Patents

Literature

30results about "Zinc compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

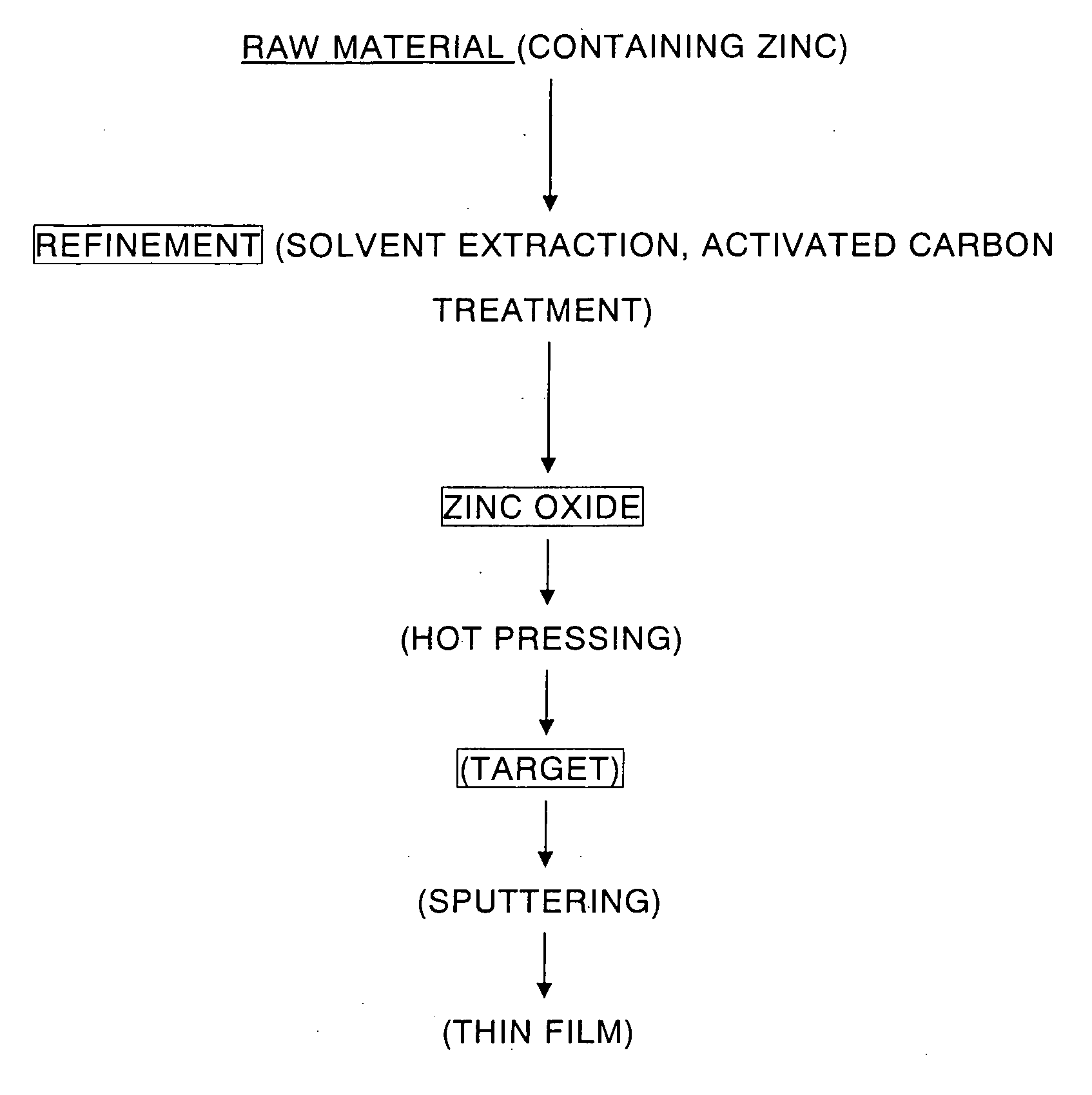

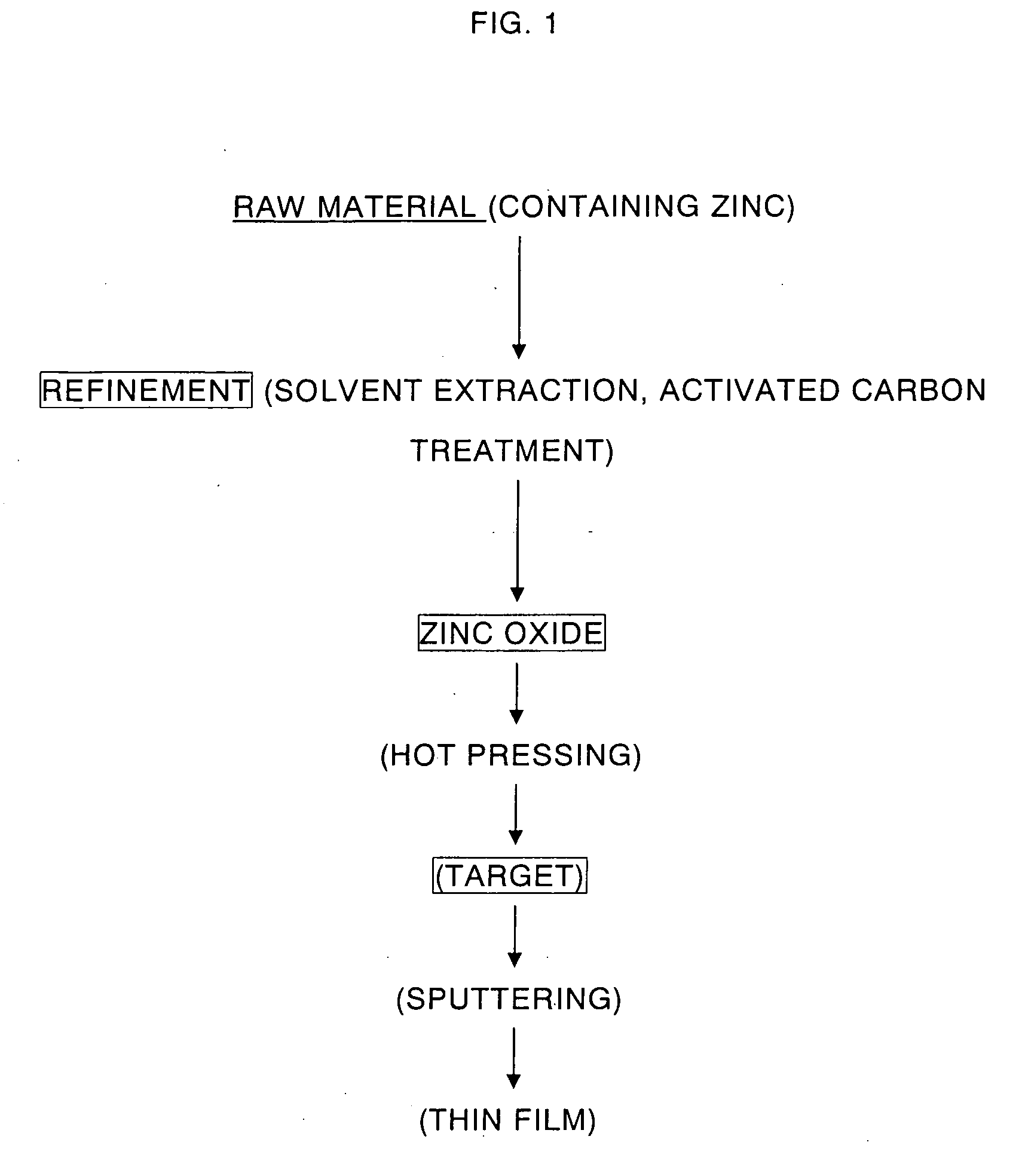

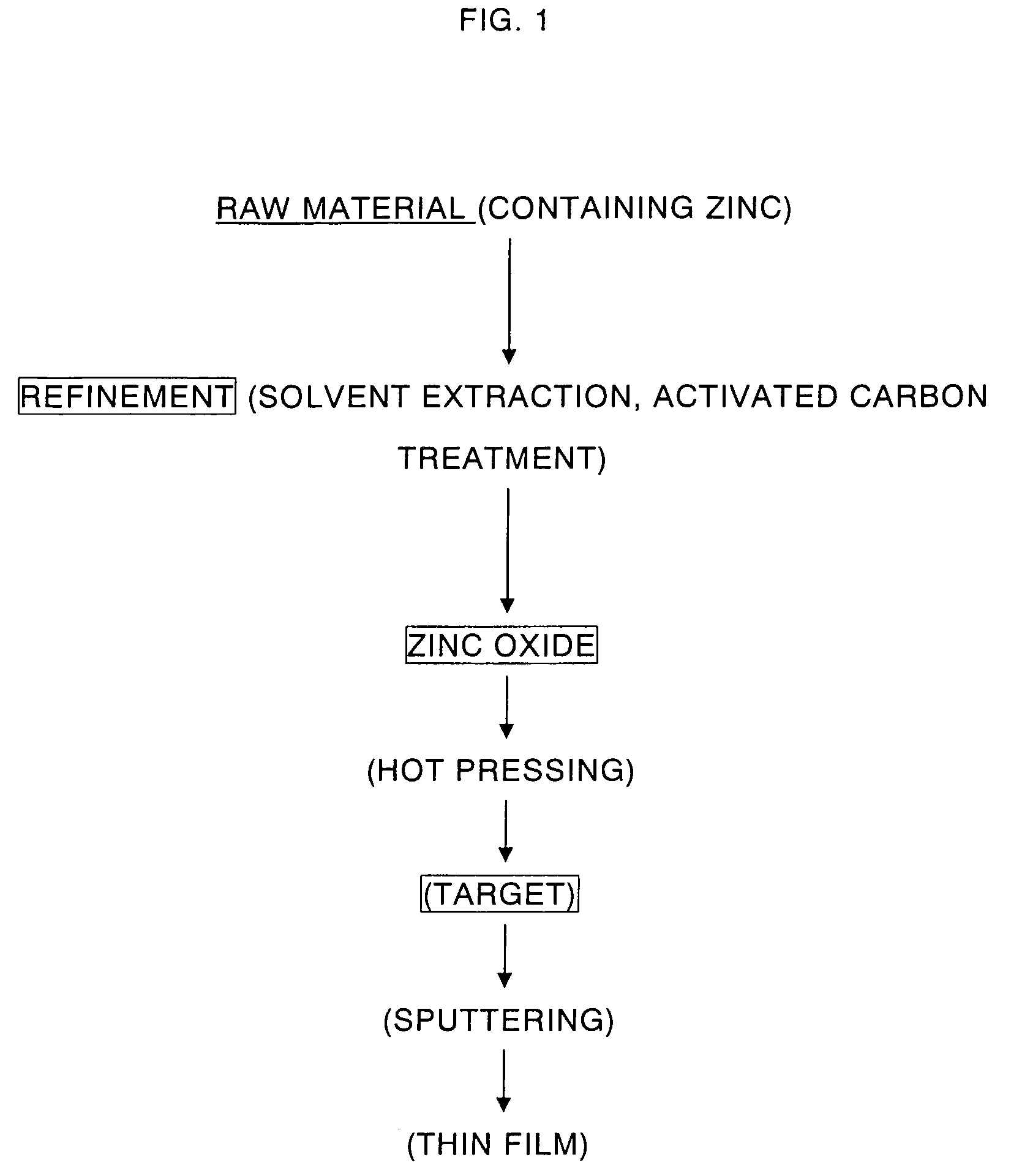

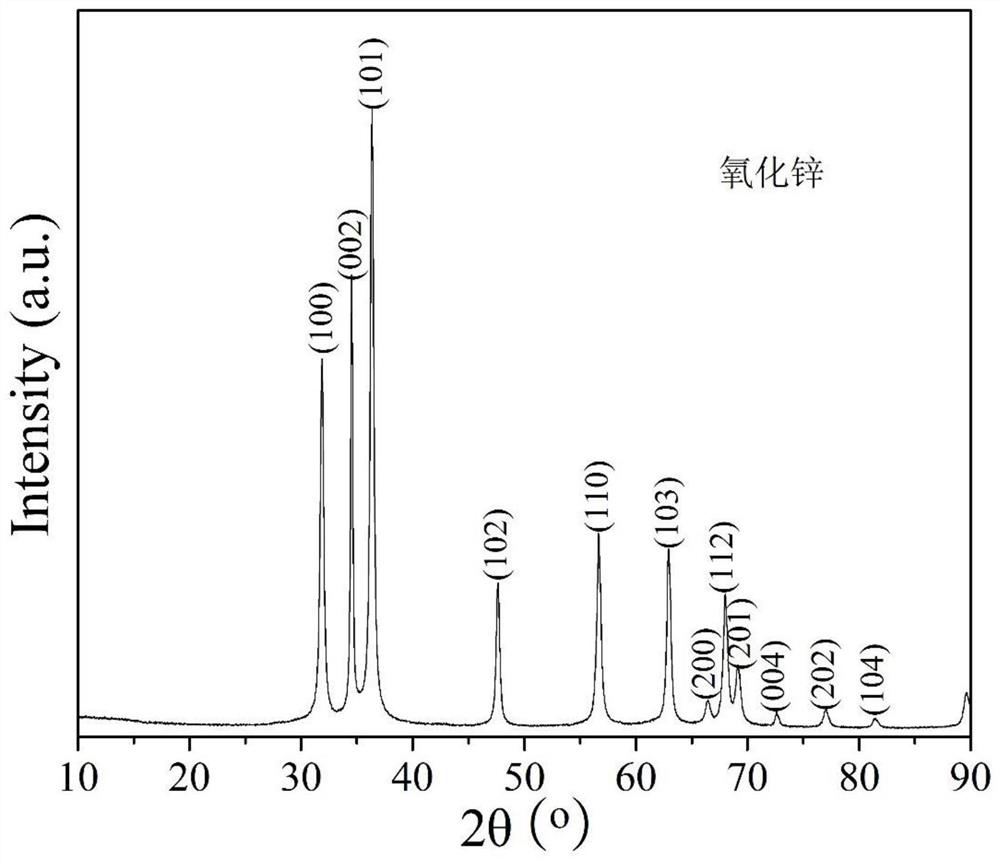

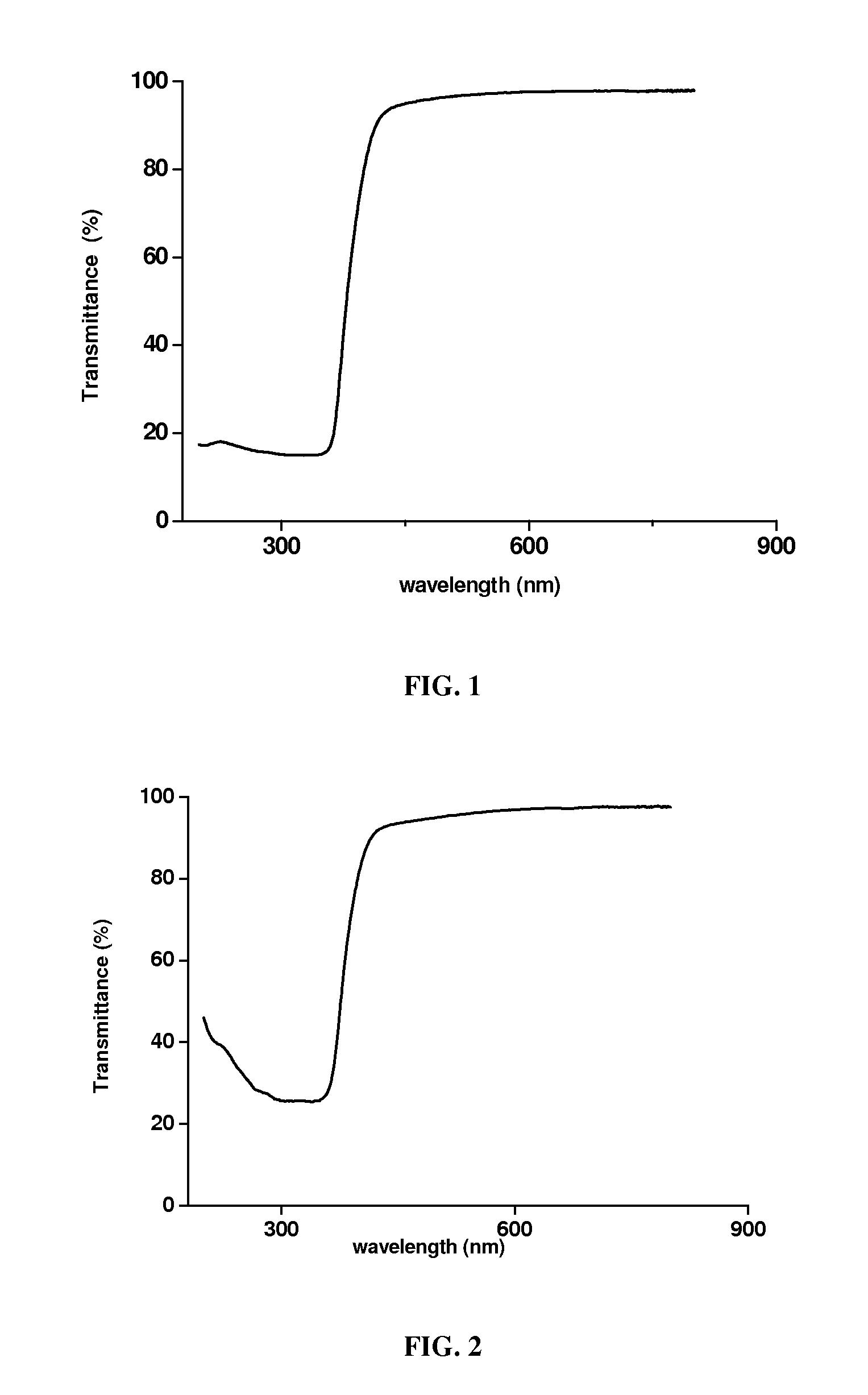

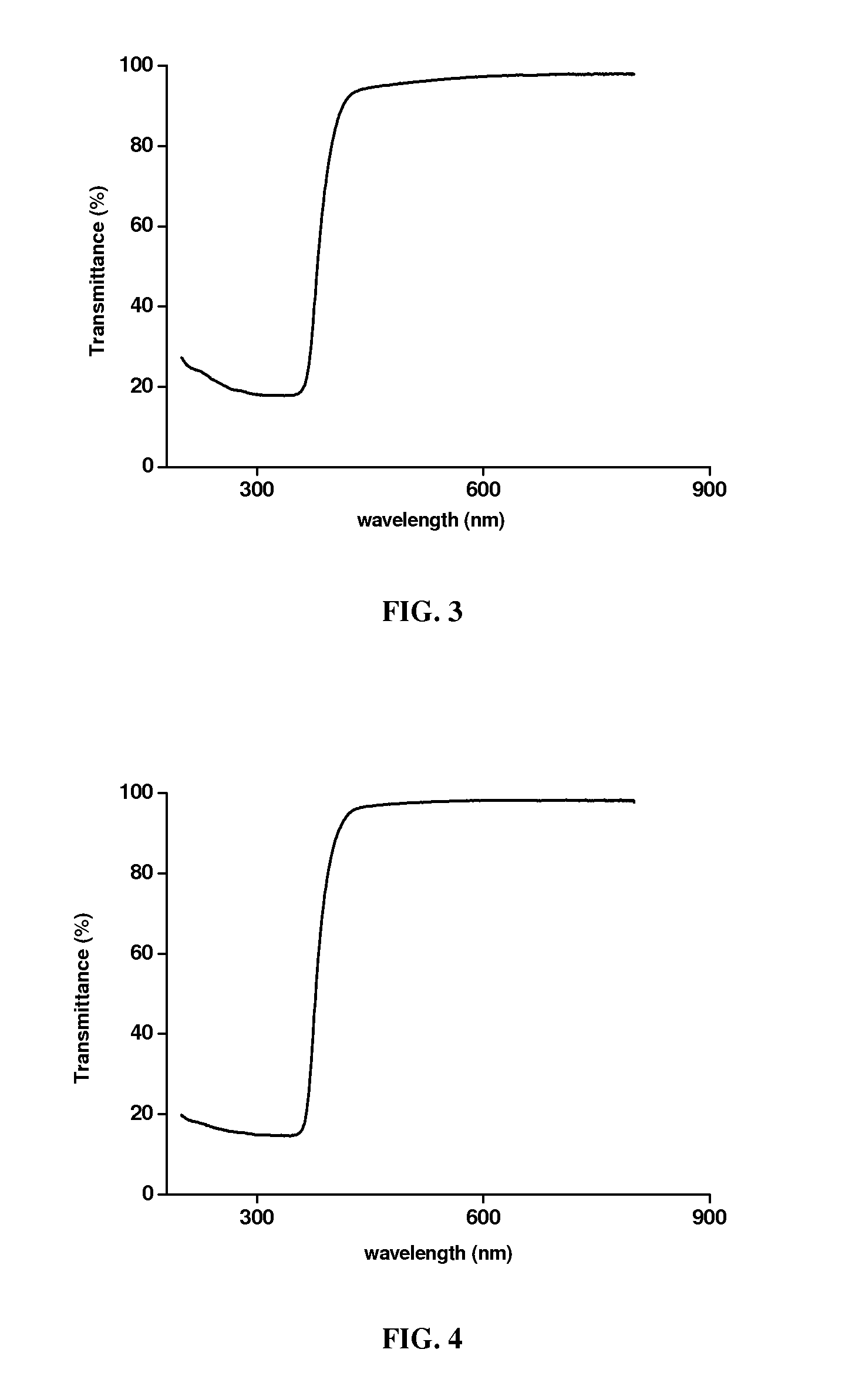

High purity zinc oxide powder and method for production thereof, and high purity zinc oxide target and thin film of high purity zinc oxide

InactiveUS20070098626A1High purityReduce manufacturing costCellsZinc halidesZinc hydroxideActivated carbon

Provided is a manufacturing method of high purity oxide powder including the steps of subjecting a raw material such as Zn-containing scrap to acid leaching or electrolytic extraction, thereafter performing solvent extraction and activated carbon treatment thereto in order to remove impurities, neutralizing the resultant solution freed of impurities with an alkaline solution to obtain zinc hydroxide, and firing the zinc hydroxide to obtain zinc oxide. Provided are high purity zinc oxide efficiently freed of impurities, in particular C, Cl, S and Pb impurities, at low cost and the manufacturing method thereof; a target manufactured by firing the high purity zinc oxide; and a high purity zinc oxide thin film obtained by the sputtering the target.

