Synthetic leather binding agent and preparation method thereof

An adhesive and synthetic leather technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, polymer adhesive additives, etc. Poor stability, affecting the performance and quality of synthetic leather, etc., to achieve the effects of excellent leveling and spreading, good environmental protection, and excellent light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

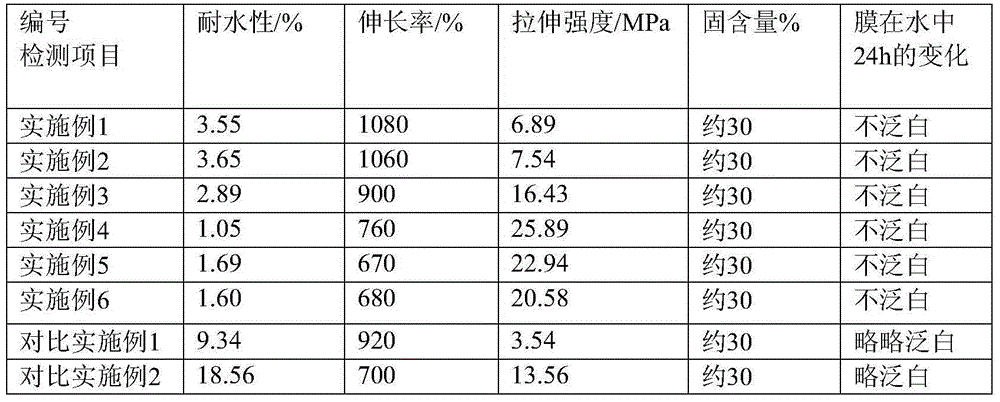

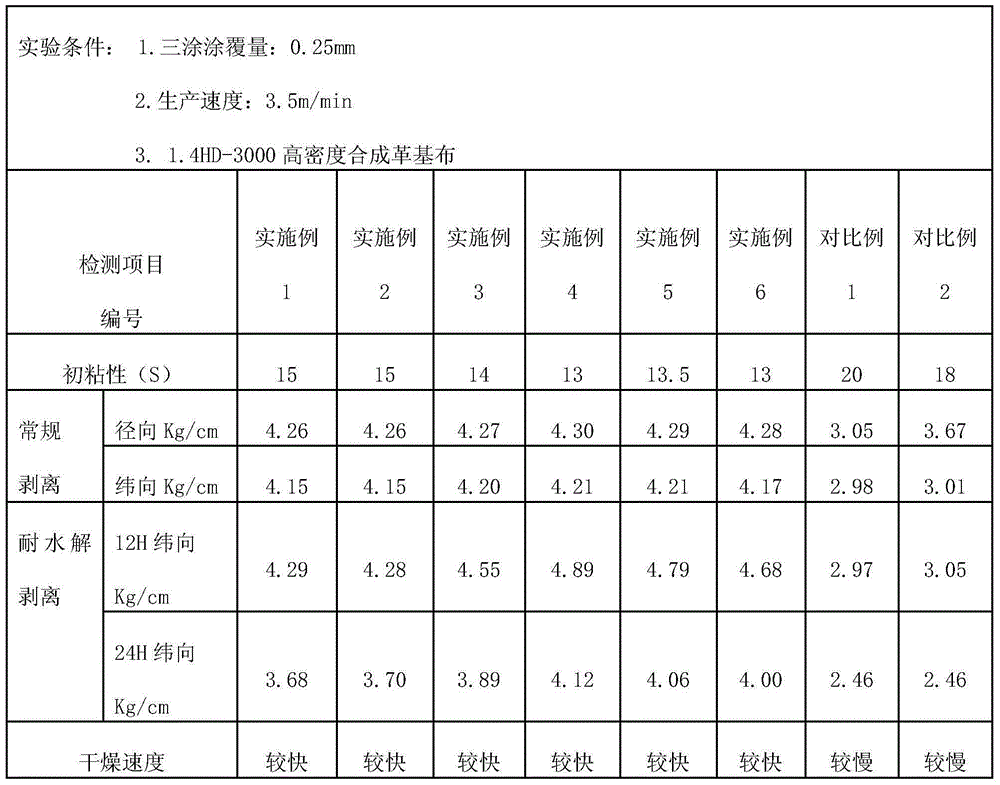

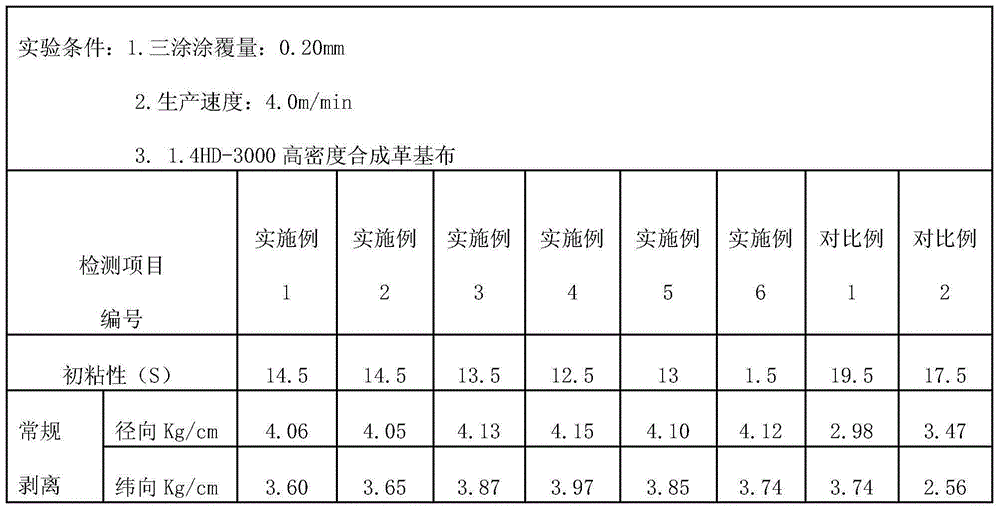

Examples

Embodiment 1

[0056] Taking the production of about 500 kg of epoxy resin-modified water-based polyurethane adhesives as an example, the raw material formula ratio adopts the lower limit of isocyanate, and uses HDI, stannous octoate, dimethylol propionic acid, 1.6-hexanediol, di Methylaminoethanol, ethylenediamine, and hydroxyethyl cellulose are used as raw materials.

[0057] Raw material components and formula: polytetrahydrofuran ether diol 2000: 73 kg, polytetrahydrofuran ether diol 3000: 12 kg, polycarbonate diol 1000: 6 kg, HDI: 23.1 kg, stannous octoate: 0.0045 kg, dihydroxy Methylpropionic acid: 5.7 kg, 1,6-hexanediol: 0.6 kg, trimethylolpropane: 0.3 kg, epoxy resin E-44: 4.8 kg, acetone: 40 kg, dimethylaminoethanol: 3.78 kg , Antioxidant 1010: 0.3 kg, deionized water: 342 kg, ethylenediamine: 1.5 kg, wetting agent 245: 1.5 kg, leveling agent 440: 1.5 kg, hydroxyethyl cellulose thickener: 4.0 kg .

[0058] Its preparation method steps are as follows:

[0059] (1) Synthesis of pol...

Embodiment 2

[0070] Taking the production of about 500 kg of epoxy resin-modified water-based polyurethane adhesive as an example, the raw material formula ratio adopts the lower limit of isocyanate, and uses IPDI, dibutyltin dilaurate, dimethylol propionic acid, and 1.6-hexanediol , dimethylaminoethanol, ethylenediamine, hydroxyethyl cellulose as raw materials.

