Application of feed additive in preparation of laying hen feed for improving egg quality and egg laying capability

A feed additive and laying hen feed technology, which is applied in the field of feed additive processing, can solve problems such as poor digestive system and reproductive system function, unfavorable egg production level and egg quality, and strict storage environment requirements, so as to improve egg production performance, Enhance the anti-stress ability and improve the effect of eggshell strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The formula of the feed additive is: 20% glycerol monolaurate, 25% glycerol dilaurate, 35% glycerol monostearate and 20% carrier (silicon dioxide) in terms of weight percentage.

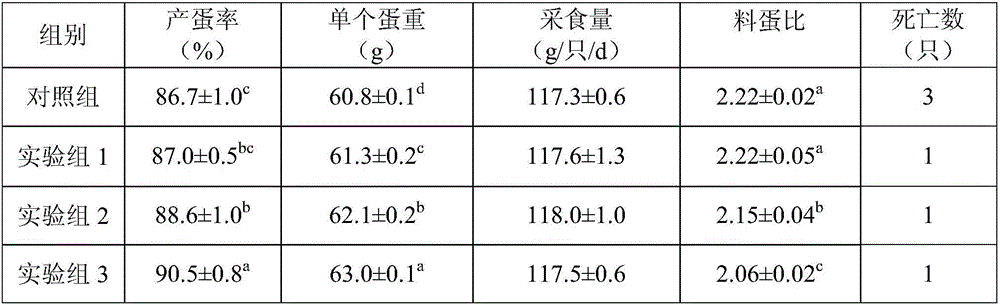

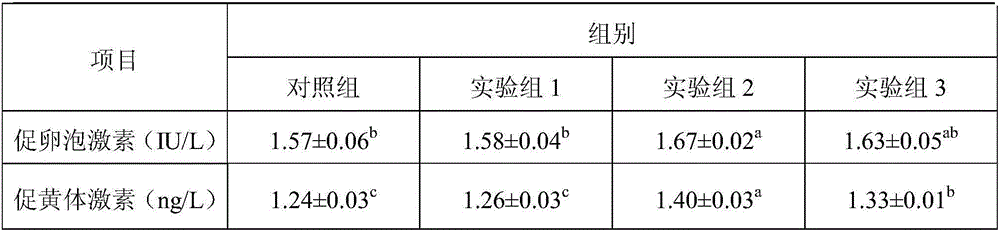

[0038] 180 44-week-old Hailan brown laying hens were randomly divided into 4 groups with 3 replicates in each group and 15 chickens in each replicate. The control group was fed basal diet, and the experimental groups 1, 2, and 3 were added with the above-mentioned feed additives with a mass fraction of 0.1%, 0.2%, and 0.3% on the basis of the basal diet respectively. The test period was 8 weeks.

[0039] The experimental chickens were raised in a stepped cage, fed twice a day, and picked eggs once. Feeding, drinking, cleaning, disinfection, and epidemic prevention were carried out in accordance with the current measures of the chicken farm. During the experiment, the temperature and humidity of the feeding farm were recorded every day on a repeat basis. Egg samples were randomly selected one day b...

Embodiment 2

[0047] The formula of feed additive is: 40% glyceryl monolaurate, 15% glyceryl dilaurate, 30% glyceryl monostearate and 15% of the carrier (starch) in terms of weight percentage.

[0048] Ninety 18-week-old Hailan brown laying hens were randomly divided into 3 groups with 3 replicates in each group and 10 chickens in each replicate. The control group was fed basal diets, and the experimental groups 1 and 2 were added with 0.05% and 0.1% of the above-mentioned feed additives on the basis of basal diets respectively. The test period was 35 weeks.

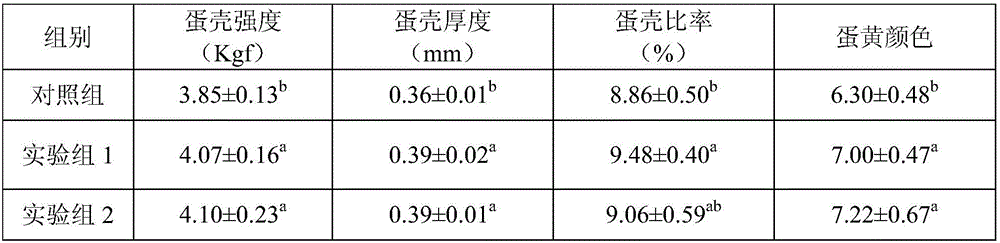

[0049] The experimental chickens were raised in a stepped cage, fed twice a day, and picked eggs once. Feeding, drinking, cleaning, disinfection, and epidemic prevention were carried out in accordance with the current measures of the chicken farm. During the test, the temperature and humidity of the feeding farm were recorded every day with repetition as the unit. Egg samples were randomly selected one day before the end of the test period...

Embodiment 3

[0056] The formula of the feed additive is: 10% glycerol monolaurate, 30% glyceryl dilaurate, 50% glycerol monostearate and 10% of the carrier (silicon dioxide) in terms of weight percentage.

[0057] 135 44-week-old Hailan brown laying hens were randomly divided into 3 groups with 3 replicates in each group and 15 chickens in each replicate. The control group was fed basal diet, and experimental groups 1 and 2 were added with the above-mentioned feed additives with a mass fraction of 0.2% and 0.3% on the basis of the basal diet, respectively, for a total of 8 weeks.

[0058] The experimental chickens were raised in a stepped cage, fed twice a day, and picked eggs once. Feeding, drinking, cleaning, disinfection, and epidemic prevention were carried out in accordance with the current measures of the chicken farm. During the experiment, the temperature and humidity of the feeding farm were recorded every day on a repeat basis. At the end of the test period, the chicken jejunum was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com