Owner:JX NIPPON MINING& METALS CORP

High purity zinc oxide powder and method for production thereof, and high purity zinc oxide target and thin film of high purity zinc oxide

Owner:JX NIPPON MINING & METALS CORP

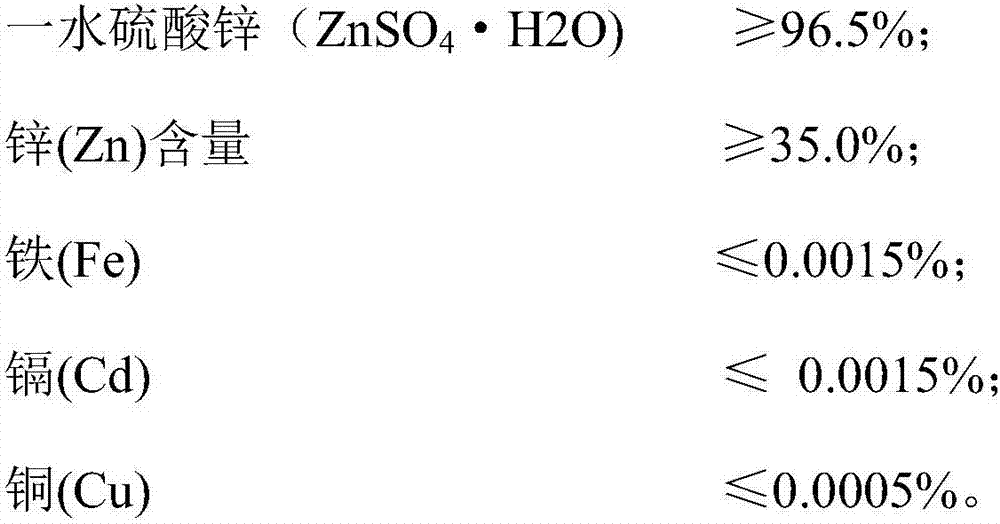

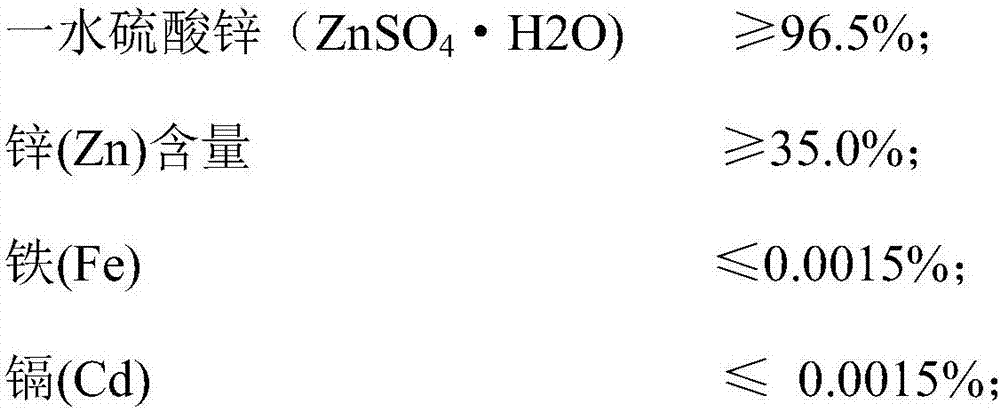

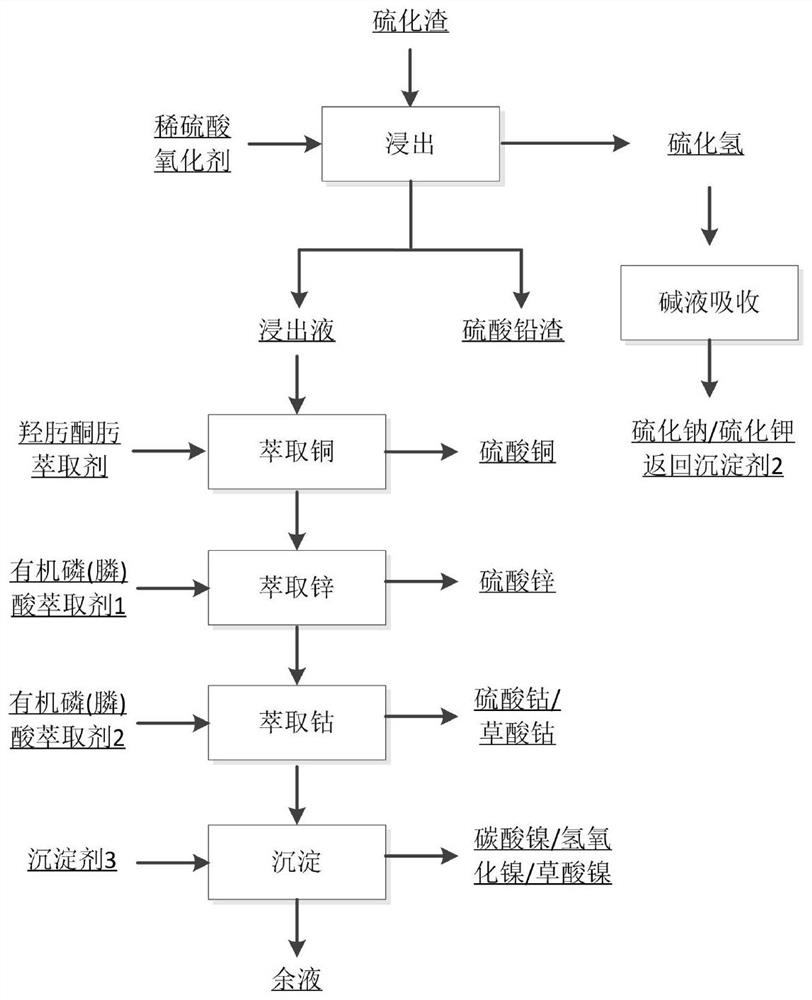

Method for preparing zinc sulphate monohydrate from zinc-containing waste residues

The invention discloses a method for preparing zinc sulphate monohydrate from zinc-containing waste residues. The method is characterized by comprising the following steps of (1), acid leaching; (2), oxidation for iron removal; (3), extraction of copper; (4), replacement for cadmium removal; (5), concentration and crystallization. The method for preparing the zinc sulphate monohydrate from the zinc-containing waste residues is a low-carbon and environmentally-friendly scheme, the preparation raw material is low in cost, waste is reutilized, the environmental problem that existing zinc-containing waste residues cannot be recycled and utilized is solved, the preparation process is energy-saving and environmentally-friendly, no waste gas or waste water is generated, a reagent unfriendly to the environment is not used, meanwhile metal, such as the copper and cadmium, is recycled, and the waste residues are reutilized.

Owner:台山市化工厂有限公司

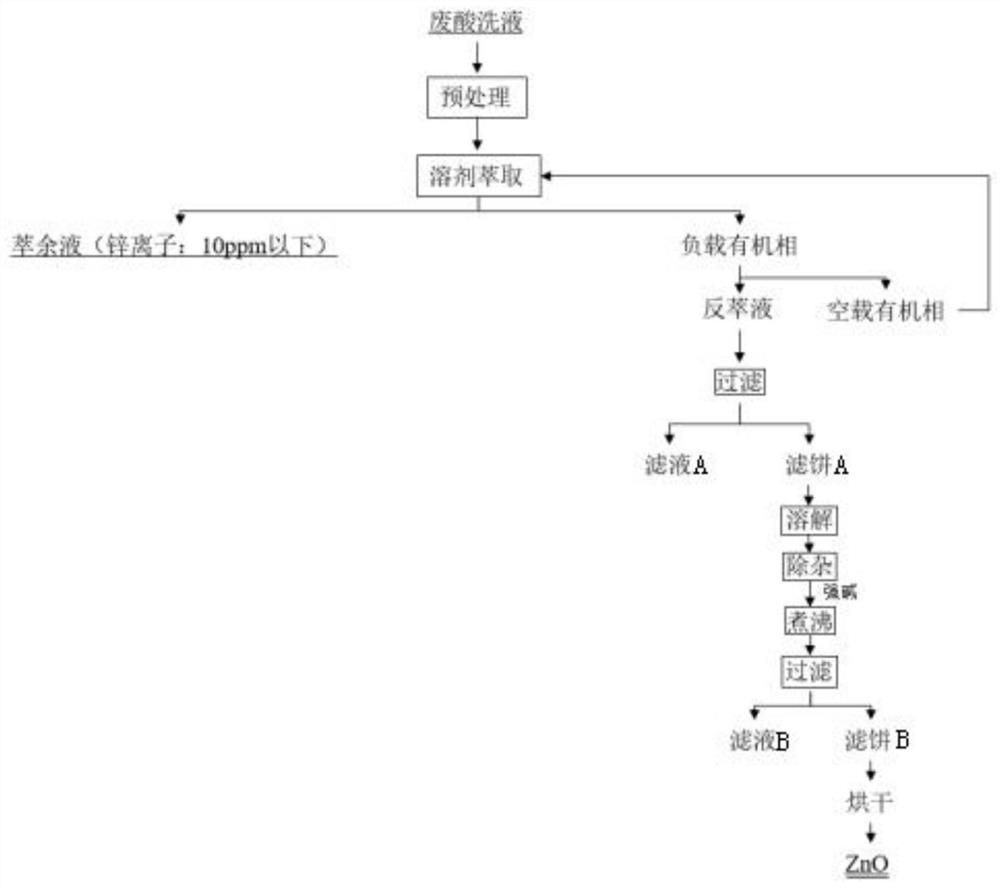

Resourceful treatment method for hot galvanizing pickling waste liquid

PendingCN112408459AHigh purityRealize resource processingIron compounds preparationZinc compounds preparationProcess engineeringSuspended matter

The invention discloses a resourceful treatment method of hot galvanizing pickling waste liquid, which comprises the following steps: filtering the pickling waste liquid to remove suspended matters and insoluble solids, and adding a reducing agent to reduce Fe < 3 + > in the pickling waste liquid into Fe < 2 + >; carrying out multi-stage countercurrent extraction on the pickling waste liquid through an extraction agent, carrying out reverse extraction on an organic phase through a reverse extraction agent, filtering reverse extraction liquid to obtain a filter cake A, dissolving the filter cake A with diluted hydrochloric acid, and adding a small amount of pickling waste liquid to obtain a solution A; adjusting the pH value of the solution A by using ammonia water and ammonium chloride toremove Fe < 3 + > to obtain a solution B; adding strong alkali into the solution B, and heating and boiling until no ammonia smell exists, so as to obtain a solution C containing white precipitate; and filtering the white precipitate to obtain a filter cake B, and drying the filter cake B to obtain zinc oxide. The recovery treatment method for the hot galvanizing pickling waste liquid is simple, low in energy consumption, safe to operate, low in investment cost, capable of achieving maximum resourceful utilization of the hot galvanizing pickling waste liquid, convenient to implement, easy to maintain and manage and worthy of being further popularized in industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Production method for zinc sulfate

The invention provides a production method for zinc sulfate. The production method comprises the following steps: grinding and crushing zinc concentrate into powder with a particle size of 50 to 80 meshes and adding the powder into a hermetic container; adding ferrous sulfate accounting for 1 to 3 wt% of the zinc concentrate powder into the container as a catalyst and adding a sulfur acid solution at the same time; starting an electric mixer, carrying out heating to 80 to 90 DEG C and maintaining the temperature for 3 to 5 h; successively carrying out filtering, cooling and pumping filtration so as to obtain leachate and leaching residues; and separating the leachate by using a solvent extraction method and subjecting the leachate to acidity adjustment, concentration, evaporation, crystallization, centrifugation and drying so as to obtain zinc sulfate. The production method provided by the invention can guarantee the purity of the zinc sulfate product and enables resources to be maximally utilized.

Owner:HENGYANG YISHUN CHEM CO LTD

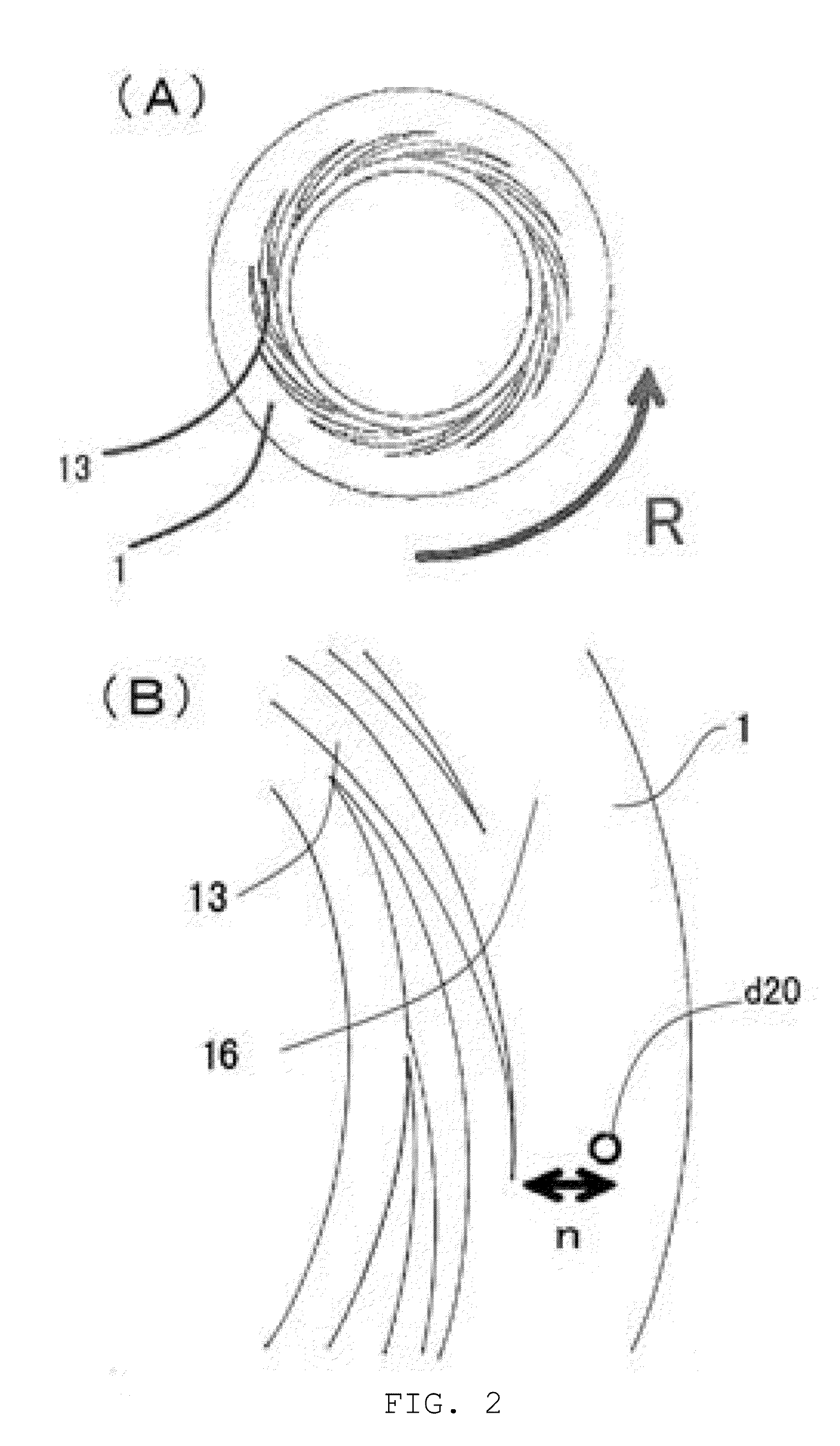

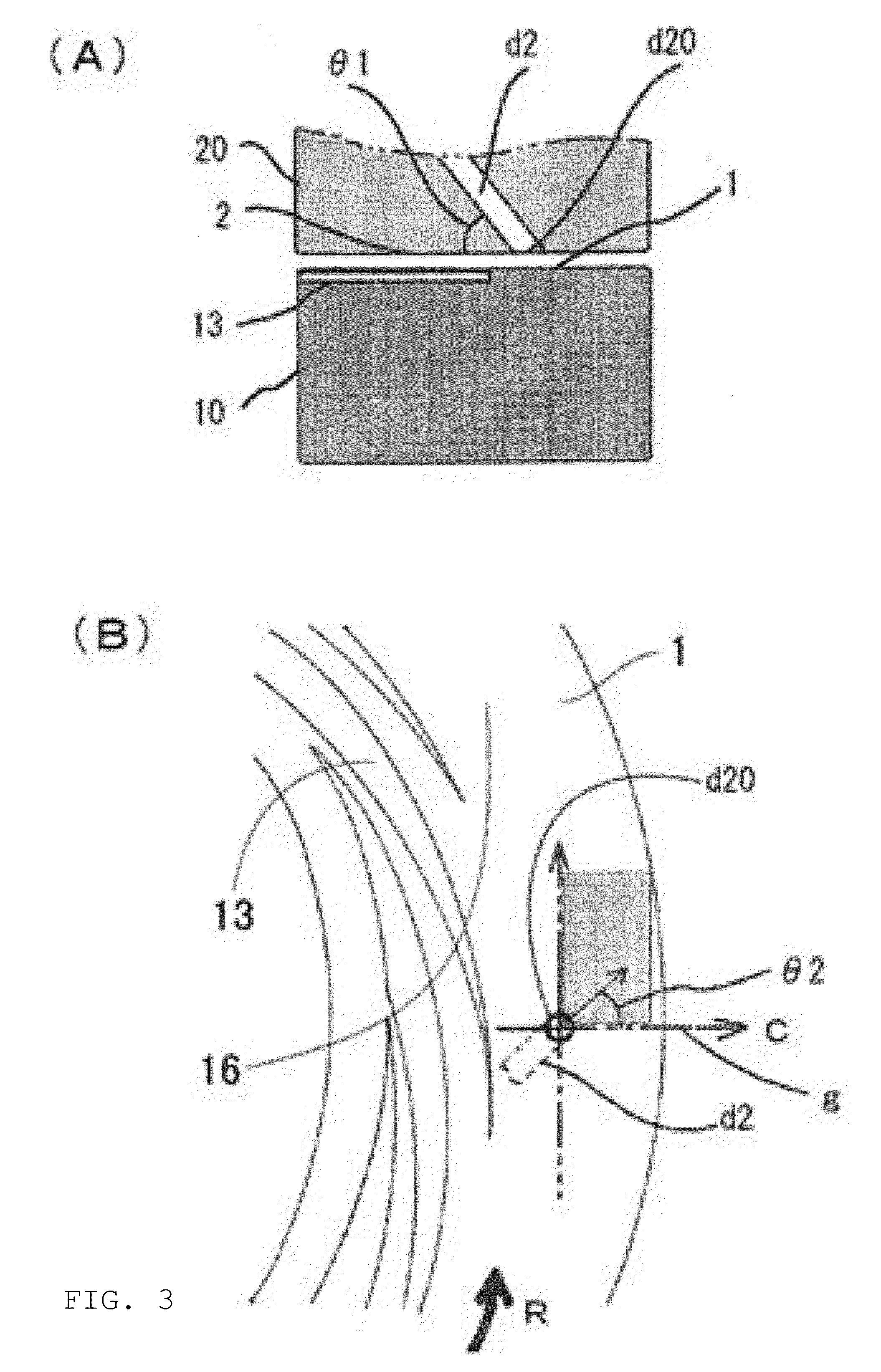

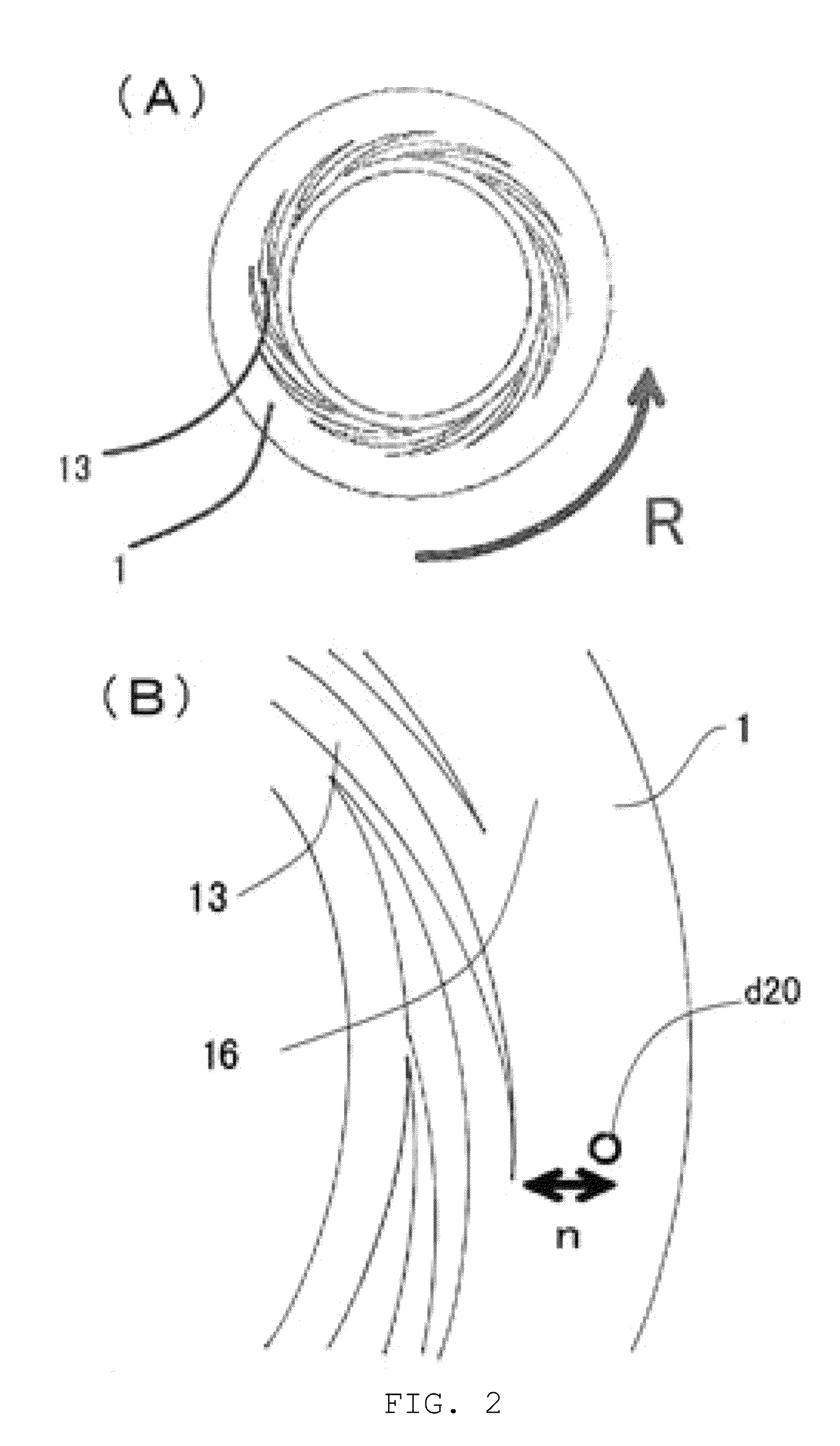

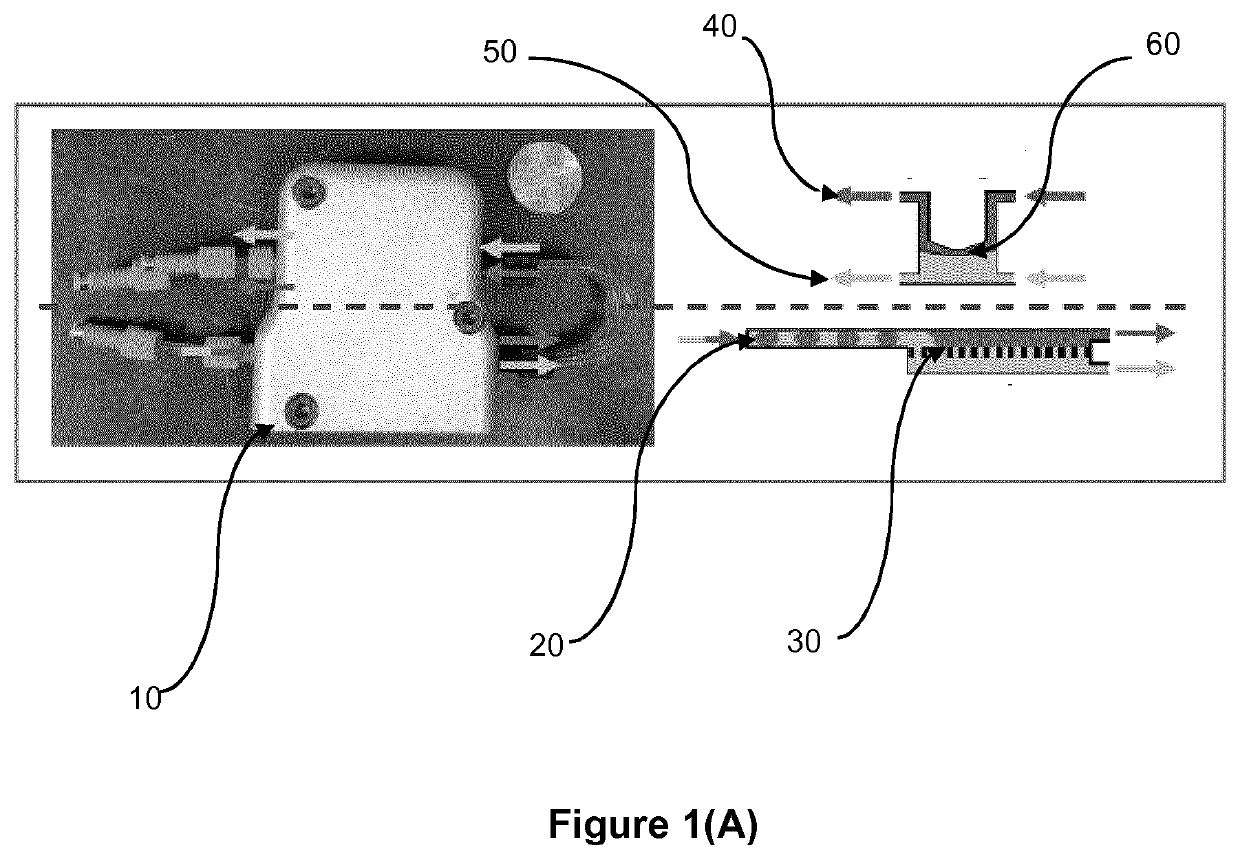

Method for producing substances to be separated having controlled amounts of dopant element

ActiveUS20130034490A1Weaken energyLow costPigmenting treatmentCrystallization separationDopantSolubility

A method is provided for producing separated substances, particularly metal compounds, the dopant element amounts of which have been controlled by the use of an apparatus that processes fluid between the processing surfaces of a processing member that can be made to approach / separate and which rotate relative to each other. The substance to be separated is separated by mixing a raw material solution, wherein the substance to be separated is solubilized in a solvent, with the solvent for separation and with the dopant element or dopant element-containing substance solubilized in at least one solvent selected from the solvent of said raw material solution, said solvent for separation or a solvent other than that of said raw material solution or said solution for separation. Separated substances with controlled dopant element amounts are obtained by controlling the solubility of the dopant element or dopant element-containing substance in the solvent for separation.

