Treatment method of waste acid solution containing heavy metals

A treatment method and acid solution technology, applied in water/sewage treatment, chemical instruments and methods, extraction water/sewage treatment, etc., can solve problems such as low filtration efficiency, poor precision of by-products or poor added value of products, and achieve reduction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

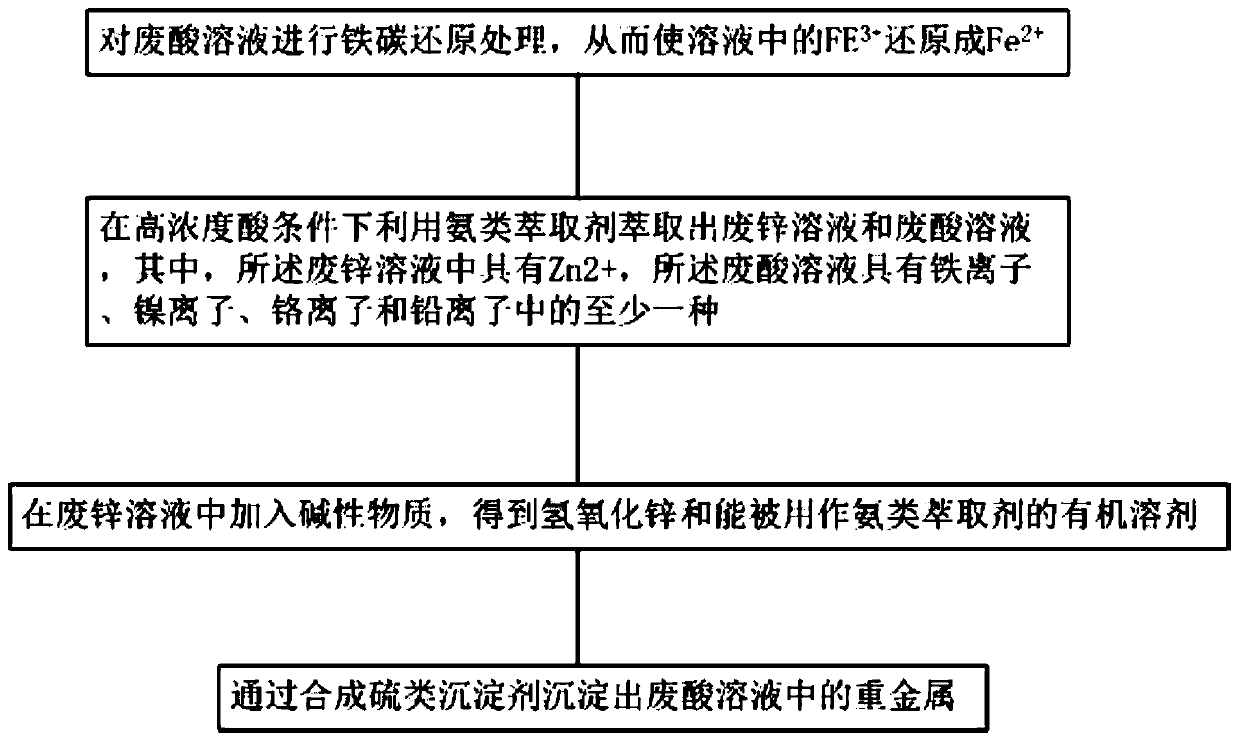

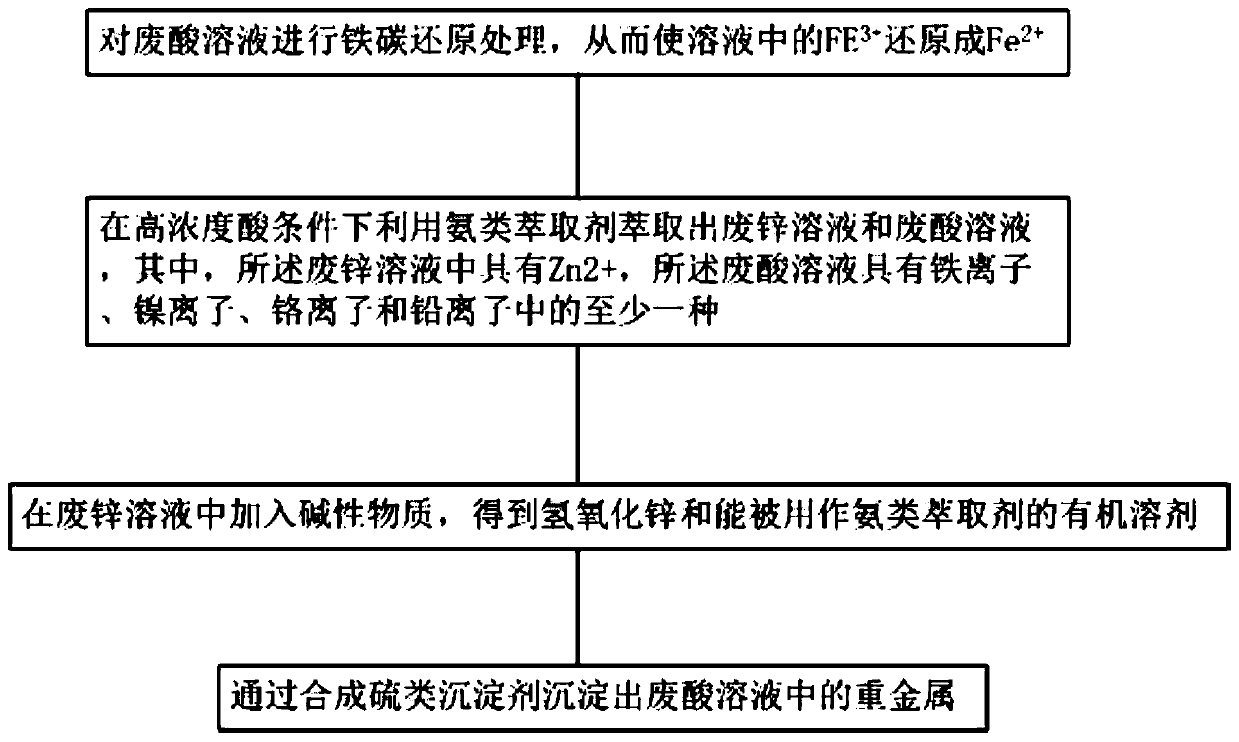

[0039] Under the action of a noble metal catalyst, the waste acid solution is subjected to iron-carbon reduction treatment;

[0040] Under the condition of high-concentration acid, use ammonia extractant to extract waste zinc solution and waste acid solution;

[0041] Alkaline substances are added to the waste zinc solution to obtain zinc hydroxide and an organic solvent that can be used as an ammonia extraction agent.

[0042] The nickel chromium lead in the spent acid solution was precipitated by synthetic sulfur precipitant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com