Patents

Literature

59 results about "GLYCERYL MONOLAURATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

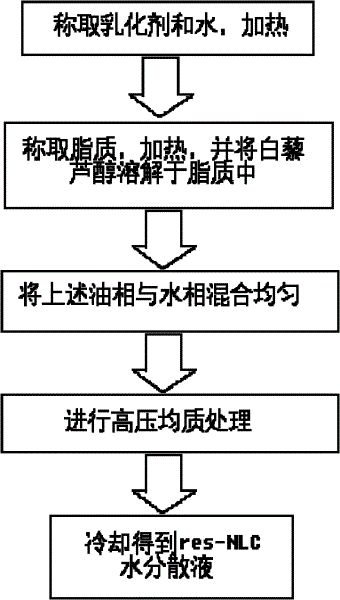

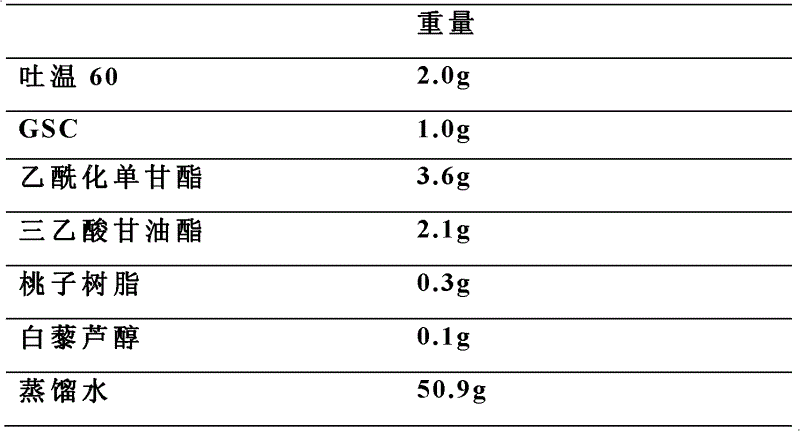

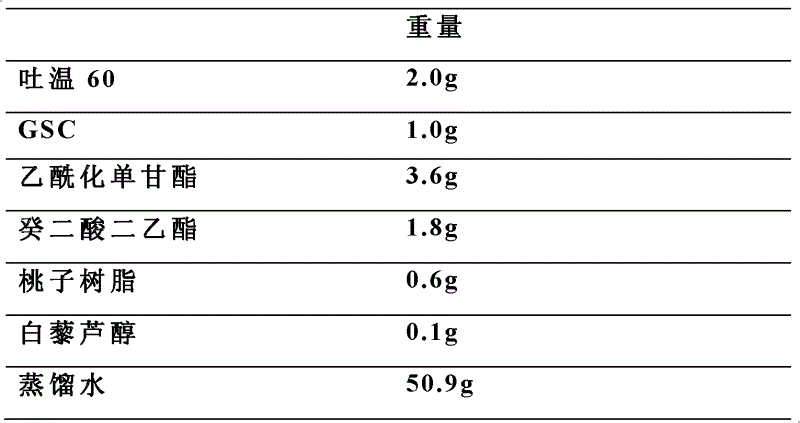

Resveratrol nanostructured lipid carrier and preparation method thereof

InactiveCN102614091AStructural disorderImprove stabilityCosmetic preparationsToilet preparationsLipid formationSolubility

The invention discloses a resveratrol nanostructured lipid carrier. The resveratrol nanostructured lipid carrier is loaded with active pharmaceutical ingredients of resveratrol and is characterized by comprising 0.1 to 1wt% of resveratrol, 2 to 20wt% of at least one emulsifier, 2 to 30wt% of a composite lipid material and the balance water, wherein the composite lipid material is a mixture of at least one solid lipid material and at least one liquid lipid material. The at least one solid lipid material and the at least one liquid lipid material are selected from glyceryl triacetate, acetylated monoglyceride, diethyl sebacate, diisopropyl adipate, diisopropyl sebacate, glycerol monolaurate, peach resin and an octadecyl alcohol. The resveratrol nanostructured lipid carrier has good stability and water-solubility. The preparation method of the resveratrol nanostructured lipid carrier is simple and controllable and has good repeatability. The resveratrol nanostructured lipid carrier can be utilized in preparation of resveratrol-containing cosmetics.

Owner:夏强 +1

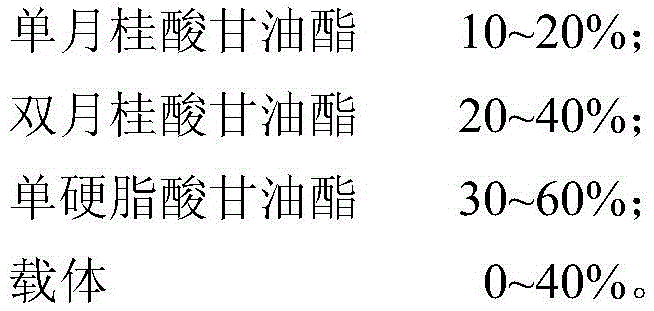

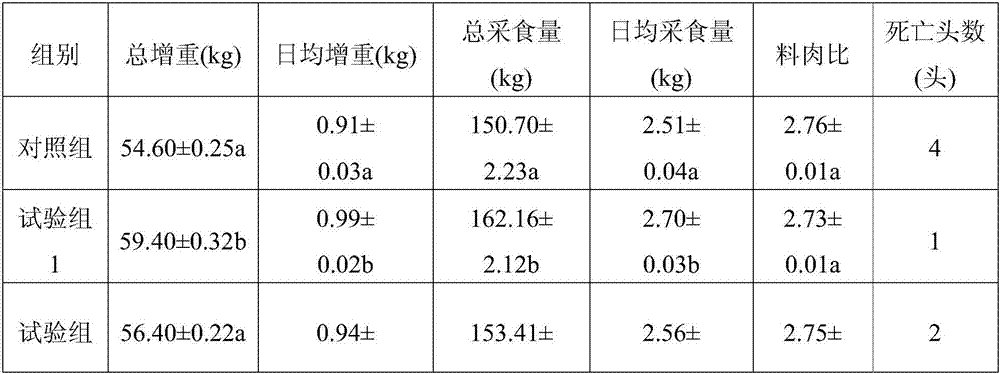

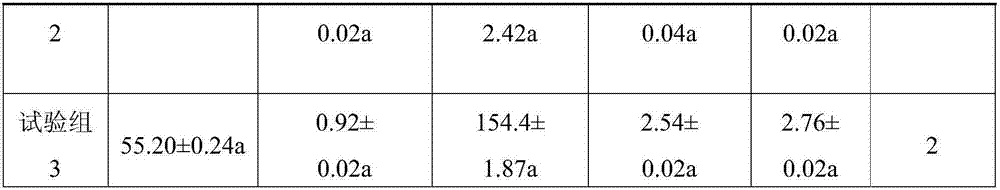

Feed additive capable of replacing antibiotics and application of feed additive

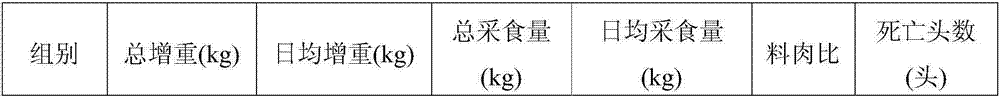

The invention discloses a feed additive capable of replacing antibiotics and application of the feed additive. The feed additive is prepared from the following raw materials in weight percent: 10 % to 20% of glyceryl monolaurate, 20% to 40% of didansylhistamine, 30% to 60% of glycerin monostearate and 0 to 40% of a carrier. The feed additive provided by the invention is prepared by taking the glyceryl monolaurate, the didansylhistamine and the glycerin monostearate as the main raw materials and compounding according to a proper ratio and can replace the antibiotics in a piglet cultivation process; the disease-resisting capability of piglets is improved, the development of intestinal tracts is promoted and the functions of the intestinal tracts are improved; the daily gain and feed intake are remarkably improved, the diarrhea rate and the death and culling rate are remarkably reduced, the feed conversion ratio is improved, the growth and development are promoted, the economic benefits of cultivation are improved, the utilization of the antibiotics is reduced, the environment pollution is reduced, and the green, safe and healthy development of a pig industry is facilitated.

Owner:ZHEJIANG UNIV +1

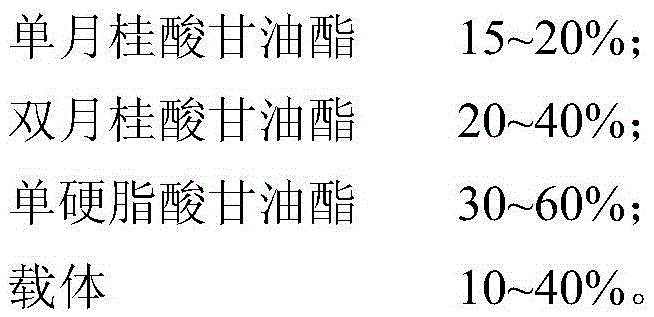

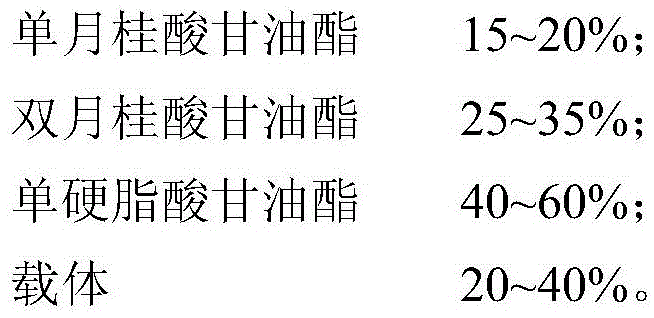

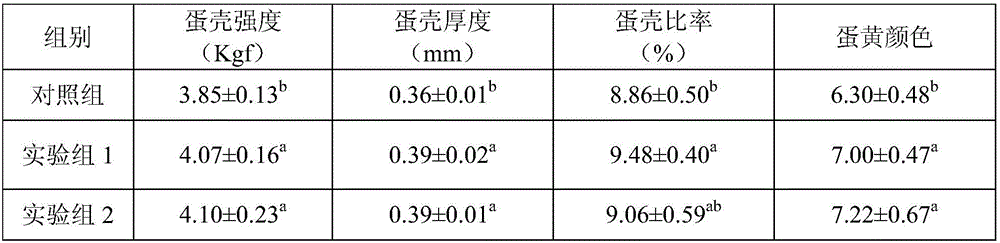

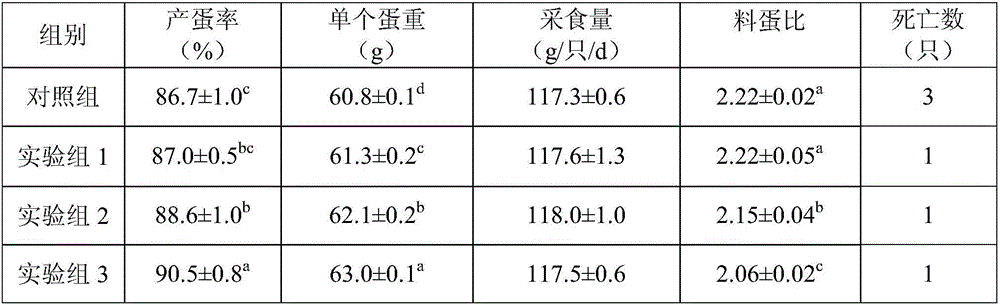

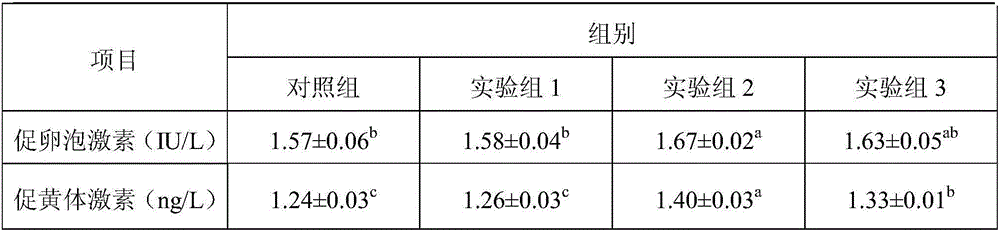

Application of feed additive in preparation of laying hen feed for improving egg quality and egg laying capability

ActiveCN105901390AImprove qualityImprove egg production performanceFood processingAnimal feeding stuffAnimal scienceGlycerol

The invention discloses an application of a feed additive in preparation of a laying hen feed for improving egg quality and egg laying capability. The feed additive includes, by weight, 10-45% of glycerol monolaurate, 10-30% of glycerol dilaurate, 30-50% of glycerol monostearate, and 0-20% of a carrier. In feed additive, the glycerol monolaurate, the glycerol dilaurate and the glycerol monostearate are combined together, so that the feed additive significantly improves the egg quality and improves the egg laying capability of a laying hen.