Owner:M TECHN

Superfine particle zinc oxide powder production technology

InactiveCN106115765ASimple production processProduction Technology ScienceZinc compounds preparationZinc oxides/hydroxidesZincOxide

The invention discloses a superfine particle zinc oxide powder production technology. The production technology comprises the following steps of 1 leaching, 2 oxidation treating, 3 filtering, 4 replacing and 5 extracting and grinding. The zinc oxide production technology is simple, therefore, energy consumption is low, and the production cost is reduced; the production technology is more scientific, and by adding the replacing step, the prepared zinc oxide product is higher in purity; through grinding treatment of grinding equipment, the diameters of particles of zinc oxide are smaller, the sizes of the particles of zinc oxide are more uniform, and therefore the using range of zinc oxide produced through the scheme is wider.

Owner:安徽省含山县锦华氧化锌厂

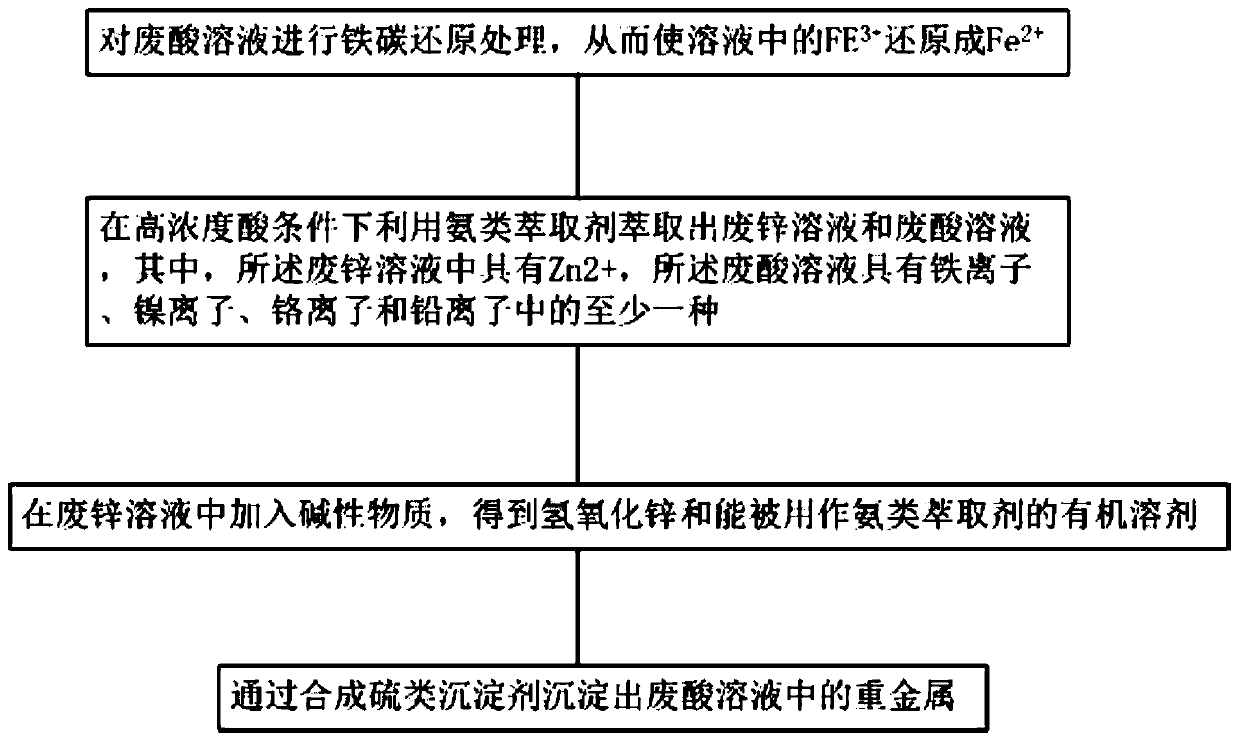

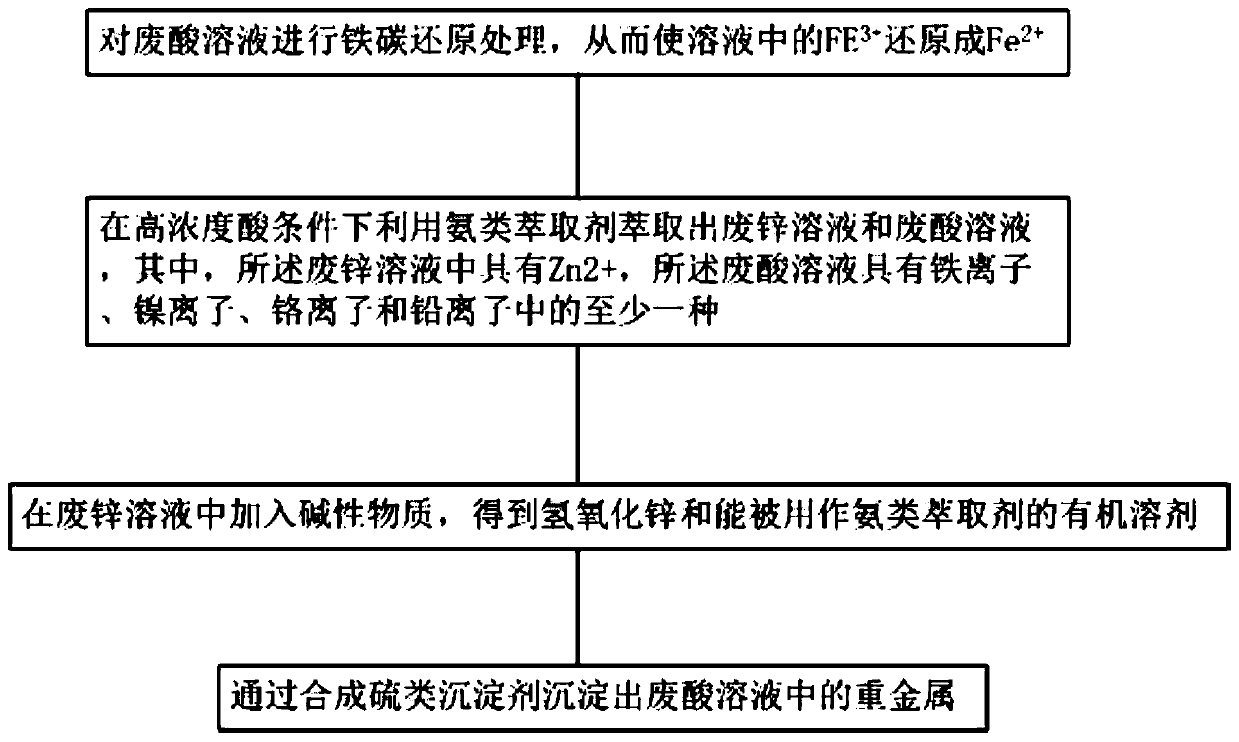

Treatment method of waste acid solution containing heavy metals

InactiveCN111170509ALow free acidLow costIron compounds preparationZinc compounds preparationFree acidEnvironmental chemistry

The invention provides a treatment method of a waste acid solution containing heavy metals, which comprises the following steps: carrying out iron-carbon reduction treatment on the waste acid solutionto reduce Fe< 3 + > in the solution into Fe < 2 + >; under the condition of high-concentration acid, adopting an ammonia extraction agent toextracta waste zinc solution and a waste acid solution, wherein the waste zinc solution contains Zn < 2 + >, and the waste acid solution contains at least one of iron ions, nickel ions, chromium ions and lead ions; adding an alkaline substance into the wastezinc solution to obtain zinc hydroxide and an organic solvent can be used as theammonia extraction agent; and precipitating heavy metals in the waste acid solutionby a synthestic sulfur precipitant. Compared with the prior art, the method has the following advantages that ferric ions are reduced, free acid is reduced and a small amount of heavy metalsarereplaced by utilizing an iron elementary substance while iron-carbon pretreatment is carried out; the zinc separation rate can reach 99.8% or above; the obtained zinc oxide product with the content of 98% or above can be used for selling; one part of an obtained supernatant can be used for circulating water, and the other part can be used for industrial water.

Owner:大康环境技术(苏州)有限公司

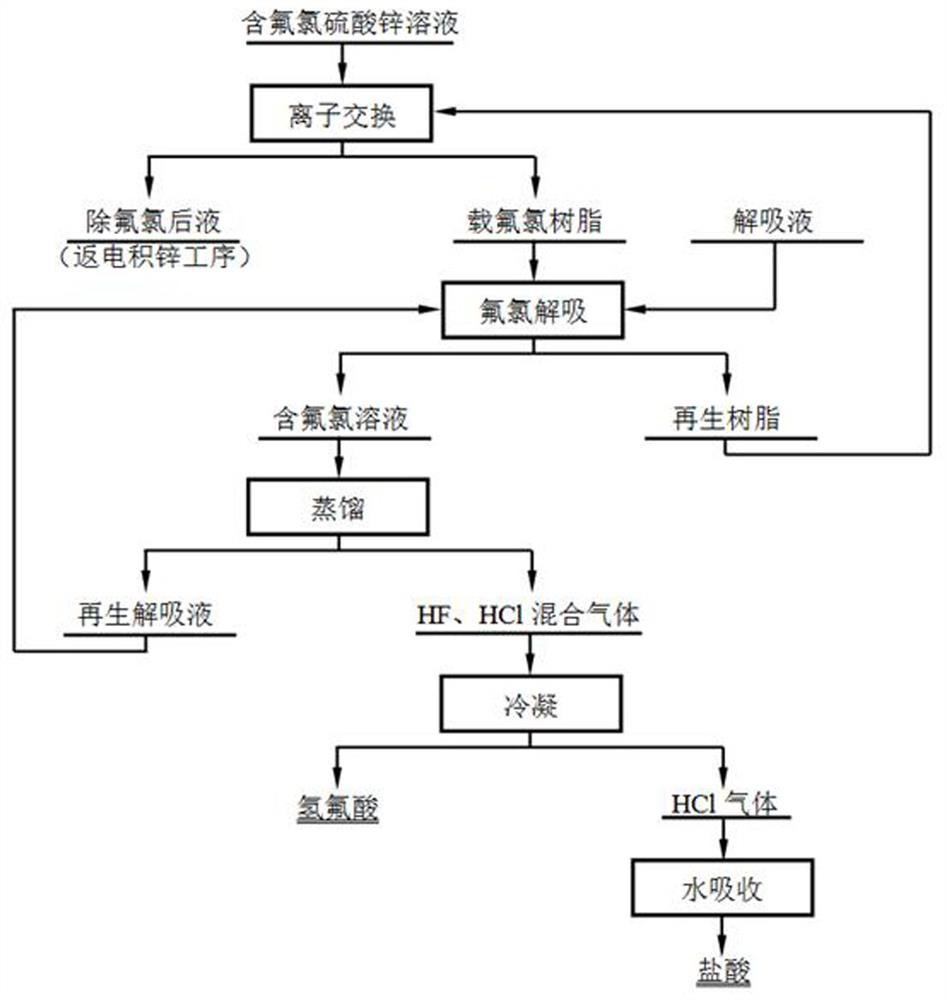

Method for removing and recovering fluorine and chlorine from zinc sulfate solution

ActiveCN112357950ARealize separate recyclingDisposal costs are highChlorine/hydrogen-chloride purificationZinc sulatesSulfate zincIon exchange

The invention discloses a method for removing and recovering fluorine and chlorine from a zinc sulfate solution, which comprises the steps of adsorption, resin regeneration, desorption solution regeneration and fluorine and chlorine recycling, and specifically comprises the following steps: sequentially passing a zinc sulfate solution containing fluorine and chlorine through an ion exchange columnfrom bottom to top to obtain fluorine and chlorine-loaded resin a, carrying out countercurrent desorption by using a sulfuric acid solution to obtain a desorbed solution c, distilling to obtain a regenerated desorption solution d and a mixed gas of HF and HCl, condensing to obtain a hydrofluoric acid product, and absorbing the residual HCl gas with water to obtain a hydrochloric acid product, thereby respectively recycling fluorine and chlorine. The method has the advantages of simple process, recycling of the desorption solution, solving of the problems of large ion exchange desorption solution use amount and large wastewater amount, realization of preparation of hydrofluoric acid and hydrochloric acid products from fluorine and chlorine impurities, high fluorine and chlorine removal efficiency, low production cost, greenness, environmental protection, no generation of three wastes in the process, easiness in connection with a zinc smelting system, and industrial production promotionand application values.

Owner:KUNMING METALLURGY INST +1

Method for recycling iron-containing zinc-containing sludge to prepare zinc hydroxide and dye-grade iron oxide yellow

InactiveCN106745192AEliminate secondary pollutionHigh purityIron compounds preparationZinc compounds preparationZinc hydroxideSludge

The invention relates to a method for recycling iron-containing zinc-containing sludge to prepare zinc hydroxide and dye-grade iron oxide yellow and belongs to the field of waste resourceful treatment. The method comprises the steps of adding hydrochloric acid into iron-containing zinc-containing sludge to adjusting a pH value, then adding steel scrap, stirring, extracting in an extraction agent, classifying and deoiling; performing back extraction on zinc-containing load organic phase to prepare zinc hydroxide; adding alkaline substance into ferrous chloride solution with the zinc content smaller than or equal to 1g / L to adjust a pH value as 3.0 to 7.5 in 12 to 32 DEG C, introducing oxidizing gas, performing low-temperature oxidization with oxidization time of 60 to 1200min, warming to 50 to 90 DEG C, adding alkaline substance to adjust a pH value to be 2.8 to 3.6, introducing oxidizing gas, oxidizing for 30 to 115h, guaranteeing the pH value of liquid to be 2.8 to 3.6 in an oxidizing process, finishing oxidization, filtering and drying to obtain the dye-grade iron oxide yellow. The method is a recycling technology of iron-containing zinc-containing sludge in a hot galvanizing factory and has the advantages of small equipment invest, low energy consumption and high purity of a prepared product.

