Patents

Literature

97 results about "Zinc sulphate monohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

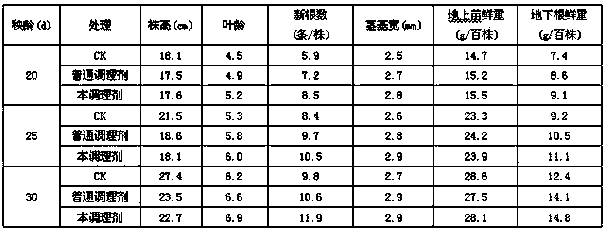

Polymorphic nitrogenous fertilizer and preparation method thereof

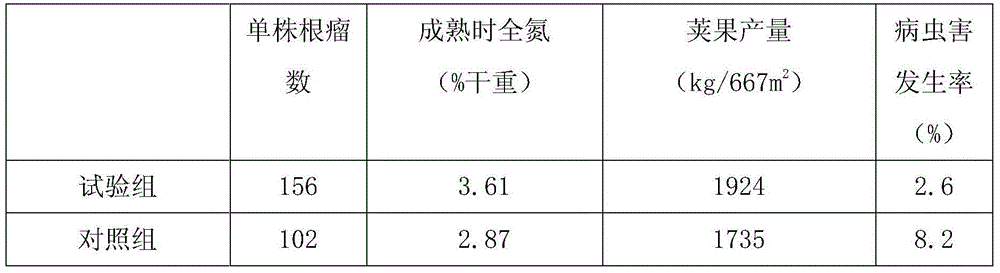

The invention discloses polymorphic nitrogenous fertilizer and a preparation method thereof. The polymorphic nitrogenous fertilizer comprises, by weight, 13-18 parts of urea, 63-65 parts of ammonium sulfate, 13-15 parts of ammonium chloride, 3-4 parts of animal hairs and feathers, 14-16 parts of modified attapulgite, 0.6-0.8 part of zinc sulphate monohydrate, 0.2-0.4 part of micronutrients fertilizer, 3-8 parts of ferrous sulfate, 0.3-0.5 part of nitrogen-fixing bacteria, 2-4 parts of modified nanocarbon, 1-3 parts of fructus cnidii, 5-7 parts of pomegranate tree roots and 9-11 parts of willow leaves. The feathers and the like are hydrolyzed by acid to form amino acid, secondary and trace elements are chelated, carboxymethyl cellulose increases a chelation structure of the secondary and trace elements so as to facilitate effective utilization of the secondary and trace elements, and invalid release of the secondary and trace elements is reduced. The polymorphic nitrogenous fertilizer is suitable for crops of wheat, rice, corn, soybean, rape and the like, can urge the wheat and the rice to turn green rapidly, be much in shooting and longing resistant and enhance chill-proof, drought-resistant and disease and insect resistant capacity, and enables cotton and linen crops to enhance tension and strength of fiber and improve output and quality remarkably.

Owner:安徽田间云生物科技有限公司

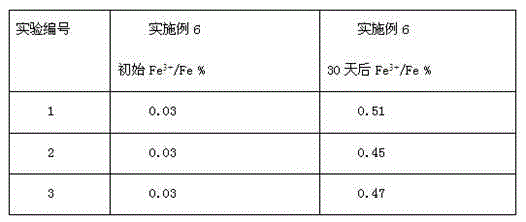

Liquid compound trace element fertilizer and preparation method thereof

ActiveCN104892208AImprove absorption efficiencyImprove absorption and utilization efficiencyFertilizer mixturesVitamin CAntioxidant

The invention discloses a liquid compound trace element fertilizer and a preparation method thereof. The fertilizer comprises the following ingredients by weight percent: 0-1.0% of citric acid, 0-1.0% of ascorbic acid (vitamin C), 0-1.0% of hydroxylamine hydrochloride, 0-1.0% of sorbitol, 0-1.0% of xylitol, 0-1.0% of mannitol, 0.46-38% of ferrous sulfate heptahydrate, 0.13-24% of manganese sulfate monohydrate, 0.18-3.3% of copper sulfate pentahydrate, 0.25-2.3% of zinc sulphate monohydrate, 0.25-4% of disodium octaborate tetrahydrate, 0.08-1.5% of ammonium molybdate, and the balance of pure water, wherein the dosage of the citric acid, the dosage of the ascorbic acid and the dosage of the hydroxylamine hydrochloride cannot be 0 at the same time, and the dosage of sorbitol, the dosage of xylitol and the dosage of mannitol cannot be 0 at the same time. According to the invention, an antioxidant prepared from one, two or more of the citric acid, ascorbic acid and hydroxylamine hydrochloride can effectively inhibit ferrous ions from being hydrolyzed into ferric ions, so that the iron ion absorption efficiency is improved, and the color of the product does not change at a high temperature; the raw material resources are rich, the production cost is low, and the equipment and production technologies are simple.

Owner:中化农业(新疆)生物科技有限公司

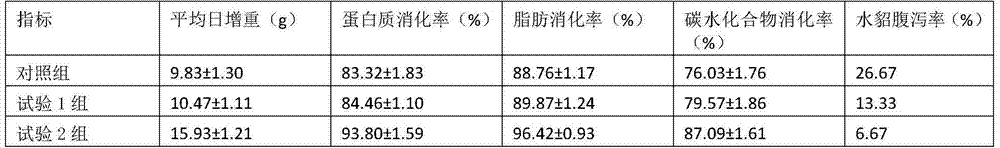

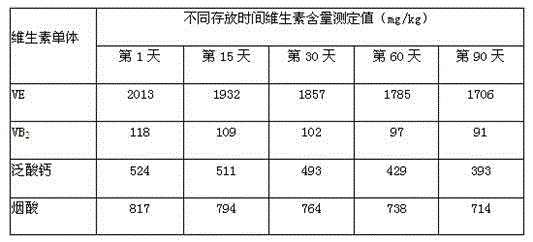

Premixed feed for minks at breeding period and preparation method thereof

InactiveCN103875996AReduce the incidence of intestinal diseasesLow costAnimal feeding stuffPantothenic acidZinc sulphate monohydrate

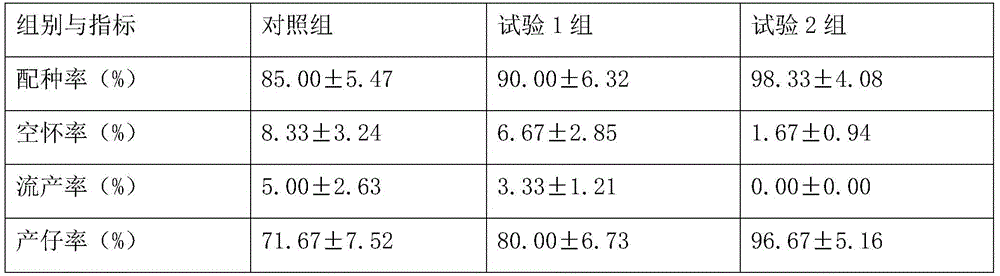

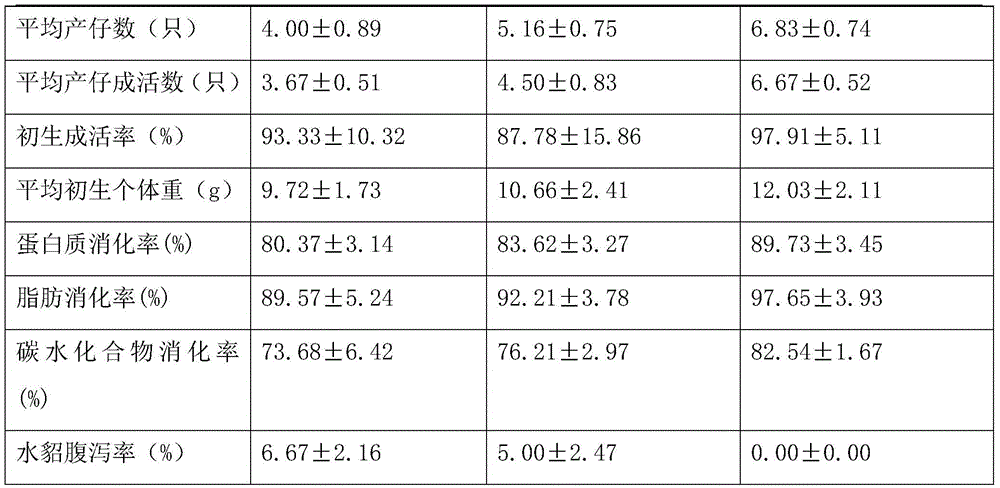

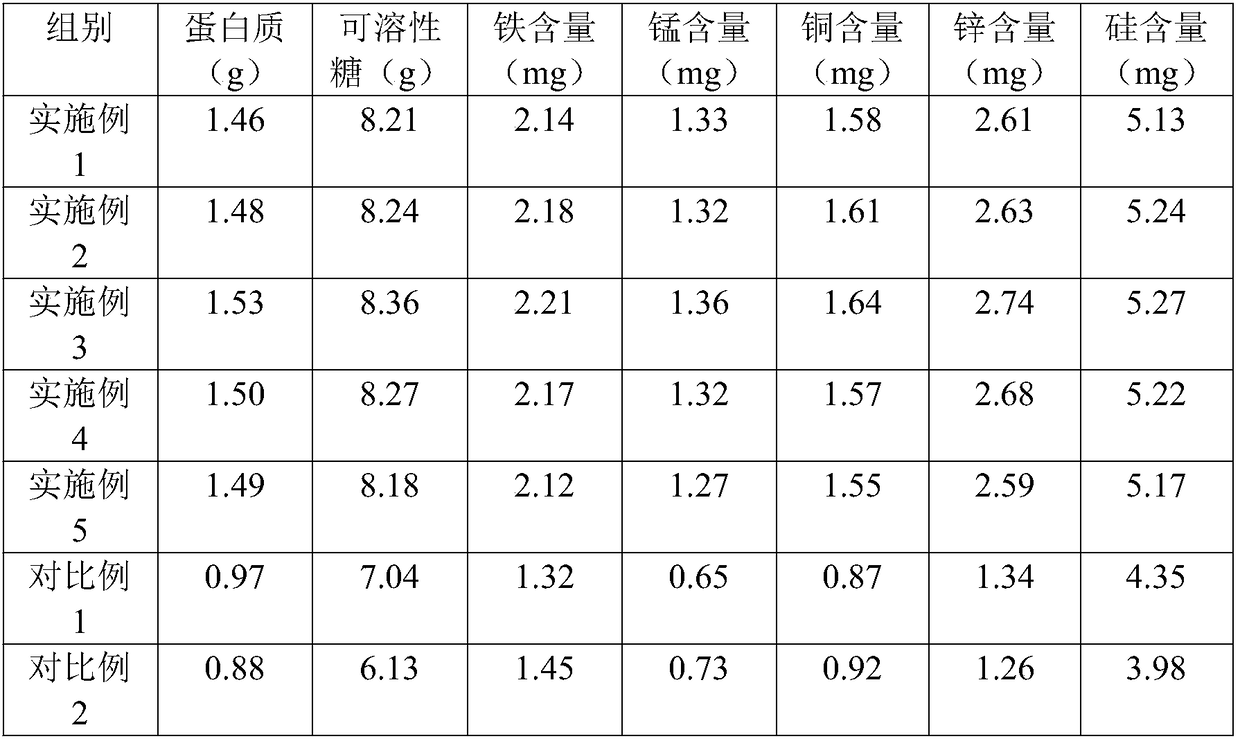

The invention discloses premixed feed for improving the growth speed and the nutrient substance digestion rate of minks at a breeding period. The premixed feed per one kilogram comprises the following raw material components: 265g-300g of corn protein powder, 15g-20g of compound vitamin B, 25g-35g of a complex enzyme preparation, 250000-300000 IU of vitamin A, 12g-15g of vitamin C, 2000-2500 IU of vitamin E, 50000-80000 IU of vitamin D, 0.6g-1g of vitamin K, 25g-28g of methionine, 15g-18g of lysine, 0.5g-1g of biotin, 55g-70g of choline chloride, 7g-9g of ferrous sulfate monohydrate, 9g-12g of copper sulfate pentahydrate, 10g-12.5g of manganese sulfate, 16g-20g of zinc sulphate monohydrate, 5g-6g of sodium selenite, 6g-8g of cobalt chloride, 5g-6g of potassium iodate, 10g-15g of yeast, 0.5g-0.6g of pantothenic acid, 3g-5g of nicotinamide, 0.5g-0.6g of folic acid, 140g-150g of calcium hydrogen phosphate, 30g-40g of table salt and 260g-300g of puffed corn powder. The premixed feed can be used for effectively improving the daily gain and the digestion rate of proteins, fat and carbohydrates of the minks at a breeding period, reducing the diarrhea rate of the minks and improving the culture benefits of the minks.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