Owner:ZHEJIANG UNIV +1

Anti-fogging and non-dropping film and preparation method thereof

The invention provides an anti-fogging and non-dropping film. The anti-fogging and non-dropping film comprises the following components in parts by weight: 70 to 200 parts of LLDPE (Linear Low Density Polyethylene), 15 to 50 parts of LDPE (Low-Density Polyethylene), 10 to 30 parts of EVA (Ethylene-vinyl Acetate), 20 to 50 parts of DOP (Dioctyl-Phthalate), 15 to 30 parts of BBP (Butyl Benzyl Phthalate), 0.5 to 2 parts of dibutyl tin dialurate, 3 to 7 parts of 2-ethylhexyl ester of epoxy fatty acids, 4 to 8 parts of tricresyl phosphate, 1.5 to 4 parts of glyceryl monolaurate, 1 to 6 parts of triphenyl phosphate, 0.2 to 0.8 part of ultraviolet light absorber, 0.5 to 0.9 part of calcium carbonate, 1 to 5 parts of cadmium stearate, 2 to 8 parts of barium stearate, and 0.2 to 0.7 part of sorbitan monostearate. The preparation method comprises the following steps of: drying LLDPE, LDPE and EVA under vacuum; adding other components; performing film blowing through a horizontal extruding and blowing method by utilizing a single-screw extruding film blowing device, thus obtaining the anti-fogging and non-dropping film. The anti-fogging and non-dropping film shows remarkable advantages that water on the surface of the film can flow into the soil along the surface of the film, thus moisture in the air in a greenhouse is reduced, and the anti-fogging effect is realized.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

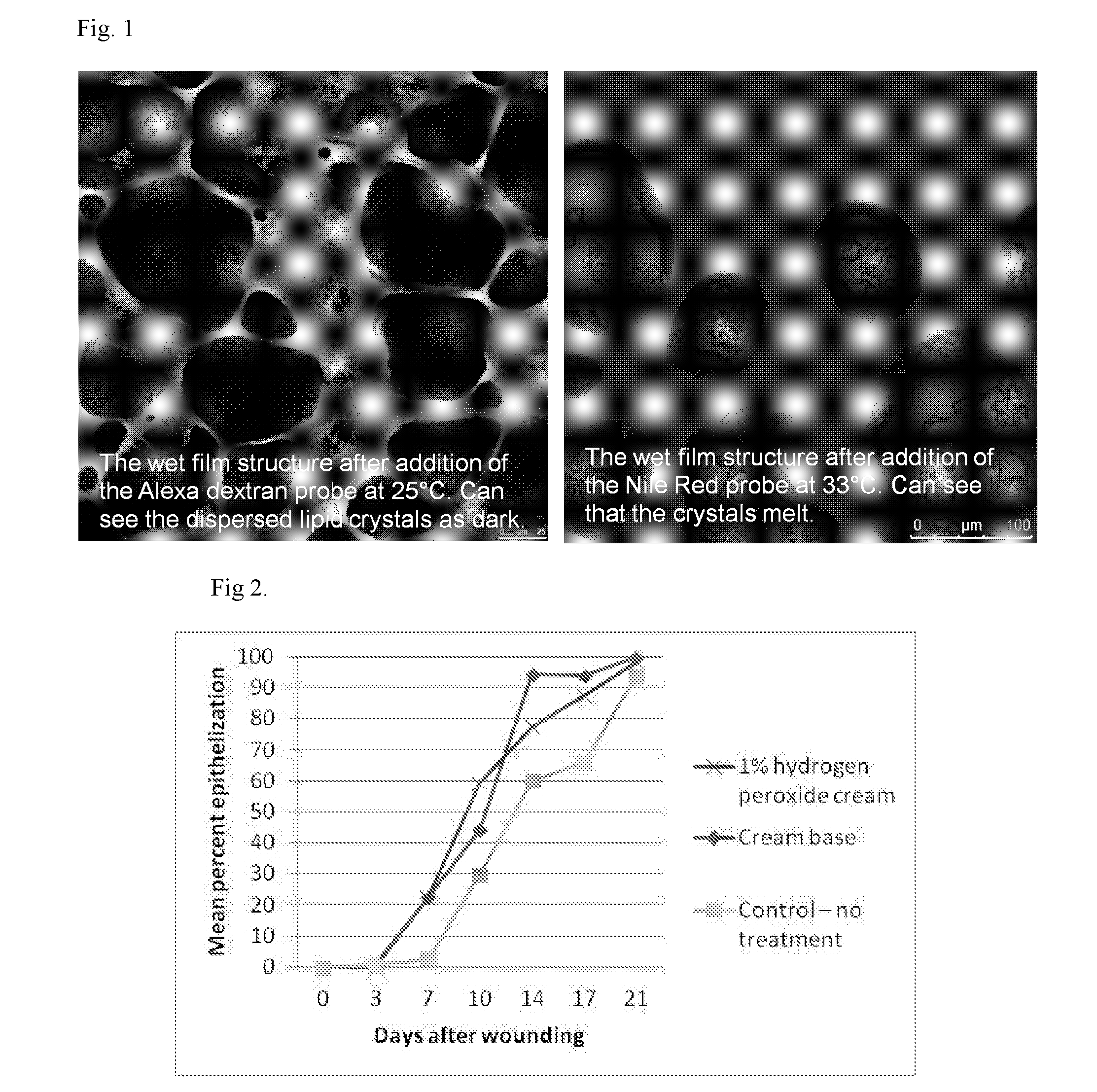

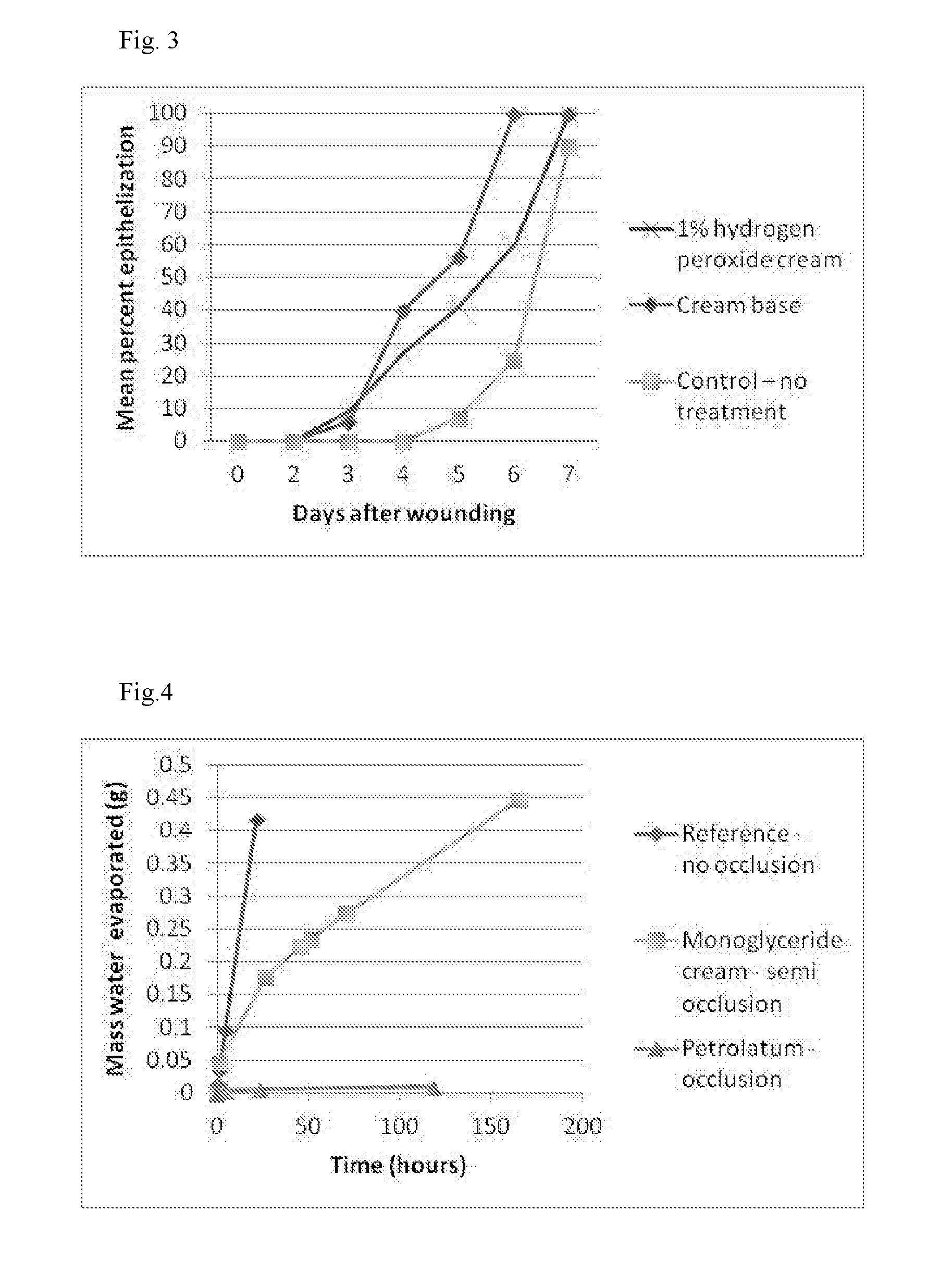

Composition for use in reducing scab formation and promoting healing

InactiveUS20160081968A1Reducing scab formationPromote healingBiocideAerosol deliveryLiquid crystallineMyristic acid

The present invention relates to a composition comprising at least one mono-glyceride chosen from glyceryl monocaprylate, glyceryl monolaurate and glyceryl monomyristate, and hydrophilic solvent, having a liquid crystalline lamellar structure at a temperature of above about 37° C., a solid crystalline lamellar structure below about 30° C. and a transformation of said solid and liquid crystalline lamellar structures at from about 30° C. to about 37° C., for use in treatment of cuts and wounds, said composition providing a moisturizing effect of said injury or wound, for reducing scab formation and promote healing in connection with injuries or wounds.

