Process for producing zinc sulphate monohydrate from waste acid and waste zinc dross

A technology of zinc sulfate and zinc sulfate solution, which is applied in the direction of improving process efficiency, etc., and can solve problems such as poor environmental conditions, soil organic matter pollution, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

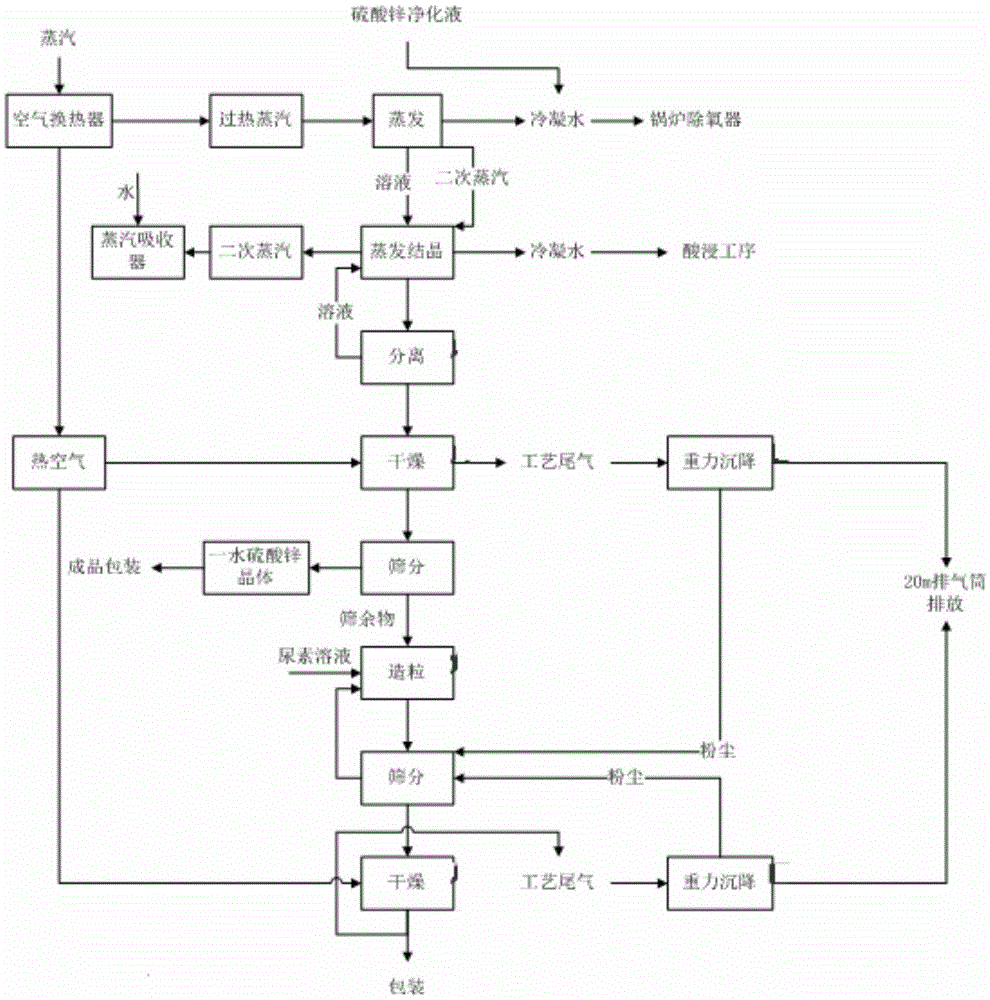

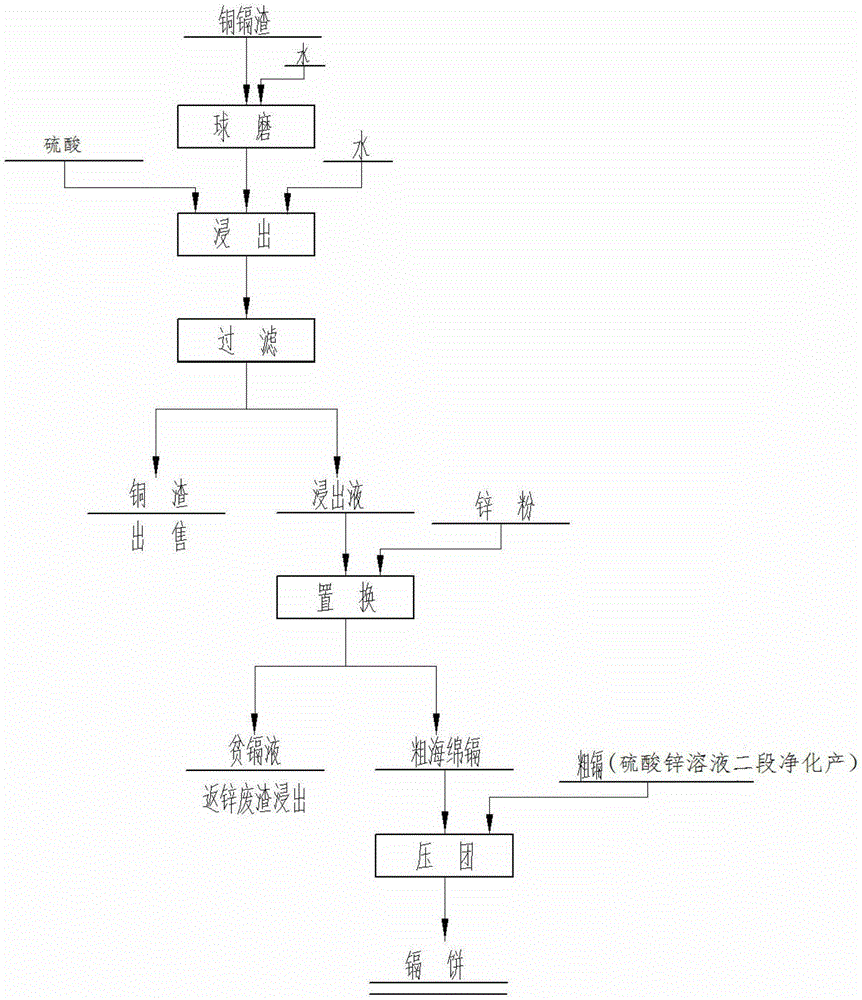

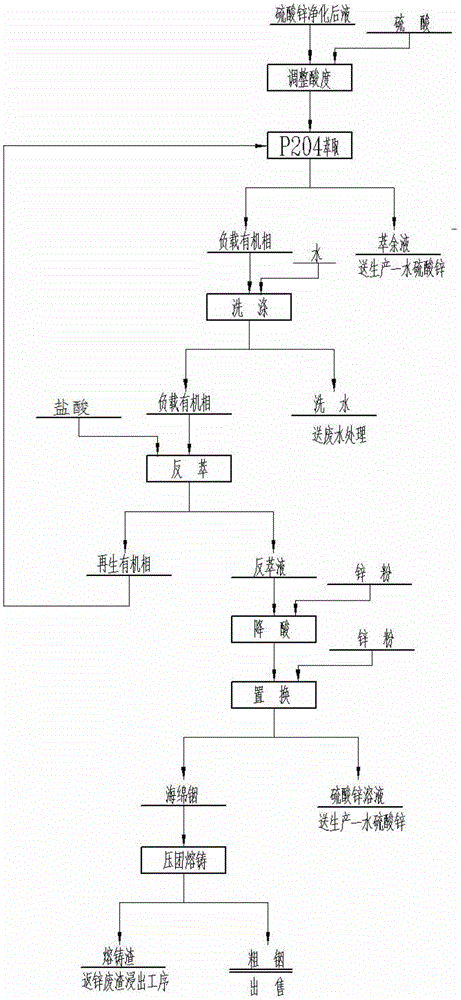

Method used

Image

Examples

Embodiment 1

[0064] a) Acidic leaching: use sulfuric acid solution, waste acid (waste acid containing Zn50-55g / l, sulfuric acid 50-60g / l), sulfuric acid solution about 60wt%, waste acid about 40wt%, close the bottom valve of the barrel, add Waste liquid 120m 3 , that is, the liquid height is 4m, and the bottom zinc water is added 10m 3 , and finally add waste zinc slag 18m 3 (zinc waste slag, copper cadmium slag come from wet electrolytic zinc enterprise, its component composition of zinc waste slag is Zn10-20wt%, Cu0.5-1.5wt%, Pb2.0-10.0wt%, Fe1.0-1.5wt%, Cd0. 001-0.005wt%, copper cadmium slag Cu0.5-2.0wt%, Zn25-40wt%, Cd0.5-1.0wt%), after finishing adding slag, the acidity must be detected with pH test paper, and then sent to the laboratory for testing. The completion time of slag addition, acidity, if the acidity is lower than 50g / l, it must be replenished in time and in place at one time. The initial acidity should be controlled at 25-45g / l. Temperature: 90-95℃, time: 12-14h, solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com