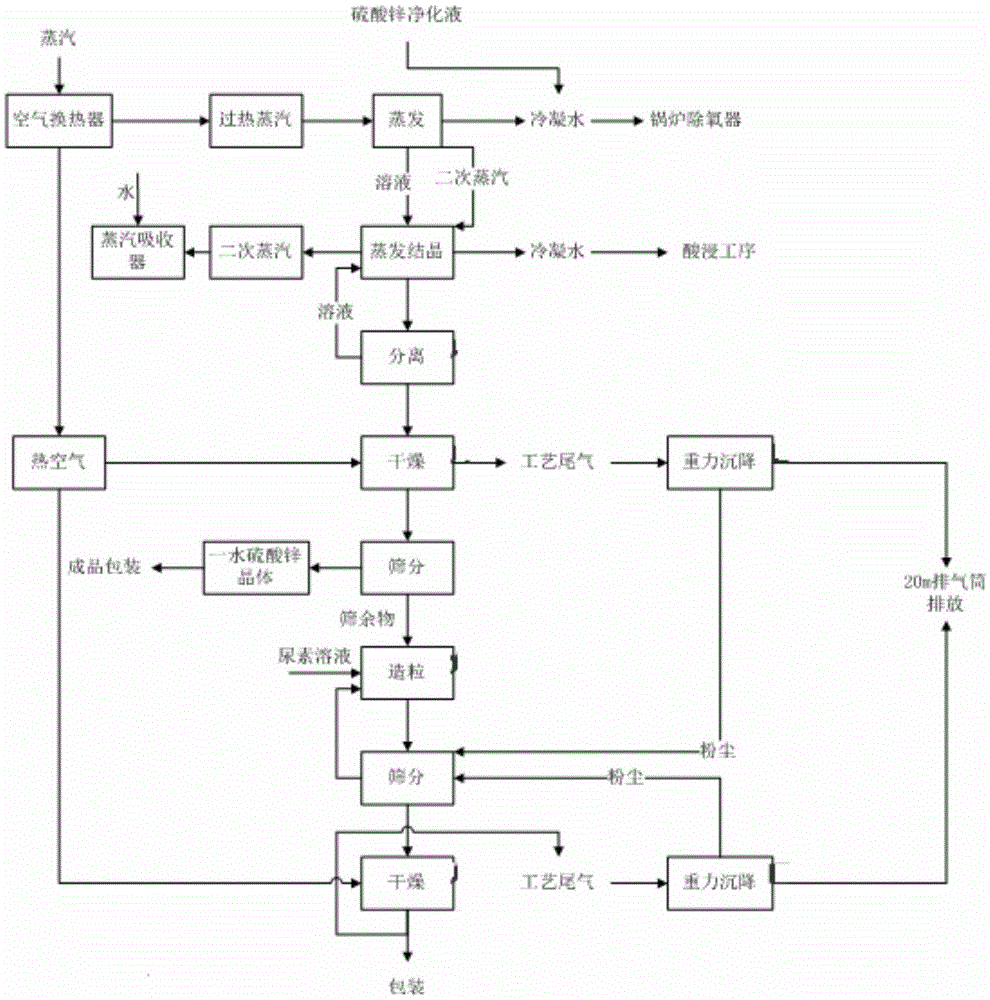

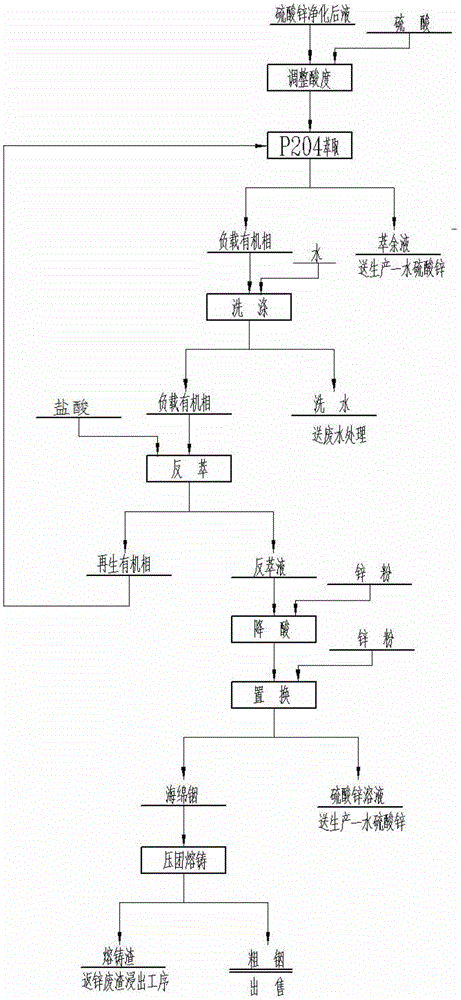

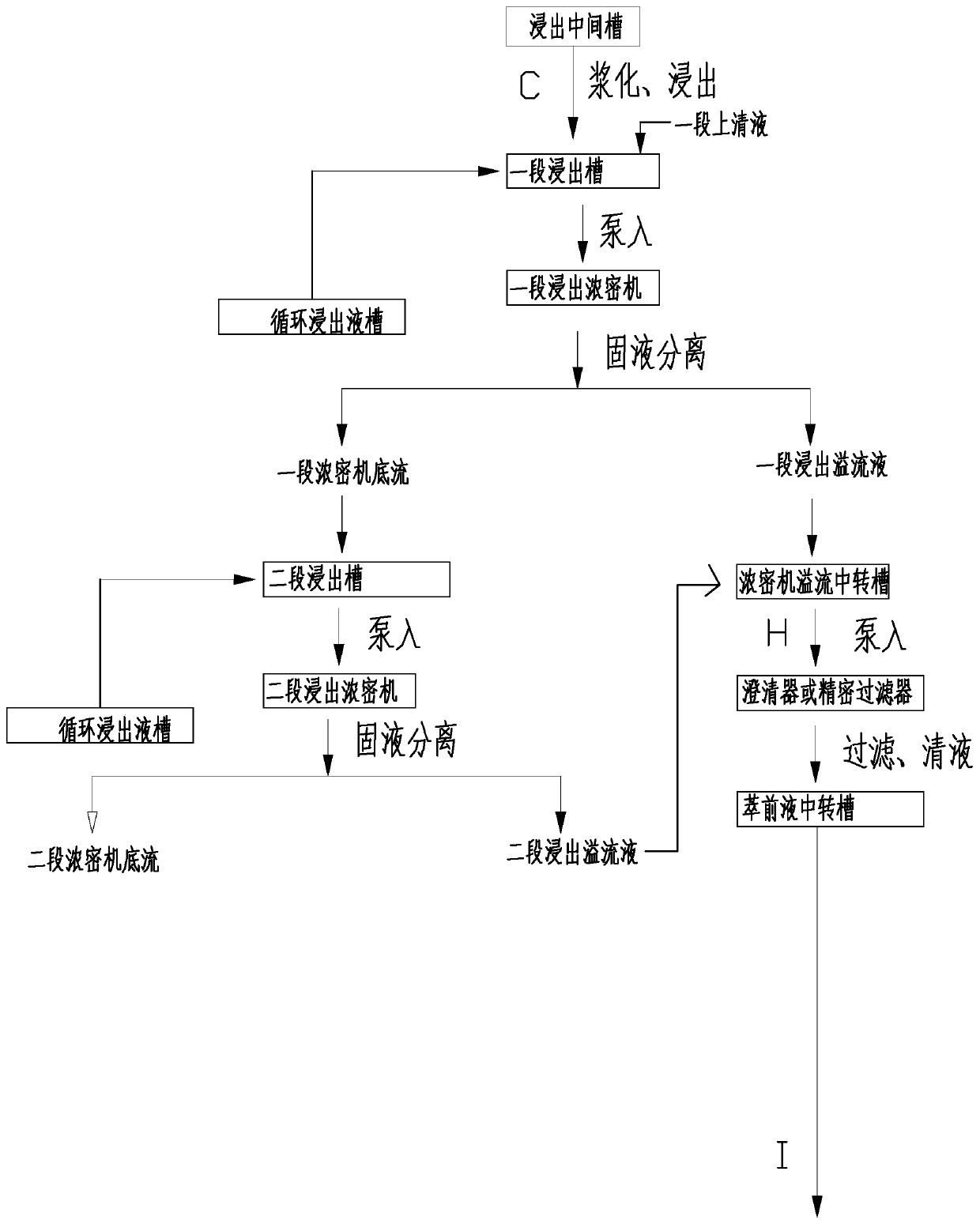

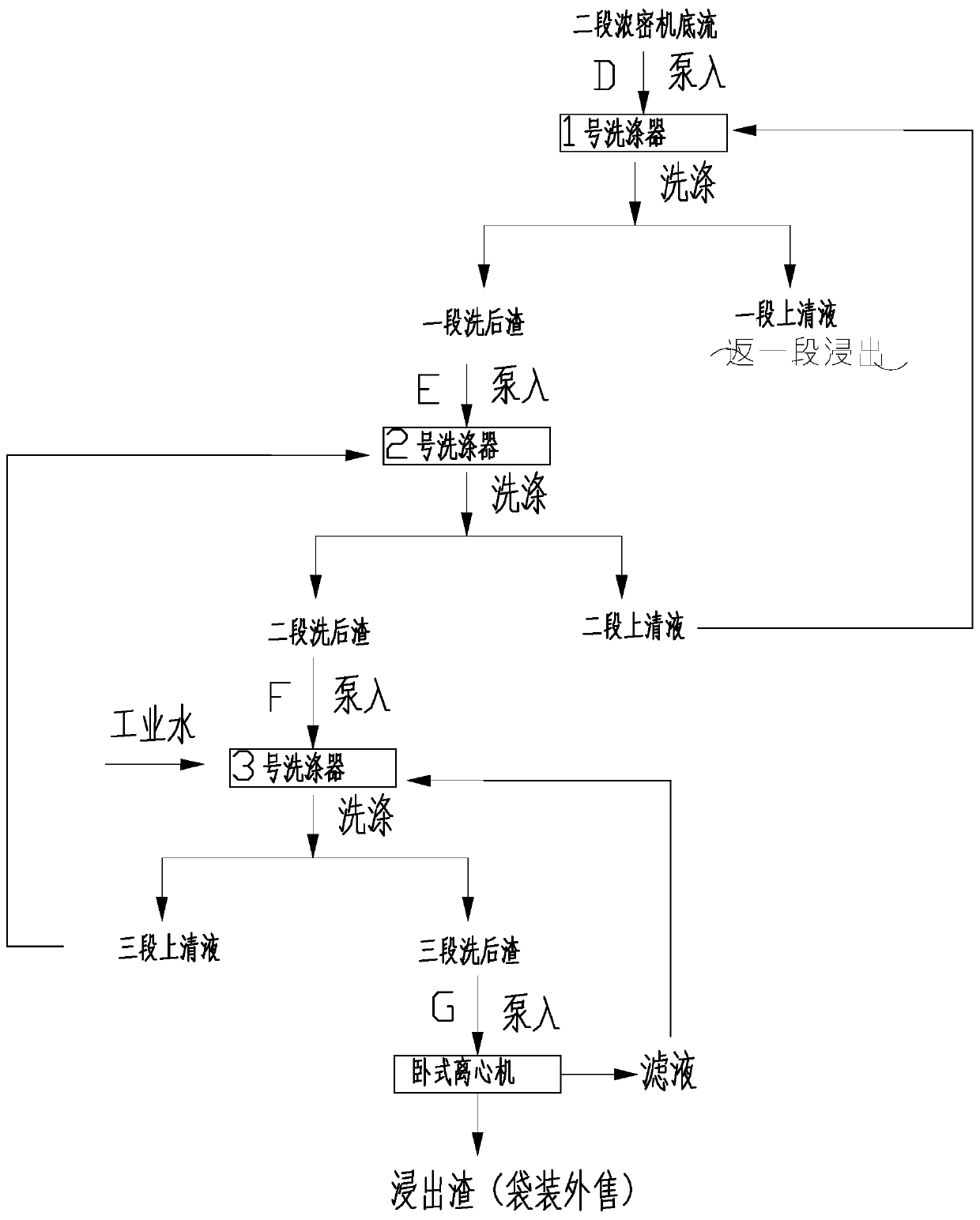

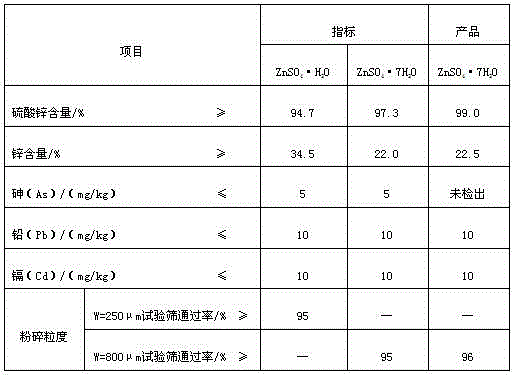

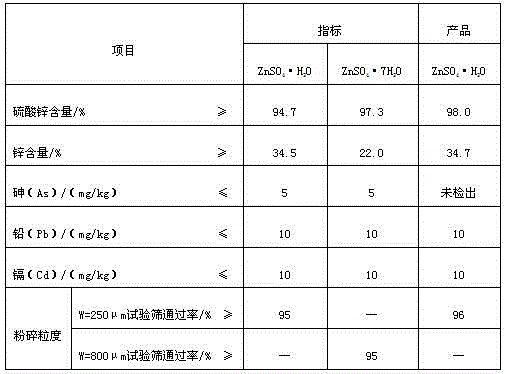

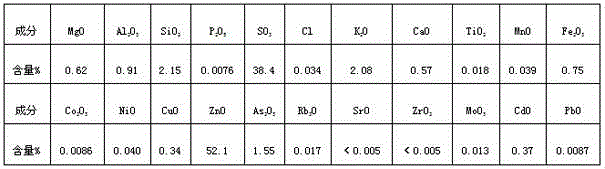

Process for producing zinc sulphate monohydrate from waste acid and waste zinc dross

ActiveCN105274342AAchieve recyclingStructural changeProcess efficiency improvementIndiumCadmium Cation

A process for producing zinc sulphate monohydrate (feed grade) from waste acid and waste zinc dross includes the steps of (a) sulfuric acid leaching, (b) deironing, (c) purification for copper and cadmium removal, (d) dechloridation, (e) defluorination, (f) indium and cadmium extraction and (g) evaporative crystallization. The feed-grade zinc sulphate monohydrate is produced from the waste acid, waste zinc dross and the like, comprehensive utilization of waste is achieved, and the production cost of raw materials is reduced, so that resources are saved. Therefore the waste of massive zinc enterprises in China is recycled to produce economic benefits, the waste is changed into the valuable, a disadvantage is turned into an advantage, secondary utilization of the waste is achieved, comprehensive recycling of waste acid and waste dross resources is achieved, solid and liquid are separated, and the concentration crystallization and drying technology, the energy saving technology and the like are improved. The work of energy conservation, water conservation, comprehensive utilization, environment protection and the like is completed, the social benefits are remarkable, and remarkable environmental protection benefits and economic benefits are achieved.

