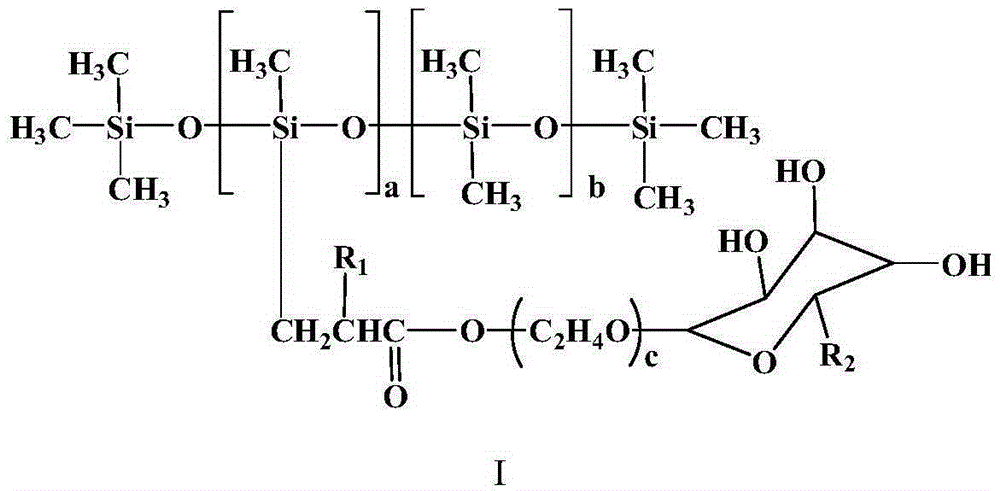

Self-emulsifying concrete defoamer and preparation method thereof

A technology for concrete and defoaming agent, applied in the field of self-emulsifying concrete defoaming agent and its preparation, can solve the problems of poor elimination ability of dense foam, poor acid and alkali resistance, and high cost, achieve excellent self-emulsifying performance and improve working performance , The effect of strong acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