Owner:BIOGLAN AB

Compound spicy food preservative

InactiveCN101336745APrevent spoilageImprove the preservation effectFood preservationSodium acetateAdditive ingredient

A composite spicy food preservation agent including Single-laurate glyceride, dehydro sodium acetate, potassium sorbate, Nipagin acetate, sodium diacetate, Natamycin, Nisin, and other components. Using preservation of biological and chemical composition which are safe to human body , the preservation agent can prevent the deterioration caused by microorganism, improve the save performance, and extend the guarantee period of spicy food to at least one time longer than the similar commercial preservation agents.

Owner:唐洪权

Bean product preservative and application thereof

ActiveCN103783629AExtended shelf lifeGrowth inhibitionClimate change adaptationFood preservationPreservativeNational standard

The invention discloses a bean product preservative and application thereof. The bean product preservative comprises the following components in percentage by weight: 20%-60% of lauric acid monoglyceride, 20%-40% of an acidifying agent and 20%-50% of monostearin. The invention also provides application of the preservative to bean product preservation. The bean product preservative is capable of effectively inhibiting the growth of spoilage microorganisms in bean products and prolonging the shelf life of the bean products and also has a good defoaming effect; the components in the bean product preservative meet the national standard and can be applied to all the bean products; the bean product preservative is convenient to use, and the conventional process is not required to be changed, so that the bean product preservative can be widely used in the bean product preservation technology.

Owner:ZHEJIANG UNIV +1

Nutrient milk with rich neurotic acids and acer truncatum oil and its preparation

InactiveCN1711858ASolve the problem of lack of nervous acidActive cranial nerveMilk preparationNervonic acidPolyglycerol monostearate

A nutritive fresh Pterocarys stenoptera milk rich in nervonic acids is prepared through proportionally adding tripolyglyceride monostearate (PGFE), glyceride monolaurate (GML), calcium stearyllactate-sodium stearyllactate (CSL-SSL), purified water and Pterocarya stenoptera oil into container, homogenizing while emulsifying, and mixing with fresh milk. It can nourish brain and delay senility.

Owner:杨凌圣羊乳业有限公司

Skin care cosmetic containing liposome recombinant human growth hormone and preparation method thereof

InactiveCN101711729AHigh encapsulation efficiencyThe activity can be maintained for a long timeCosmetic preparationsToilet preparationsGlycerolAlpha-Lipoic Acid

The invention relates to a skin care cosmetic, in particular to a skin care cosmetic containing liposome recombinant human growth hormone. The cosmetic comprises polyoxyethylene fatty alcohol ether, polysorbate 60, monolaurin, hexadecanol, liquid paraffin, glycerol, sodium polyacrylate, polyvinylpyrrolidone K30, alpha-lipoic acid, perfume, preservative, ionized water, liposome human growth hormone. A surface active agent is introduced in the preparation process of liposome so that the encapsulation rate of the liposome human growth hormone is obviously improved. The invention can emulsify a product by a production technology of micro-emulsion to prepare millimicro-emulsion with the grain diameter of 100-200mm, thereby improving the local penetrability of the cosmetic on the skin, enabling an active substance to directly act on the horny layer to be uniformly distributed and showing more favorable effects of aging resistance, facial care, and the like and being more suitable for sensitive skin.

Owner:江西宇骏生物工程有限公司

Corrosion-resistant anti-microbial aluminum-profile rare-earth silane treating fluid and preparation method thereof

InactiveCN105200416AGood film formingImprove antibacterial propertiesMetallic material coating processesSilanesRare earth

The invention discloses a corrosion-resistant anti-microbial aluminum-profile rare-earth silane treating fluid. The corrosion-resistant anti-microbial aluminum-profile rare-earth silane treating fluid is prepared from, by weight, 120-130 parts of CeCl<3>7H2O, 180-190 parts of H2O2, 0.5-0.6 part of poly-sebacic glyceryl monolaurate, 0.3-0.4 part of nano samarium, 0.4-0.6 part of turpentine oil liquid anhydride, 0.4-0.5 part of itaconic acid, an appropriate amount of deionized water, 1-1.2 parts of tetraethyl orthosilicate, 5-5.2 parts of methyl triethoxysilane, 50-53 parts of ethanol, 10-11 parts of ammonia water, 15-15.6 parts of fluorine and silicon-containing polyacrylate emulsion and 2-2.5 parts of nano zirconium dioxide. The compactness of a film formed by the treating fluid is greatly improved, and the film has certain water-repellent performance. The film forming speed is high and the film is uniform and compact by using the poly-sebacic glyceryl monolaurate, the turpentine oil liquid anhydride and the itaconic acid. The antibacterial property, the oxidation resistance and abrasion resistance of the film are improved by using the nano samarium.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