Owner:NORTHEASTERN UNIV

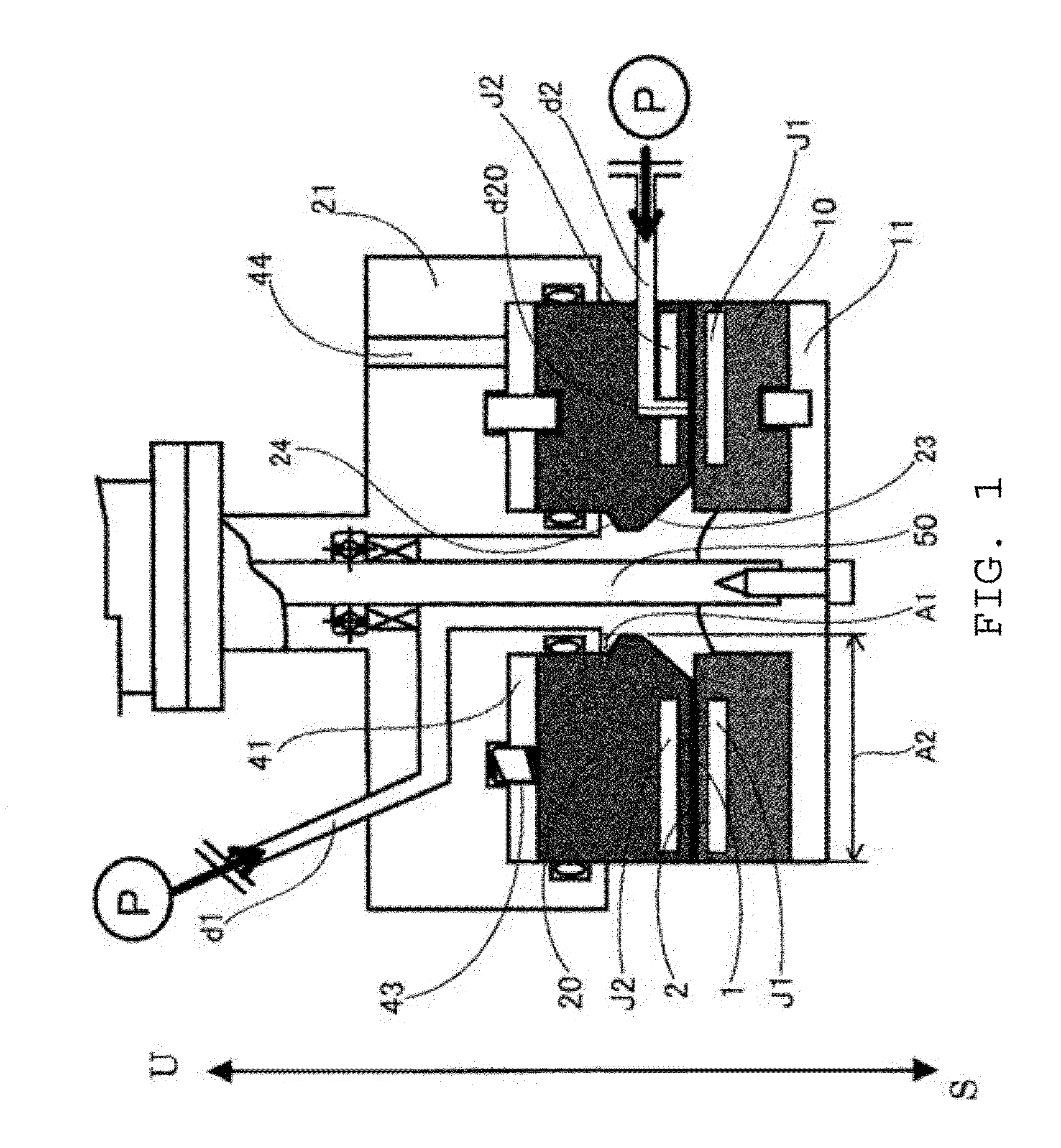

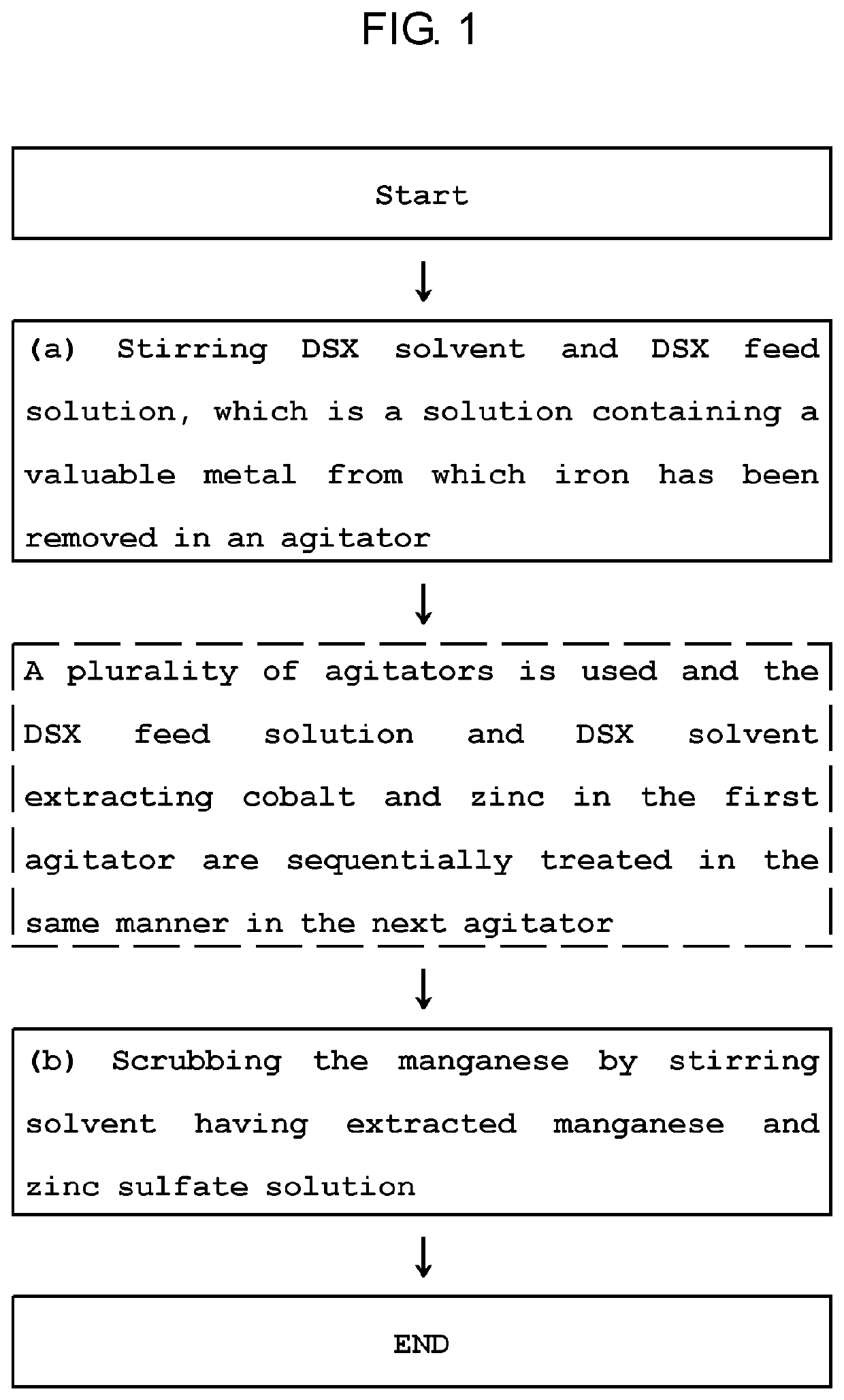

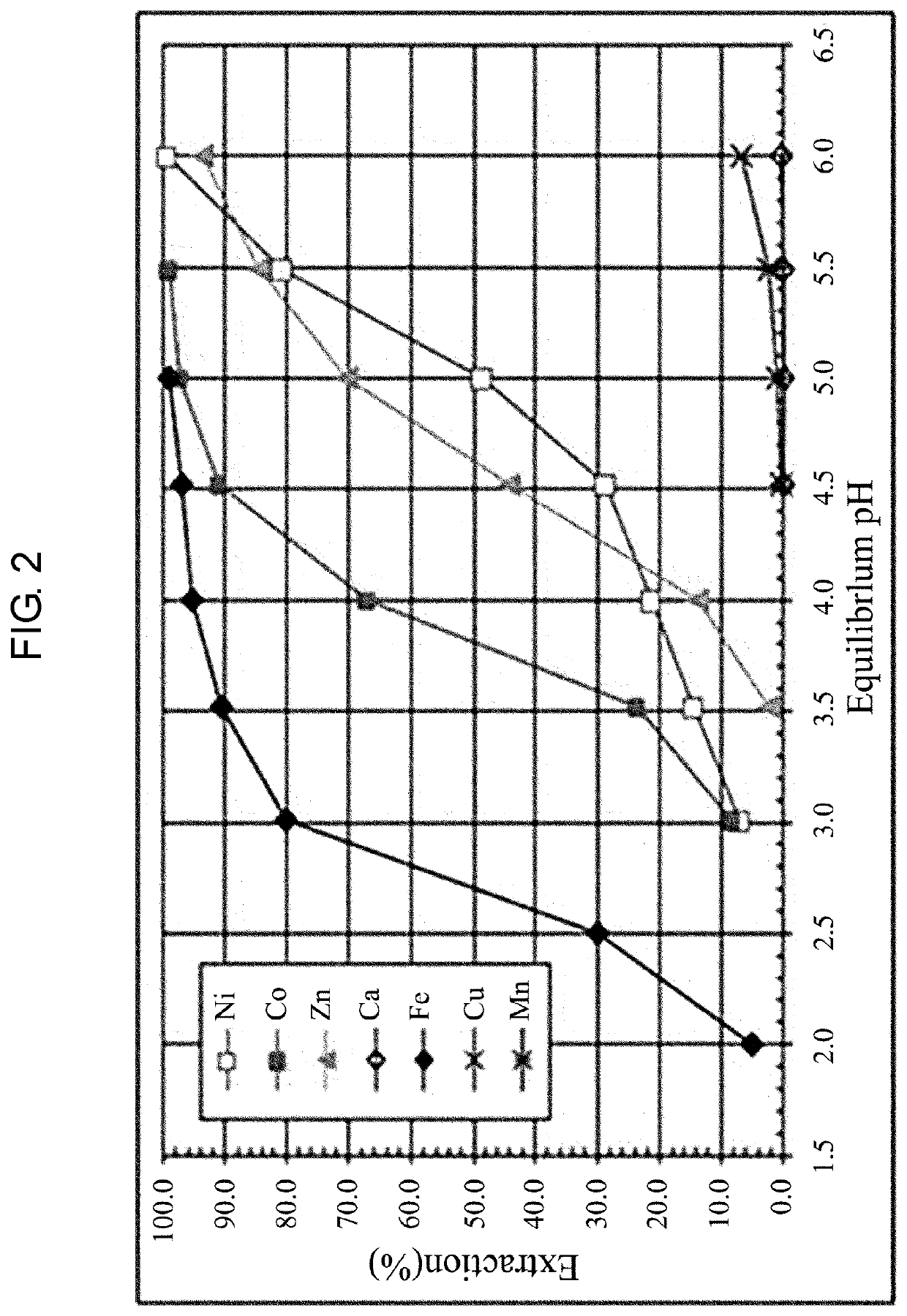

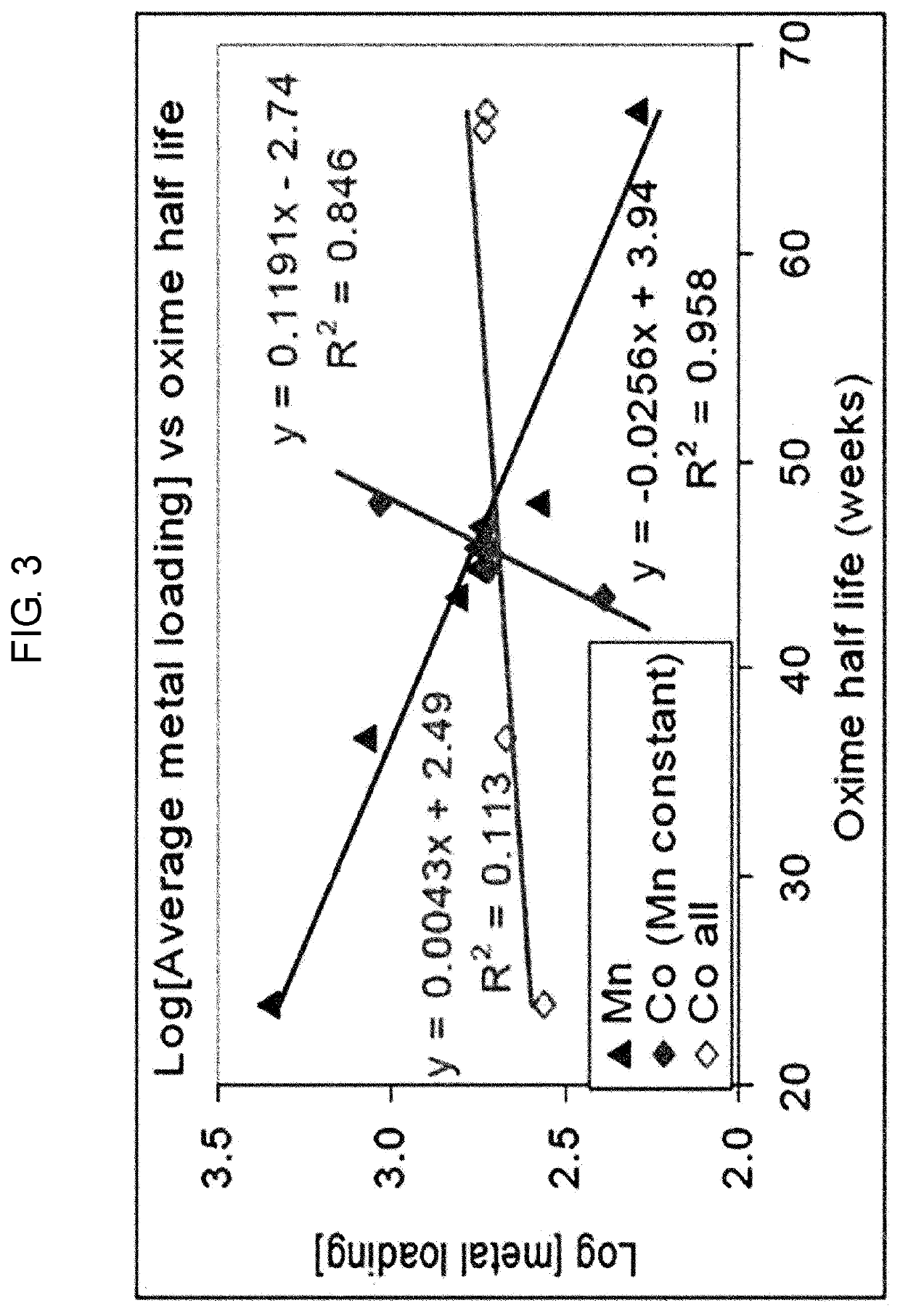

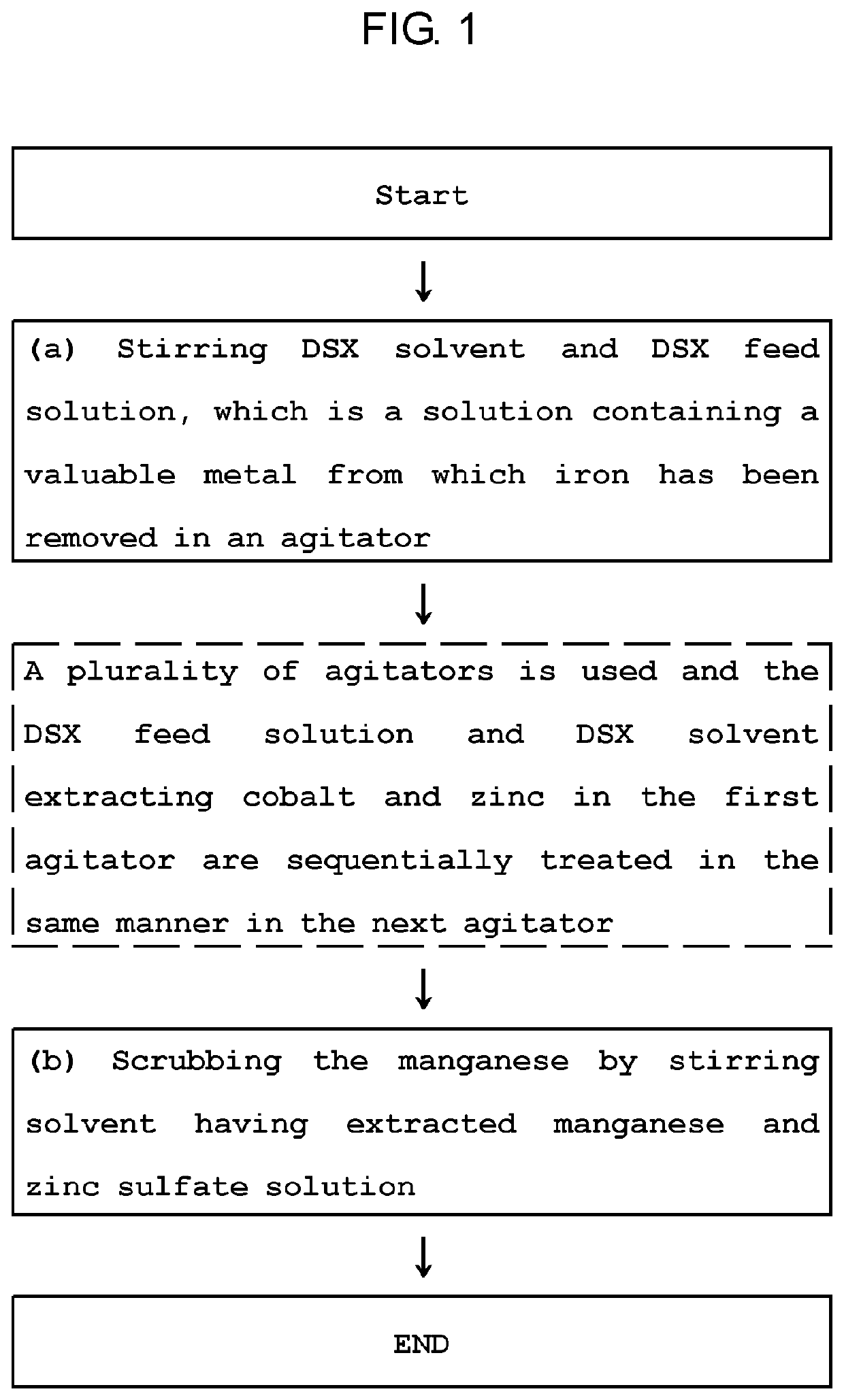

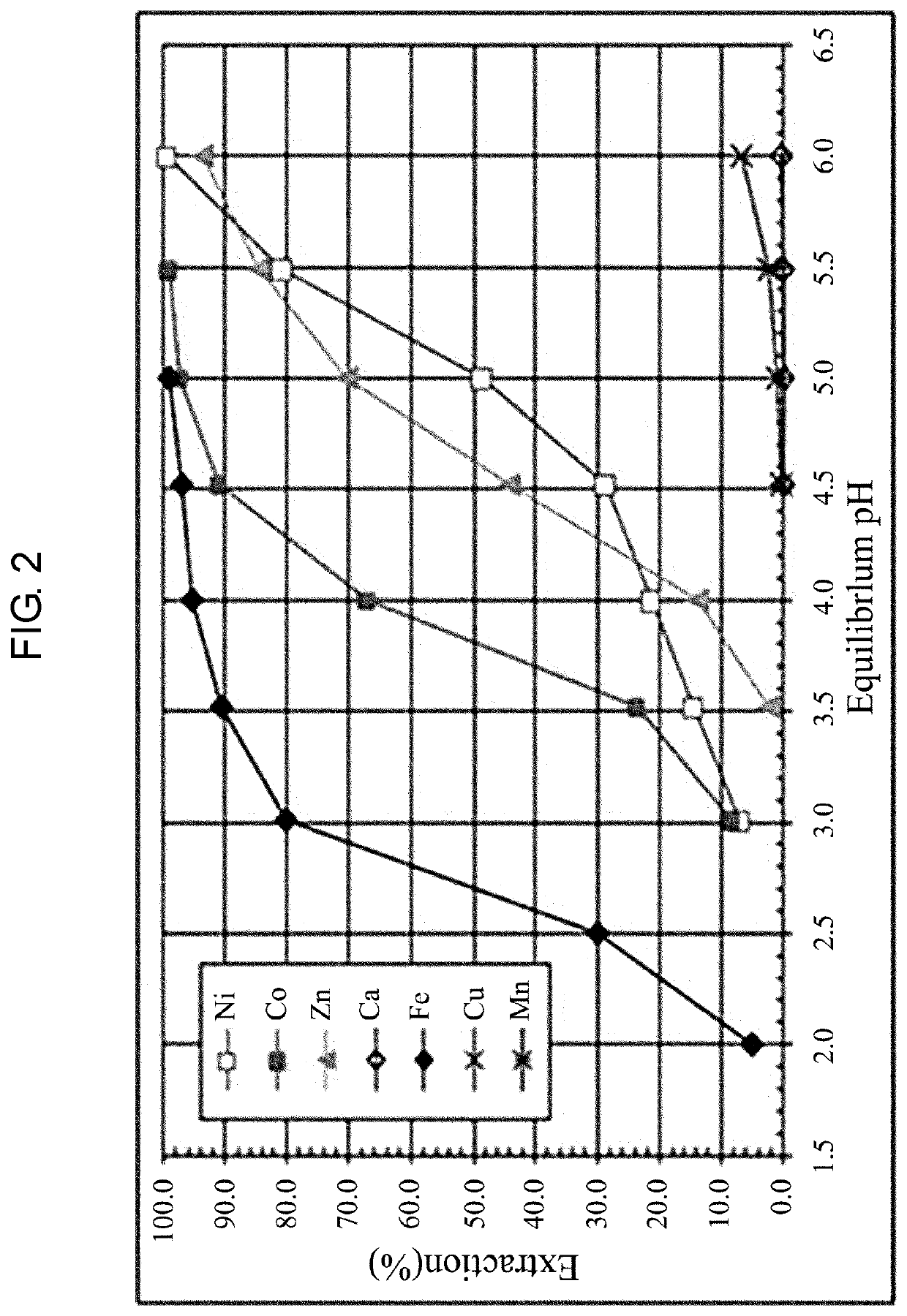

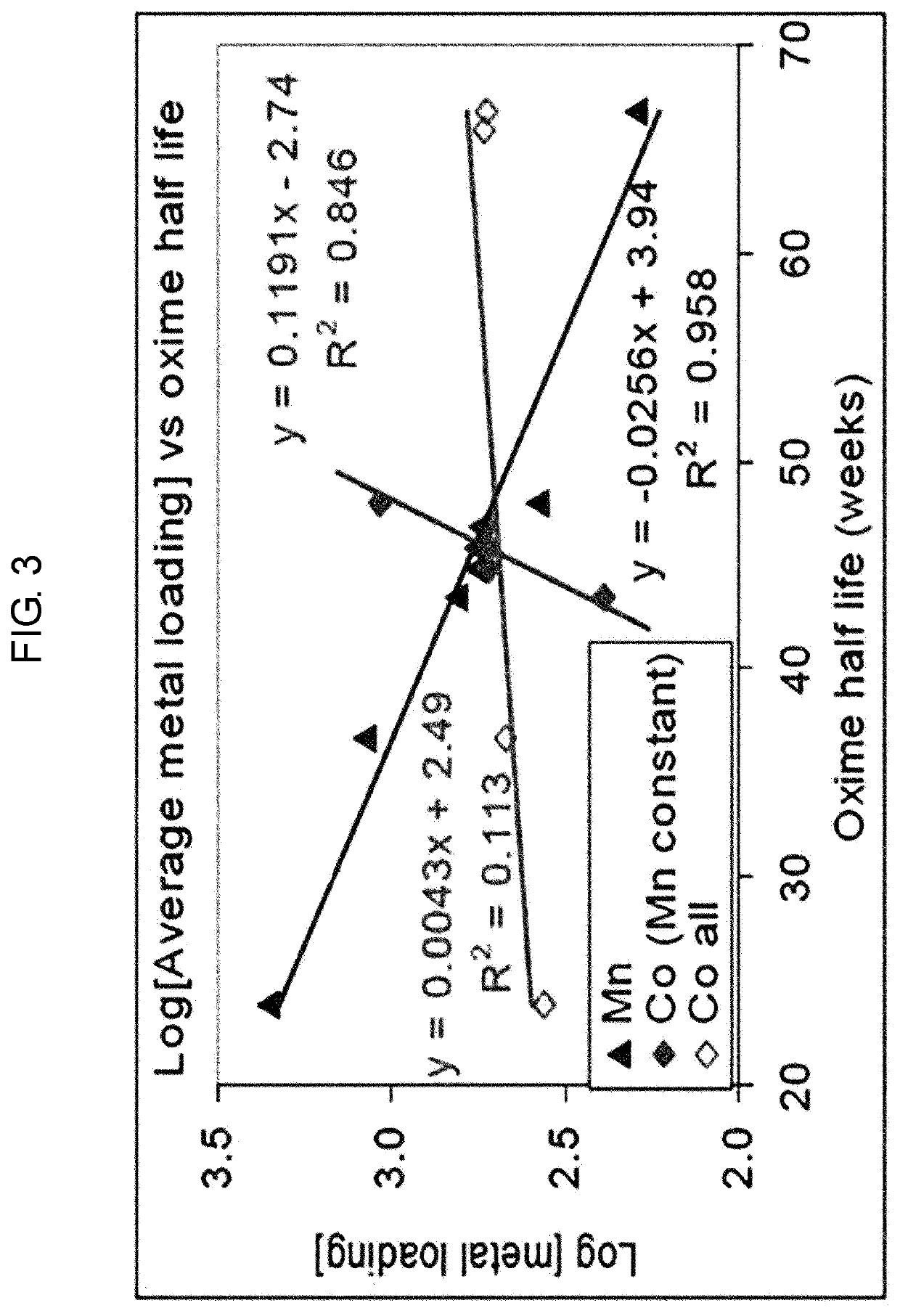

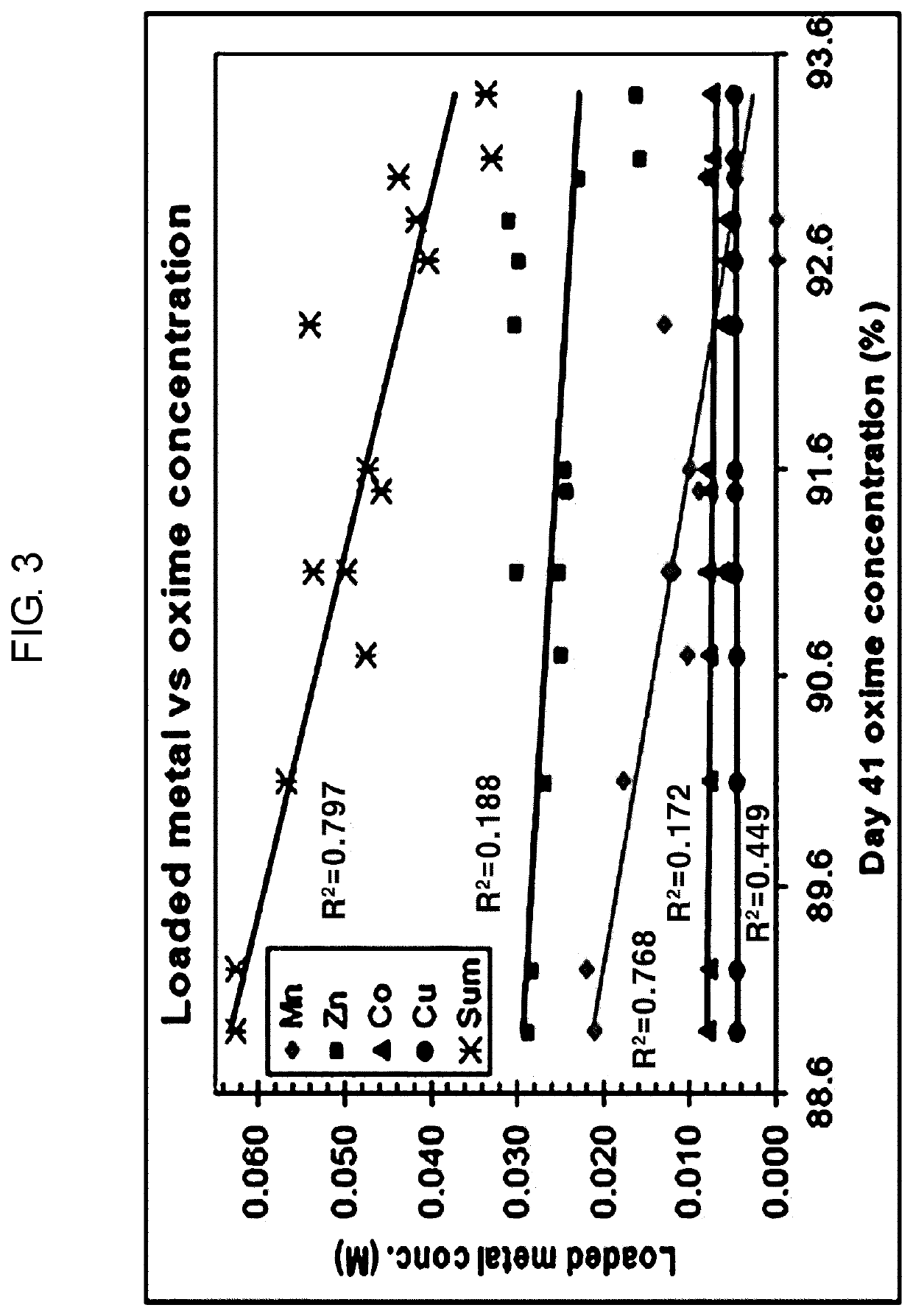

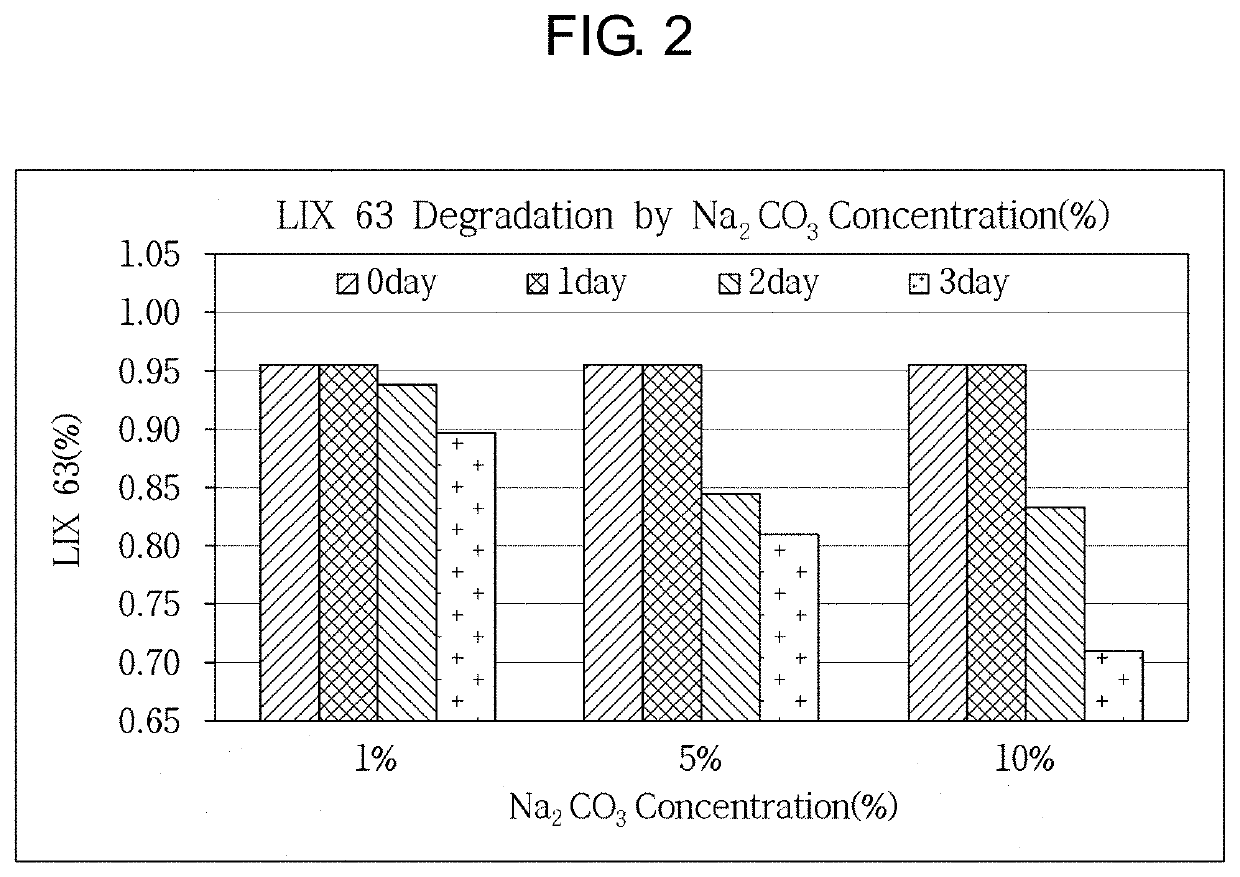

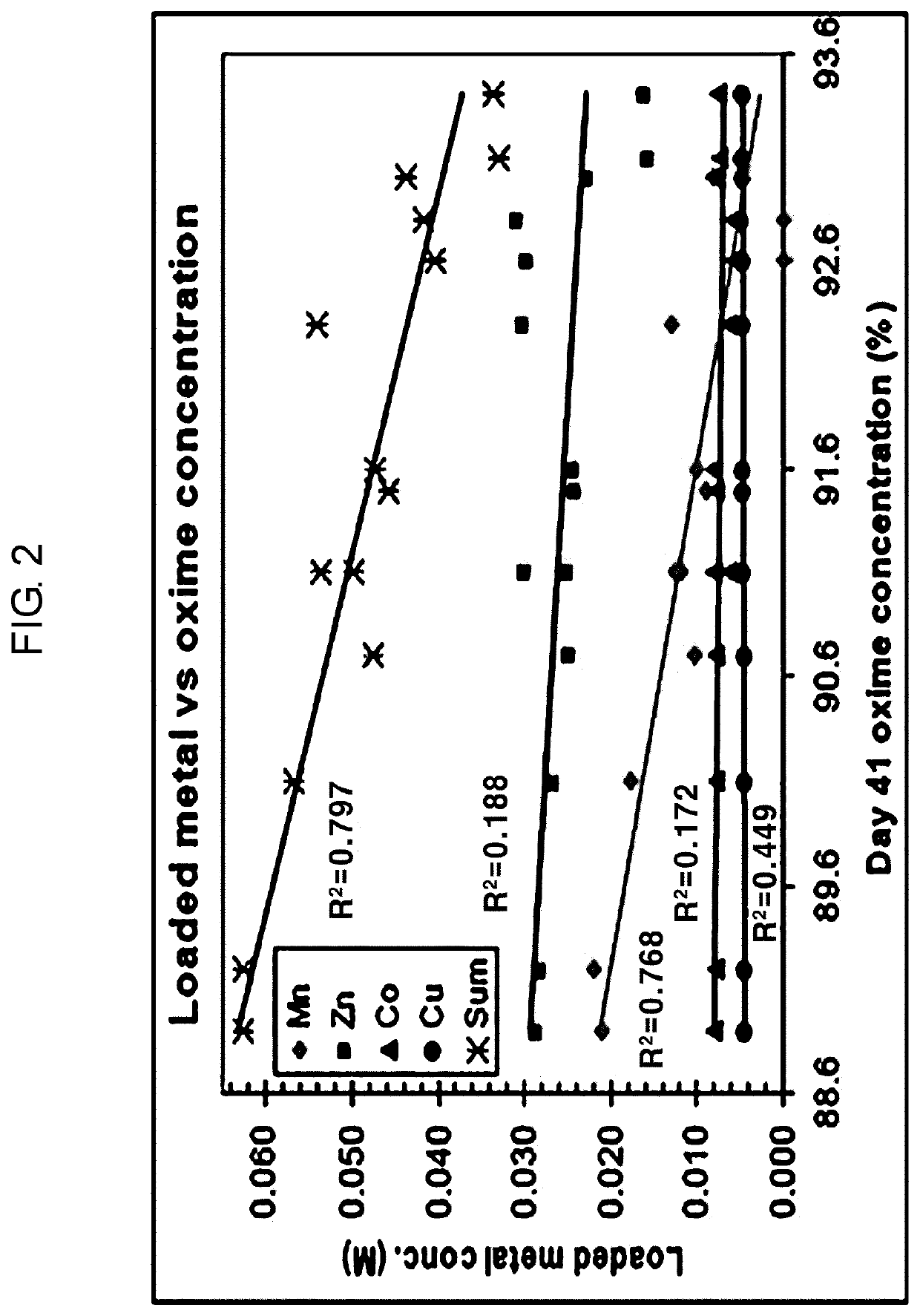

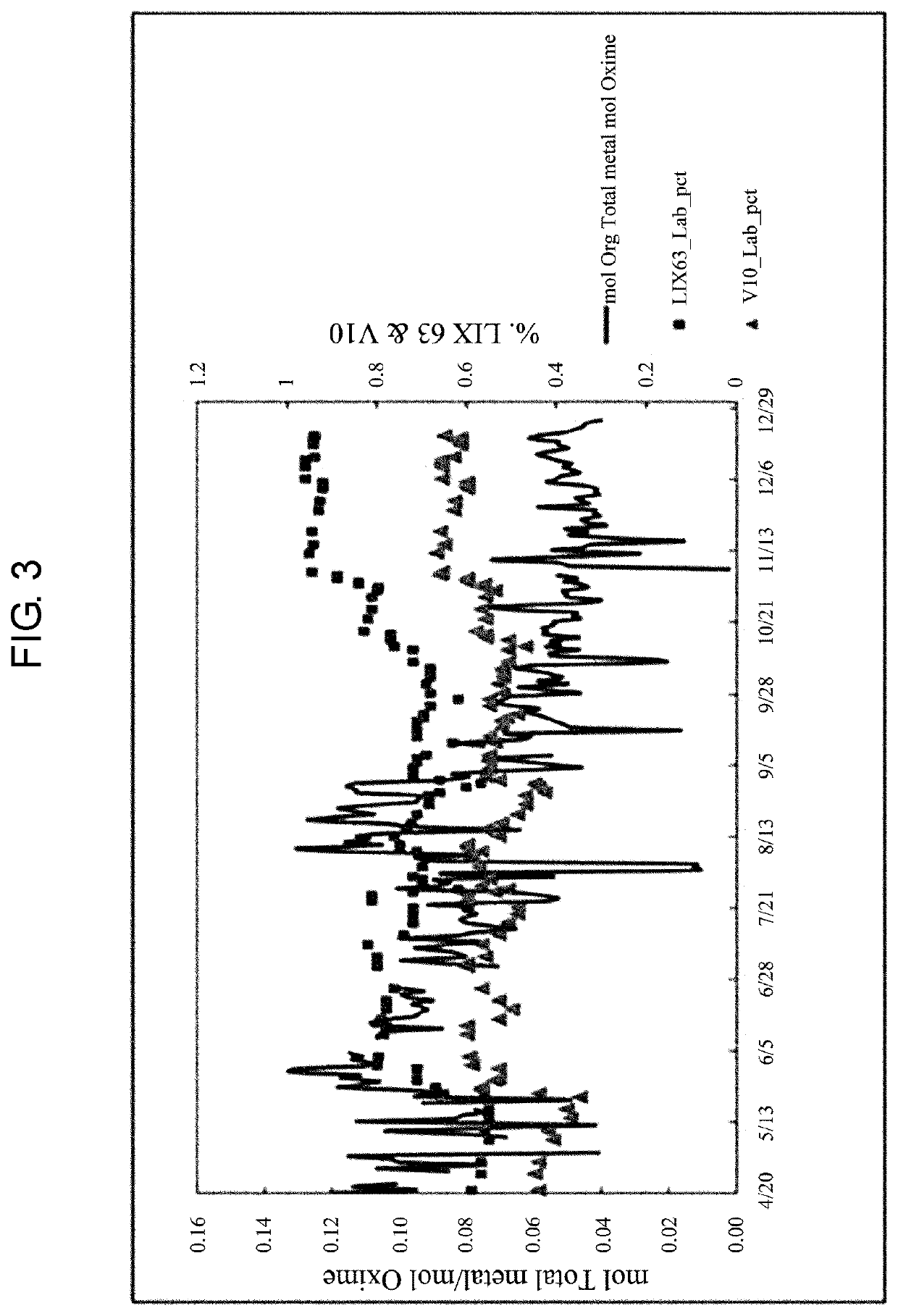

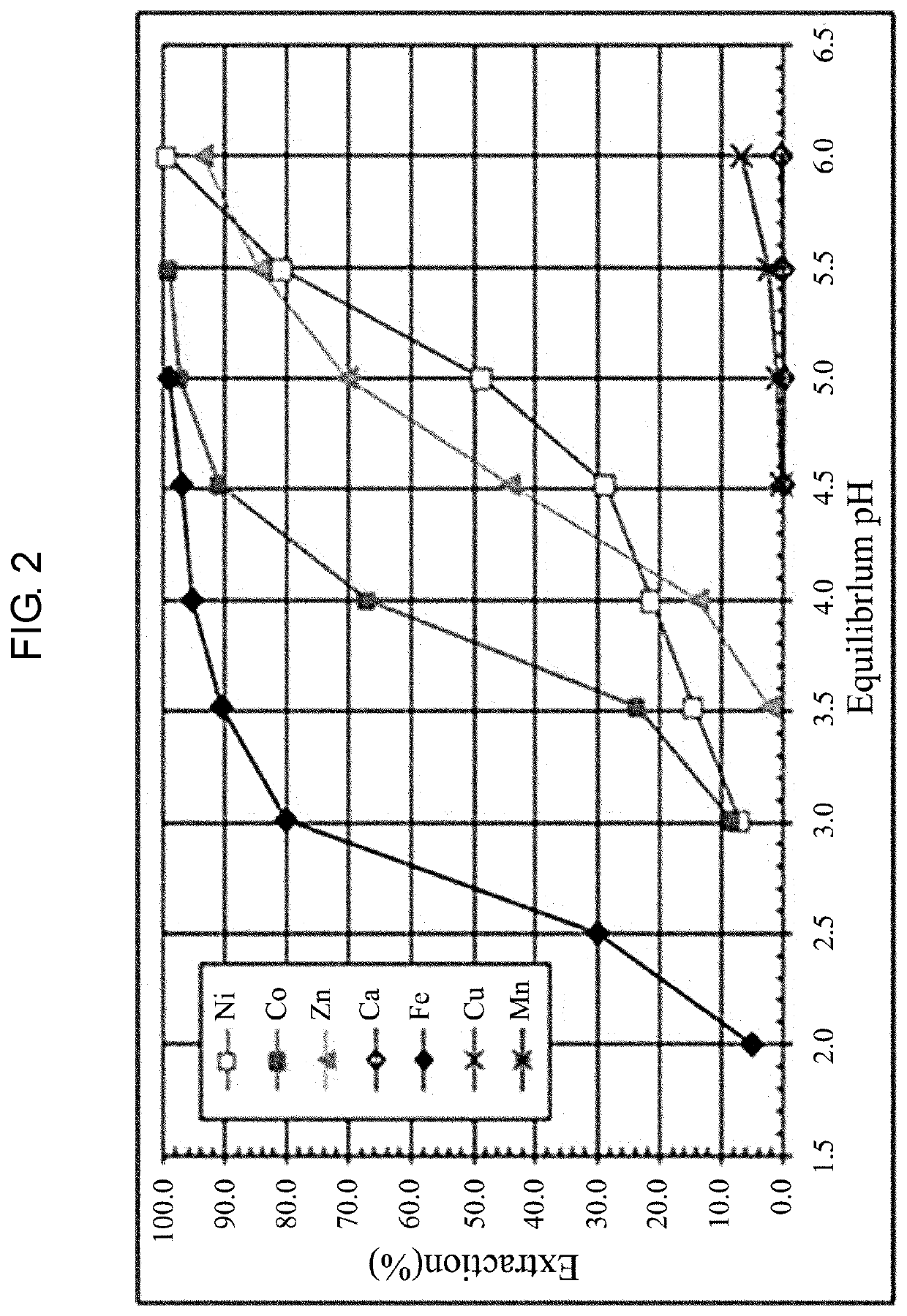

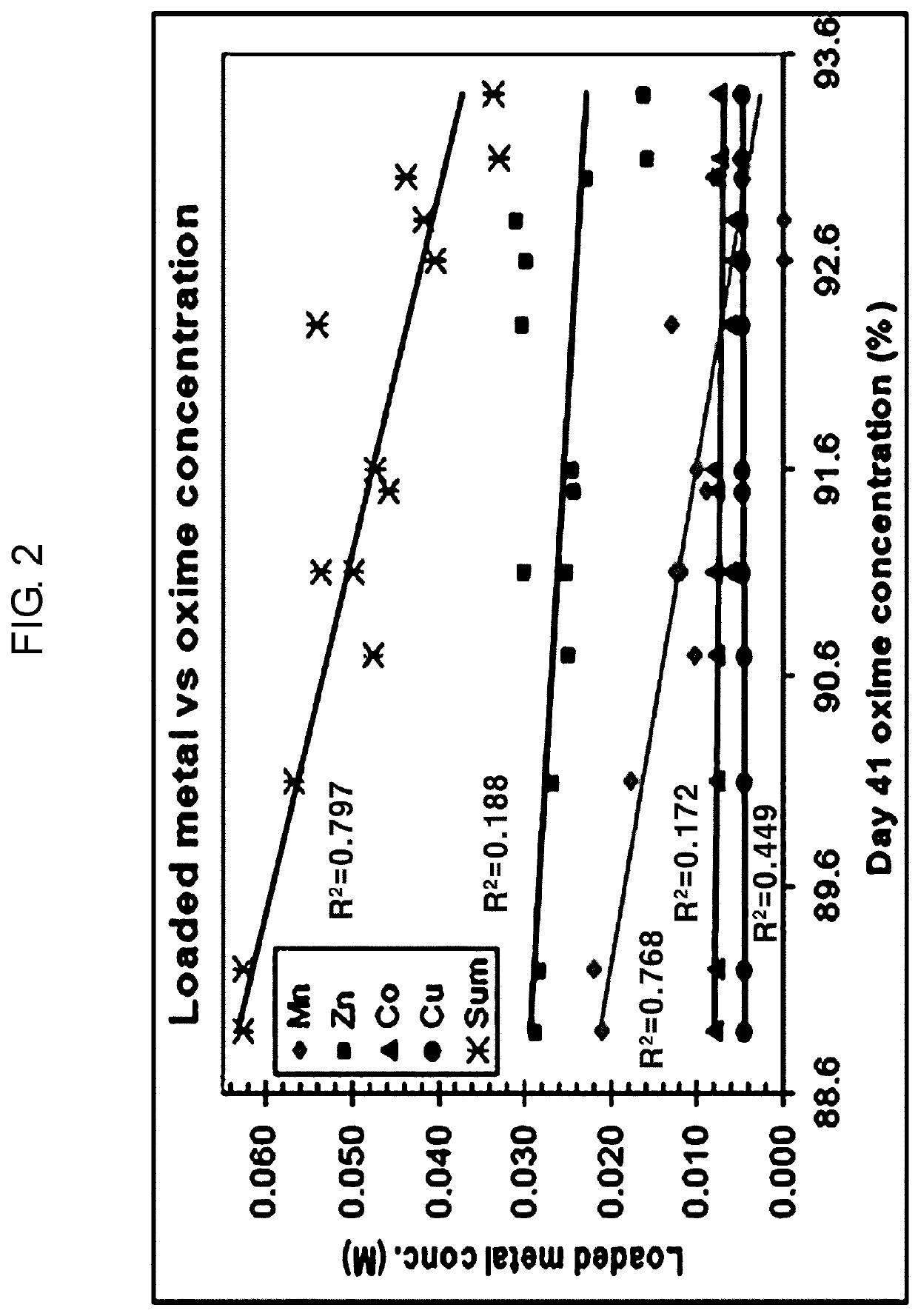

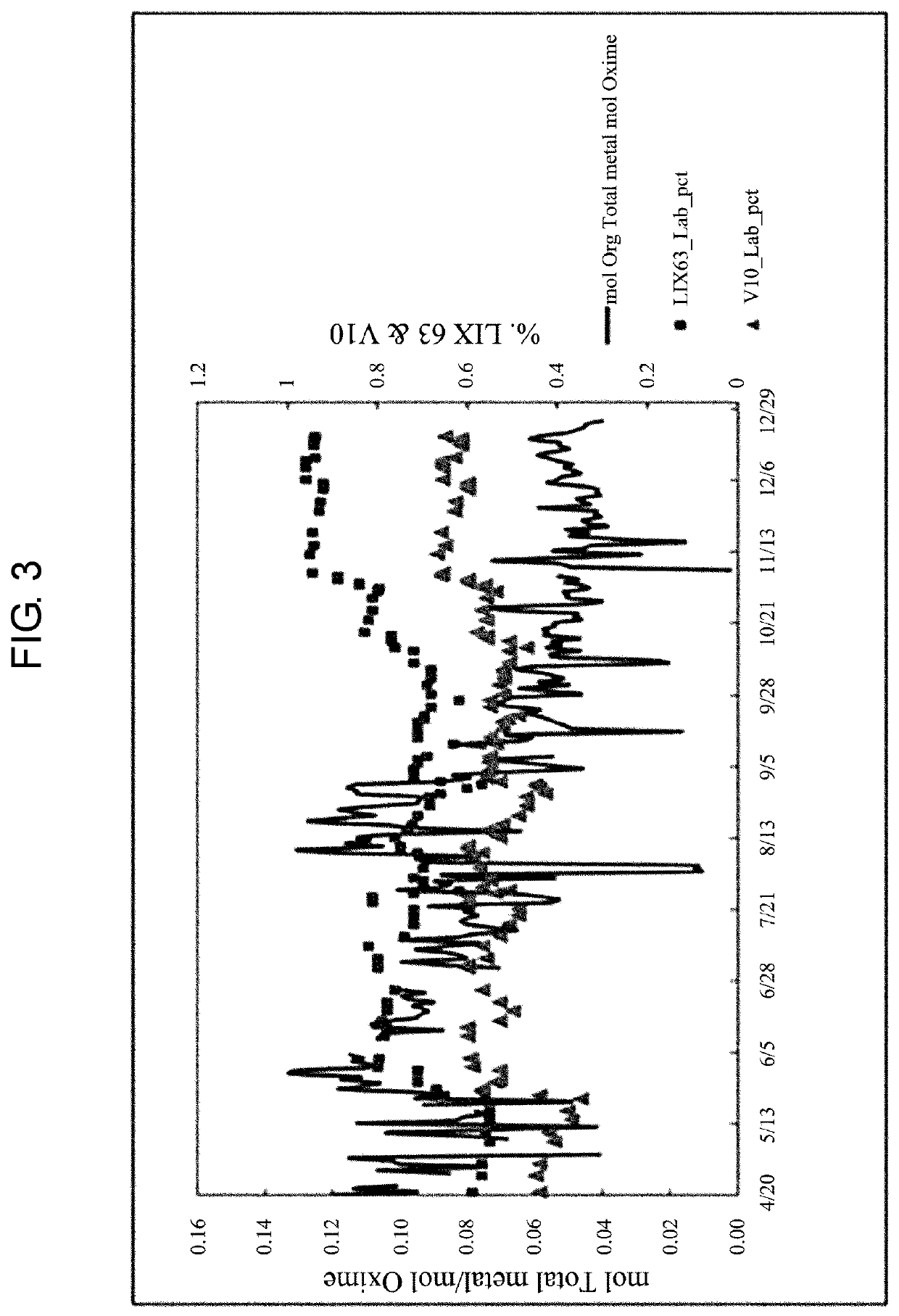

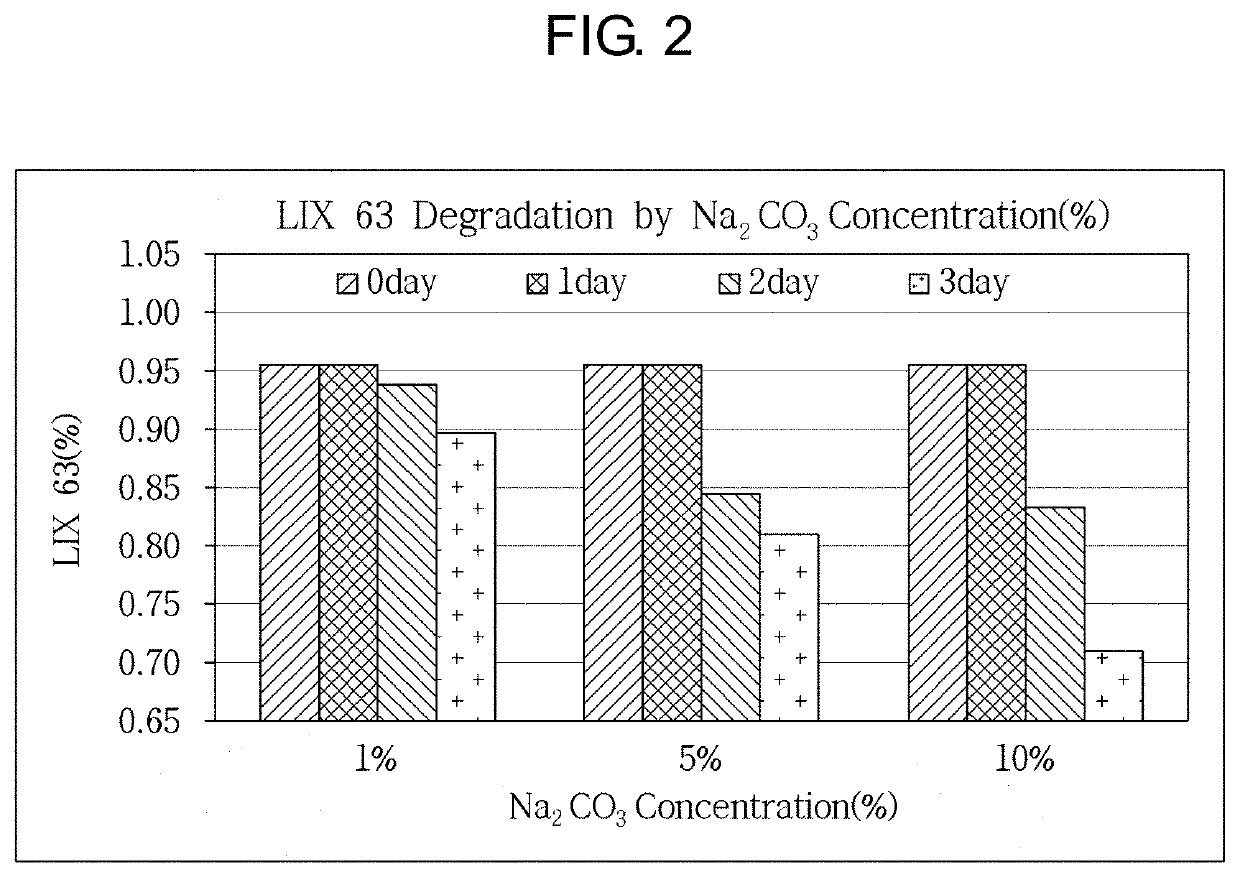

Method for inhibiting extractant degradation of dsx process through manganese extraction control

ActiveUS20210024366A1Minimizing extractionPrevent degradationZinc compounds preparationProcess efficiency improvementManganeseSolvent

Provided is a method for inhibiting extractant degradation in the DSX process through the manganese extraction control, the method comprising: (a) stirring DSX solvent and DSX feed solution, which is a solution containing a valuable metal from which iron has been removed in an agitator, in which soda ash (Na2CO3) is further added to maintain a constant pH; and (b) scrubbing the manganese from the DSX solvent, extracted in step (a).

