Method for preparing composite water-based polyurethane

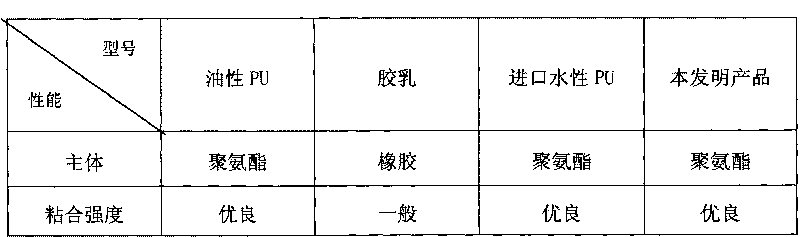

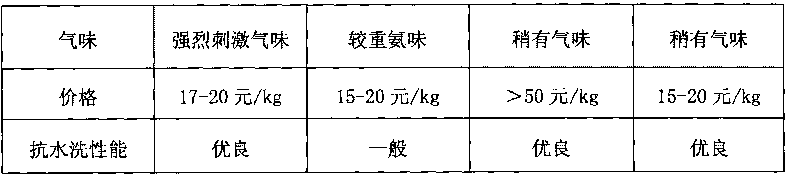

A technology of water-based polyurethane and polyether, which is applied in the fields of wood and clothing, can solve the problems of high price, heavy ammonia smell, and loss of strength, and achieve the effects of excellent washing resistance, convenient use, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

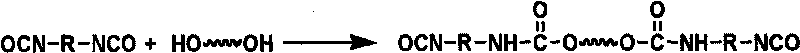

Method used

Image

Examples

Embodiment 1

[0026] Add 100 parts of polyether PPG210, 5 parts of epoxy resin E51, 34.05 parts of toluene diisocyanate TDI-80, 6.08 parts of crude MDI (diphenylmethane diisocyanate), add 0.015 parts of Dibutyltin dilaurate, heated to 78°C, pre-polymerized for two hours; measure the -NCO value 30 minutes in advance, and the -NCO value is determined by the di-n-butylamine chemical method in GB / T1722. After the -NCO value reaches 5.5-6, add 9 parts of dimethylol propionic acid, react for 3.5 hours, and measure the -NCO value again when it is 4.5-5; cool down to 50°C, add 60 parts of acetone, stir and cool down to 40 ℃, discharge material; put it into the dispersion bucket immediately, add 6.78 parts of triethylamine, stir for 5 minutes, add 357 parts of water, disperse at a high speed above 1000 rpm; disperse at high speed for 5 minutes, after the dispersion is uniform, add 1.5 parts of ethylenediamine , continue the chain extension reaction, reduce the speed to 50 rpm, and stir for 2.5 hours...

Embodiment 2

[0029] Put 80 parts of polyether PPG210, 3.5 parts of epoxy resin E51, 30 parts of toluene diisocyanate TDI-80, 4.5 parts of crude MDI (diphenylmethane diisocyanate), add 0.01 parts of Dibutyltin dilaurate, heated to 72°C, pre-polymerized for 1.5 hours; measure the -NCO value 25 minutes in advance, and the -NCO value is determined by the di-n-butylamine chemical method in GB / T1722. After reaching 5.5-6, add 7 parts of dimethylolpropionic acid, react for 2.5 hours, and measure again when the -NCO value is in the range of 4.5-5; cool down to 45°C, add 50 parts of acetone, stir and cool down to 30 ℃, discharge; immediately put into the dispersion bucket, add 5 parts of triethylamine, stir for 4 minutes, add 320 parts of water, disperse at a high speed above 1000 rpm; disperse at high speed for 4 minutes, add 0.7 parts of ethylenediamine after the dispersion is uniform , continue the chain extension reaction, reduce the speed to 30 rpm, and stir for 2 hours; airtight and static fo...

Embodiment 3

[0032] Add 120 parts of polyether PPG210, 8 parts of epoxy resin E51, 40 parts of toluene diisocyanate TDI-80, and 9 parts of crude MDI (diphenylmethane diisocyanate) into the reactor, and add 0.02 parts The dibutyltin dilaurate is heated to 82°C and pre-polymerized for 3 hours; the -NCO value is measured 40 minutes in advance, and the -NCO value is determined by the di-n-butylamine chemical method in GB / T1722. After reaching 5.5-6, add 12 parts of dimethylolpropionic acid, react for 5 hours, and measure the -NCO value again at 4.5-5; cool down to 55°C, add 70 parts of acetone, stir and cool down to 50°C, and release material; put it into the dispersion bucket immediately, add 8 parts of triethylamine, stir for 8 minutes, add 400 parts of water, and disperse at a high speed above 1000 rpm; disperse at a high speed for 7.5 minutes, add 3 parts of ethylenediamine after the dispersion is uniform, and continue to expand Chain reaction, reduce the speed to 40 rpm, stir for 3 hours;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com