Owner:湖南鑫海环保科技有限公司

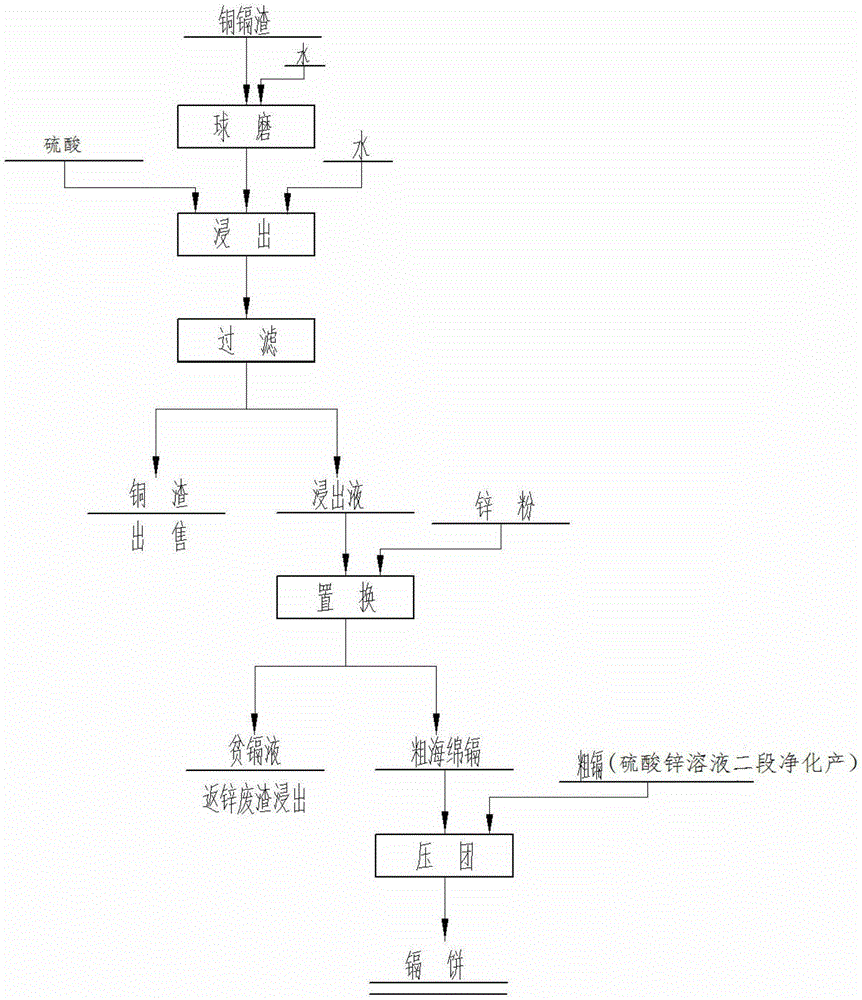

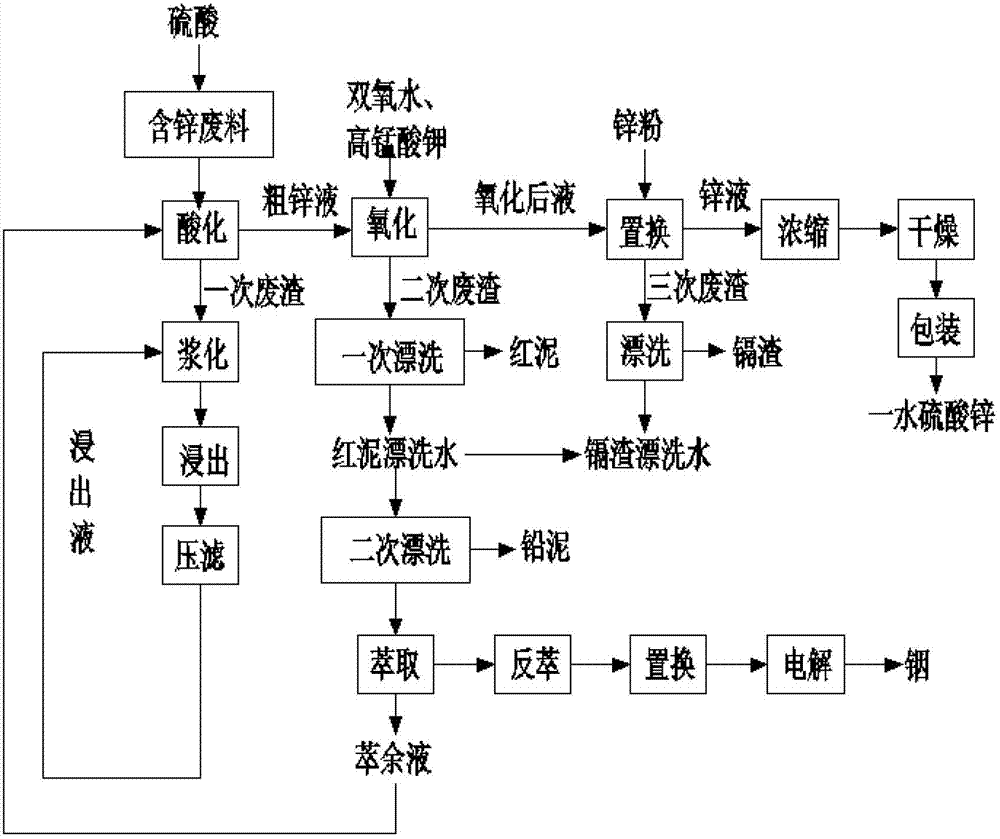

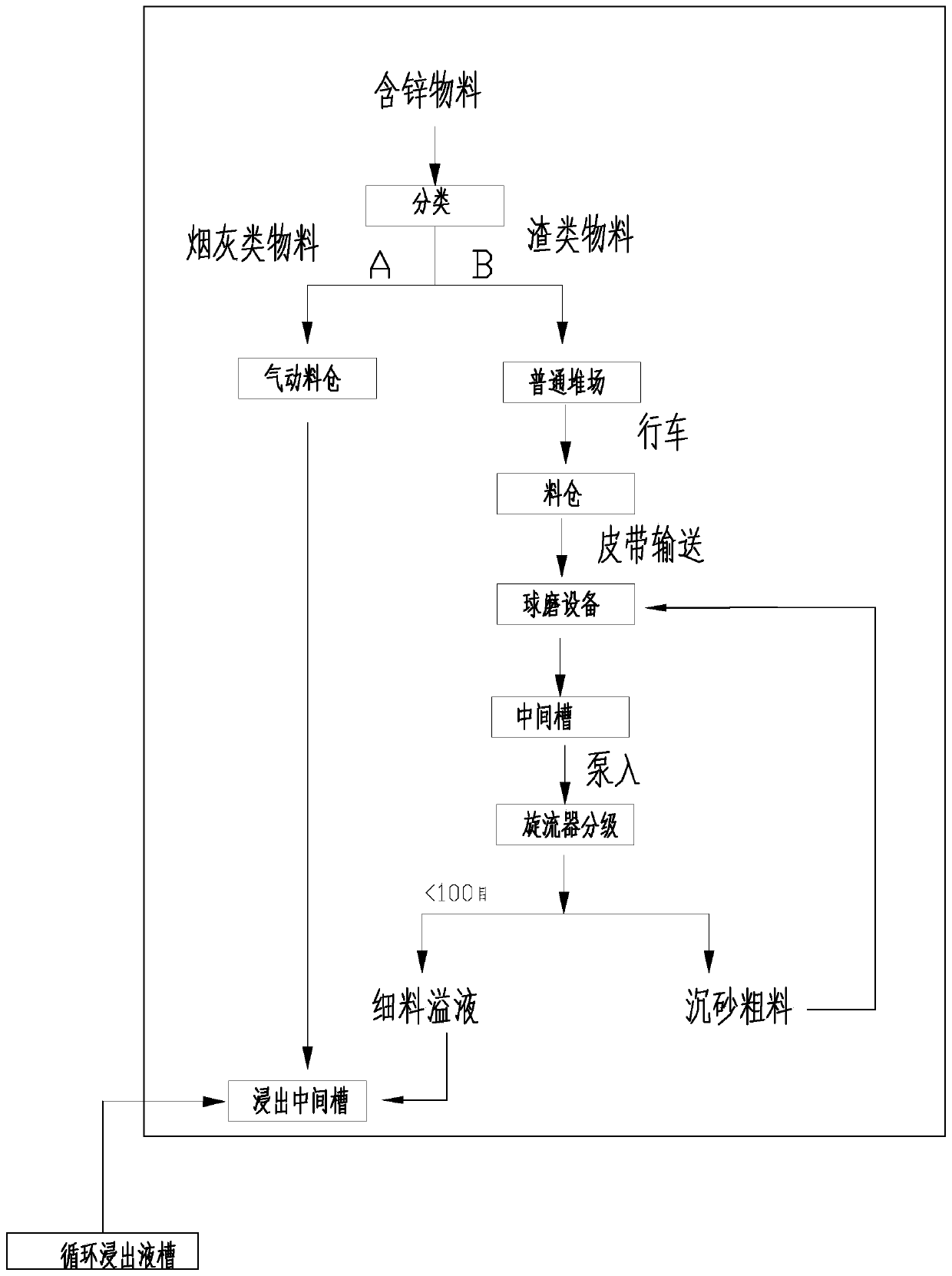

Method for extracting valuable metals and refining zinc sulphate monohydrate from zinc-containing waste material

ActiveCN102732731ASimple processReduce manufacturing costProcess efficiency improvementIndiumElectrolysis

The invention discloses a method for extracting valuable metals and refining zinc sulphate monohydrate from zinc-containing waste material. The method comprises the steps of refining the zinc sulphate monohydrate and extracting cadmium, lead, indium and other valuable metals, wherein the technology for refining the zinc sulphate monohydrate comprises the steps of: acidification, oxidization, zinc replacement, concentration, drying, packaging and the like; the technology for extracting cadmium comprises the steps of: acidification, oxidization, replacement, cadmium residue rinsing and the like; the technology for extracting lead comprises the steps of: acidification, oxidization, primary rinsing, secondary rinsing and the like; the technology for extracting indium comprises the steps of: acidification, oxidization, primary rinsing, secondary rinsing, extraction, back extraction, indium replacement, electrolysis and the like; and the extracted raffinate can be added into the next circulation to be recycled. Thus the zinc sulphate monohydrate and the valuable metals such as cadmium, lead and indium can be obtained, the process is simplified, the production cost is reduced, and the method is convenient for operation, simple in technology and high in recovery rate. The method has the advantages of low cost and energy consumption, etc.

