Self-emulsifying fluorosilicone modified dual-component waterborne epoxy floor coating

A technology of epoxy floor paint and fluorine-silicon modification, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of poor water resistance and low emulsification efficiency of epoxy resin, and achieve convenient operation, easy industrial production, and improved hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

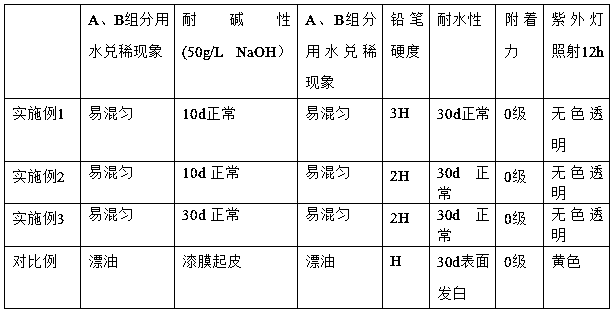

Examples

Embodiment 1

[0019] A self-emulsifying fluorosilicone modified two-component water-based epoxy floor paint is characterized in that it consists of components A and B, and in parts by weight, component A consists of: 40 parts of isophorone diamine, 3 parts of tetra-n-propyl zirconate, 20 parts of isopropanol; component B is 50 parts of emulsifiable organofluorosilicon epoxy resin X, 1 part of polyether modified silicone leveling agent, 0.8 parts of non-ionic Polyoxyethylene ether wetting and dispersing agent, 0.3 parts of mineral oil defoamer, 15 parts of talc.

[0020] Wherein, the emulsifiable organofluorosilicon epoxy resin X is prepared by the method of Example 1 in the applied invention patent "an emulsifiable organofluorosilicon epoxy resin".

Embodiment 2

[0022] A self-emulsifying fluorosilicone modified two-component water-based epoxy floor paint, characterized in that it consists of components A and B, and in parts by weight, component A consists of 30 parts of 3,3'-dimethyl base-4,4-diaminodicyclohexylmethane, 5 parts of tetraisopropyl zirconate; component B is 80 parts of emulsifiable organic fluorosilicon epoxy resin Y, 0.5 parts of polyether modified silicone leveling Agent, 1.5 parts of non-ionic polyoxyethylene ether wetting and dispersing agent, 0.1 part of mineral oil defoamer, 50 parts of titanium dioxide.

[0023] Wherein, the emulsifiable organofluorosilicon epoxy resin Y is prepared by the method of Example 2 in the applied invention patent "an emulsifiable organofluorosilicon epoxy resin".

Embodiment 3

[0025] A self-emulsifying fluorosilicone modified two-component water-based epoxy floor paint is characterized in that it consists of components A and B, and in parts by weight, component A consists of: 35 parts of triethylenetetramine, 4 parts Commercially available zirconate coupling agent FD-NZ97, 6 parts of ethylene glycol monomethyl ether; component B is 70 parts of emulsifiable organic fluorosilicon epoxy resin Z, 0.6 parts of polyether modified silicone leveling agent, 1 part of non-ionic polyoxyethylene ether wetting and dispersing agent, 0.2 part of mineral oil defoamer, 30 parts of heavy calcium carbonate.

[0026] Wherein, the emulsifiable organofluorosilicon epoxy resin Z is prepared by the method of Example 3 in the applied invention patent "an emulsifiable organofluorosilicon epoxy resin".

[0027] The preparation method of the self-emulsifying fluorosilicon modified two-component waterborne epoxy floor paint described in embodiment 1-3 is as follows:

[0028] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com