Lutein ester microcapsule powder and preparation method thereof

A technology of lutein ester and microcapsule powder is applied in the field of preparation of cold water dispersible lutein ester microcapsule powder, can solve problems such as limiting the scope of application fields, and achieves green environmental protection technology, good stability and uniform color long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

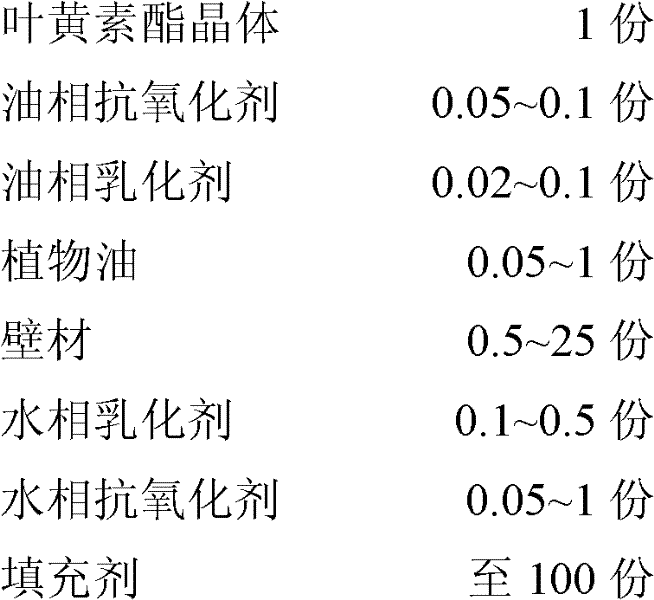

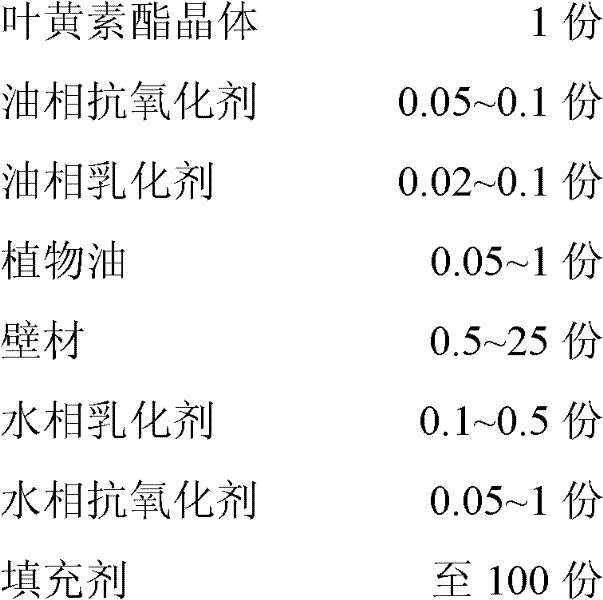

[0027] Prepare lutein ester microcapsule powder, first according to Table 1 ingredients (unit: gram):

[0028] Table 1

[0029] raw material name

Example 1

Example 2

Example 3

Example 4

Lutein Ester Crystals (Purity 68%)

1.5g

7.5g

15g

30g

dl-α-tocopherol: mixed natural VE (weight ratio) = 1:1

0.15g

0.75g

1.5g

3g

0.15g

0.75g

1.5g

3g

1.5g

3.5g

7g

10g

OSA-modified gum arabic

10g

18g

23g

30g

Sucrose palmitate: modified soybean lecithin (weight ratio) = 1: 2.5

0.15g

3.75g

7g

10g

Sodium ascorbate: tea polyphenols (weight ratio) = 2:1

0.15g

0.75g

1.5g

3g

White sugar

86.4g

72.5g

58.5g

41g

water

100g

200g

450g

900g

[0030] ① Weigh lutein...

Embodiment 5~8

[0038] Prepare lutein ester microcapsule powder, first according to Table 3 ingredients (unit: gram):

[0039] table 3

[0040] raw material name

Example 5

Example 6

Example 7

Example 8

Lutein Ester Crystals (Purity 68%)

1.5g

7.5g

15g

30g

dl-alpha-tocopherol

0.075g

0.52g

0.75g

1.2g

glyceryl monooleate

0.12g

0.68g

0.60g

0.60g

0.22g

7.5g

0.75g

24g

OSA-modified gum arabic

37.5g

22.5g

15g

18g

Modified Soy Lecithin

0.3g

2.6g

6.5g

14.4g

sodium ascorbate

0.12g

3.0g

0.75g

7.5g

glucose

60.165g

55.7g

60.65g

4.3g

water

150g

300g

450g

500g

[0041]① Weigh lutein ester crystals, dl-α-tocopherol, glyceryl monooleate and glyceryl caprylate according to the above tabl...

Embodiment 9~12

[0049] Prepare lutein ester microcapsule powder, first according to Table 5 ingredients (unit: gram):

[0050] table 5

[0051] raw material name

Example 9

Example 10

Example 11

Example 12

Lutein Ester Crystals (Purity 68%)

1.5g

7.5g

15g

30g

Mix natural VE

0.11g

0.6g

0.9g

2.8g

0.10g

0.33g

0.70g

2.3g

sunflower oil

3g

15g

9g

10g

OSA-modified starch

30g

24g

45g

30g

0.65g

2.55g

3.5g

3.3g

Tea polyphenols

0.25g

1.5g

1.2g

3.2g

64.39g

48.52g

24.7g

18.4g

water

200g

250g

500g

600g

[0052] ① Weigh lutein ester crystals, dl-α-tocopherol, glyceryl monooleate and glyceryl caprylate according to the above table 5, mix thoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com