Owner:HUNAN ZHONGLIAO TECH

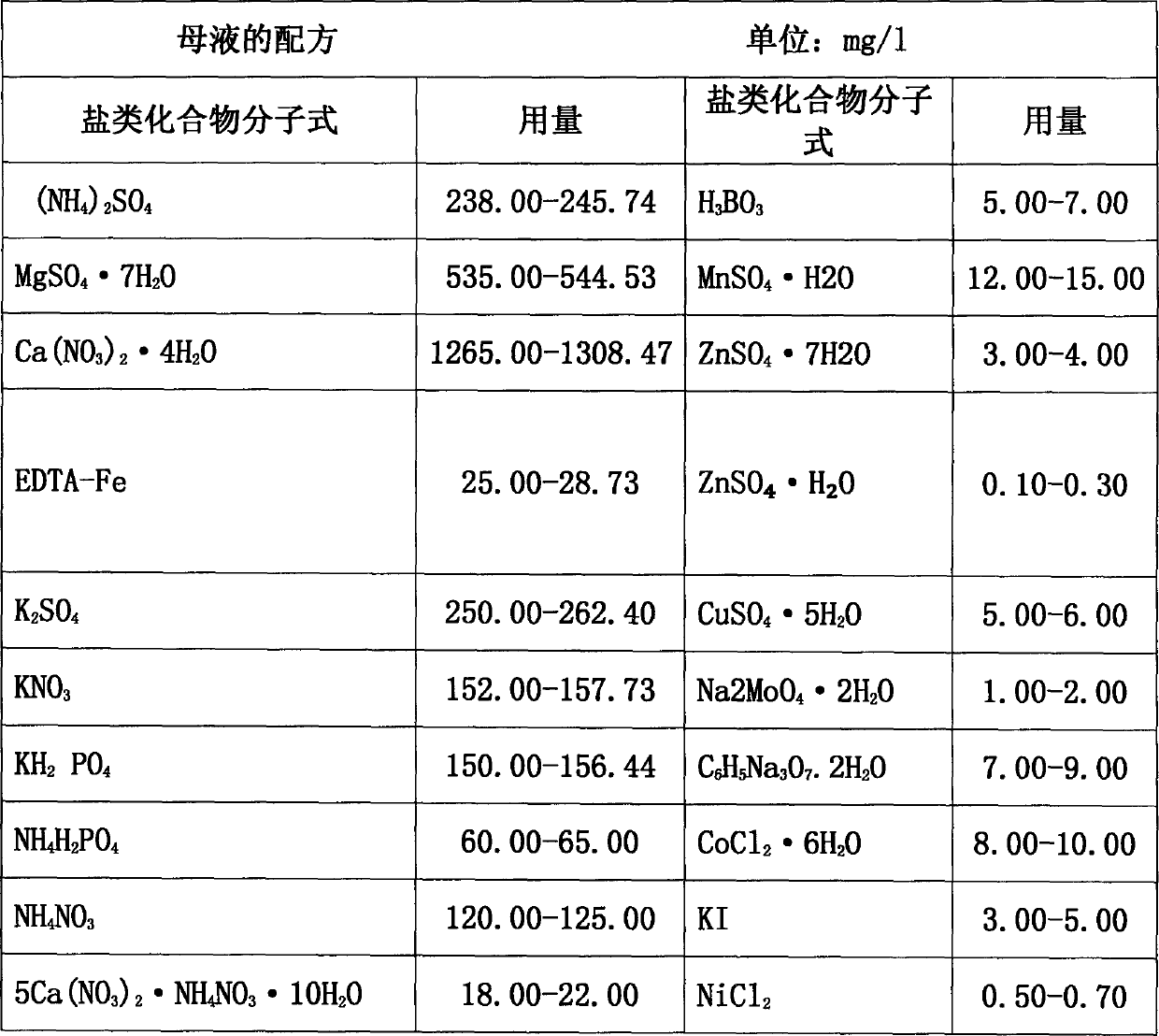

Water planting nutrient liquor for green vegetables

InactiveCN103274788ASolve the phenomenon prone to rotSimple processFertilizer mixturesMonopotassium phosphatePotassium iodine

The invention relates to water planting nutrient liquor for green vegetables. The liquor contains macroelements, microelements and water required by growth of green vegetables, wherein macroelements comprise C, H, O, N, S, P, Ca, Mg and K, and microelements comprise Fe, B, Mn, Zn, Cu, Mo, Na, Cl, I and Ni. The water planting nutrient liquor for green vegetables comprises ammonium sulfate, magnesium sulfate heptahydrate, calcium nitrate terahydrate, ferroethylene diamine tetraacetic acid disodium, monopotassium phosphate, potassium sulphate, potassium nitrate, ammonium dihydrogen phosphate, ammonium nitrate, calcium ammonium nitrate, boric acid, manganese sulfate, zinc sulfate heptahydrate, zinc sulphate monohydrate, copper sulfate, sodium molybdate, sodium citrate, cobalt chloride, potassium iodide and nickel chloride. The water planting nutrient liquor for green vegetables is simple in nutritional component, convenient to prepare and lower in preparation cost, and has a certain popularization practical value.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