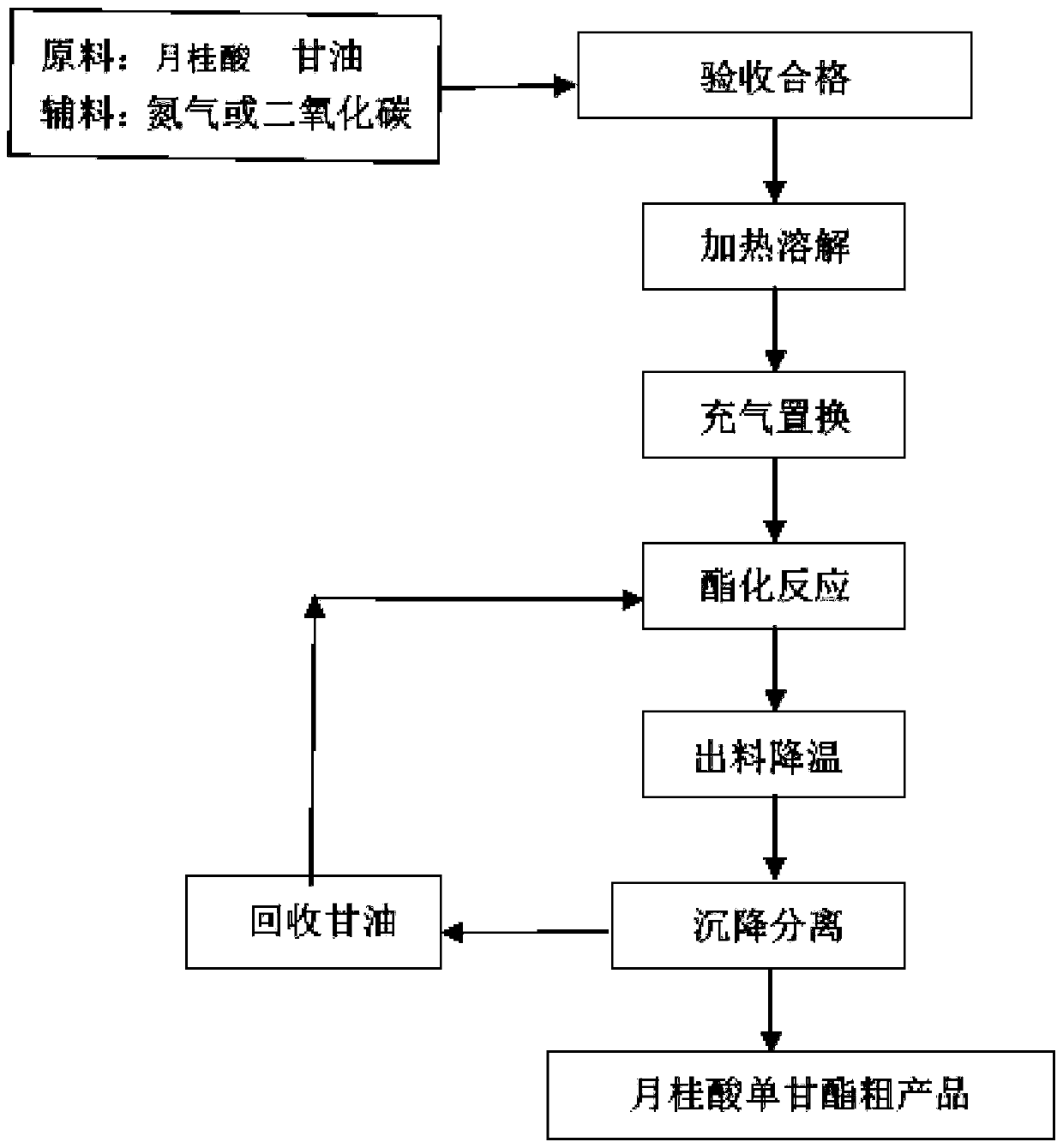

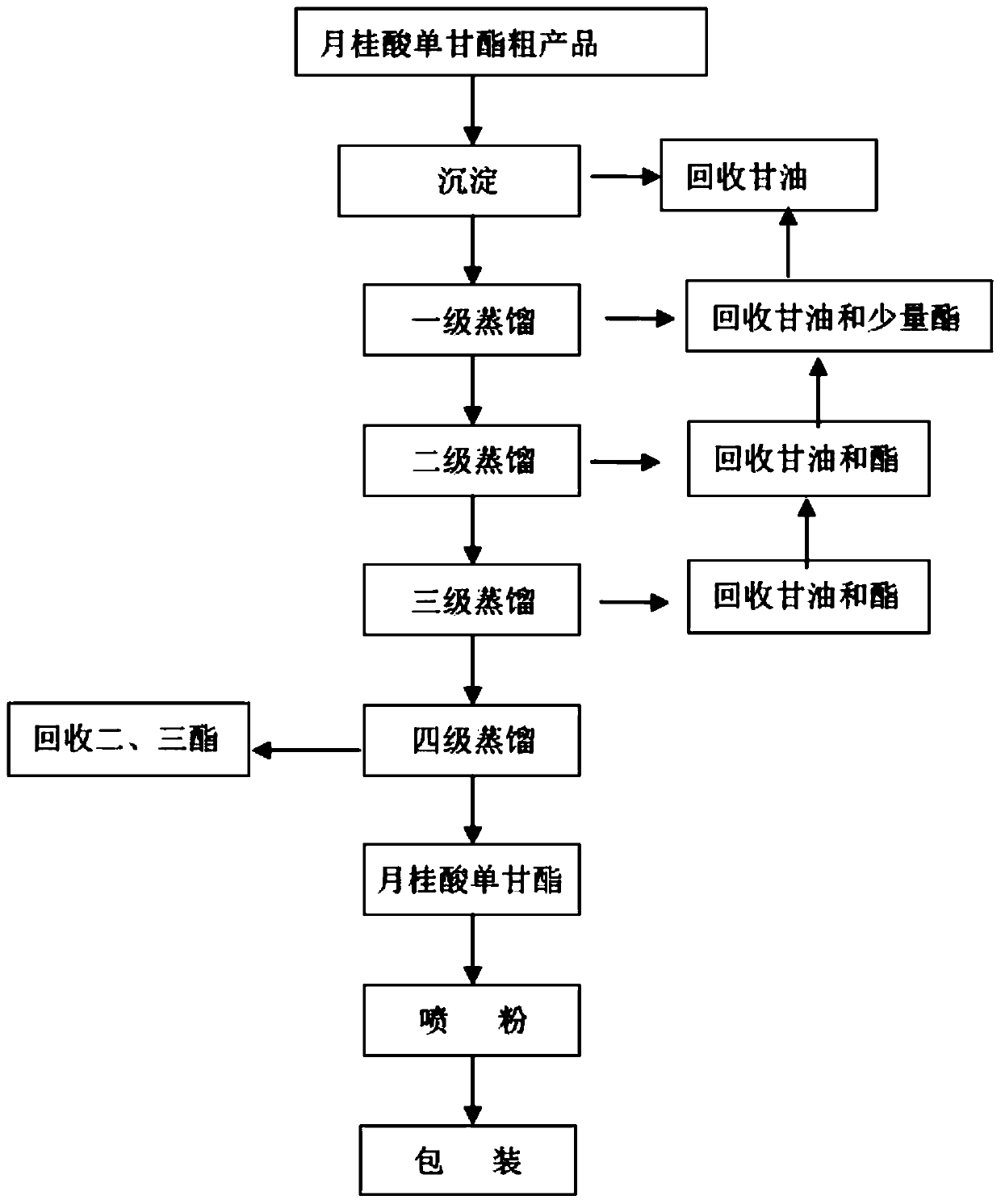

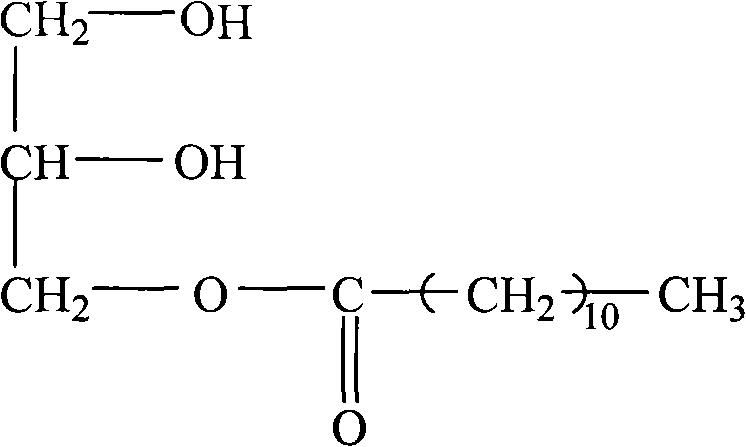

Preparation method for high-purity glyceryl monolaurate

ActiveCN105418417AHigh purityWide variety of sourcesOrganic compound preparationCarboxylic acid esters preparationDistillationGLYCERYL MONOLAURATE

The invention provides a preparation method for high-purity glyceryl monolaurate. The preparation method comprises the steps of: mixing lauric acid, glycerinum and a catalyst to obtain a mixed liquid; preheating the mixed liquid; then adding the heated mixed liquid into a vacuum reaction for reaction; after reaction, obtaining a coarse ester; quickly cooling the coarse ester to 120-150 DEG C; filtering the coarse ester to obtain the supernatant so as to obtain the glyceryl monolaurate with the purity of 35-45%; and finally, performing four-stage distillation to obtain the glyceryl monolaurate with the purity of 85-95%.

Owner:HANGZHOU FUCHUN FOOD ADDITIVE

Antibacterial environment-friendly composite board and preparation method thereof

InactiveCN104692760AGood antibacterial effectHigh strengthSolid waste managementGlycerolOleic Acid Triglyceride

The invention discloses an antibacterial environment-friendly composite board. The antibacterial environment-friendly composite board is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of shrimp shell meal, 10-15 parts of pine bark powder, 5-10 parts of kaoline, 5-10 parts of bagasse, 5-10 parts of tea residue, 0.1-0.2 part of dodecyl glucoside, 2-4 parts of silicone-acrylate emulsion, 1-2 parts of glycerol, 2-4 parts of oleic acid, 0.2-0.4 part of glyceryl monolaurate and 10-20 parts of binding aid. The composite board has excellent antibacterial effect, and is capable of purifying the indoor air and improving the indoor environment; the composite board is excellent in strength and toughness, stable in properties, uniform in texture and good in usability; and in addition, the composite board is wide in raw material source, economical and practical, non-toxic and harmless, green and environment-friendly, and is suitable for indoor environments.

Owner:安徽忠盛新型装饰材料有限公司

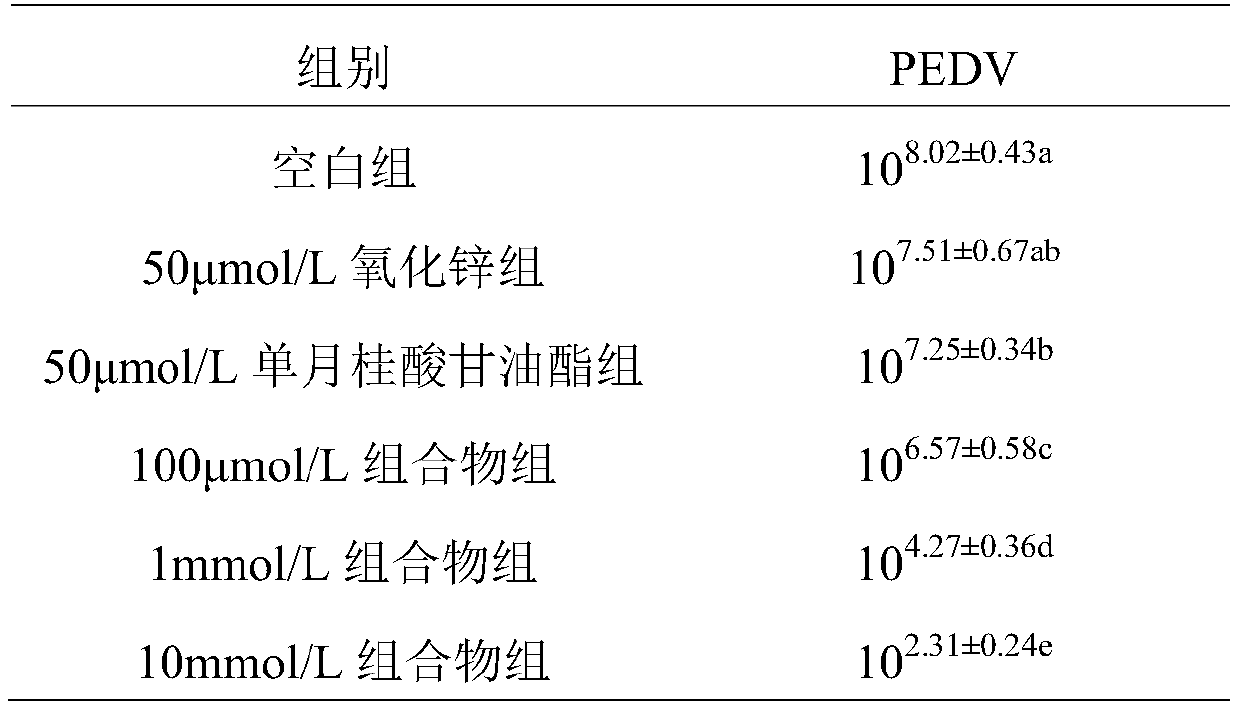

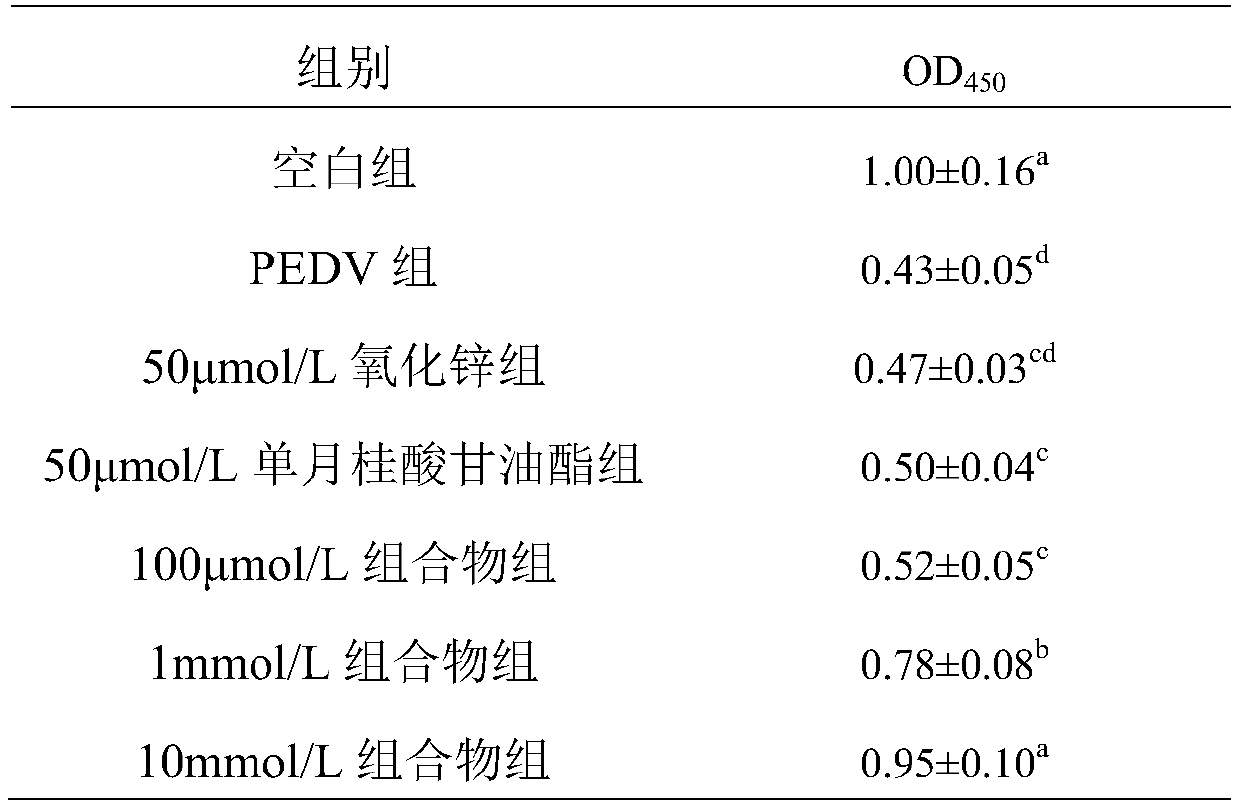

Composition resisting porcine epidemic diarrhea virus infection and application thereof

ActiveCN110354139APrevent proliferationGive full play to the synergistic anti-PEDV effectInorganic active ingredientsAntiviralsAntiviral drugSide effect

The invention discloses a composition resisting porcine epidemic diarrhea virus infection and application thereof. The composition comprises zinc oxide and glycerol monolaurate in a mass ratio of (0.5-2):1. The composition has the remarkable effects of inhibiting the replication of the porcine epidemic diarrhea virus and reducing the virulence of the porcine epidemic diarrhea virus, can serve as afeed additive or an oral agent, overcomes the defects of immunity failure possibly occurring after vaccination and virus variation caused by the use of antiviral drugs, has no toxic or side effect onanimals, and can be used safely.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Preparation method of VI-type slowly-digestible starch

The invention relates to a preparation method of VI-type slowly-digestible starch. The preparation method comprises the following steps of: adding 0.3-0.8 percent by mass of monoglyceryl laurate ester into high-amylose corns serving as raw materials; dispersing a mixture obtained from the former step into 40 percent of ethanol solutions (w / v) of which the volume is seven times that of the mixture; dropwise adding 1.5mol / L of KOH solution (w / v) of which the volume is five times that of the mixture; at the end of reaction, performing heat non-crystallizing for 24 hours by using alkali in 1.5mol / L of citric acid neutralizing system after dehydration, desalination and impurity removal; and pulverizing and screening to obtain the VI-type slowly-digestible starch. An external digestion experiment result shows that the content of the VI-type slowly-digestible starch is about 78 percent; by using a differential scanning calorimeter and an X-ray diffraction technology, the analysis on heat stability and crystal forms of the VI-type slowly-digestible starch is carried out; and a result shows that the thermal decomposition temperature (Tp) of the VI-type slowly-digestible starch prepared by using the technology is up to 100 DEG C, and enthalpy change (delta H) is 20-23J.g-1; and moreover, the VI-type slowly-digestible starch belongs to a VI-type starch complex.

