Preparation method for cysteamine chelation zinc

A technology for chelating zinc and cysteamine, which is applied in the preparation of cysteamine chelated zinc and cysteamine chelated zinc products, and can solve the problem of poor stability and the use of cysteamine hydrochloride coated Restrictions and other issues, to achieve the effect of low cost, conducive to large-scale popularization and application, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

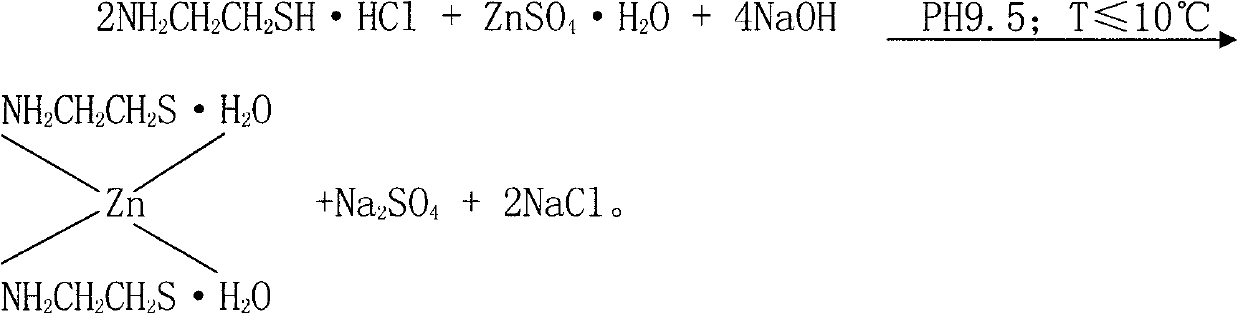

Method used

Image

Examples

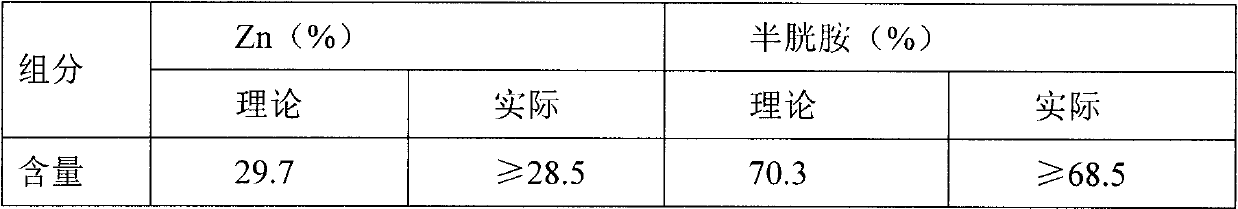

Embodiment 1

[0022] A preparation method for cysteamine chelated zinc, which comprises the steps of: a, adding 150ml water in a 500ml three-neck bottle, then adding 24g of cysteamine hydrochloride with a mass percentage of 95%, and dissolving the cysteamine hydrochloride by ice water Control the temperature of the aqueous solution below 10°C, stir vigorously to dissolve for 5 minutes, and stir until the solution is clear and transparent; b, add 19g of zinc sulfate monohydrate with a mass percentage of 98%, stir and dissolve at low temperature for 5 minutes, make it completely dissolve, and the pH value is 2.5 to 3.0; c, slowly add 18g of 96% sodium hydroxide by mass percentage, adjust the pH to 9.5, so that the aqueous solution is a milky white turbid liquid; d, keep stirring at 9°C to 10°C for 2 hours; e, suction filter, and The filter cake was dried in an electric constant temperature drying oven at 80° C., and the crystals were crushed to obtain 24.2 g of off-white powdery crystals of cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com