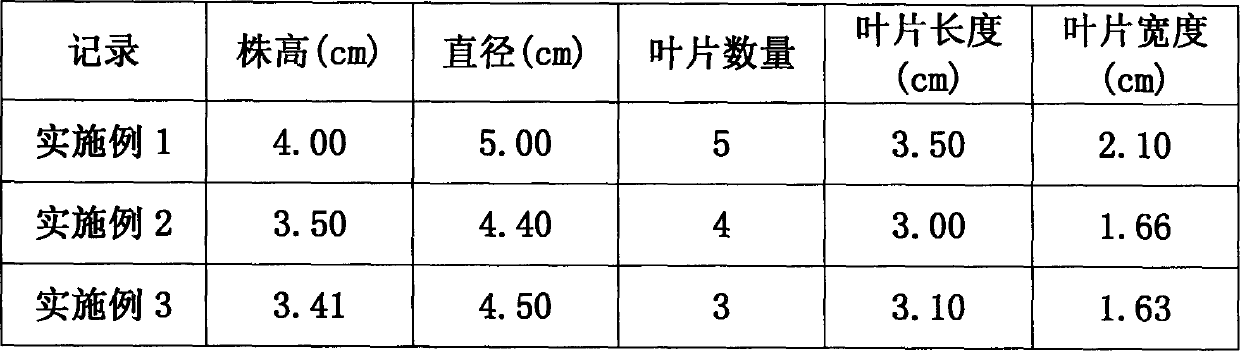

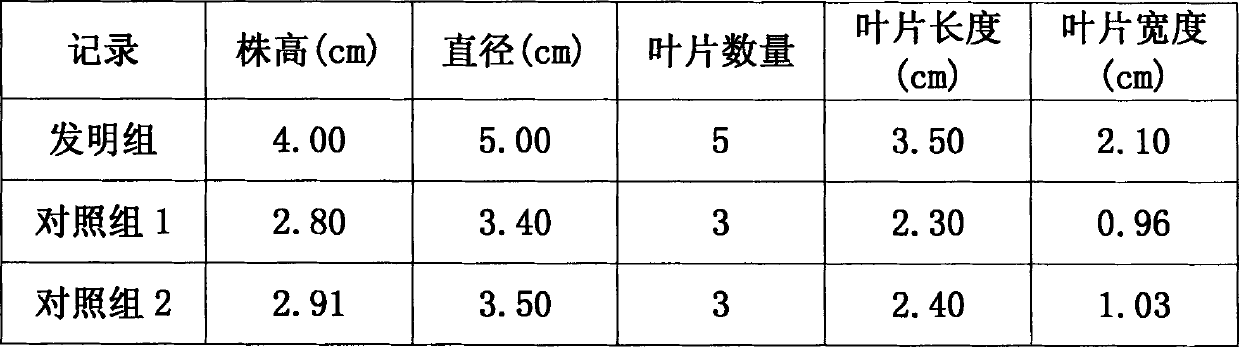

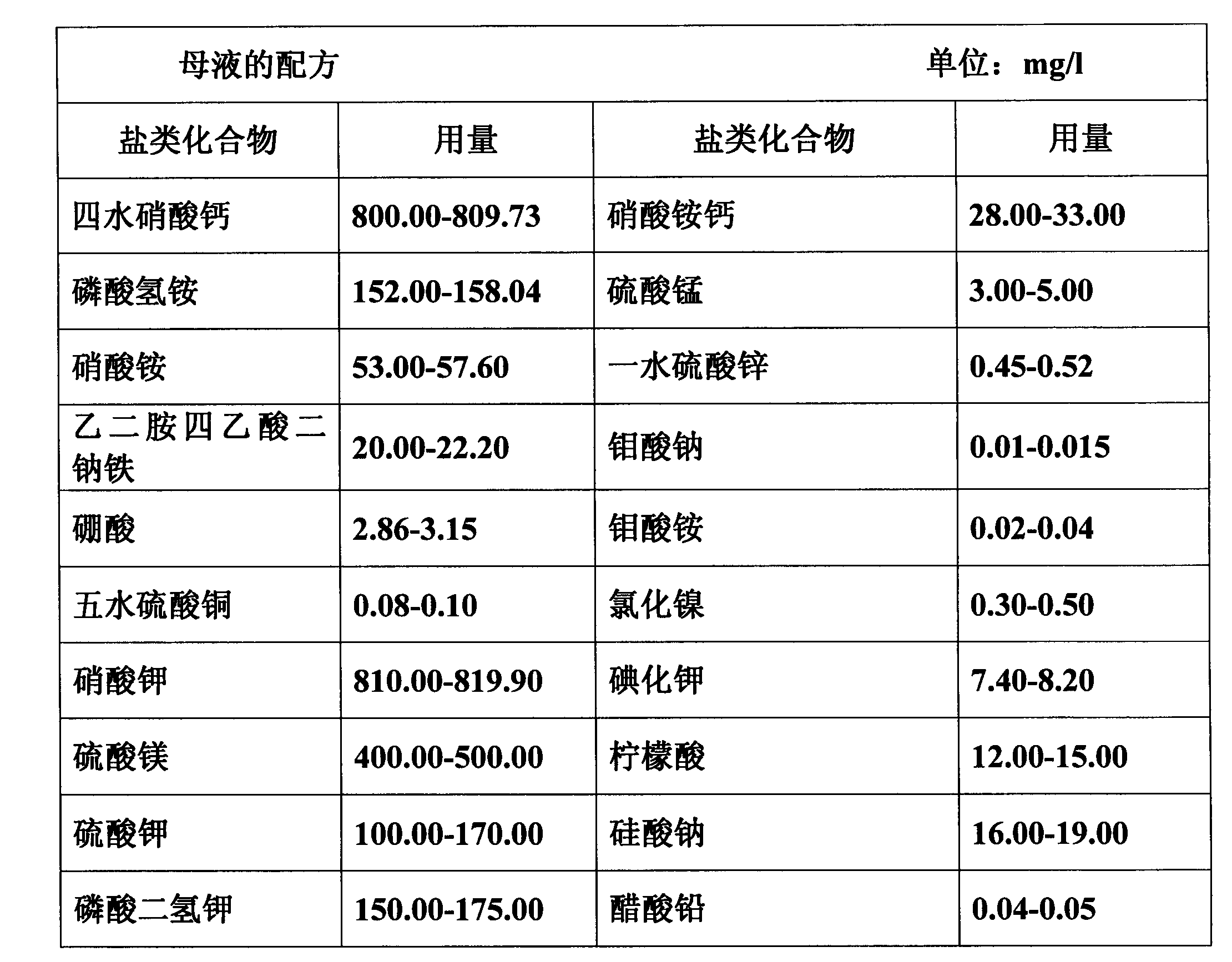

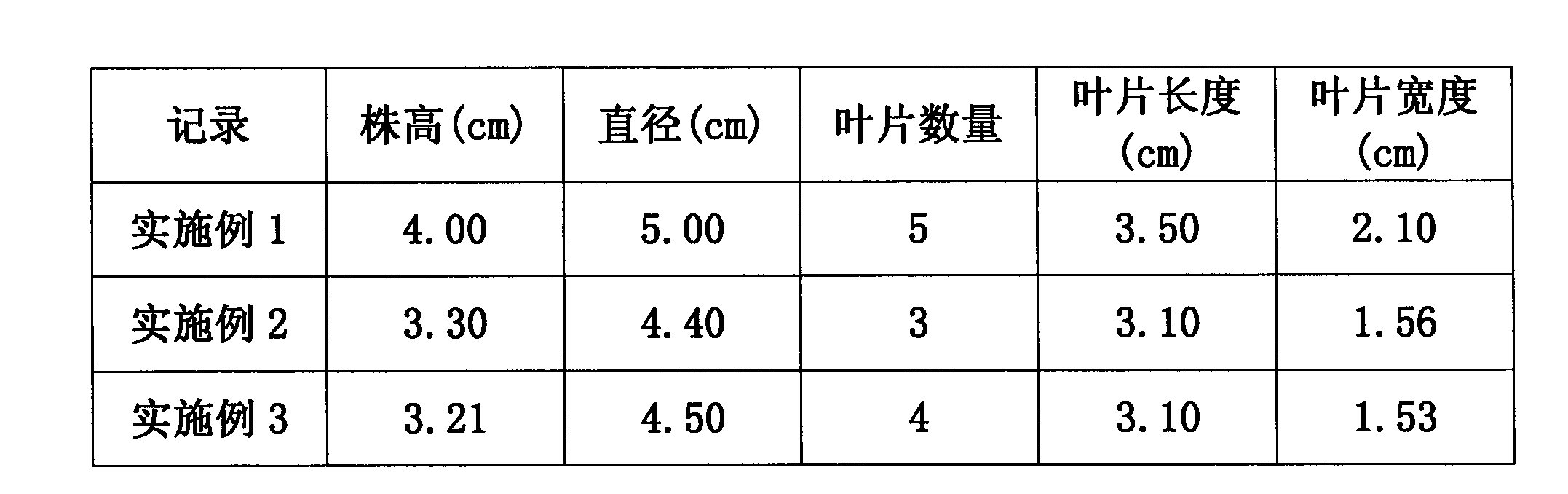

Water planting nutrient solution for edible amaranth

InactiveCN103288513AExtended growth cyclePromote growthFertilizer mixturesPhosphateAdditive ingredient

The invention relates to a water planting nutrient solution for edible amaranth, which consists of macroelements, microelements and water. Every 1000ml of the nutrient solution comprises 800.00-809.73mg of calcium nitrate terahydrate, 152.00-158.04mg of ammonium hydrogen phosphate, 53.00-57.60mg of ammonium nitrate, 20.00-22.20mg of sodium ferric ethylene diamine tetraacetic acid, 2.86-3.15mg of boric acid, 0.08-0.10mg of copper sulfate pentahydrate, 810.00-819.90mg of potassium nitrate, 400-500mg of magnesium sulfate, 100-170mg of potassium sulphate, 150-175mg of potassium dihydrogen phosphate, 28-33mg of calcium ammonium nitrate, 3-5mg of manganese sulfate, 0.45-0.52mg of zinc sulphate monohydrate, 0.01-0.015mg of sodium molybdate, 0.02-0.04mg of ammonium molybdate, 0.3-0.5mg of nickel chloride, 7.4-8.2mg of potassium iodide, 12-15mg of citric acid, 16-19mg of sodium silicate and 0.04-0.05mg of lead acetate. The water planting nutrient solution for edible amaranth is complete in nutritional ingredient, simple to prepare and high in practicality, and has a certain popularizing and practical value.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Method for preparing zinc sulphate monohydrate from zinc-containing waste residues

The invention discloses a method for preparing zinc sulphate monohydrate from zinc-containing waste residues. The method is characterized by comprising the following steps of (1), acid leaching; (2), oxidation for iron removal; (3), extraction of copper; (4), replacement for cadmium removal; (5), concentration and crystallization. The method for preparing the zinc sulphate monohydrate from the zinc-containing waste residues is a low-carbon and environmentally-friendly scheme, the preparation raw material is low in cost, waste is reutilized, the environmental problem that existing zinc-containing waste residues cannot be recycled and utilized is solved, the preparation process is energy-saving and environmentally-friendly, no waste gas or waste water is generated, a reagent unfriendly to the environment is not used, meanwhile metal, such as the copper and cadmium, is recycled, and the waste residues are reutilized.

Owner:台山市化工厂有限公司

Molybdenum-cobalt-iron rhizobium synergist and preparation method thereof

InactiveCN103601551AImprove fertilityPromote reproductionFertilizer mixturesPhosphateMonopotassium phosphate

The invention discloses a molybdenum-cobalt-iron rhizobium synergist and a preparation method thereof. The molybdenum-cobalt-iron rhizobium synergist is prepared from the following raw materials in parts by weight: 100-150 parts of potassium dihydrogen phosphate, 50-100 parts of ammonium sulfate, 30-50 parts of calcium superphosphate, 10-15 parts of ammonium molybdate, 10-15 parts of cobalt sulfate, 100-150 parts of ferrous sulfate heptahydrate, 40-60 parts of zinc sulphate monohydrate, 20-30 parts of aloe powder, 15-25 parts of bread crumbs, 35-45 parts of peat soil, 10-15 parts of corncob, 50-80 parts of modified zeolite powder and 10-15 parts of bagasse. The synergist disclosed by the invention meets the nutrition for the rhizobium growth, promotes quick mass propagation of rhizobium, remarkably improves the nitrogen fixing activity and provides sufficient nitrogen nutrition to the crops, thus the use of chemical nitrogen fertilizer is reduced, the soil is improved, the fertility is improved, the quick growth of crops is promoted, the stress resistance of the crops is enhanced, and the pest and disease damage is reduced; and moreover, the output is increased, the quality is improved, and important economic benefits are created.

Owner:安徽省文胜生物工程股份有限公司

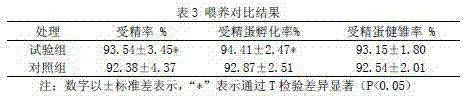

Duck premix for enhancing hatching egg fertilization rate

ActiveCN102948623AConsider comprehensivelyReduced stress resistanceAnimal feeding stuffVitamin K3Vitamin B12

The invention discloses a duck premix for enhancing the hatching egg fertilization rate. The premix is composed of various vitamins and trace elements necessary in a duck growth process and a ball-milled mixture of rice bran and hulls. Specifically, the vitamins include vitamin A, vitamin D3, vitamin E, vitamin B2, vitamin B1, vitamin B6, vitamin B12 and vitamin K3; and the trace elements include calcium pantothenate, niacin, folic acid, biotin, ferrous sulfate monohydrate, copper sulfate pentahydrate, zinc sulphate monohydrate, manganese sulfate monohydrate, sodium selenite, and chromium picolinate. The premix provided in the invention not only meets the basic nutritional needs of ducks, but also appropriately increases the content of some trace elements, thus being able to effectively prevent the decline of duck semen quality and ensure the fertilization rate and hatching rate of hatching eggs. By combining bulk raw materials with the premix provided in the invention, other nutritional substances needed by hatching drakes during a breeding period can be replenished. Therefore, the premix is very convenient and is easy for mass promotion.