Owner:JIANGNAN UNIV

Feeding composite organic microelement additive and preparation method thereof

InactiveCN105494955AIncrease the gapPromote formationAccessory food factorsFeed additiveZinc sulphate monohydrate

The invention relates to the technical field of feed additive pretreatment, and in particular to a feeding composite organic microelement additive and a preparation method thereof. The additive is prepared by coating the surface of a composite organic microelement particle with a glycerol monolaurate layer and a pregelatinized starch layer from inside to outside in sequence, wherein the composite organic microelement particle is mainly prepared from the following raw materials: ferrous sulfate monohydrate, blue copperas, zinc sulphate monohydrate, manganese sulfate monohydrate, cobaltous sulfate heptahydrate, sodium selenite, organic acid, polysaccharide, peptide and protein. According to the additive, by taking the organic acid, the polysaccharide, the peptide and the protein as organic ligands to compound with various composite inorganic microelement compounds, the composite organic microelement microcrystal grains are produced, and the surface of each particle is coated with glycerol monolaurate and pregelatinized starch so as to isolate dissociation of gastric acid to composite organic microelements; after entering intestinal tracts, the composite organic microelement microcrystal particles release core composite organic microelements, therefore bioavailability of the composite organic microelements is increased.

Owner:河南艾德昕生物科技有限公司

Paphiopedilum body wash and processing method thereof

InactiveCN107349164AModerate decontamination abilityRefreshingCosmetic preparationsNervous disorderSOAPGardenia yellow

The invention discloses paphiopedilum body wash. The paphiopedilum body wash is prepared from raw materials in parts by weight as follows: 10-20 parts of paphiopedilum, 5-8 parts of aloe, 5-8 parts of mint leaves, 4-6 parts of chaenomeles sinensis, 4-6 parts of fresh ginger, 3-5 parts of sulfur soap, 5-15 parts of almond oil, 1-3 parts of propylene glycol, 1-3 parts of sodium glyceryl monolaurate sulfate, 1-2 parts of citric acid, 1-3 parts of sodium chloride, 0.01-0.1 parts of sorbic acid, 0.05-0.1 parts of gardenia yellow pigment and 50-80 parts of deionized water. The invention further discloses a processing method of paphiopedilum body wash. The processing method comprises seven processing steps as follows: extraction, abstraction, boiling, blending, sampling detection, defoaming and inspection and can filling. The paphiopedilum body wash has slight faint scent, has functions of refreshing and restoring consciousness, moisturizing and beautifying skin, nourishing skin and retaining water, and is particularly suitable for middle-aged women and worthy of popularization.

Owner:QIANXINAN LVYUAN ANIMAL SCI & TECH DEV

Artificial low-fat butter and preparation method thereof

The present invention discloses an artificial low-fat butter and a preparation method thereof. The artificial low-fat butter is made from the following raw materials: low-fat butter, refined corn oil, refined peanut oil, refined olive oil, hydrogenated palm kernel oil, selenium-rich wheat germ oil, grape seed oil , water, whole milk powder, potato starch, fructooligosaccharides, sodium caseinate, microcrystalline cellulose, sucrose fatty acid ester, glycerylmonolaurate, glycerylmonostearate, soy lecithin, edible essence, beta-carotene, lycopene, edible salt, glutathione, antioxidant of bamboo leaves, tea polyphenols and sodium dehydroacetate. The product is harmony in fragrance, delicate in tissue, cut neat, shiny, sweet, salty and delicious, and oily but not greasy. By adding a variety of nutrients, the artificial low-fat butter increases health-care function, benefits human body health, has efficacies of preventing against aging and cancers, preventing cardiovascular and cerebrovascular diseases, beautifying features and nourishing skin, and promoting digestion, and can mitigate the adverse effects of high fat on the human body, and suppress the generation of cardiovascular and cerebrovascular diseases.

Owner:ANHUI TIANXIANG GRAIN & OIL FOOD

Emulsifying agent for feed and production technology of emulsifying agent

InactiveCN107581357AIncrease profitIncrease production capacityAccessory food factorsMonoglycerideSucrose

The invention discloses an emulsifying agent for a feed. The emulsifying agent comprises the following components in parts by weight: 10-40 parts of soybean phospholipid, 10-20 parts of a soybean mealemulsion, 4-10 parts of sucrose fatty acid esters, 2-10 parts of glycerol monolaurate, 2-10 parts of polyglycerin esters, 20-40 parts of monoglycerides, 1-3 parts of lipases, and 2-6 parts of guar gum. A production technology of the emulsifying agent comprises the following steps of (1) preparing the soybean meal emulsion; (2) weighing the monoglycerides which is one third of the formula additiveamount as a dissolving substrate, adding the sucrose fatty acid esters and the glycerol monolaurate, so that sufficient dissolving and swelling are realized, and a solution A is prepared; (3) preparing a solution B; (4) preparing a solution C; and (5) adding the soybean meal emulsion and the solution C to an emulsifying kettle, performing uniform stirring, then adding the polyglycerin esters to the emulsifying kettle, and performing uniforms stirring, so as to obtain the emulsifying agent. The emulsifying agent disclosed by the invention can be widely applied to the field of feeds, and is good in emulsifying effect, the utilization rate of fat in the feed is increased, the breeding cost is saved and the breeding benefits are increased. The emulsifying agent has favorable nutrients, has the functions of resisting bacteria, diminishing inflammation and the like, and has the effect of being antiseptic.

Owner:MAILUN ZHANGZHOU BIOTECH CO LTD

Cleaning agent for bottom of steel ship and preparation method of cleaning agent

The invention provides a cleaning agent for the bottom of a steel ship and a preparation method of the cleaning agent. The cleaning agent comprises the following raw materials in parts by mass: 5-20 parts of Urbacid, 3-13 parts of oleic diethanolamide, 5-15 parts of sodium silicate, 2-8 parts of tricresyl phosphate, 6-17 parts of potassium hydroxide, 6-16 parts of kaolin, 2-5 parts of paraffin, 6-18 parts of iron oxide red, 10-20 parts of sorbitol, 2-10 parts of sodium stearate, 1-5 parts of glyceryl monolaurate, 1-6 parts of polyacrylic acid and 10-22 parts of xylene. The cleaning agent for the bottom of the steel ship is capable of removing all the dirt on the surface of the bottom of the steel ship without harm to the bottom of the ship, and also capable of effectively removing and preventing the attachment of oil contaminations and marine organisms.

Owner:WUXI EPIC TECH

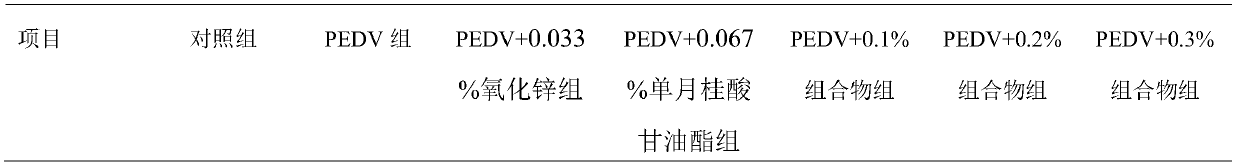

Application of additive composition in preparation of swine fattening feed for improving pork quality or growth performance

InactiveCN106901007AIntegrity guaranteedImproves villi developmentAccessory food factorsWorking-up animal fodderFlavorFood additive

The invention discloses application of an additive composition in preparation of swine fattening feed for improving the pork quality or growth performance, and belongs to the technical field of feed additives. The additive composition is prepared from the following components in percentage by mass: 20-50 percent of glyceryl monolaurate, 10-40 percent of dilaurin and 20-60 percent of carrier. By compounding glyceryl monolaurate and dilaurin according to proper content and proportion, the additive composition used in swine fattening phase can be used for improving the growth performance in the fattening phase and increasing cultivation economic benefit. The feed additive can remarkably improve the redness and intramuscular fat of pork and accelerate digestion and absorption of exogenous nutrients, so that the nutritional quality of pork can be improved, and the cooked pork has better flavor. The feed additive guarantees safe and harmless meat product quality, brings safety protection to swine production, and has a great application value.

Owner:ZHEJIANG UNIV +1

Water-soluble lubricant for metal material processing

InactiveCN110452767AImprove extreme pressure performanceImprove Oxidation StabilityAdditivesSolubilityMetallic materials

The invention discloses a water-soluble lubricant for metal material processing. The lubricant is prepared from the following raw materials in parts by weight: 50-55 parts of modified vegetable oleicacid, 20-25 parts of glycerinum, 5-8 parts of sodium sulfamate, 30-35 parts of absolute ethyl alcohol, 5-8 parts of an antirust auxiliary agent, 3-5 parts of a mildew-proof sterilization auxiliary agent, 3-5 parts of glyceryl monolaurate and 60-65 parts of deionized water. The invention further discloses a preparation method of the water-soluble lubricant for metal material processing. In the preparation process of the water-soluble lubricant for metal material processing provided by the invention, the modified vegetable oleic acid, the antirust auxiliary agent, the mildew-proof sterilizationauxiliary agent, the glyceryl monolaurate and the sodium sulfamate are added, so that the extreme pressure property, antirust property, oxidation stability, water solubility, mildew-proof bactericidalproperties and hygroscopicity of the lubricant are greatly improved, the processability of a metal material is improved, the service life of a tool is prolonged, the antirust, mildew-proof and bactericidal properties of a processed object are improved, and the lubricant has good market application prospects.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Feeding microelement amino acid chelate additive and preparation method thereof

InactiveCN105614075AGood dispersionImprove bioavailabilityAccessory food factorsStrong acidsBioavailability

The invention relates to the technical field of feed additive pretreatment, and particularly discloses a feeding microelement amino acid chelate additive and a preparation method thereof. The additive is prepared by coating the surface of a microelement amino acid chelate with a glycerin monostearate layer and a monolaurin layer in sequence from inside to outside, wherein the parts by weight of all raw materials are 5-7 parts of the microelement amino acid chelate, 1-2 parts of glycerin monostearate and 1-2 parts of monolaurin. Both the glycerin monostearate and the monolaurin have strong acid resistance, and separate the dissociation of gastric acid to the microelement amino acid chelate; after the additive enters the intestinal tract, the coating layers are digested, further the microelement amino acid chelate inside is released and is quickly absorbed and utilized, and the bioavailability of the microelement amino acid chelate is increased. The preparation method is simple and convenient to operate, easy to control, and suitable for industrial popularization and application.

Owner:河南艾德昕生物科技有限公司

Compound emulsifier for solid-content-containing soft capsule and preparation method thereof

InactiveCN107019201AMeet the needs of emulsificationIn line with health theoryFood scienceSucroseMonoglyceride

The invention relates to a compound emulsifier for a solid-content-containing soft capsule and a preparation method thereof. The compound emulsifier comprises soyabean lecithin, sucrose fatty acid ester, glycerol monolaurate and monoglyceride. The compound emulsifier overcomes the limitation of adding the single emulsifier into the solid-content-containing soft capsule; the characteristics are improved through adding a plant oil-based compound emulsifier; the advantages of high safety, simple processing work procedures, high emulsification capability and the like are realized; meanwhile, the effects of certain thickening, defoaming, grease coagulation control and the like are achieved. When the compound emulsifier is added into the soft capsule; the oil powder separation phenomenon can be effectively prevented; the product stability is maintained for a long time.

