Coating layer coating microelements and production method of coating layer

A technology of trace elements and production methods, applied in the fields of application, animal feed, animal feed, etc., can solve problems affecting animal production performance, complex production process, volatile loss of iodine, etc., so that feed intake is not easy to reduce, and it is not easy to oxidize Reaction, avoiding the effect of oxidation and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] A method for producing a coating coated with trace elements, comprising the steps of:

[0091] (1) Drying and moisture-proof treatment: Dry ferrous sulfate monohydrate, copper sulfate pentahydrate, manganese sulfate monohydrate, zinc sulfate monohydrate, sodium selenite monohydrate, cobalt chloride hexahydrate to remove all free water;

[0092] (2) Fine granulation: Combine calcium iodate with ferrous sulfate monohydrate, copper sulfate pentahydrate, manganese sulfate monohydrate, zinc sulfate monohydrate, sodium selenite monohydrate, hexa Cobalt chloride hydrate is pulverized to 80 mesh and then mixed, and stirred evenly;

[0093] (3) Add anti-caking agent: Add sodium aluminosilicate and starch as anti-caking agent to the material in step (2), and mix evenly, then spray microcrystalline cellulose on the above-mentioned uniformly mixed material to obtain a package Coated with trace elements.

[0094] The addition of above-mentioned each raw material is referring to th...

Embodiment 2

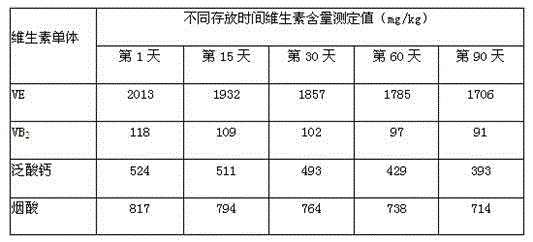

[0103] Table 2 Effects on vitamins

[0104]

[0105] The control group is the data of the vitamin content detected after adding common trace elements to the growing pig premix, and Example 2 is the data of the vitamin content after adding the coating coated with trace elements added to the growing pig premix in Example 1 , the two trace element additions of the embodiment 2 group and the control group are identical.

[0106] It can be seen from the above comparison that the microelements coated with the coating have little damage to vitamins and can reduce the damage of vitamins.

Embodiment 3

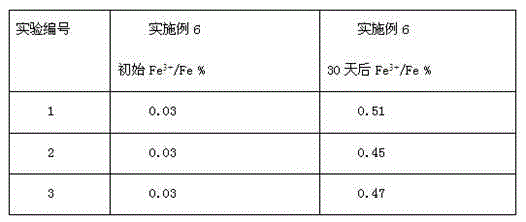

[0108] Table 3 The change of the content of ferric iron in the product of Example 1 after 30 days

[0109]

[0110] The control group is the data of ferric iron ion content detected after the growing pig premix and common trace elements are mixed, and the trace elements in the control group have not been coated.

[0111] It can be seen from the above data that, compared with the control group, the retention rate of ferrous ions in the premix coated with trace elements in Example 1 of the present invention is much higher than that of the control group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com