Owner:唐山铁骑力士饲料有限公司

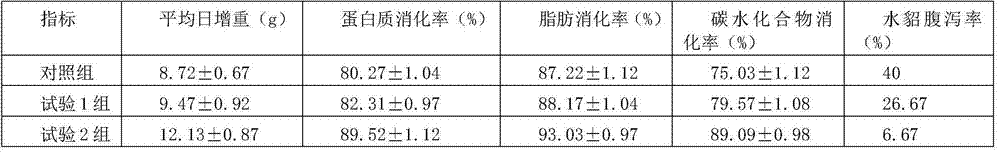

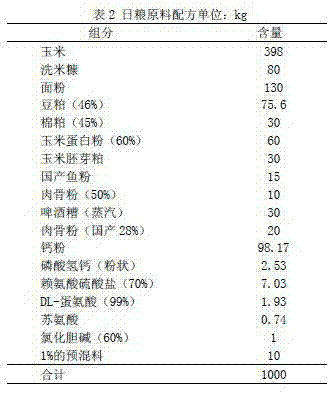

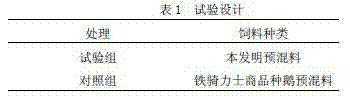

Premix feed for female minks in reproduction period and preparation method

InactiveCN105454699AImprove the breeding rateImprove litter rateFood processingAnimal feeding stuffVitamin K2Arginine

The invention discloses a premix feed for improving the growth speed of female minks in the reproduction period and the nutritional substance digestion rate. The premix feed is prepared from the following raw material components in kilogram: whey powder, vitamin, vitamin B5, vitamin B6, vitamin B9, vitamin B12, biotin, compound enzyme preparations, vitamin A, vitamin C, vitamin E, vitamin D, vitamin K, methionine, lysine, arginine, threonine, choline chloride, ferrous sulfate, copper sulfate pentahydrate, manganese sulfate, zinc sulphate monohydrate, sodium selenite, cobalt chloride, potassium iodate, yeast chromium, dihydropyridine, probiotics, calcium hydrogen phosphate, edible salt and bean cake powder. The premix feed can effectively improve the breeding performance of the female minks, increase the nutritional substance digestion rate of the female minks in the reproduction period, reduce the mobility of intestinal diseases of the female minks, and increase the breeding benefit.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Coating layer coating microelements and production method of coating layer

ActiveCN104824381AAvoid contactLess prone to corrosion hazardsAnimal feeding stuffDispersityRetention time

The invention belongs to the technical field of microelement processing, particularly relates to a coating layer coating microelements, and further relates to a production method of the coating layer coating the microelements. The coating layer comprises the following ingredients: ferrous sulfate monohydrate, copper sulfate pentahydrate, manganese sulfate monohydrate, zinc sulphate monohydrate, sodium selenite monohydrate, calcium iodate, cobalt chloride hexahydrate, chelated microelements, an anticaking agent and an excipient. The coating layer coating the microelements and made of the raw materials has the advantages that the coating layer does not cake, is anti-static, good in dispersity, uniform in flow, easy to mix, high in mixing uniformity, stable in property, and long in retention time, and avoids various microelements and contact between the microelements and other active ingredients; and the possibilities of an oxidizing reaction, a saponification reaction, and mucous membrane corrosion harms are low.

Owner:河北和利美生物科技有限公司

Process for comprehensively recycling valuable metals from zinc-containing material

InactiveCN109777958AComprehensive benefits are not obviousImprove qualityProcess efficiency improvementSmelting processSulfate

The invention discloses a process for comprehensively recycling valuable metals from a zinc-containing material. The process can recycle other valuable metals, expect from zinc, such as copper, lead and cadmium from the zinc-containing material. The conventional wet-process smelting process only can recycle one or two main materials, and other metals are in the slag, so that the comprehensive benefits are not obvious. Zinc sulfate and copper sulfate products produced in the process have the advantages of being high in quality, low in production cost and the like in comparison with products produced by a conventional method. According to the process disclosed by the invention, zinc leaching efficiency in the zinc-containing material is 85-97% and copper leaching efficiency in the zinc-containing material is 85-95%; a zinc extracting agent I has extracting efficiency of 95% or higher on zinc, and a copper extracting agent II has extracting efficiency of 95% or higher on copper; purity ofproduced zinc sulphate monohydrate is 99.9% or higher; and the diameters of produced copper sulfate pentahydrate crystalline grains can reach 2 mm, and purity of the produced copper sulfate pentahydrate crystalline grains is 99.6% or higher.

Owner:江西思远再生资源有限公司

Rice seedbed conditioner and production method thereof

InactiveCN103467215AImprove water vapor permeabilityImprove germination rateFertilizer mixturesPhosphatePotassium

The invention discloses a rice seedbed conditioner and a production method thereof, belonging to the field of the production technology of a conditioner for raising rice seedlings. The method comprises the steps of uniformly stirring and mixing ammonium sulfate and potassium dihydrogen phosphate; mixing zinc sulphate monohydrate and humic acid, then adding paclobutrazol wettable powder, and uniformly stirring and mixing; uniformly mixing the two mixtures and the washed coal ash sandy soil; discharging, sieving, sub-packaging and packaging. By adopting the prepared rice seedbed conditioner, the pH value of the product is faintly acid due to the physiologically acid nutritive salt, thus the product is very suitable for the growth of the rice seedlings, and the content of organic matters in soil is increased; meanwhile, since humic acid contains an active multifunctional group, the germination rate of rice seeds can be improved, and the emergence rate and strong seedlings are promoted.

Owner:YANGZHOU CHUNQUAN TECH CO LTD

Feed for improving Qinghai yak meat quality and preparation method thereof

InactiveCN103652397AImprove qualityImprove flesh colorFood processingAnimal feeding stuffCalcium bicarbonateVitamin C

The invention provides a feed for improving Qinghai yak meat quality and a preparation method thereof. The feed is characterized by comprising corns, bean pulp, rapeseed dregs, calcium bicarbonate, table salt, vitamin C, vitamin E, zinc sulphate monohydrate, copper sulfate pentahydrate, manganese sulfate and a traditional Chinese medicine additive. Due to the feed, the Qinghai yak body can be regulated, the regulation can be influenced, so that the indexes such as the color of the yak meat, water absorption, muscle tenderness and dressing percentage can be improved, and further the Qinghai yak meat quality can be improved.

Owner:青海裕泰畜产品有限公司

Instant microelement water-soluble fertilizer capable of increasing soil organic matter content

InactiveCN105646084AImprove physical and chemical conditionsImprove biological characteristicsBioloigcal waste fertilisersAmmonium salt fertilisersSodium bicarbonateDrip irrigation

The invention relates to fertilizer, in particular to instant microelement water-soluble fertilizer capable of increasing the soil organic matter content. The instant microelement water-soluble fertilizer capable of increasing the soil organic matter content is prepared form components in parts by weight as follows: 450-550 parts of concentrated molasses yeast powder, 8-15 parts of poly potassium aspartate, 50-80 parts of citric acid, 20-40 parts of sodium bicarbonate, 20-40 parts of disodium octaborate tetrahydrate, 150-300 parts of zinc sulphate monohydrate, 100-200 parts of manganese sulfate, 5-15 parts of iron EDTA (ethylene diamine tetraacetic acid), 5-15 parts of copper EDTA and 0.5-1.5 parts of ammonium molybdate. The fertilizer can be quickly dissolved, is fully water-soluble, can be applied to facility agriculture such as sprinkling and drip irrigation and the like and realizes integration of water and fertilizer and the efficiency of saving water, fertilizer and labor. The fertilizer can provide organic matters and various microelement nutrients for soil and crops after usage.

Owner:张学杰

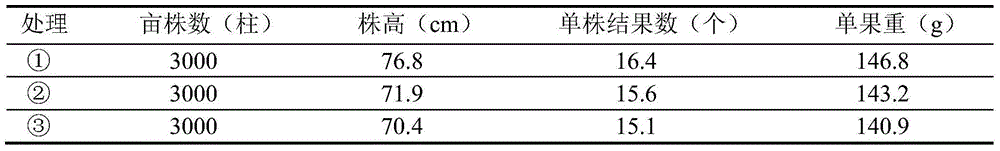

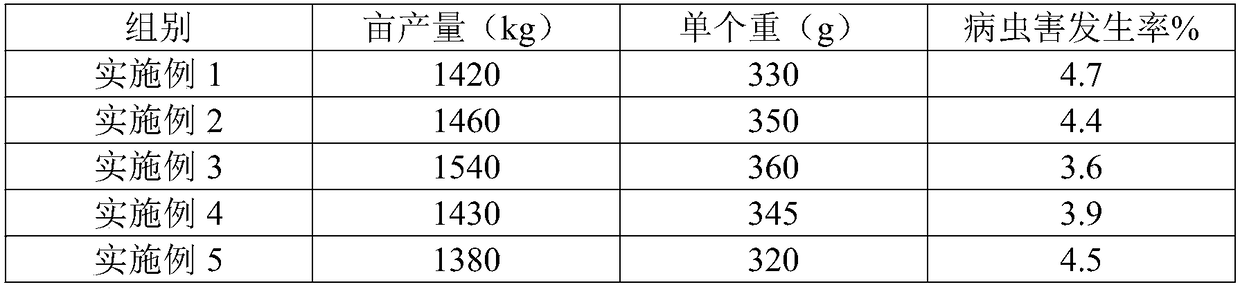

Planting method of juicy peach containing multiple trace elements

InactiveCN108184534ARich sourcesThe ratio is scientific and reasonableCalcareous fertilisersMagnesium fertilisersTrace element compositionAntioxidant

The invention belongs to the technical field of fruit planting, and particularly relates to a planting method of juicy peach containing multiple trace elements. The planting method includes steps of (1), soil preparation; (2), fixed planting; (3), fertilization management; (4), pest control; (5), reshaping and trimming; (6), harvesting. Through using planting base fertilizer consisting of seaweedfertilizer, chelating agent, antioxidant and trace elements, the absorbing efficiency of crops can be effectively improved, and the juicy peach is rich in multiple trace elements and other nutrient components; the planting base fertilizer has extremely strong effect in promoting crops growth and improving its nutrition value; besides, by applying the leaf fertilizer, fruit expanding fertilizer andothers, the fruit tree has faster absorbing speed, the nutrition use is more sufficient; the planting base fertilizer is prepared from seaweed fertilizer, ascorbic acid, hydroxylamine hydrochloride,xylitol, mannite, iron vitriol, manganese sulfate monohydrate, blue copperas, zinc sulphate monohydrate, disodium octaborate tetrahydrate, magnesium sulfate, and ammonium molybdate.

Owner:FOSHAN TUIQI AGRI RES INST GENERAL PARTNERSHIP +1

Feeding composite organic microelement additive and preparation method thereof

InactiveCN105494955AIncrease the gapPromote formationAccessory food factorsFeed additiveZinc sulphate monohydrate

The invention relates to the technical field of feed additive pretreatment, and in particular to a feeding composite organic microelement additive and a preparation method thereof. The additive is prepared by coating the surface of a composite organic microelement particle with a glycerol monolaurate layer and a pregelatinized starch layer from inside to outside in sequence, wherein the composite organic microelement particle is mainly prepared from the following raw materials: ferrous sulfate monohydrate, blue copperas, zinc sulphate monohydrate, manganese sulfate monohydrate, cobaltous sulfate heptahydrate, sodium selenite, organic acid, polysaccharide, peptide and protein. According to the additive, by taking the organic acid, the polysaccharide, the peptide and the protein as organic ligands to compound with various composite inorganic microelement compounds, the composite organic microelement microcrystal grains are produced, and the surface of each particle is coated with glycerol monolaurate and pregelatinized starch so as to isolate dissociation of gastric acid to composite organic microelements; after entering intestinal tracts, the composite organic microelement microcrystal particles release core composite organic microelements, therefore bioavailability of the composite organic microelements is increased.