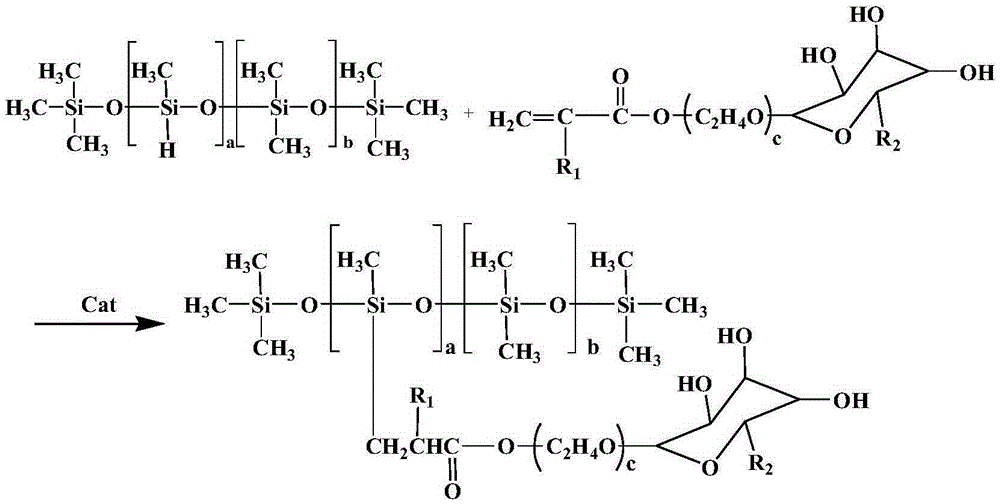

Method used

Image

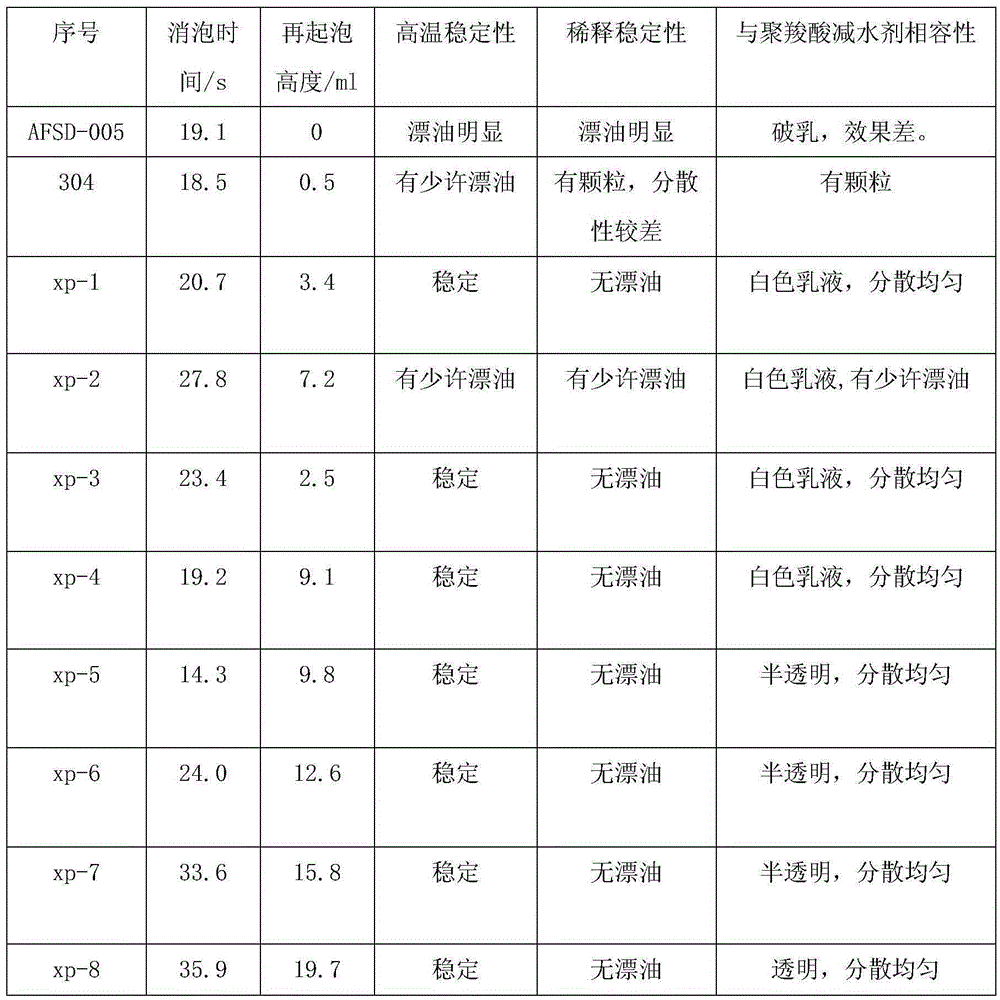

Examples

Embodiment 1

[0026] A self-emulsifying concrete defoamer, prepared by the following method:

[0027] (1) Vacuum distilling siloxane with low hydrogen content (0.18% hydrogen content) and glucose oxyethyl acrylate until the water content is below 0.1% for subsequent use;

[0028] (2) In a round bottom flask equipped with a thermometer, a stirrer, a reflux condenser and a nitrogen purge device, 1.5mol glucose oxyethyl acrylate is added to the reaction device, stirred, 0.6mol xylene is added, and Nitrogen is purged to remove the oxygen in the reaction system, the temperature is raised to 90° C., and 59 ppm of chloroplatinic acid in isopropanol is added as a catalyst;

[0029] (3) Add 1.45 mol of siloxane with low hydrogen content dropwise. After the reaction, vacuum distillation removes low boilers and solvents, obtained from defoamer for emulsified concrete, denoted as xp-1.

Embodiment 2

[0031] A self-emulsifying concrete defoamer, prepared by the following method:

[0032] (1) Vacuum distilling siloxane with low hydrogen content (0.18% hydrogen content) and glucose oxyethyl acrylate until the water content is below 0.1% for subsequent use;

[0033] (2) In a round bottom flask equipped with a thermometer, a stirrer, a reflux condenser and a nitrogen purge device, 1.5mol glucose oxyethyl acrylate is added to the reaction device, stirred, 0.6mol xylene is added, and Nitrogen gas is purged to remove the oxygen in the reaction system, the temperature is raised to 80° C., and the ethanol solution of 45 ppm of chloroplatinic acid is added as a catalyst;

[0034] (3) Add 1.45 mol of siloxane with low hydrogen content dropwise. After the reaction, vacuum distillation removes low boilers and solvents. It is obtained from the defoamer for emulsified concrete and is denoted as xp-2.

Embodiment 3

[0036] A self-emulsifying concrete defoamer, prepared by the following method:

[0037] (1) Vacuum distilling siloxane with low hydrogen content (0.18% hydrogen content) and glucose oxyethyl methacrylate until the water content is below 0.1% for subsequent use;

[0038] (2) In the round-bottomed flask equipped with thermometer, stirrer, reflux condenser and nitrogen purging device, 1.5mol glucose oxyethyl methacrylate is added in the reaction unit, stir, add 0.6mol toluene, And purging with nitrogen to remove the oxygen in the reaction system, raising the temperature to 110 ° C, adding 39 ppm of chloroplatinic acid in isopropanol as a catalyst;

[0039] (3) Add 1.5 mol of siloxane with low hydrogen content dropwise. After the reaction, vacuum distillation removes low boilers and solvents, obtained from defoamer for emulsified concrete, denoted as xp-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com