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

Method for inhibiting extractant degradation of DSX process through manganese extraction control

ActiveUS11203531B2Minimizing extractionPrevent degradationZinc compounds preparationProcess efficiency improvementManganeseSolvent

Provided is a method for inhibiting extractant degradation in the DSX process through the manganese extraction control, the method comprising: (a) stirring DSX solvent and DSX feed solution, which is a solution containing a valuable metal from which iron has been removed in an agitator, in which soda ash (Na2CO3) is further added to maintain a constant pH; and (b) scrubbing the manganese from the DSX solvent, extracted in step (a).

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

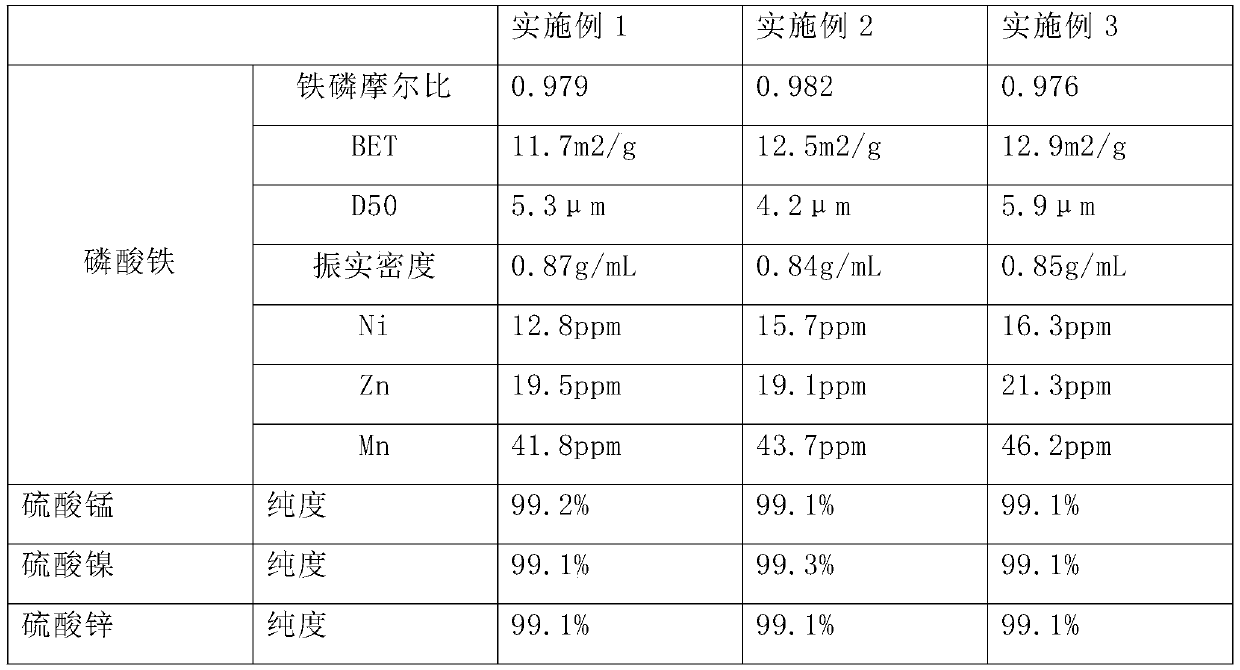

Resourceful treatment method of phosphating waste liquid

InactiveCN111392703AAchieve regenerationRealize resource utilizationZinc sulatesZinc compounds preparationO-Phosphoric AcidDistillation

The invention discloses a resourceful treatment method of phosphating waste liquid. The method is as follows: adding phosphoric acid into the phosphating waste liquid, filtering after reaction, addinghydrogen peroxide into filtrate, and continuously reacting; putting the reacted solution into a reaction kettle for reduced pressure distillation, and stirring for reaction to obtain slurry; filtering the slurry to obtain a first filtrate and a first filter residue, adding sodium hydroxide into the first filtrate, reacting, precipitating and filtering to obtain a second filtrate and a second filter residue, adding sulfuric acid into the second filter residue, dissolving to obtain a dissolved solution, adding ammonia water into the dissolved solution to adjust the pH value of the solution, stirring, reacting, and filtering to obtain a third filtrate and a third filter residue; adding pure water into the first filter residue for slurrying and washing, and drying, sintering, smashing, screening and deironing the washed filter residue to obtain battery-grade iron phosphate; and returning the second filtrate to prepare a phosphating solution. Resource utilization of nitrate radicals, zinc,iron and the like can be achieved, meanwhile, the wastewater can be returned to be used for preparing the phosphating solution, the treatment cost is low, and the environmental protection property isgood.

Owner:蒋央芳

Preparation method of high-purity homogeneous zinc sulfate heptahydrate

ActiveCN112624179AAvoid reunionEasy to separateZinc sulatesZinc compounds preparationSulfate zincPhysical chemistry

The invention discloses a preparation method of high-purity homogeneous zinc sulfate heptahydrate, wherein the preparation method comprises the following steps: S1, preparing a zinc salt aqueous solution, and preparing a composite extractant; and carrying out mixed extraction, standing and phase splitting on the two solutions, and taking an organic phase to obtain a microemulsion A containing Zn<2+>; S2, carrying out mixed extraction on a sulfuric acid solution and a composite extraction agent, standing, carrying out phase splitting, and taking an organic phase to obtain a microemulsion B containing SO4<2->; and S3, mixing the microemulsion A containing Zn<2+> and the microemulsion B containing SO4<2->, stirring, reacting to generate a white precipitate, carrying out solid-liquid separation to obtain a precipitate which is high-purity homogeneous zinc sulfate heptahydrate, carrying out acid washing and water washing purification on the obtained organic phase, and returning to recycle. The preparation method of zinc sulfate heptahydrate is low in cost, simple to operate and easy for batch preparation, and the obtained product is high in purity and uniform in particle size distribution, and can meet the use requirements of special industrial fields.

Owner:浙江爱科新材料有限公司

Method for producing substances to be separated having controlled amounts of dopant element

ActiveUS9346685B2Weaken energyLow costPigmenting treatmentZinc compounds preparationDopantSolubility

A method is provided for producing separated substances, particularly metal compounds, the dopant element amounts of which have been controlled by the use of an apparatus that processes fluid between the processing surfaces of a processing member that can be made to approach / separate and which rotate relative to each other. The substance to be separated is separated by mixing a raw material solution, wherein the substance to be separated is solubilized in a solvent, with the solvent for separation and with the dopant element or dopant element-containing substance solubilized in at least one solvent selected from the solvent of said raw material solution, said solvent for separation or a solvent other than that of said raw material solution or said solution for separation. Separated substances with controlled dopant element amounts are obtained by controlling the solubility of the dopant element or dopant element-containing substance in the solvent for separation.

Owner:M TECH CO LTD

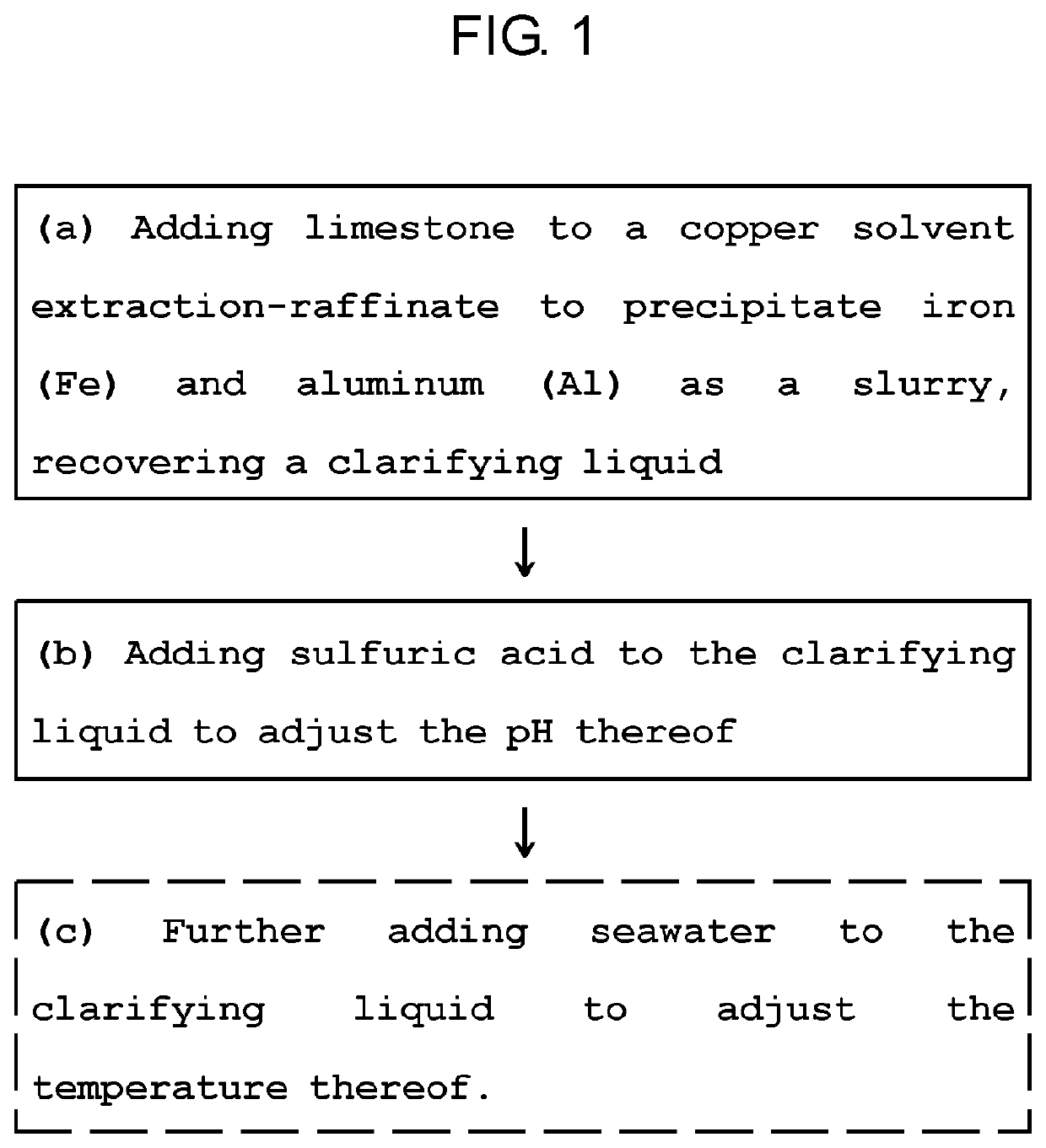

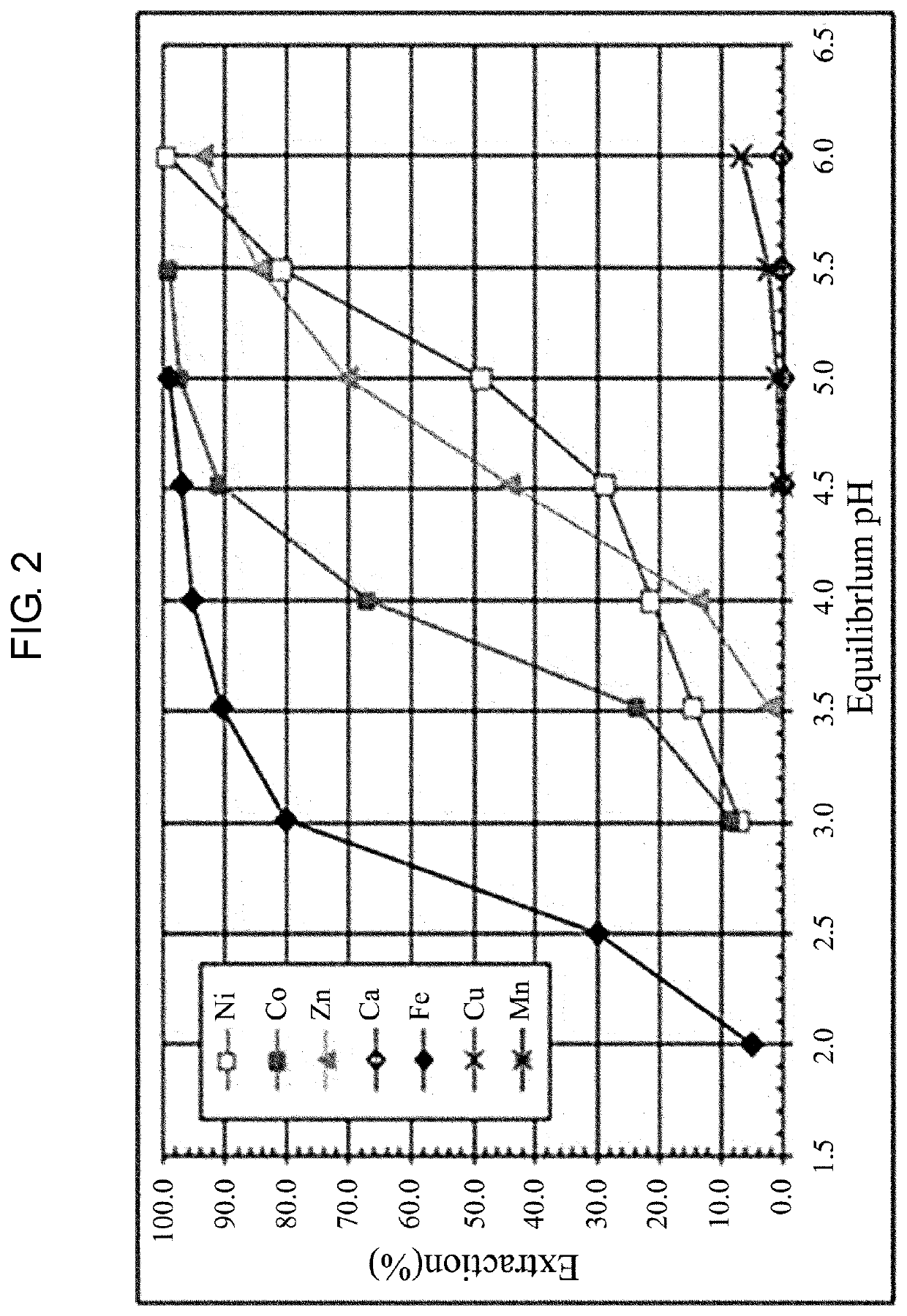

Method for inhibiting extractant degradation of dsx process through metal extraction control

ActiveUS20210024367A1Minimizing extractionPrevent degradationIron compounds preparationZinc compounds preparationPhysical chemistrySlurry

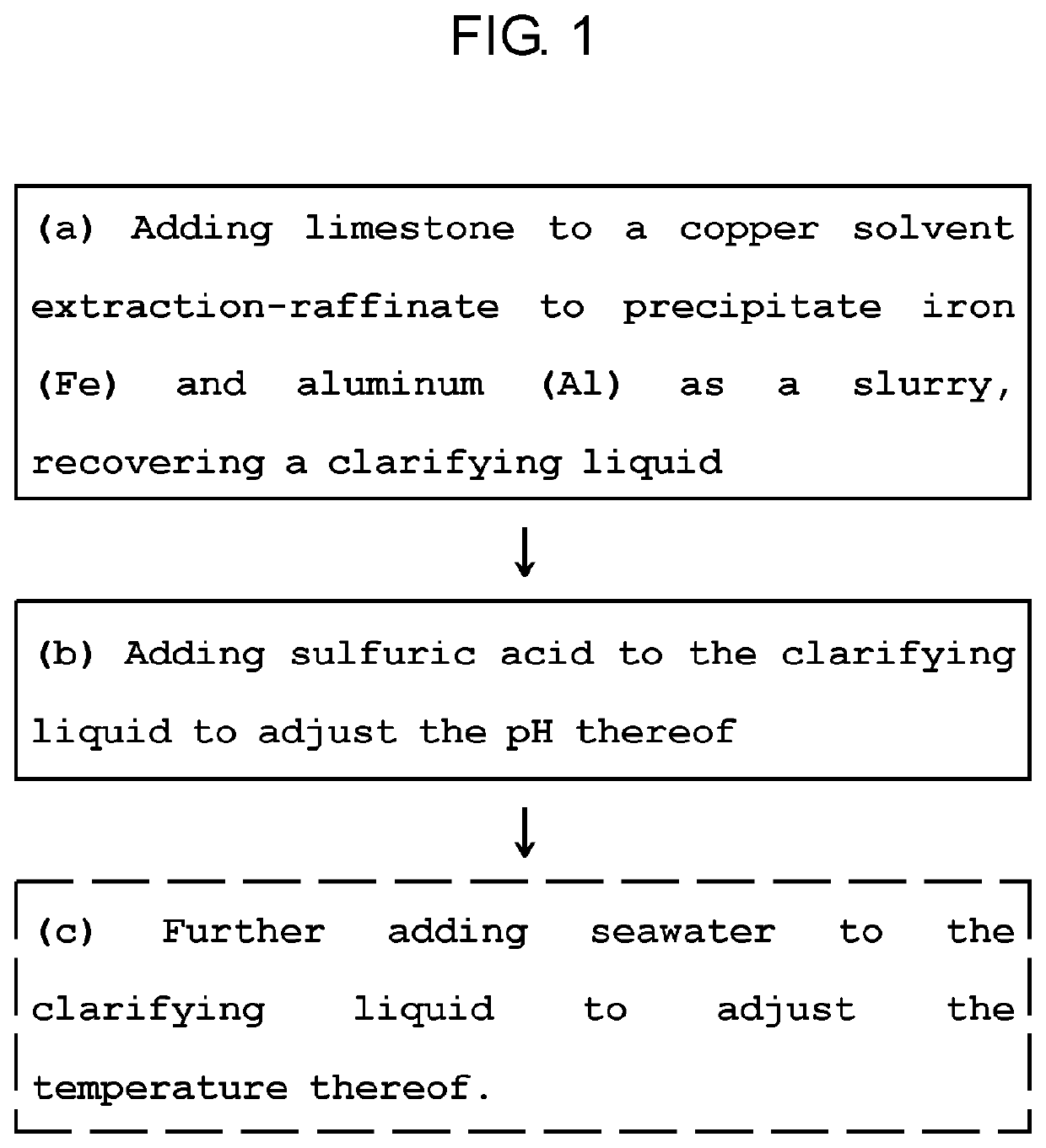

Provided is a method for inhibiting extractant degradation in the DSX process through the metal extraction control, the method comprising steps of: (a) adding limestone to a copper solvent extraction-raffinate to precipitate iron (Fe) and aluminum (Al) as a slurry, recovering a clarifying liquid; and (b) adding sulfuric acid to the recovered clarifying liquid to adjust the pH thereof.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

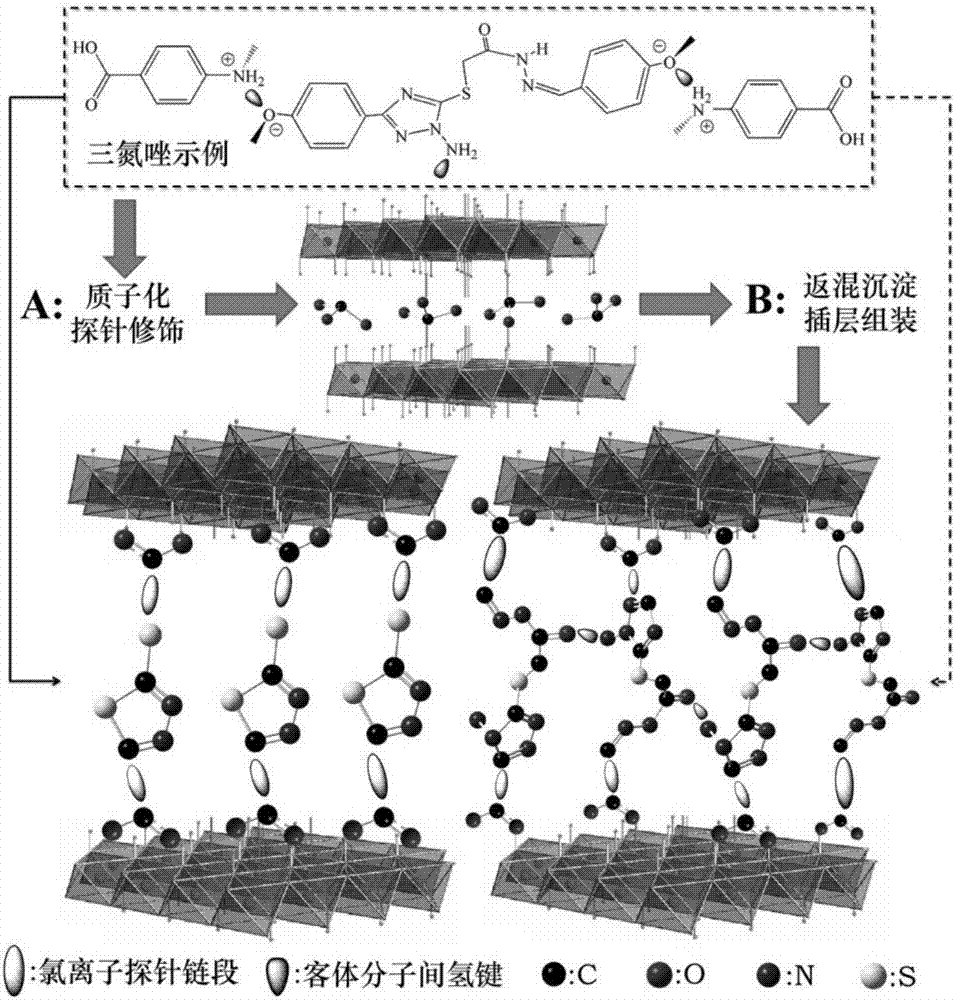

Hydrotalcite intercalation chloride ion probe modified s-triazole cyclic triazole containing corrosion inhibitor compound and application thereof