Owner:河南艾德昕生物科技有限公司

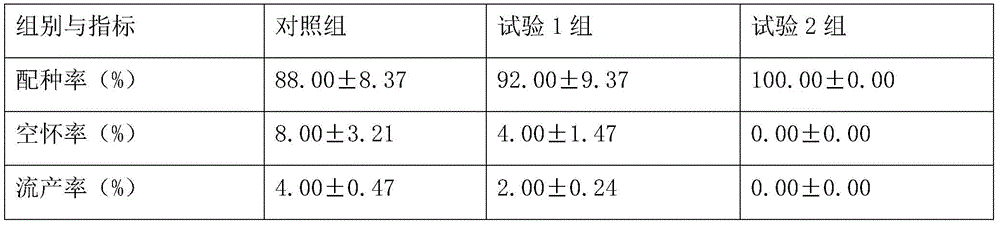

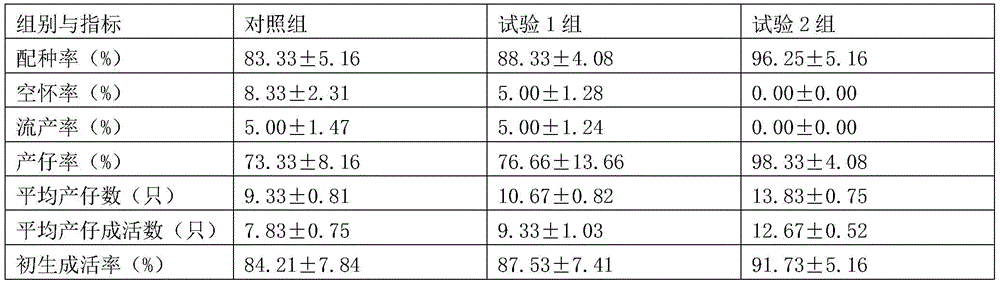

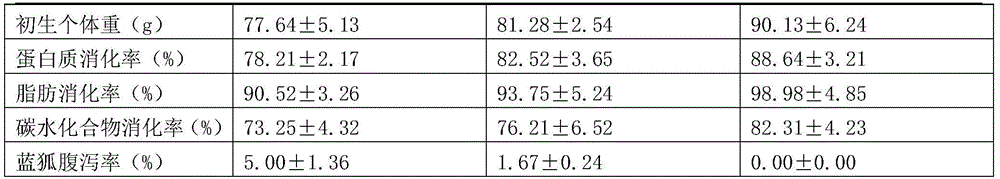

Premixed feed for blue foxes in reproduction period and preparing method thereof

InactiveCN105614028AImprove the breeding rateImprove litter rateAnimal feeding stuffAccessory food factorsVitamin K2Arginine

The invention relates to premixed feed for blue foxes in a reproduction period and a preparing method thereof. The premixed feed capable of improving blue box reproductive performance and increasing the feed use ratio is prepared from whey powder, vitamin B1, vitamin B2, vitamin B3, vitamin B5, vitamin B6, vitamin B9, vitamin B12, biotin, a compound enzyme preparation, vitamin A, vitamin C, vitamin E, vitamin D, vitamin K, methionine, lysine, arginine, threonine, choline chloride, ferrous sulfate monohydrate, copper sulfate pentahydrate, manganese sulfate, zinc sulphate monohydrate, sodium selenite, cobalt chloride, potassium iodate, yeast chromium, dihydropyridine, probiotics, calcium hydrophosphate and the like. Female fox reproductive performance can be effectively improved, nutrient substance digestibility of female foxes in the reproduction period is improved, intestines disease incidence of the female foxes is reduced, and breeding benefits are increased.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Multifunctional long-effect slow-release rice fertilizer

InactiveCN109761703AIncrease profitReduce inputFertilizer mixturesHigh activityZinc sulphate monohydrate

The invention relates to a multifunctional long-effect slow-release rice fertilizer, which is prepared from urea, ammonium chloride, ammonium phosphate, calcium magnesium phosphate fertilizers, ordinary calcium superphosphate, potassium chloride, zinc sulphate monohydrate, high-activity organic matter, non-coating composite slow release agents, high-activity soil conditioning agents. The multifunctional long-effect slow-release rice fertilizer can promote the rice tillering; the rice spike number and the spike grain number can be emphatically increased, so that the yield is improved. Meanwhile, the absorption of the rice stems and seeds on N, P and K nutrients can be obviously improved; the fertilizer utilization rate is improved; the fertilizer consumption is reduced; meanwhile, the economic benefits of the rice are improved. By using the multifunctional long-effect slow-release rice fertilizer provided by the invention, the rice quality can be obviously improved; the obvious influence is particularly realized on fine rice rate, protein content and straight chain starch content.

Owner:HUBEI YISHIZHUANG AGRI TECH

Organic fertilizer for olea europaea

InactiveCN106946611ANutritional diversityPromote reproductionSuperphosphatesBio-organic fraction processingDecompositionRhizobium

The invention discloses an organic fertilizer for olea europaea. The organic fertilizer is prepared from the following raw materials in parts by weight: 450-500 parts of chicken manure, 100-120 parts of sheep manure, 50-90 parts of rice bran powder, 80-120 parts of Chinese white olive dregs, 40-60 parts of calcium superphosphate, 80-120 parts of humic acid, 20-40 parts of a starter, 1-4 parts of bacillus subtilis, 1-4 parts of rhizobium, 1-2 parts of actinomycetes, 1-2 parts of protease, 1-2 parts of cellulase, 1-2 parts of lactic acid bacteria, 1-2 parts of antagonistic bacteria, 8-12 parts of maize meal, 4-6 parts of boric acid, 5-10 parts of zinc sulphate monohydrate, 18-22 parts of magnesium sulfate monohydrate, 8-12 parts of ferrous sulfate monohydrate and 0.1-0.5 part of ammonium molybdate. The organic fertilizer for the olea europaea contains various nutrients and abundant organic matters required by crops, and is slow in decomposition and long in fertilizer efficiency after being applied to soil, the nutrients are not easy to lose, and the quality and the yield of the olea europaea are improved.

Owner:重庆市巴昌农业发展有限公司

Technical method for producing feed-grade zinc sulfate in environment-friendly manner by electrolytic zinc slag

ActiveCN104556205ASolving Recycling ProblemsSimple production processZinc sulatesEnvironmental resistanceElectrolysis

The invention discloses a technical method for producing feed-grade zinc sulfate in an environment-friendly manner by electrolytic zinc slag. The technical method comprises the steps: stirring to dissolve the electrolytic zinc slag by hot water at the temperature of 60-80 DEG C, adjusting the pH of a solution to be 4.5-5.1 by saturated lime whey liquid, filtering out and removing part of sediments, heating filtrate to 80-90 DEG C, feeding air or oxygen to remove most of iron impurities, adding a small amount of calcium powder or second zinc oxide powder into the solution to remove trace iron impurities in the solution, adding metal zinc powder into the filtrate after filtering under the condition that the pH is 4.2-4.5 to further remove the residual heavy metal impurities, adding active carbon powder and a chelating agent into the solution to remove a small quantity of organic impurities from the solution, concentrating and crystallizing a pure zinc sulfate solution to prepare a feed-grade heptahydrate or zinc sulphate monohydrate product after filtering. According to the method, the electrolytic zinc slag is used as a raw material; due to full-closed-loop cyclic production, the method is environment-friendly, low in production cost and high in economic benefit.

Owner:湖南鑫科思生物科技有限公司

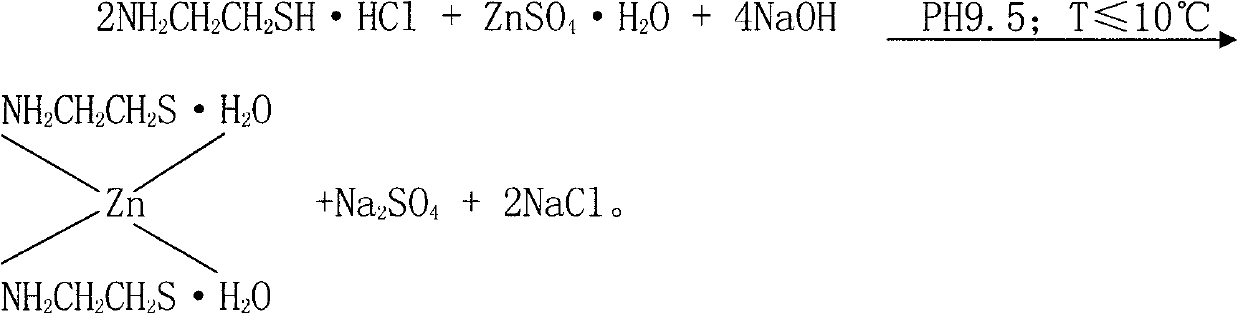

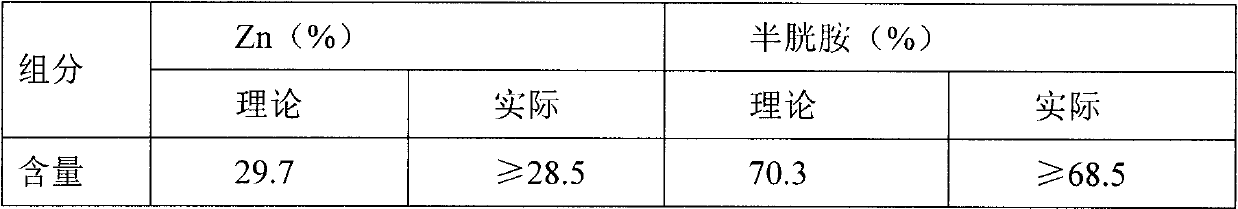

Preparation method for cysteamine chelation zinc

InactiveCN102827044AFix stability issuesReduce manufacturing costThiol preparationAnimal feeding stuffChelationZinc sulphate monohydrate

The invention relates to a preparation method for cysteamine chelation zinc. The preparation method comprises the following steps of: (1) dissolving mercaptamine in water, controlling water temperature and stirring to sufficiently dissolve the mercaptamine in the water, and forming a transparent solution; (2) adding zinc sulphate monohydrate, and sufficiently stirring to completely dissolve; (3) slowly adding sodium hydroxide, adjusting a PH value to be 8-13 and enabling a reaction system to be a hoary muddy solution; (4) stirring and preserving heat for 2 hours at a room temperature; and (5) conducting vacuum filtration, stoving a filter cake in a 80-DEG C electrothermal constant-temperature dry box, grinding, and obtaining similar white powdery crystal, namely, finished products of the cysteamine chelation zinc. The preparation method for the cysteamine chelation zinc is low in cost, needs no expensive instruments and raw materials, and is simple in preparation step, easy to operate, low in raw material cost. The cysteamine chelation zinc prepared by the preparation method can be easily absorbed in intestinal tracts and is safe, free of stimulation, high in finished product yield and favorable for large-scale popularization and application.

Owner:湖北广华生物有限公司

Environment-friendly phosphorus-free scale and corrosion inhibitor and manufacturing method for same

InactiveCN102515369AAct as scale and corrosion inhibitorNo pollution in the processTreatment using complexing/solubilising chemicalsSodium molybdateBenzotriazole

The invention relates to the technical field of water treatment, particularly to an environment-friendly phosphorus-free scale and corrosion inhibitor and a manufacturing method for the same. The scale and corrosion inhibitor comprises the following ingredients in parts by weight: 15-30 parts of acrylic acid-acrylate copolymer, 5-10 parts of sodium molybdate, 5-10 parts of benzotriazole, 3-8 parts of zinc sulphate monohydrate and 60-80 parts of distilled water. The scale and corrosion inhibitor disclosed by the invention is phosphorus-free and pollution-free for environment, as well as is an environment-friendly water treatment chemical.