Owner:WEIHAI BAIHE BIOTECH

Preservative for bean products and preparation method thereof

InactiveCN107518246AExtended shelf lifeSimple preparation processSugar food ingredientsClimate change adaptationMonoglycerideGlycerol

The present invention discloses a preservative for bean products and a preparation method thereof. The preservative for the bean products comprises the following raw materials in weight percentages: 0.7-1.4% of monoglycerides, 0.7-1.4% of glycerol monolaurate, 0.2-0.4% of glucose, 0.04-0.06% of edible acid, 0.02-0.04% of calcium propionate, 0.05-0.12% of sorbic acid and / or sorbate, 0.2-0.9% of chitosan and the balance water. The preparation method comprises the following steps: (1) water is added into the chitosan and edible acid, and the materials are mixed evenly; (2) the monoglyceride and glycerol monolaurate are added and the materials are mixed evenly at a condition of 55-70 DEG C; and (3) the remaining components are added and the materials are mixed evenly to obtain the preservative for the bean products. The preservative for the bean products can effectively inhibit a growth of spoilage microorganisms, prolongs a shelf life, and is simple in preparation technology, easy in operations and mild in conditions.

Owner:SUZHOU ANTEK INDAL

Medical hemostatic composite material and preparation method thereof

The invention discloses a medical hemostatic composite material. The medical hemostatic composite material comprises the following raw materials: 30-60 parts of a self-made modified compound polysaccharide solution, 1-3 parts of Arabic gum, 1-4 parts of gelatin, 1-4 parts of sodium hyaluronate, 5-12 parts of calcium chloride, 2-4 parts of stearic acid, 2-8 parts of polyethylene glycol, 0.5-4 parts of polyoxyethylene sorbitan monooleate, 2-4 parts of glycerol monolaurate, 10-20 parts of glycerol, 0.5-2 parts of hydrogen peroxide, 0.5-2 parts of tannic acid and 45-70 parts of deionized water. The invention also discloses a preparation method of the medical hemostatic composite material. The medical hemostatic composite material prepared by the invention has good hemostatic and antibacterial effects.

Owner:广州市周平喜医疗科技有限公司

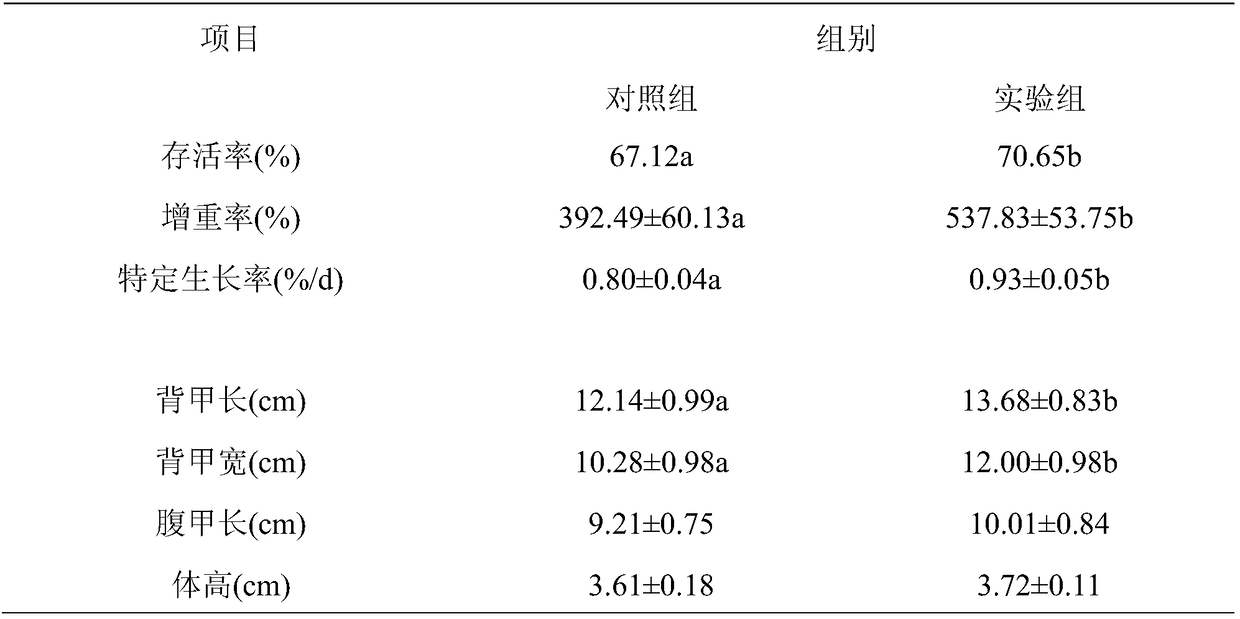

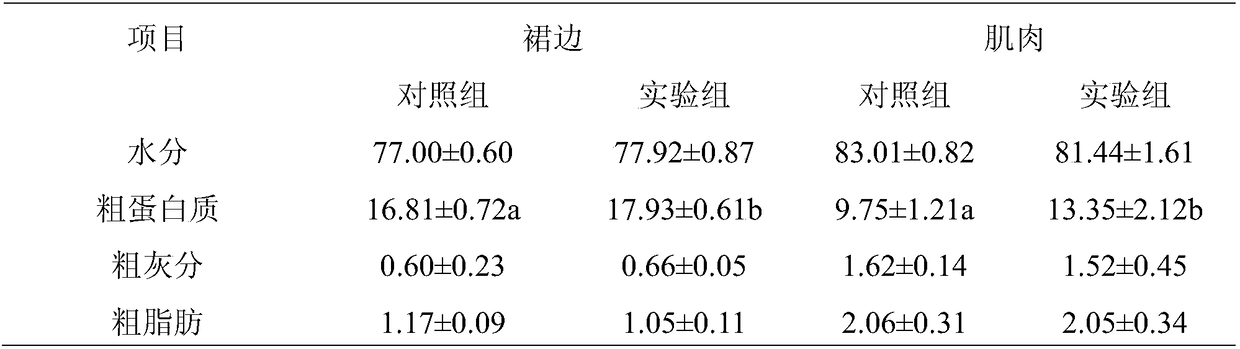

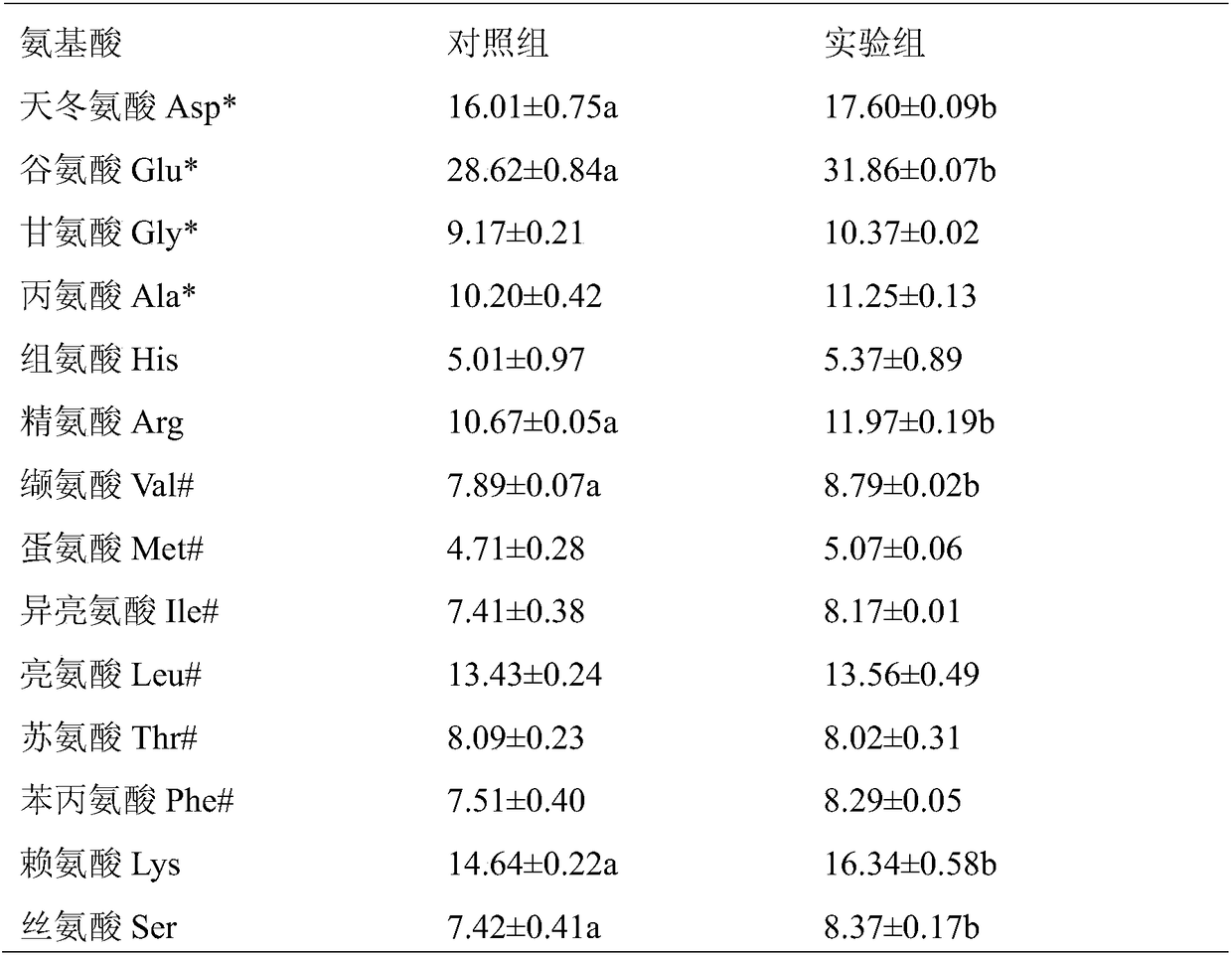

Application of feed additive to soft-shelled turtle feed capable of improving meat quality and growing performance of soft-shelled turtles

PendingCN108157614AIncrease weight gainIncrease specific growth rateFood processingAnimal feeding stuffGrowth phaseFood additive

The invention discloses an application of a feed additive to a soft-shelled turtle feed capable of improving meat quality and growing performance of soft-shelled turtles, and belongs to the technicalfield of feed additives. The feed additive comprises 10-45% of glycerol monolaurate, 10-30% of glyceryl dilaurate, 30-55% of glycerol monostearate and 5-15% of a carrier. The glycerol monolaurate, theglyceryl dilaurate, the glycerol monostearate are compounded according to the appropriate content and proportion, so that the feed additive is prepared. The feed additive can be used for trionyx sinensis during growth phase, the growing properties of the trionyx sinensis can be improved, and further, the breeding economic benefits are increased. The feed additive can notably increase the muscle of the trionyx sinensis and the content of crude proteins, the total content of amino acids, the content of necessary amino acids and the content of palatable taste amino acids in turtle edges of the trionyx sinensis can be notably increased, the nutritional quality, the mouth feel and the flavor of the trionyx sinensis are effectively improved, and contradiction between growth rate and quality issolved.

