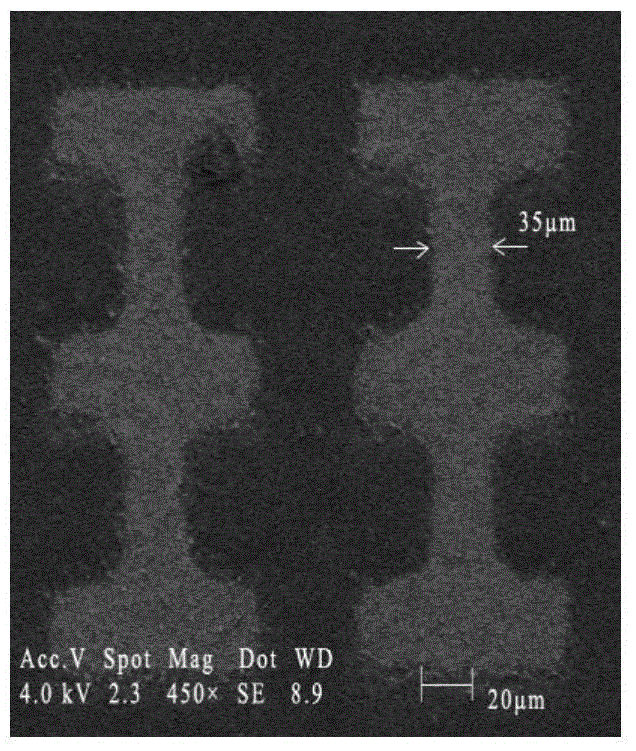

Image

Examples

Embodiment 1

[0085] Example 1: Negative Photoresist Composition

[0086] Add 50g of ethylene glycol butyl ether (BCS) into a 250ml four-neck flask, stir at 85°C and add dropwise a mixed solution containing 24g of cyclohexyl vinyl ether, 40g of EHA, 40g of AA, 0.62g of AIBN and 0.31g of β-ME, within 3 hours Finish. After maintaining the reaction temperature for 1 hour, add 0.20 g of AIBN dissolved in 5 g of butyl acetate, drop it off within 0.5 hours, and maintain the reaction temperature for 2.5 hours to obtain an acrylic acid copolymer.

[0087] Then the temperature of the copolymer was raised to 105°C, and a mixture of 15.8 g GMA and 26.7 g BCS dissolved in 0.97 g triphenylphosphine (TPP), 1.20 g p-hydroxyanisole (MHEQ) was added dropwise, and the drop rate was controlled within 1 hour. The reactants except the solvent accounted for about 60% of the total feed, and the solvent accounted for the remaining 40%. After the dripping, the temperature was raised to 110°C, and the acid value wa...

Embodiment 2

[0089] Example 2: Negative Photoresist Composition

[0090] Mix 10g of the photosensitive acrylic AED base material in Example 1 with 0.11g of photoinitiator ITX, 0.15g of photosensitizer 907, and 1.2g of TMP(EO)3TA to form a homogeneous phase, then add 1.53g of triethylamine dropwise, stir well and drop slowly Add 63g of deionized water for emulsification, continue stirring after dripping, add 0.15g of water-based color paste after aging for 24 hours, and obtain a negative photoresist after stirring evenly.

Embodiment 3

[0091] Example 3: Negative Photoresist Composition

[0092] The temperature of the acrylic acid copolymer obtained in Example 1 was raised to 110°C, and a mixture of 31.6 g GMA and 37.5 g BCS dissolved in 0.84 g of triethylbenzyl ammonium chloride and 1.4 g of p-hydroxyanisole (MHEQ) was added dropwise to control the dropwise The dripping is completed within 1 hour, the reactants except the solvent account for about 60% of the total feed, and the solvent accounts for the remaining 40%. After the dripping is completed, the temperature rises to 115°C. The acid value is detected during the reaction, and the change within one hour does not exceed 2mgKOH / g , the reaction can be stopped to obtain a photosensitive acrylic AED base material.

[0093] Mix 10g of photosensitive acrylic AED base material with 0.32g of photoinitiator 1173 and 0.6g of TMP(EO)3TA to form a homogeneous phase, then add 1.02g of triethylamine dropwise, stir evenly, slowly add 63g of deionized water to emulsify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com