Owner:上海久安水质稳定剂厂

Additive premix for mixed culture of Litopenaeus vannamei and Siganus oramin and preparation method of additive premix

InactiveCN103549142AMeeting micro-ingredient needsImprove autoimmune resistanceAnimal feeding stuffAntioxidantAdditive ingredient

The invention discloses an additive premix for mixed culture of Litopenaeus vannamei and Siganus oramin and a preparation method of the additive premix. The additive premix is prepared from multivitamins and complex mineral salts, wherein the multivitamins are prepared from multiplex vitamins, DL-calcium pantothenate, nicotinic acid, folic acid, inositol, biotin, vitamin C, carnitine, choline chloride, bacillus subtillis, mannan, cholesterin, an antioxidant, a mildew preventive, and defatted rice bran; the complex mineral salts are prepared from cobalt chloride, copper sulfate pentahydrate, ferric citrate, magnesium sulfate, manganese glycinate, potassium iodide, sodium selenite, zinc sulphate monohydrate, sodium chloride, sodium dihydrogen phosphate, calcium lactate, ammonium molybdate, monocalcium phosphate, monopotassium phosphate and zeolite powder. The additive premix is added with the multiple components to meet the requirements of the Litopenaeus vannamei and the Siganus oramin for microconstituents such as the vitamins, mineral substances and the like in a mixed culture mode, has the high cost performance of a feed, and makes up the deficiency on nutrition research on the mixed culture of the Litopenaeus vannamei and the Siganus oramin.

Owner:湛江粤海预混料科技有限公司

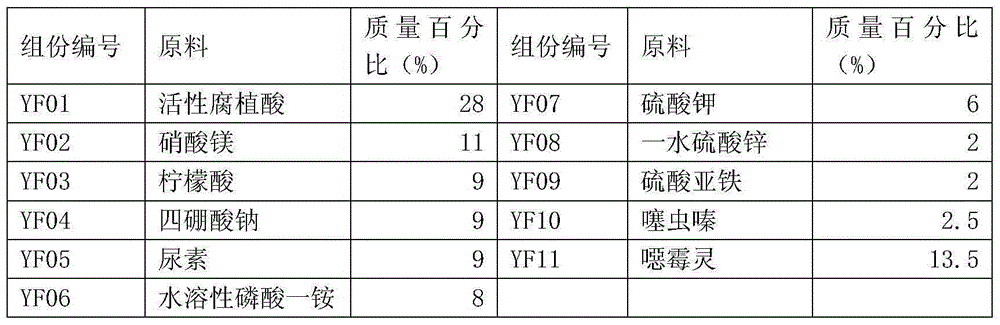

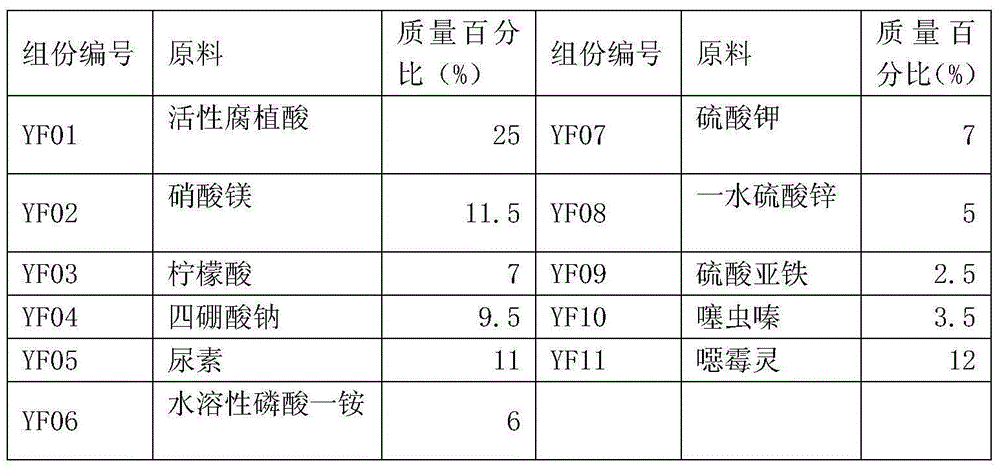

Water-soluble humic acid fertilizer and preparation method

InactiveCN105111016AMeet planting requirementsReasonable formulaFertilizer mixturesPhosphateDisease damage

The invention discloses water-soluble humic acid fertilizer and a preparation method. The water-soluble humic acid fertilizer is composed of 20-30% of bio-active humic acid, 10-15% of magnesium nitrate, 7-11% of citric acid, 8-12.5% of sodium tetraborate, 8-13% of urea, 2-8% of water-soluble monoammonium phosphate, 4-9% of potassium sulphate, 2-7% of zinc sulphate monohydrate, 1-6% of ferrous sulfate, 1-6% of thiamethoxam and 10.5-15% of hymexazol. The water-soluble humic acid fertilizer integrates the humic acid, major, medium and trace elements and pesticide, therefore, the utilization rate of lemons to the trace elements is improved, the etiolation phenomenon due to the fact that the lemons are lack of the necessary medium and trace elements is effectively improved, and meanwhile the etiolation phenomenon caused by pest and disease damage such as planococcodes robustus, thrips, root rot and damping off can be effectively controlled. According to the water-soluble humic acid fertilizer, the fast-acting property and the durability are integrated, the fertilizer application amount and the application times are decreased, soil hardening is reduced, the control effect is improved, the labor cost is lowered, the toxic effects of the pesticide on natural enemies and pollution of the pesticide to water are reduced, and the economical and biological benefits are significant.

Owner:INST OF TROPICAL & SUBTROPICAL CASH CROP YUNNAN ACAD OF AGRI SCI

Full nutrient blended fertilizer and preparation method thereof

InactiveCN106631456AIncrease productionImprove qualityMagnesium fertilisersAlkali orthophosphate fertiliserPhosphateMicrobial agent

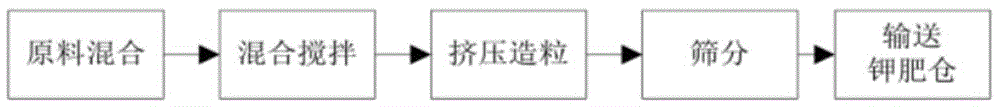

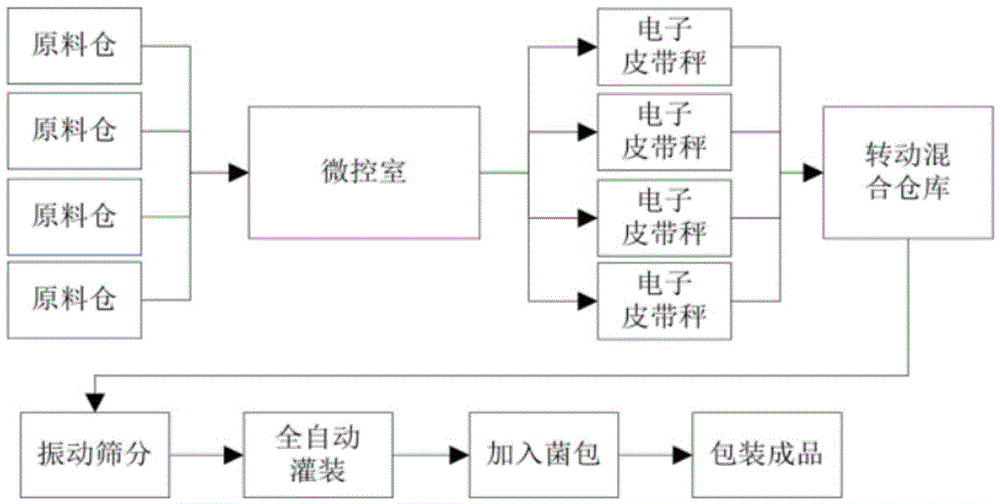

The invention provides a full nutrient blended fertilizer and a preparation method thereof. The problem of single nutrition of the existing fertilizer is at least solved. The full nutrient blended fertilizer comprises an organic fertilizer, urea, monoammonium phosphate, a potash fertilizer and a composite microbial agent, wherein the potash fertilizer is prepared by mixing potassium sulphate, amino acid, fulvic acid, boracic acid, zinc sulphate monohydrate and magnesium sulfate monohydrate, and then performing stirring, extrusion and granulation; the raw materials are conveyed into a mixed cabin according to the recipe proportion; the materials are sieved to 1 to 4.75mm in the mixed cabin; after the sieving, the materials are filled into a finished product; a composite microbial agent bag is put into a finished product bag; after the result is qualified through inspection, a finished product is put into a warehouse. The full nutrient blended fertilizer is obtained by reasonably matching the inorganic fertilizers and the organic fertilizers, adding trace elements, and compounding the trace microbial agent, and has the advantages of full nutrients and high utilization rate; the growth requirements of different crops can be met; the nutrient release period is controlled; the crop yield and the quality are improved; the yield improvement amplitude is 20 percent or higher.

Owner:山西中农化生物技术股份有限公司

Selenium-rich leaf fertilizer

InactiveCN109293443AHigh in nutrientsQuickly relieve obesityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSelenium methionineMonopotassium phosphate

A selenium-rich leaf fertilizer comprises, by weight, 40-45 parts of zinc sulphate monohydrate, 6-11 parts of sodium hyaluronate, 5-9 parts of strontium chloride, 65-70 parts of basic acid stoste, 7-10 parts of selenium methionine, 0.5-1.5 parts of selenium-rich yeast, 7-10 parts of monopotassium phosphate, 10-12 parts of boric acid, 25-30 parts of citric acid monohydrate, 3-6 parts of compound sodium nitrophenolate, 2-5 parts of calcium nitrate, 5-9 parts of ordinary sugar, 5-9 parts of glucose, 2-6 parts of chelated trace elements and 30-40 parts of distilled water. The leaf fertilizer is reasonable and economical in formula, low in cost and durable in function and has remarkable visual effects, yield increasing effects and selenium enrichment effects when be applied to plants.

Owner:徐州聚友信息技术有限公司

Breeding goose premix for improving egg hatching rate

ActiveCN102948651AConsider comprehensivelyMeet basic nutritional needsAnimal feeding stuffPhysiologyPantothenic acid

The invention discloses a breeding goose premix, and particularly relates to the breeding goose premix for improving egg hatching rate, and belongs to the technical field of a poultry feed. The premix contains various vitamins and trace elements, which are all required by breeding geese in a growing process, wherein the vitamins include vitamin A, vitamin D, vitamin E, vitamin K, vitamin B1, vitamin B2, vitamin B6, vitamin B12, nicotinic acid, pantothenic acid, folic acid and a biotin; and the trace elements include ferrous sulfate monohydrate, copper sulfate pentahydrate, zinc sulphate monohydrate, manganese sulfate monohydrate, sodium selenite and chromium picolinate. Due to the matching between the premix and conventional raw materials, the requirements of the breeding geese on basic nutrition are met, the content of some vitamins and the content of some trace elements are properly increased, the semen quality of male geese can be improved, and the fertility rate of breeding eggs is ensured.

Owner:铁骑力士食品有限责任公司

Anti-diarrhea fast-growing concentrated feed for nursery pigs

InactiveCN103583897AImprove conversion rateGain weight fastFood processingAnimal feeding stuffFeed conversion ratioPhytase

The invention discloses an anti-diarrhea fast-growing concentrated feed for nursery pigs. The feed comprises the following raw materials: expanded soybean, import fish meal, whey powder, lysine, methionine, 536 type rovimix, vitamin E, vitamin C, choline chloride, piglet composite enzyme, phytase, honey, an acidifier, earth frankincense, calcium hydrogen phosphate, stone powder, table salt, ferrous sulfate monohydrate, zinc sulphate monohydrate, copper sulfate pentahydrate, manganese sulfate monohydrate, an iodine premixing agent, a selenium premixing agent, zinc oxide, arsanilic acid, tylosin, and colistin. The prepared concentrated feed (with the addition proportion of 25%) can allows the diarrhea rate of the nursery pigs to be controlled below 2%, allows the weight increment to be increased by more than 10%, and allows the feed conversion rate to be increased more than 8%.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com