InactiveCN107973334AAvoid corrosionWide variety of sourcesZinc compounds preparationPhysical chemistryHydrotalcite

The invention relates to a corrosion inhibitor, and particularly speaking, discloses a hydrotalcite intercalation chloride ion probe modified s-triazole cyclic triazole containing corrosion inhibitorcompound and application thereof. Through chloride ion probe modification and intercalation assembly, a chloride ion trigger switch capable of regulating and controlling the release of an s-triazole cyclic triazole containing corrosion inhibitor is embedded between layers of zinc-aluminum hydrotalcite, so as to form the compound. The mass production can be realized by adopting the corrosion inhibitor compound provided by the invention; the release in response to a corrosive environment and the repair of already rusted carbon steel can be achieved; moreover, a long-time protection effect can beactualized; the corrosion prevention can be effectively carried out on carbon steel, and the corrosion inhibitor compound has obvious application value and a wide market prospect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

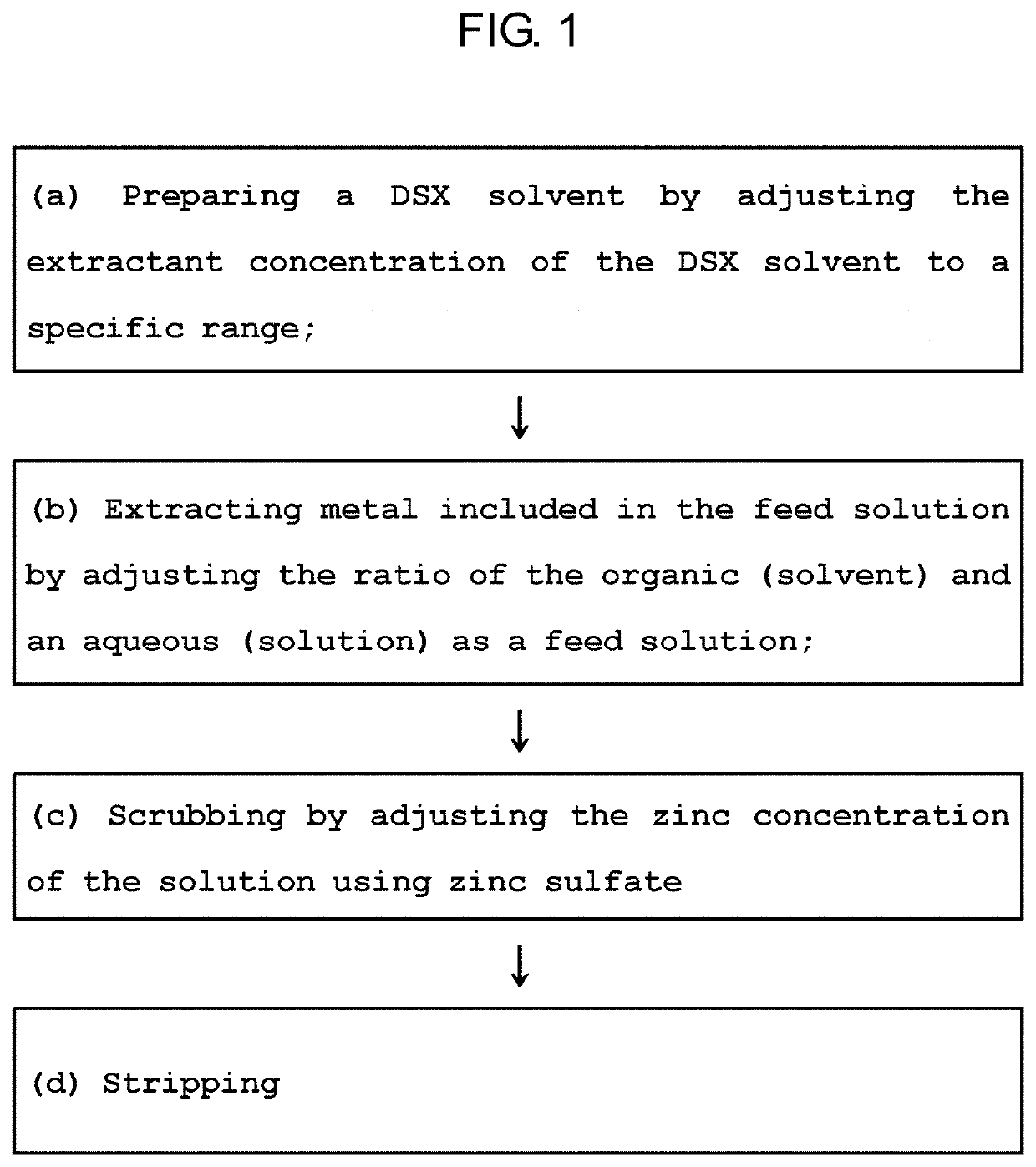

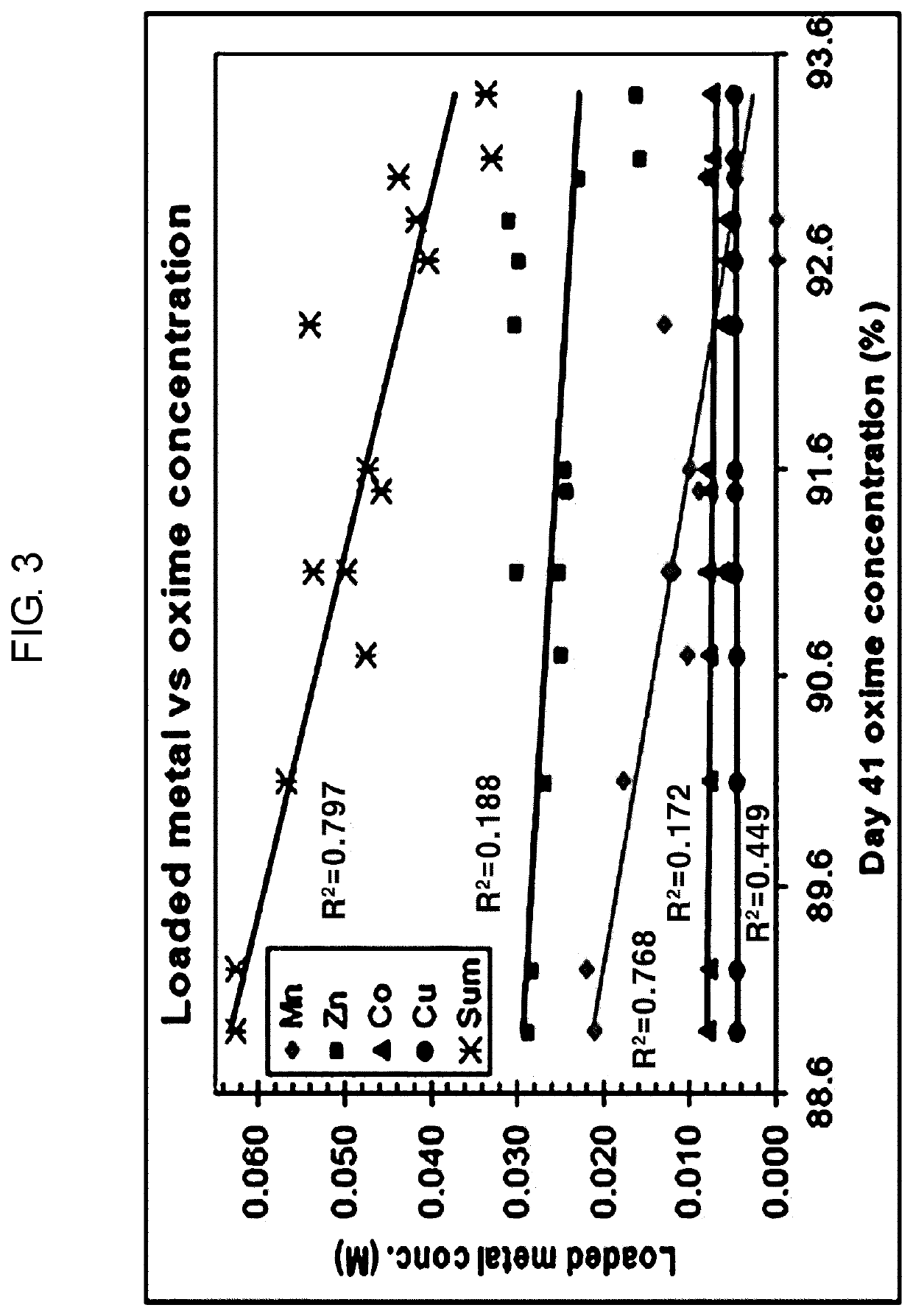

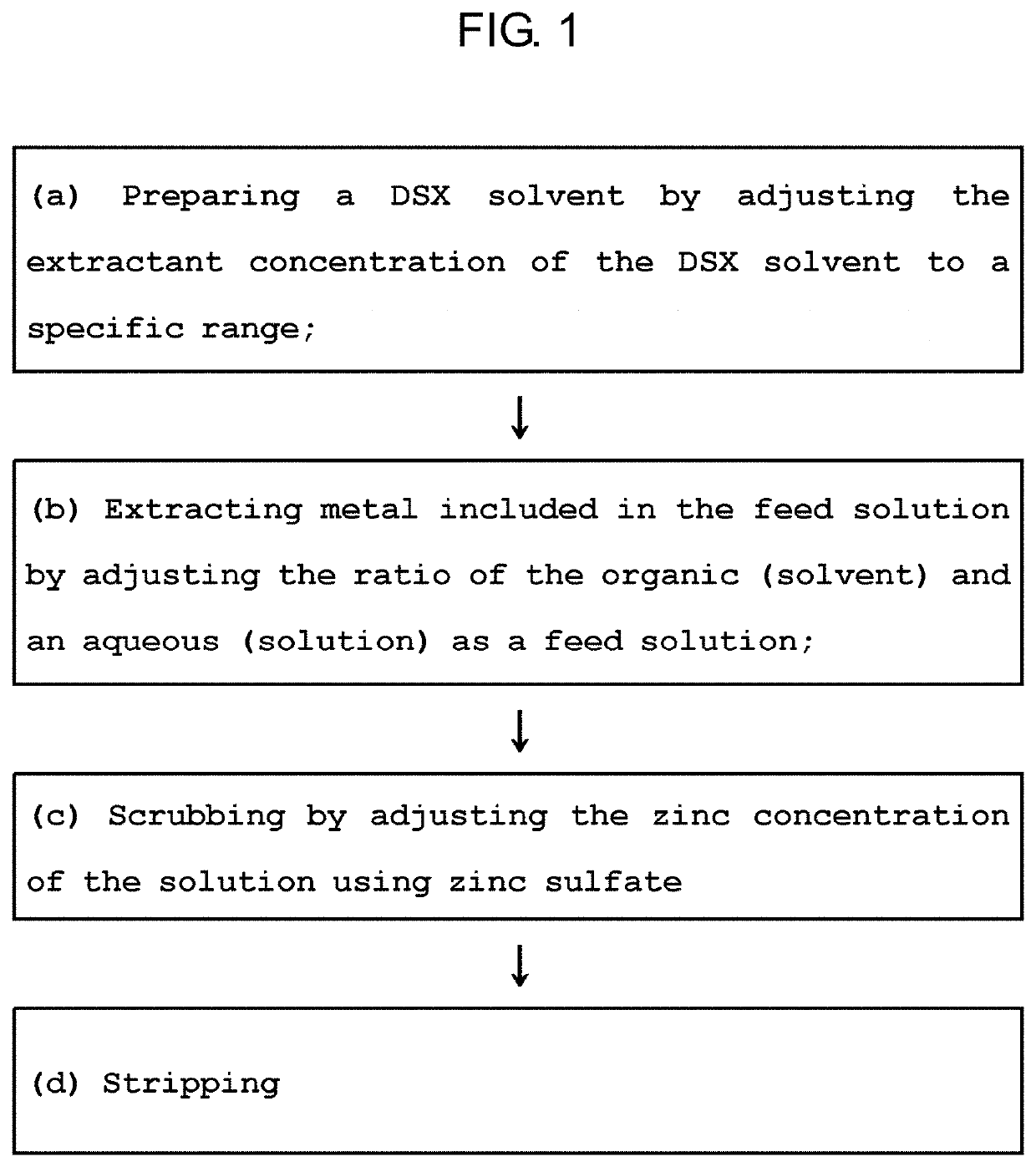

Method of inhibiting extractant degradation by controlling extractive capacity and preventing direct degradation

ActiveUS20210024369A1Inhibits extractant degradationImprove extraction efficiencyZinc compounds preparationProcess efficiency improvementSulfate zincSolvent

Provided is a method for inhibiting extractant degradation comprising preparing step, extracting step and scrubbing step, the method including: (a) the preparing step of a DSX solvent by adjusting the extractant concentration of the DSX solvent to a specific range; (b) the extracting step of metal included in the feed solution by adjusting the ratio of the organic (solvent) and an aqueous (solution) as a feed solution; (c) the scrubbing step of adjusting the zinc concentration of the solution using zinc sulfate; and (d) stripping step.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

Decontamination of radioactive metals

The present invention relates to a method for the volumetric decontamination of radioactive metals. The method includes the step of precipitating out radioactive gamma and beta emitting nucleotides and then recovering non-radioactive metal compounds.

Owner:RETRIEV TECH

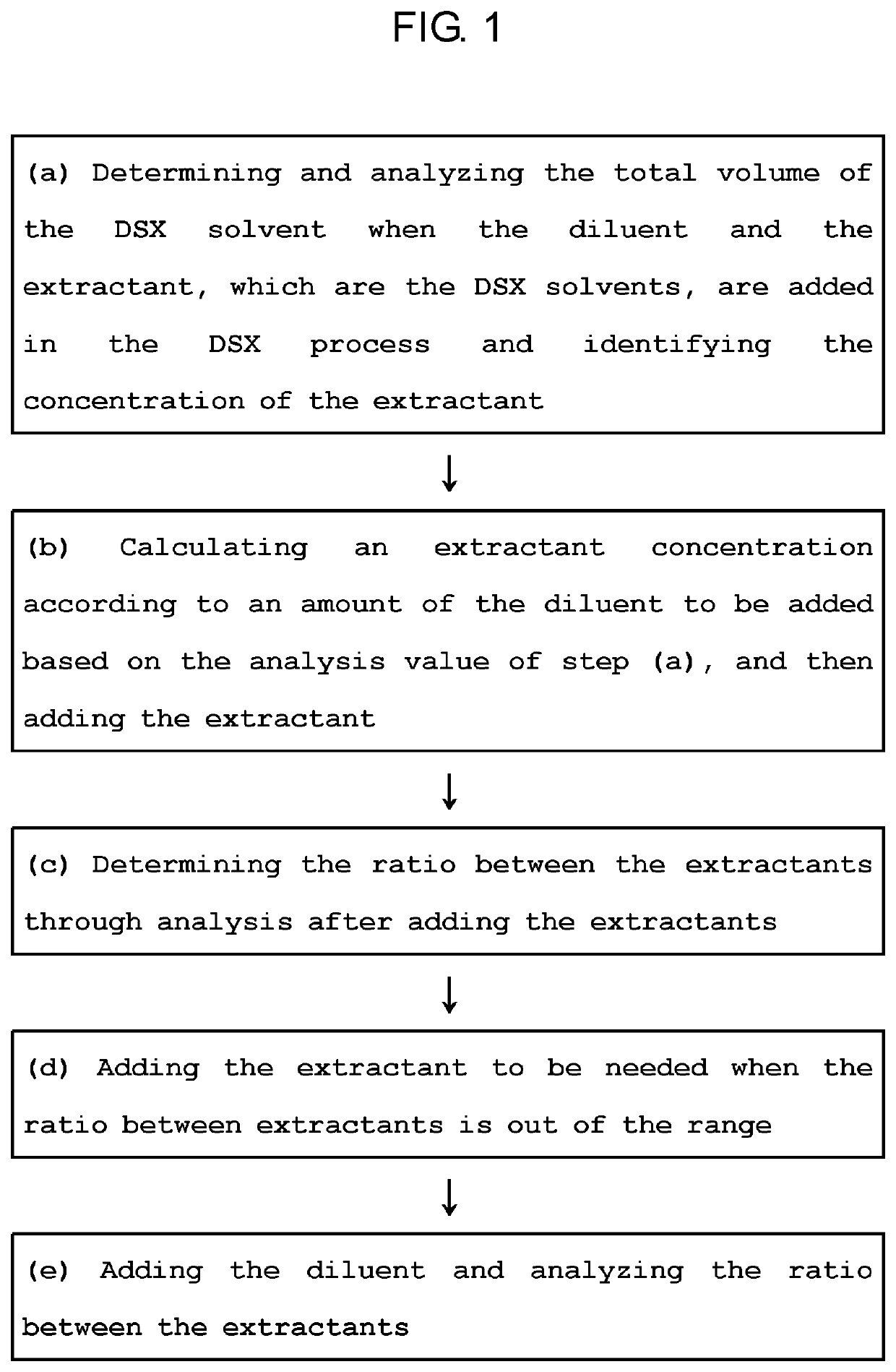

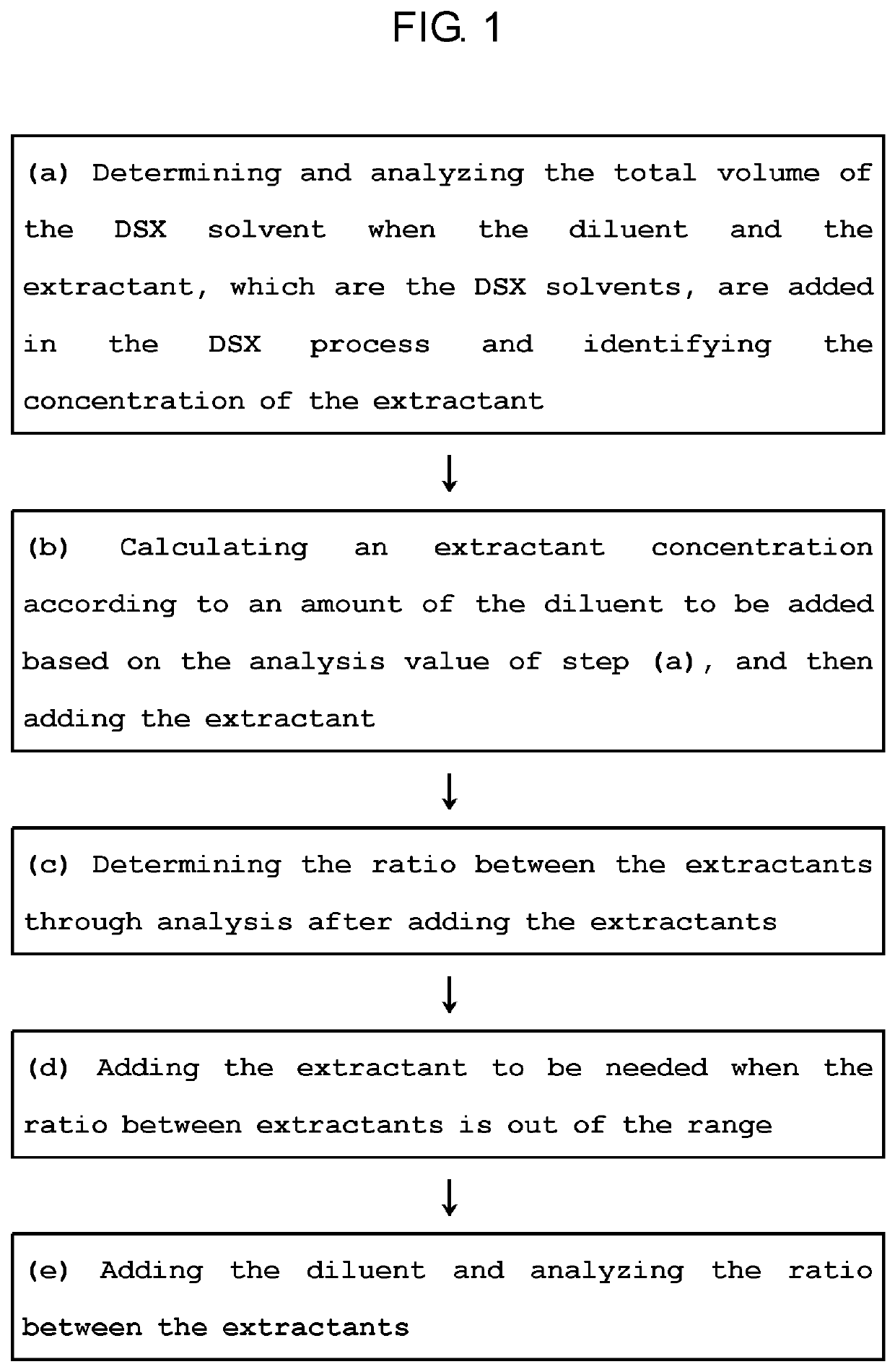

Method for inhibiting extractant degradation by diluent and extractant input method

ActiveUS20210024368A1Inhibiting extractant degradationPrevent degradationZinc compounds preparationComponent separationSolventEnvironmental chemistry

Provided is a method for inhibiting extractant degradation by a diluent and an extractant input manner, the method including steps of: (a) determining and analyzing the total volume of the DSX solvent when the diluent and the extractant, which are the DSX solvents, are added in the DSX process and identifying the concentration of the extractant; (b) calculating an extractant concentration according to an amount of the diluent to be added based on the analysis value of step (a), and then adding the extractant; (c) determining the ratio between the extractants through analysis after adding the extractants; (d) adding the extractant to be needed when the ratio between extractants is out of the range; and (e) adding the diluent and analyzing the ratio between the extractants.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

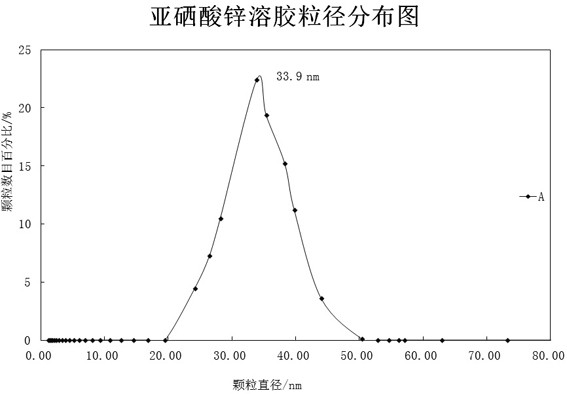

Zinc selenite sol as well as preparation method and application thereof

PendingCN114436319AAvoid enteringReduce contentBiocideMaterial nanotechnologyPhysical chemistryIon-exchange resin

The invention relates to the technical field of fertilizers, and discloses zinc selenite sol as well as a preparation method and application thereof, and the zinc selenite sol is used for reducing the cadmium content in plants and increasing the selenium content. Chitosan is added into the sol, so that the action efficiency is improved, and the action time is prolonged; the zinc element is added, so that the growth of crops is ensured while heavy metals such as cadmium are inhibited. The zinc selenite sol is prepared by the following specific steps: 1) reacting selenium element with zinc salt to obtain a precipitate; 2) adding water into the precipitate, pulping and stirring, and carrying out ultrasonic treatment; 3) stirring, heating and reacting the collected liquid through hydrogen-type weakly acidic cation exchange resin, standing, cooling, and aging to obtain a zinc selenite sol precursor; 4) adding the zinc selenite sol precursor into a mixture of hydrogen peroxide and ethanol, and reacting to obtain a zinc selenite sol precursor, and 5) adding chitosan into the zinc selenite sol precursor, and rapidly stirring until the chitosan is dissolved to obtain the zinc selenite sol.