Owner:ZHEJIANG UNIV +1

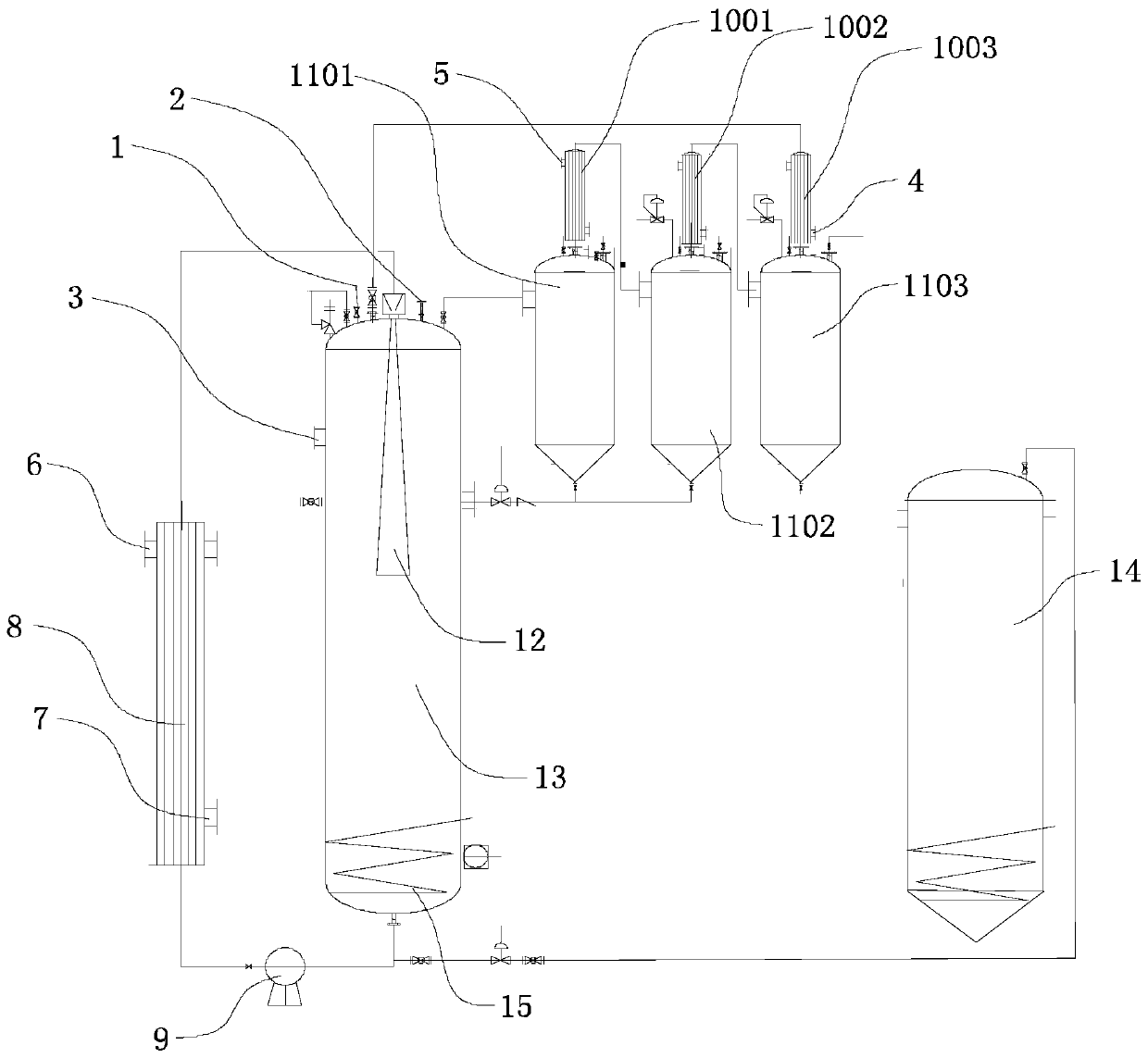

Preparation device of glycerol monolaurate and method thereof, and control system and method thereof

PendingCN111484408ASolve environmental pollutionReduce manufacturing costOrganic compound preparationCarboxylic acid esters separation/purificationPtru catalystPhosphate

The invention discloses a preparation device of glycerol monolaurate and a method thereof, and a control system and a method thereof. According to the preparation device of the glycerol monolaurate, acomputer adopts 14-point temperature acquisition, 8-point pressure acquisition and 1-point PH acquisition, and meanwhile, the opening degree of 14 valves is controlled. The preparation device of glycerol monolaurate is high in automation level and comprehensive and accurate in acquired data, multi-dimensional analysis and control of temperature, pressure and PH are performed, and product qualityand production efficiency are improved. The preparation method comprises the following step: under a nitrogen or carbon dioxide condition, reacting glycerol and lauric acid through an esterification reaction at high temperature for preparing glycerol monolaurate, no catalyst is used, no phosphate is generated, no pollution is caused to the environment, reaction equipment is totally closed and environmentally friendly, and the generated recovered glycerol is recycled to serve as a reactant of the next reaction, so that the production cost can be reduced.

Owner:广东凯闻生物科技有限公司

Skin care cosmetic containing liposome recombinant human growth hormone and preparation method thereof

InactiveCN101711729BHigh encapsulation efficiencyThe activity can be maintained for a long timeCosmetic preparationsToilet preparationsGlycerolAlpha-Lipoic Acid

The invention relates to a skin care cosmetic, in particular to a skin care cosmetic containing liposome recombinant human growth hormone. The cosmetic comprises polyoxyethylene fatty alcohol ether, polysorbate 60, monolaurin, hexadecanol, liquid paraffin, glycerol, sodium polyacrylate, polyvinylpyrrolidone K30, alpha-lipoic acid, perfume, preservative, ionized water, liposome human growth hormone. A surface active agent is introduced in the preparation process of liposome so that the encapsulation rate of the liposome human growth hormone is obviously improved. The invention can emulsify a product by a production technology of micro-emulsion to prepare millimicro-emulsion with the grain diameter of 100-200mm, thereby improving the local penetrability of the cosmetic on the skin, enabling an active substance to directly act on the horny layer to be uniformly distributed and showing more favorable effects of aging resistance, facial care, and the like and being more suitable for sensitive skin.

