Self-emulsifying water-borne epoxy resin curing agent and preparation method thereof

A water-based epoxy resin and epoxy resin technology, applied in the coating and other directions, can solve the problems of the decline of the coating film performance, pH value sensitivity, environmental pollution, etc., to achieve a good adaptation period and coating film performance, raw materials are easily available, simplified Effects of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

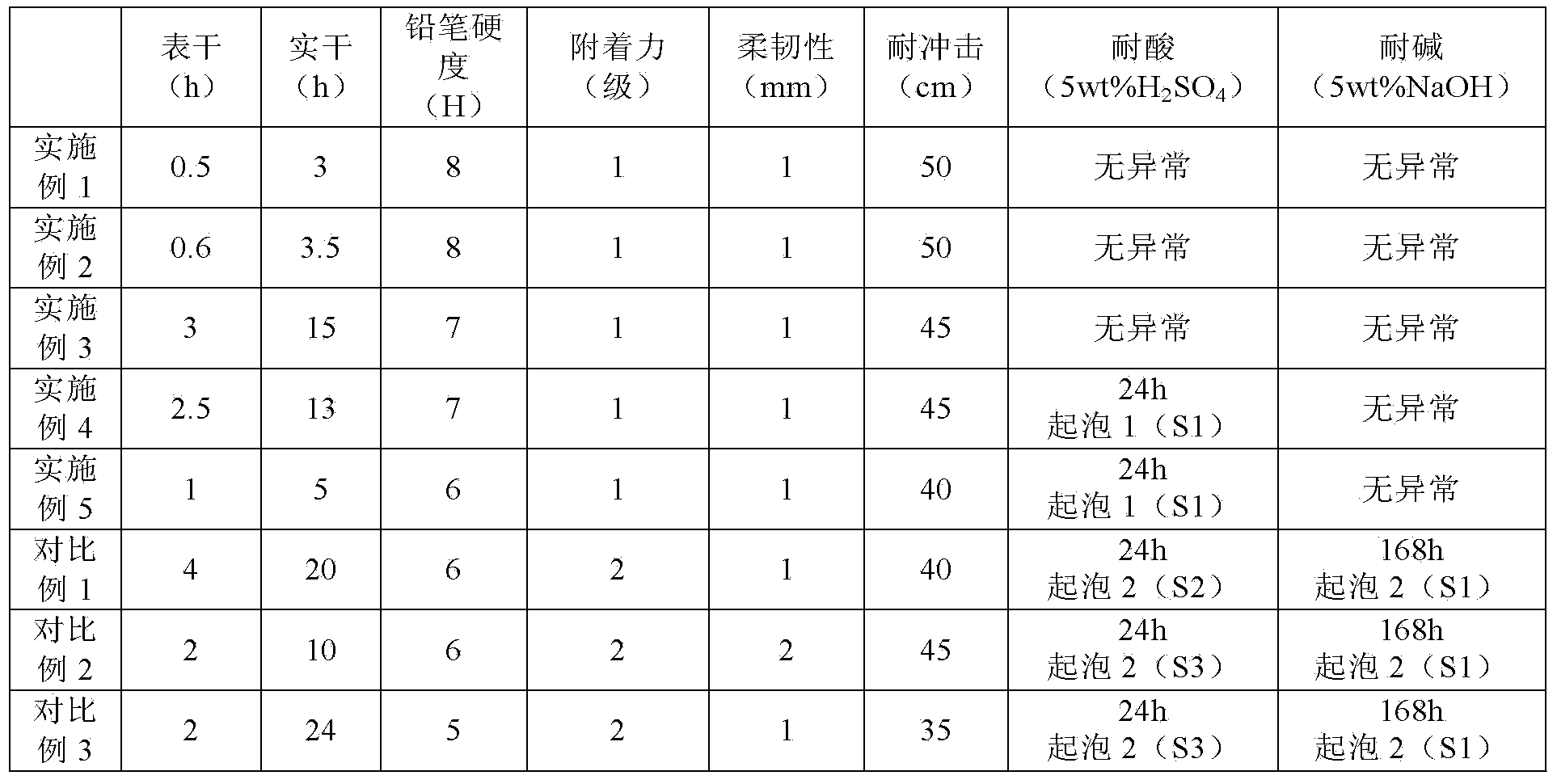

Examples

preparation example Construction

[0021] In order to solve the problems in the prior art when preparing self-emulsifying water-based epoxy resin curing agents, the performance of cationic water-based epoxy curing agent coatings formed by neutralization of end-capped products with organic acids is reduced, and flash rust is easy to occur when used on metals. Environmental pollution and sensitivity to pH value and unstable problem when used together with basic pigments and fillers, the invention provides a kind of preparation method of self-emulsifying waterborne epoxy resin curing agent, comprises the following steps: S1, will single Polyamine and epoxy resin are mixed and reacted at a molar ratio of 1.8:1 to 2.1:1 to obtain an intermediate adduct; and S2, using a single epoxy compound to cap the intermediate adduct to obtain a self-emulsifying water-based Epoxy resin curing agent.

[0022] By controlling the molar ratio of a single polyamine and epoxy resin within a certain range for the addition reaction, and...

Embodiment 1

[0039] 1) Take 200g of tetraethylenepentamine (provided by Rizhao Lidex Chemical Co., Ltd.), and add it and liquid epoxy resin E44 (provided by Langfang Nuoerxin Chemical Co., Ltd.) In the three-necked flask reaction device, the molar ratio of tetraethylenepentamine to liquid epoxy resin is 2.0:1, and the three-necked flask is slowly heated to 70°C in a water bath and reacted at a constant temperature for 4 hours to obtain an intermediate adduct, and then depressurized Distill to remove excess tetraethylenepentamine.

[0040] 2) Under the condition of keeping the temperature constant, add the end-capping agent octane epoxy to the intermediate adduct dropwise, in which the epoxy octane (provided by Shanghai Puzhen Biotechnology Co., Ltd.) and the intermediate adduct The molar ratio is 2:1, react at a constant temperature of 70°C for 4 hours, and cool down to room temperature to obtain a self-emulsifying water-based epoxy resin curing agent with a light yellow appearance.

[00...

Embodiment 2

[0044] 1) Take 200g of triethylenetetramine (provided by Tianjin Guangfu Fine Chemical Research Institute), and add it and liquid epoxy resin E51 (provided by Langfang Nuoerxin Chemical Co., Ltd.) In the three-necked flask reaction device, wherein the molar ratio of triethylenetetramine to liquid epoxy resin E51 is 2.1:1, the water bath slowly heats the three-necked flask to 50°C and reacts at a constant temperature for 6 hours to obtain an intermediate adduct, and then reduce Unreacted triethylenetetramine was removed by pressure distillation.

[0045] 2) Under the condition of keeping the temperature constant, add the capping agent o-phenylphenol glycidyl ether (provided by Hangzhou Tuomu Technology Co., Ltd.) dropwise to the intermediate adduct, in which o-phenylphenol glycidyl ether and intermediate The molar ratio of the body adduct is 1:1, react at a constant temperature of 50°C for 6 hours, and cool down to room temperature to obtain a self-emulsifying water-based epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com