Process for producing mirbane oil by gas-phase nitration

A technology of nitrobenzene and nitric acid, applied in the preparation of nitro compounds, organic chemistry, etc., can solve problems such as catalyst activity decline, and achieve the effects of easy separation, long service time and less free acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

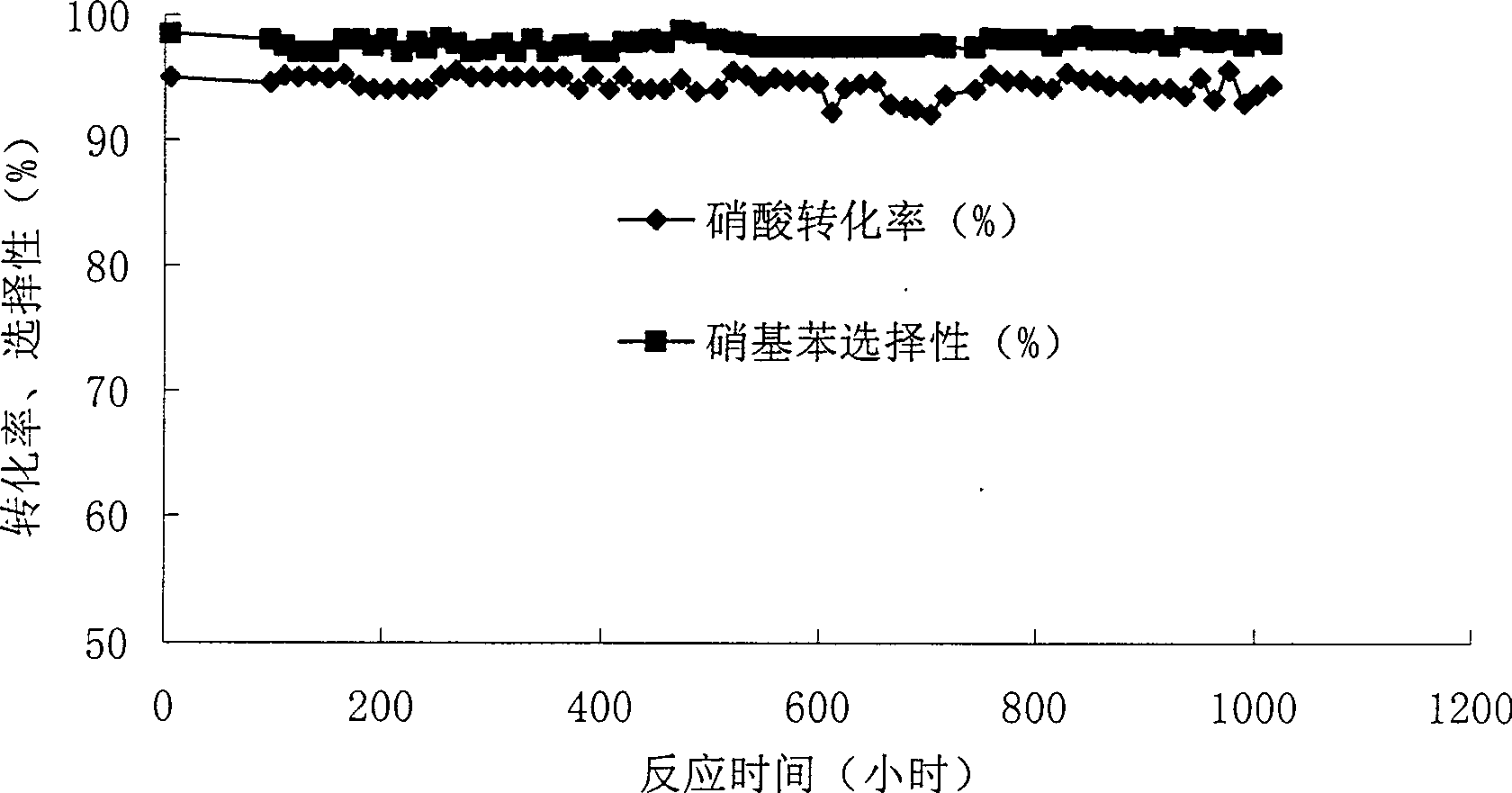

Image

Examples

Embodiment 1

[0019] Weigh 59.67g of ethyl silicate, add 40ml of water, add 12g of 0.05N dilute hydrochloric acid, stir to form a sol, then add 130g of dilute sulfuric acid (30%), stir, leave to stand for two days after 8 hours for aging, and vacuum-dry the obtained gel , to obtain solids, crush and sieve the solids to obtain 40-60 mesh particles, denoted as H 2 SO 4 -SiO 2 . H 2 SO 4 -SiO 2 Put it in an oven at 120°C and keep it for three hours, then raise the temperature to 200°C and keep it for 0.5 hour, take it out and cool it down to get a solid catalyst.

[0020] Get 4ml of the obtained catalyst and put it into the reaction tube, the upper part of the reaction tube is equipped with about 20cm of ceramic discs for the gasification of the raw material, the temperature of the heating furnace is raised to 140 °C, and 65% nitric acid and benzene are pumped in respectively, and the nitric acid feed The flow rate was 2.0 ml / h and the benzene feed flow rate was 5.0 ml / h.

[0021] React...

Embodiment 2

[0027] Same as in Example 1, the temperature of the heating furnace was changed, and the temperature of the heating furnace was raised to 160°C.

[0028] Reaction conditions: Reaction temperature 185°C;

[0029] Liquid space velocity 1.8h -1 ;

[0030] The molar ratio of benzene to nitric acid=2:1;

[0031] Reaction result: nitric acid conversion rate 97.1%;

[0032] The selectivity of nitrobenzene is 98.7%.

Embodiment 3

[0034] As in Example 1, the feed flow rate of benzene was changed, and the feed flow rate of benzene was 2.5ml / h.

[0035] Reaction conditions: Reaction temperature 155°C;

[0036] Liquid space velocity 1.1h -1 ;

[0037] The molar ratio of benzene to nitric acid = 1:1;

[0038] Reaction result: the conversion rate of nitric acid is 87.5%;

[0039] The selectivity of nitrobenzene is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com