Owner:江西宇骏生物工程有限公司

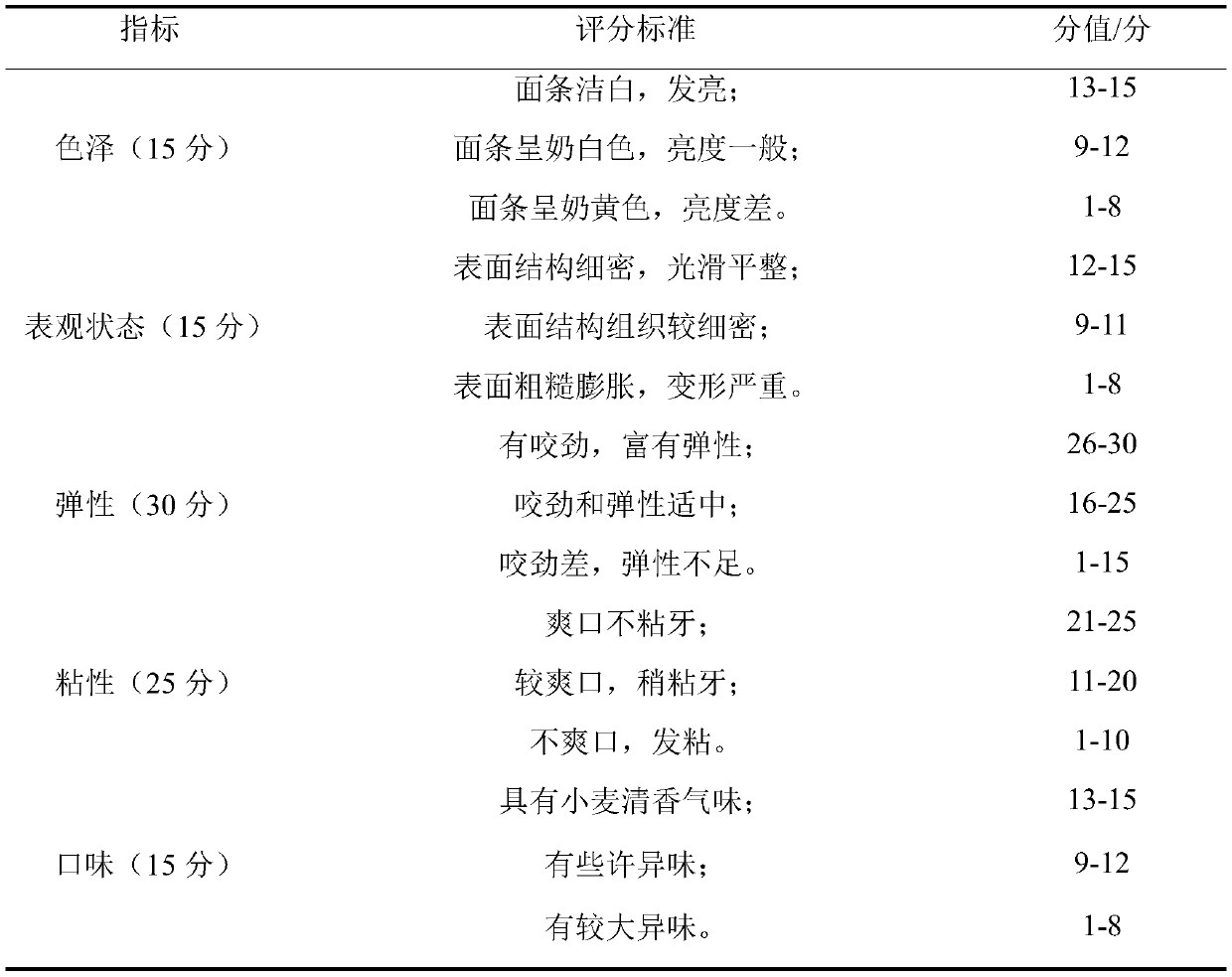

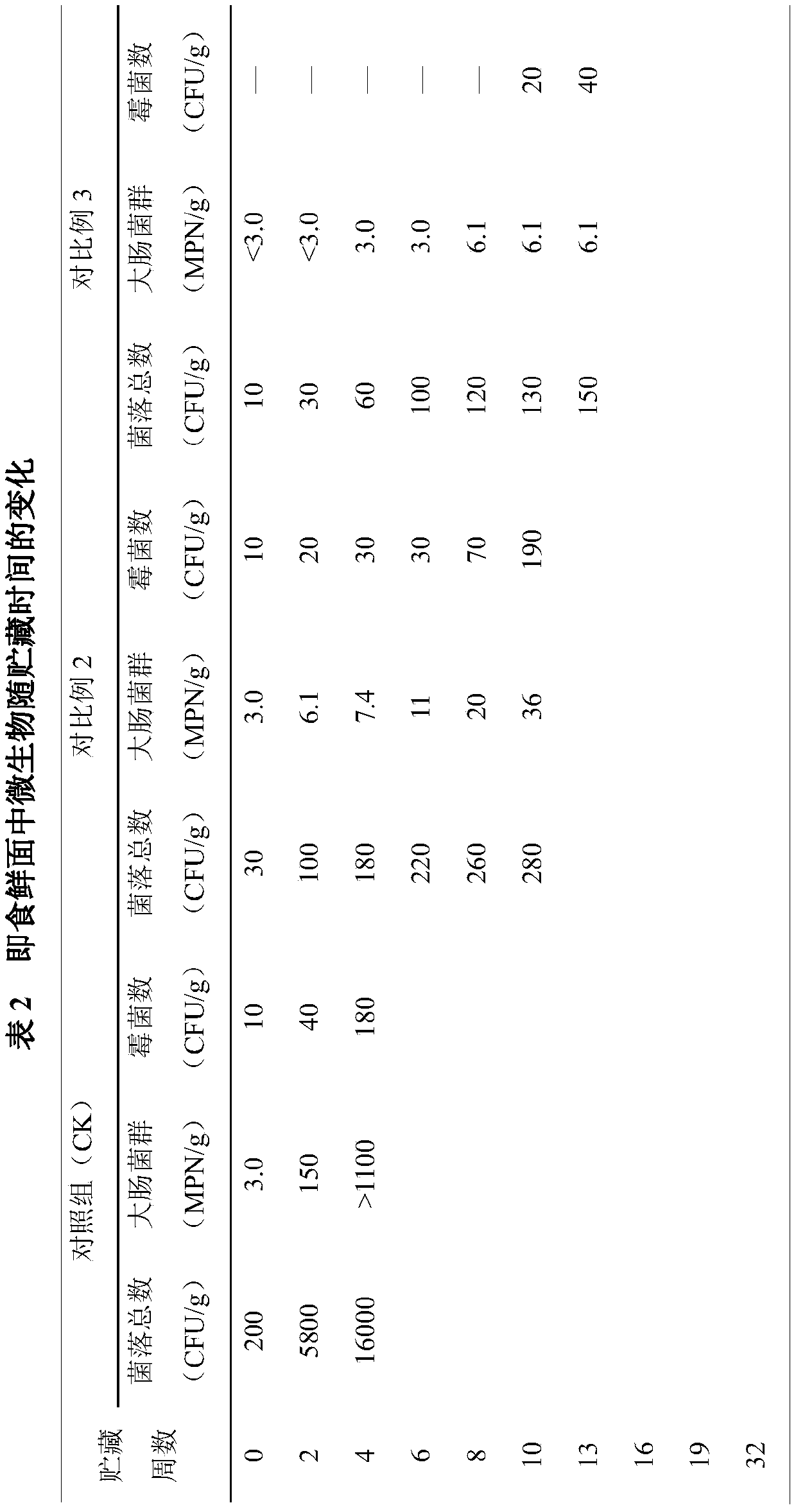

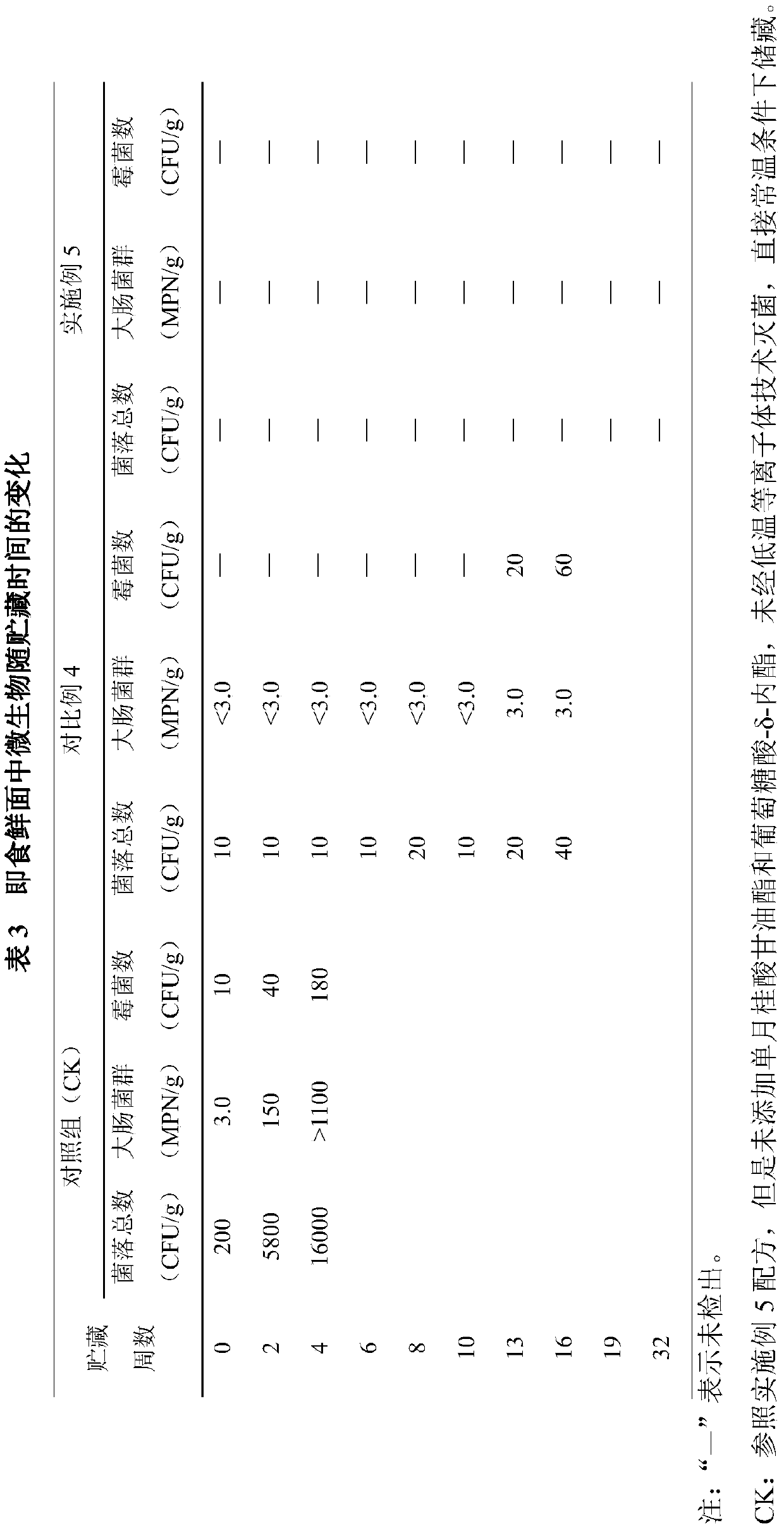

Instant fresh noodles and processing method thereof

The invention belongs to the technical field of food processing and fresh keeping and discloses instant fresh noodles and a processing method thereof. The instant noodles are made of wheat flour, starch acetate and wheat gluten as main raw materials, and edible salt, glycerol monolaurate, composite phosphate, sodium polyacrylate, gluconic acid-delta-lactone and water as auxiliary materials throughsteps of material blending, vacuum dough kneading, aging, composite compressing and grinding, noodle cutting, boiling, packaging and sterilization through a low-temperature plasma technique. The instant noodles disclosed by the invention are smooth and chewable in taste, rich in nutrition, instant to eat after being unpackaged, stable in quality and free of preservative, and the room-temperatureshelf life is up to 5 months or longer. The processing method is simple to operate, low in cost and applicable to industrial production. Convenience as "dinner" can be achieved, fast paces of life canbe met, the noodles are also applicable to eating under conditions of home living, travelling, outdoor exploration, earthquake relief work, and the like, and have wide market prospects and good social benefits.

Owner:NANJING AGRICULTURAL UNIVERSITY

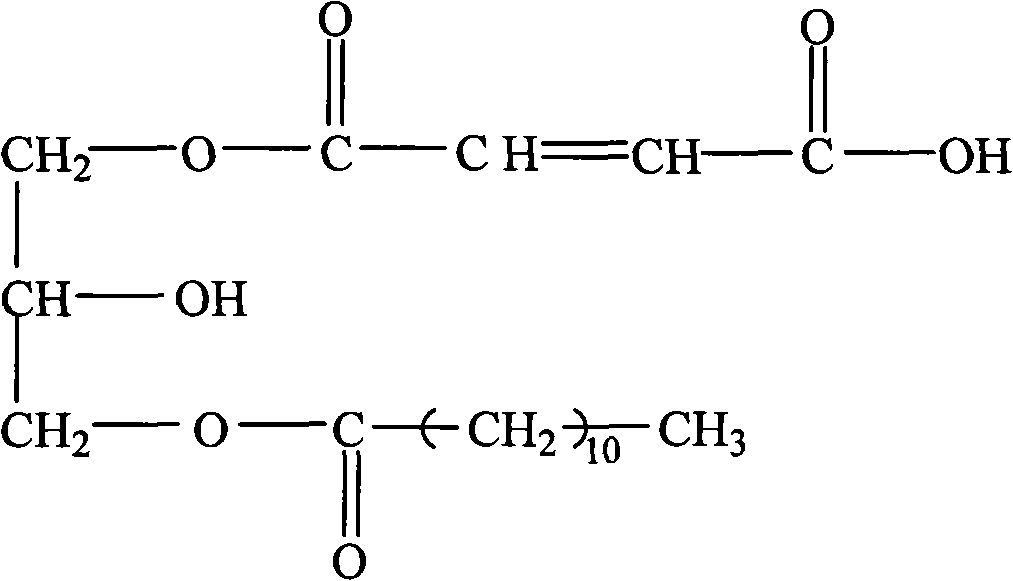

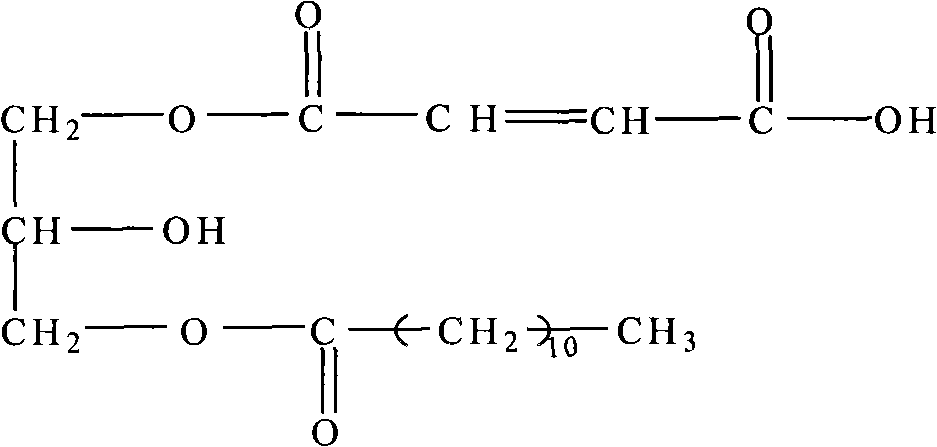

Polyolefin resin for long-lasting drip film and preparation method thereof

The invention provides a polyolefin resin for a long-lasting drip film and a preparation method thereof, wherein a functional monomer which is applied to the polyolefin resin provided by the invention is obtained by reacting glyceryl monolaurate with maleic anhydride, then the polyolefin resin is subjected into pre-radiation treatment by using beta ray and gamma ray, the polyolefin resin which is subjected into pre-radiation treatment is mixed with a polyolefin resin, and then the mixture is added into a reaction type extruder, the functional monomer and an electronic reagent are added into the reaction type extruder by means of a liquid charging opening of the reaction type extruder so as to react, extrude and graft, and then the grafted product is subjected into check rod, cooling and granulation to obtain the polyolefin resin for long-lasting drip film. The drip film which is obtained by blow moluding with the polyolefin resin provided by the invention has an effective duration of 21 to 35 days and 9 to 12 months under a condition of accelerated drip test of 60 DEG C and a condition of outdoor buckle tent, and the effective duration of a commercial drip film under the same condition is 6 to 8 days or 3 to 4 months, respectively.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com