Zinc selenite sol as well as preparation method and application thereof

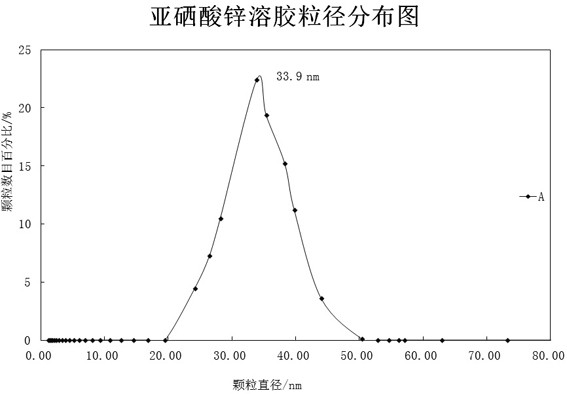

A technology of zinc selenite and sol, applied in the field of fertilizers, can solve the problems of insufficiency, large particles of zinc selenite powder, and difficulty in crop absorption, etc., and achieves the effects of improving action efficiency, good insulation and strong adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of a zinc selenite sol is carried out as follows: 1) Measure 20ml of water, add 1g of selenium powder, then add 5g of basic zinc carbonate to the reaction system, add sodium citrate after the basic zinc carbonate dissolves to adjust When the pH value of the reaction system reaches about 8, stir it to fully react for 1 hour. After sufficient reaction, filter and wash the obtained precipitate three to four times to obtain aqueous zinc selenite precipitate.

[0030] 2) Add water-containing zinc selenite precipitate and 80ml of water to beat and stir to obtain a mixed solution. After the mixed solution is stirred, insert the ultrasonic in-line processor into the mixed solution. The distance between the transmitting end of the ultrasonic in-line processor and the bottom of the container is About 7mm, the diameter of the end face of the transmitting end is 10~20mm, the intensity of the ultrasonic wave is adjusted at about 900 watts, the interval time of the ul...

Embodiment 2

[0034] The preparation of a zinc selenite sol is carried out as follows: 1) Measure 20ml of water, add 2g of selenium powder, then add 7g of basic zinc carbonate to the reaction system, add sodium citrate after the basic zinc carbonate dissolves to adjust When the pH value of the reaction system reaches about 8, stir it to fully react for 1 hour. After sufficient reaction, filter and wash the obtained precipitate three to four times to obtain aqueous zinc selenite precipitate.

[0035]2) Add the hydrated zinc selenite precipitate and 80ml of water to beat and stir. After the mixture is stirred, insert the ultrasonic in-line processor into the mixture. The distance between the transmitting end of the ultrasonic in-line processor and the bottom of the container is about 7 mm. , the diameter of the end face of the transmitting end is 10-20 mm, the intensity of the ultrasonic wave is adjusted at about 900 watts, the interval time of the ultrasonic wave is 1-10 seconds, the opening...

Embodiment 3

[0041] The preparation of a zinc selenite sol is carried out as follows: 1) Measure 20ml of water, add 1g of selenium dioxide, then add 6g of basic zinc carbonate to the reaction system, add sodium citrate after the basic zinc carbonate dissolves Adjust the pH value of the reaction system to about 8, stir to make it fully react for 1h. After sufficient reaction, filter and wash the obtained precipitate three to four times to obtain aqueous zinc selenite precipitate.

[0042] 2) Add zinc selenite precipitate and 80ml of water to beating and stir. After the mixture is stirred, insert the ultrasonic in-line processor into the mixture. The distance between the transmitting end of the ultrasonic in-line processor and the bottom of the container is about 7mm. The diameter of the end face of the end is 10-20 mm, the intensity of the ultrasonic wave is adjusted at about 900 watts, the interval time of the ultrasonic wave is 1-10 seconds, the opening time of the ultrasonic wave is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com