[0071] Raw material components and formula: polytetrahydrofuran ether diol 2000: 95.4 kg, polytetrahydrofuran ether diol 3000: 11.4 kg, polycarbonate diol 1000: 6 kg, IPDI: 30.6 kg, dibutyltin dilaurate: 0.036 kg, Dimethylol propionic acid: 5.7 kg, 1,6-hexanediol: 0.6 kg, trimethylolpropane: 0.3 kg, epoxy resin E-44: 4.8 kg, DMF: 55 kg, dimethylaminoethanol: 3.78 kg, antioxidant 1024: 1.2 kg, deionized water: 342 kg, ethylenediamine: 1.5 kg, wetting agent 245: 1.5 kg, leveling agent 440: 1.5 kg, hydroxyethyl cellulose thickener: 4 kg.

[0072] Its preparation method steps are as follows:

[0073] (1) Synthesis of polyurethane ...

Embodiment 3

[0084] Taking the production of about 500 kg of epoxy resin modified water-based polyurethane adhesives as an example, the raw material formula ratio adopts the intermediate value of isocyanate, and uses IPDI, HDI, stannous octoate, dimethylol propionic acid, 1.4-cyclohexane di Methanol, triethylamine, hexamethylenediamine, and hydroxyethyl cellulose are used as raw materials.

[0085] Raw material components and formula: polytetrahydrofuran ether diol 2000: 95.79 kg, polytetrahydrofuran ether diol 3000: 11.2 kg, polycarbonate diol 1000: 5.63 kg, IPDI: 16.56 kg, HDI: 12.54 kg, stannous octoate: 0.029 kg, dimethylolpropionic acid: 6.48 kg, 1.4-cyclohexanedimethanol: 1.2 kg, trimethylolpropane: 0.6 kg, epoxy resin E-44: 6.9 kg, acetone: 50 kg, triethyl Amine: 4.86 kg, antioxidant 1010: 0.8 kg, deionized water: 342 kg, hexamethylenediamine: 2.1 kg, wetting agent 245: 2.0 kg, leveling agent 440: 2.0 kg, hydroxyethyl cellulose thickening Dosage: 4.5 kg.

[0086] Its preparation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com