Owner:IRONMAN ENVIRONMENTAL TECH CO LTD

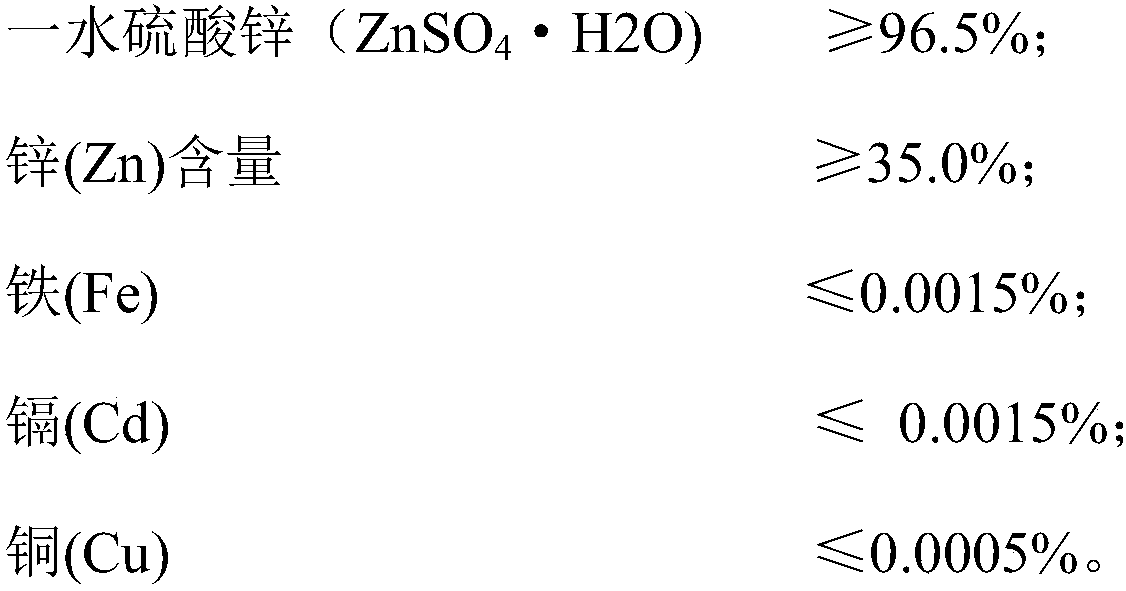

Method for preparing zinc sulfate monohydrate from zinc-containing waste residue

ActiveCN107385216BLow costSolving environmental problems that are difficult to recycleZinc sulatesZinc compounds preparationSulfate zincSlag

The invention discloses a method for preparing zinc sulphate monohydrate from zinc-containing waste residues. The method is characterized by comprising the following steps of (1), acid leaching; (2), oxidation for iron removal; (3), extraction of copper; (4), replacement for cadmium removal; (5), concentration and crystallization. The method for preparing the zinc sulphate monohydrate from the zinc-containing waste residues is a low-carbon and environmentally-friendly scheme, the preparation raw material is low in cost, waste is reutilized, the environmental problem that existing zinc-containing waste residues cannot be recycled and utilized is solved, the preparation process is energy-saving and environmentally-friendly, no waste gas or waste water is generated, a reagent unfriendly to the environment is not used, meanwhile metal, such as the copper and cadmium, is recycled, and the waste residues are reutilized.

Owner:台山市化工厂有限公司

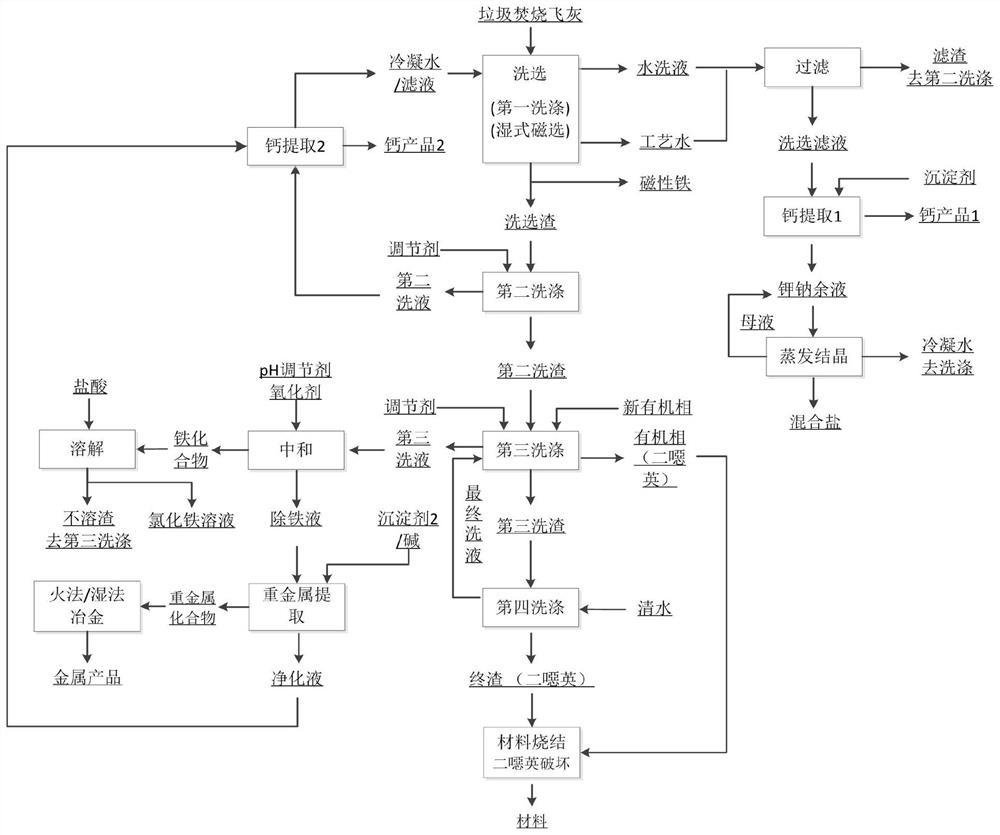

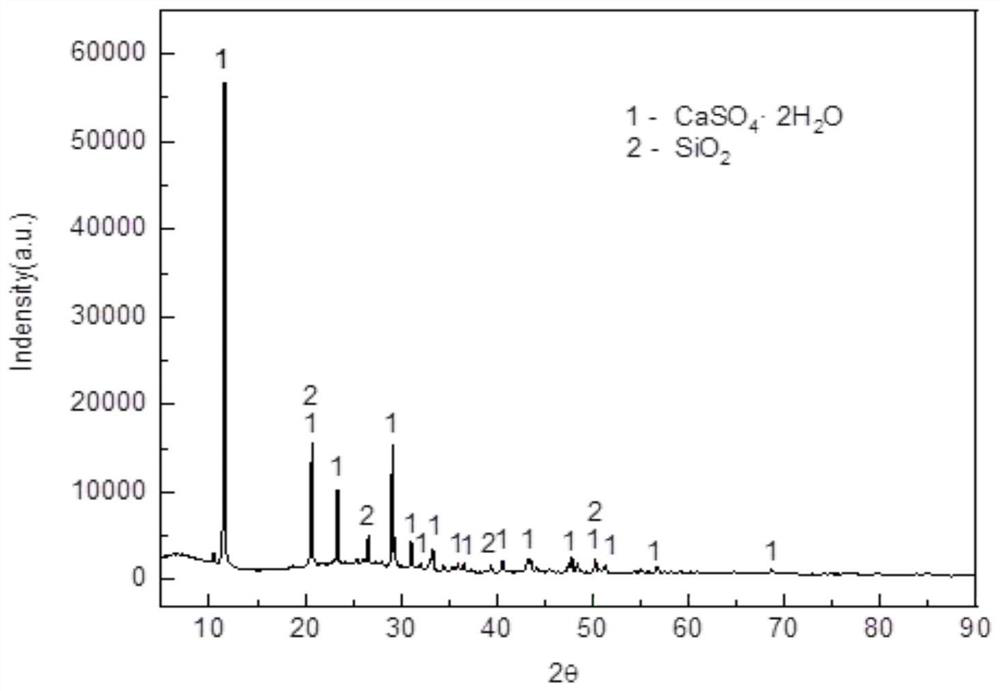

Resource utilization method of waste incineration fly ash

PendingCN114455623AImplement resourcesRealize comprehensive utilizationCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesMaterials preparationSlag

The invention belongs to the technical field of waste incineration fly ash treatment, and particularly relates to a resource utilization method of waste incineration fly ash. According to the method provided by the invention, soluble salt and magnetic substances in the waste incineration fly ash can be synchronously separated through washing, washing slag is subjected to second washing when the pH value is 6.5-8.0, and second washing slag is subjected to third washing when the pH value is 0.6-1.5. And step-by-step washing is carried out by controlling different pH values, and all extractable components in the garbage fly ash are respectively concentrated in different sections of washing liquid. According to the method, calcium salt and industrial salt extraction is carried out on the washing filtrate, calcium and heavy metal extraction is carried out on the second washing liquid and the third washing liquid, the final slag is used as a substitute raw material for building material preparation after high-temperature sintering or is directly prepared into building materials, and meanwhile dioxin is thoroughly decomposed during high-temperature treatment. According to the method provided by the invention, the garbage fly ash is completely recycled.

Owner:陈彤 +1

Method for inhibiting extractant degradation of DSX process through metal extraction control

ActiveUS11254584B2Minimizing extractionInhibition is effectiveIron compounds preparationZinc compounds preparationPhysical chemistrySlurry

Provided is a method for inhibiting extractant degradation in the DSX process through the metal extraction control, the method comprising steps of: (a) adding limestone to a copper solvent extraction-raffinate to precipitate iron (Fe) and aluminum (Al) as a slurry, recovering a clarifying liquid; and (b) adding sulfuric acid to the recovered clarifying liquid to adjust the pH thereof.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

A kind of preparation method of high-purity homogeneous zinc sulfate heptahydrate

ActiveCN112624179BAvoid reunionEasy to separateZinc sulatesZinc compounds preparationSulfate zincMicroemulsion

The invention discloses a preparation method of high-purity homogeneous zinc sulfate heptahydrate, comprising the following steps: S1: preparing an aqueous solution of zinc salt and preparing a composite extractant; mixing and extracting the two, standing, separating phases, taking an organic phase, and obtaining an organic phase containing Zn 2+ The microemulsion A of the 4 2‑ The microemulsion B; S3: will contain Zn 2+ of microemulsion A and containing SO 4 2‑ The obtained microemulsion B is mixed, stirred, the reaction produces a white precipitate, and the solid-liquid is separated, and the obtained precipitate is high-purity homogeneous zinc sulfate heptahydrate. The preparation method of zinc sulfate heptahydrate of the invention has the advantages of low cost, simple operation, easy batch preparation, high purity of the obtained product and uniform particle size distribution, and can meet the use requirements of special industrial fields.

Owner:浙江爱科新材料有限公司

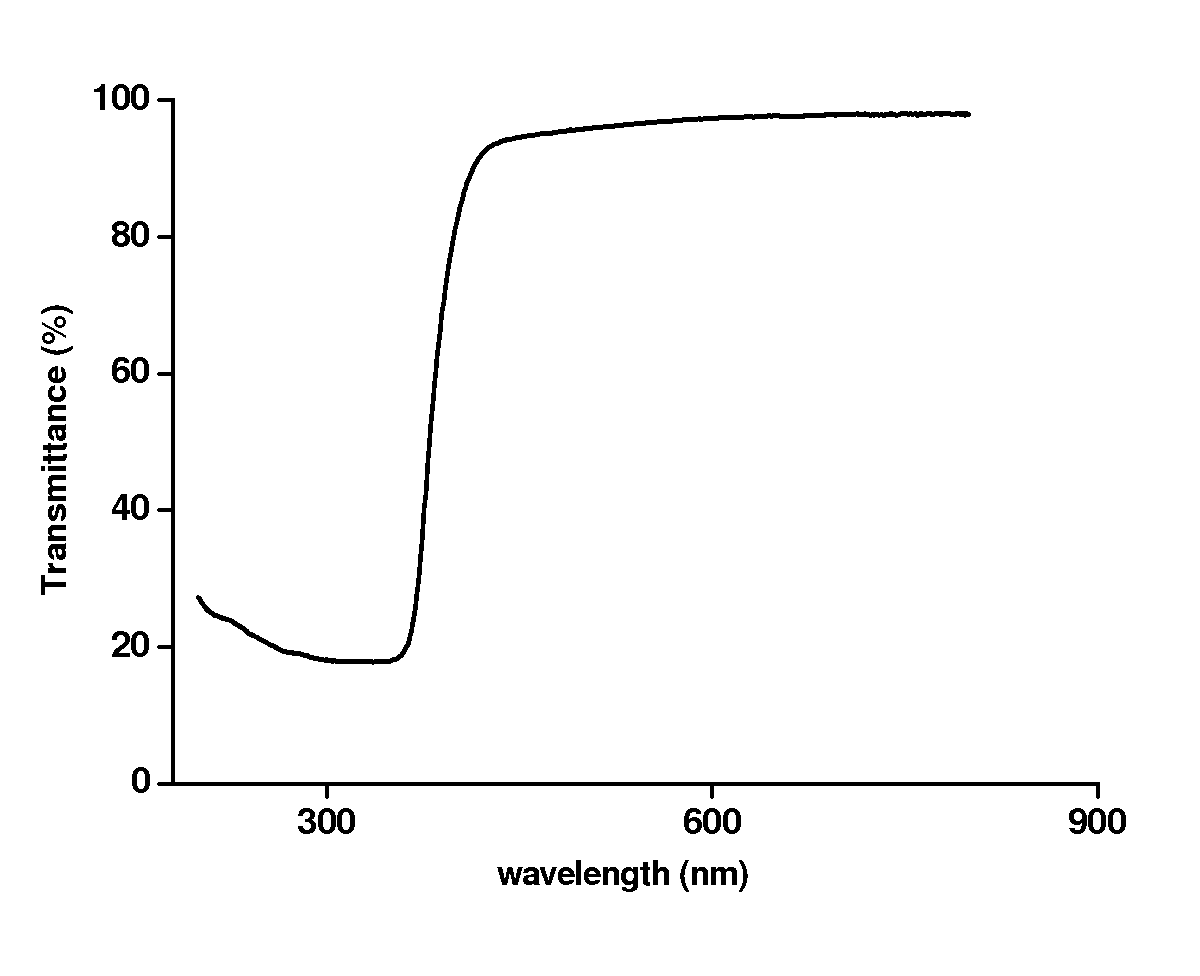

Process for the preparation of nano zinc oxide particles

A process for the preparation of nano zinc oxide particles is disclosed. The process comprises of dissolving a zinc metal precursor in a solvent to obtain a first solution and dissolving a base in an alcohol to obtain an alkali solution. The alkali solution is then added to the first solution over a predetermined period of time to obtain nano zinc oxide particles in solution.

Owner:TATA CHEM LTD

Method for inhibiting extractant degradation by diluent and extractant input method

ActiveUS11168003B2Prevent degradationZinc compounds preparationComponent separationSolventEnvironmental chemistry

Provided is a method for inhibiting extractant degradation by a diluent and an extractant input manner, the method including steps of: (a) determining and analyzing the total volume of the DSX solvent when the diluent and the extractant, which are the DSX solvents, are added in the DSX process and identifying the concentration of the extractant; (b) calculating an extractant concentration according to an amount of the diluent to be added based on the analysis value of step (a), and then adding the extractant; (c) determining the ratio between the extractants through analysis after adding the extractants; (d) adding the extractant to be needed when the ratio between extractants is out of the range; and (e) adding the diluent and analyzing the ratio between the extractants.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

Method of inhibiting extractant degradation by controlling extractive capacity and preventing direct degradation

ActiveUS11274047B2Prevent degradationImprove extraction efficiencyZinc compounds preparationProcess efficiency improvementSulfate zincSolvent

Provided is a method for inhibiting extractant degradation comprising preparing step, extracting step and scrubbing step, the method including: (a) the preparing step of a DSX solvent by adjusting the extractant concentration of the DSX solvent to a specific range; (b) the extracting step of metal included in the feed solution by adjusting the ratio of the organic (solvent) and an aqueous (solution) as a feed solution; (c) the scrubbing step of adjusting the zinc concentration of the solution using zinc sulfate; and (d) stripping step.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

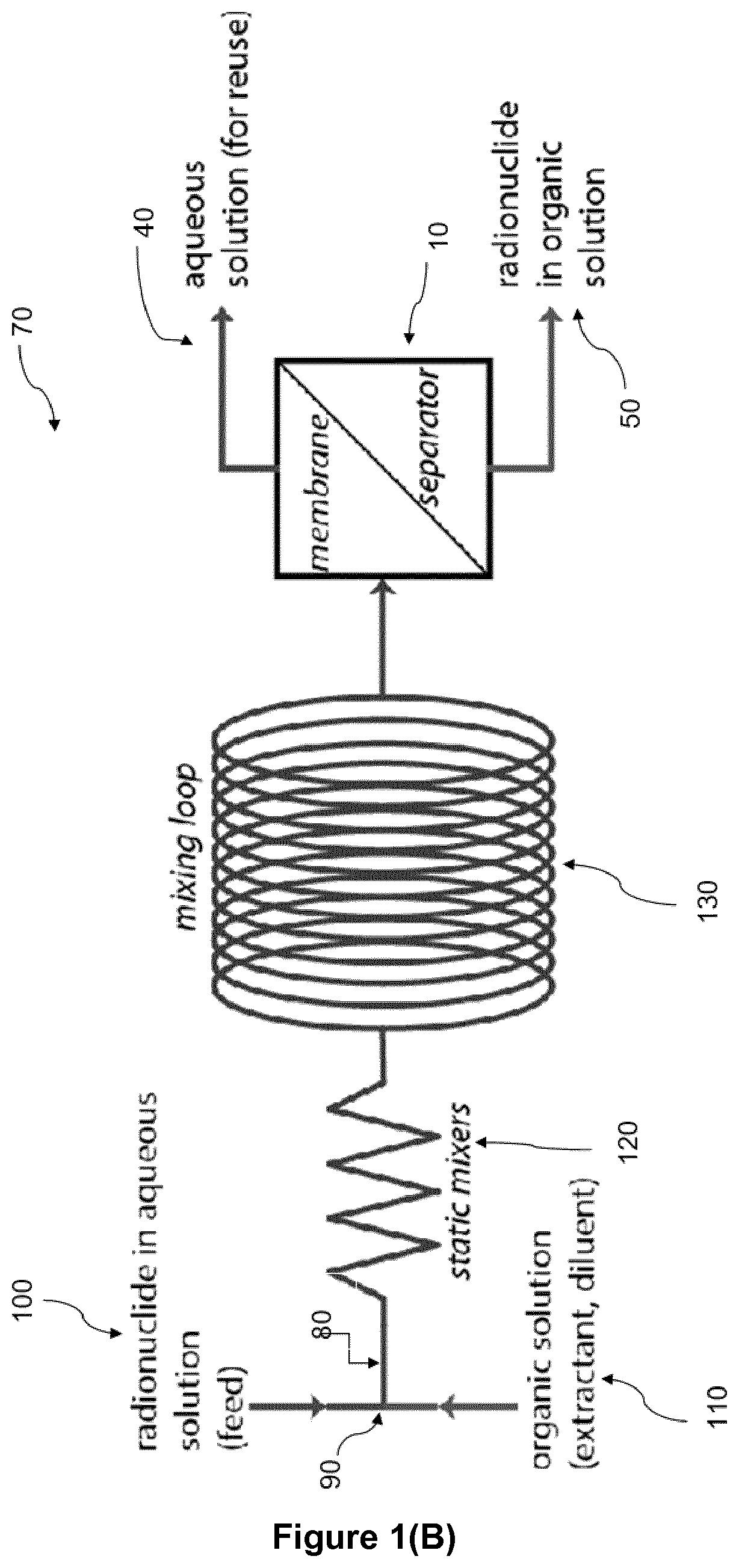

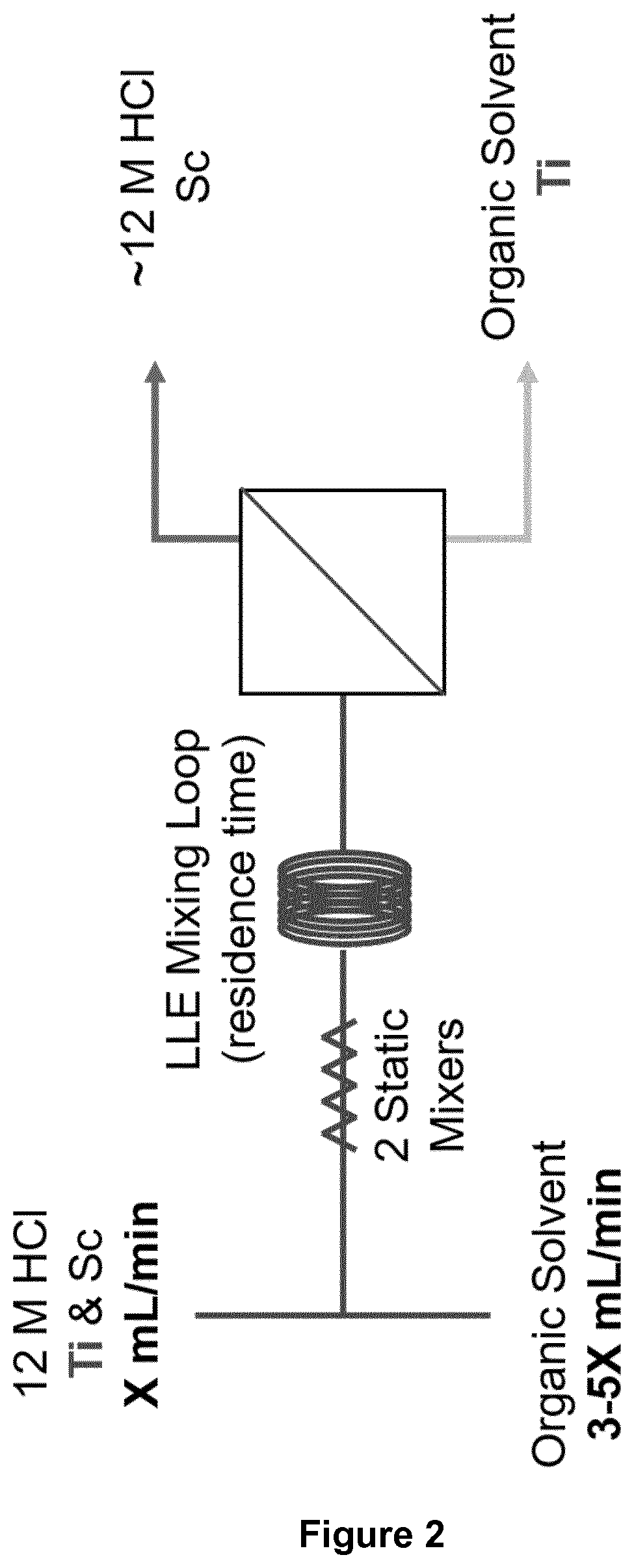

Separation of Radiometals

PendingUS20220118379A1Efficient on demand productionEfficient separationSpecific isotope recoveryMembranesMicrofiltration membranePhysical chemistry

Method of separation of a radiometal ion from a target metal ion, comprising a first liquid-liquid extraction step in which an organic phase comprising an extractant and an interfacial tension modifier is mixed with an aqueous phase comprising the radiometal ion and the target metal ion in order that the radiometal ion is at least partially transferred to the organic phase, followed by a first phase separation step, wherein the phase separation is carried out in flow comprising the use of a microfiltration membrane to separate the phases based on the interfacial tension between the phases such that a permeate phase passes through the membrane and a retentate phase does not.

Owner:MASSACHUSETTS INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com