Patents

Literature

54results about "Iron compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for resource recycling and zero discharge of steel hydrochloric acid pickling waste liquid

InactiveCN106116004ARealize recycling of resourcesNo waste dischargeGas treatmentIron compounds preparationSlagFiltration

The invention discloses a processing method for resource recycling and zero discharge of steel hydrochloric acid pickling waste liquid. The method adopts the process steps of carbide slag neutralization and pre-oxidation, air oxidation, heating synthesis, press filtration, filtrate circulation and concentration, acid gas absorption and the like so as to prepare high-iron-content magnetic iron compounds and liquid calcium chloride. The method disclosed by the invention takes industrial waste, namely carbide slag, as a raw material for processing steel hydrochloric acid pickling waste liquid, controls reasonable process parameters for recycling magnetic iron compounds which can be used for replacing iron ore powder in the iron industry, have the iron content of 52-62% and meet the iron ore powder standard as well as liquid calcium chloride which meets the 'GBT26520-2011' standard, and realizes the zero discharge of pollution control in steel enterprises. Moreover, the method is simple and stable, strong in operability, little in water consumption and low in energy consumption, greatly reduces the processing cost, and is particularly suitable for processing the steel pickling waste liquid in medium and small-sized enterprises.

Owner:TIANJIN ZHENGDA SCI &TECH CO LTD +2

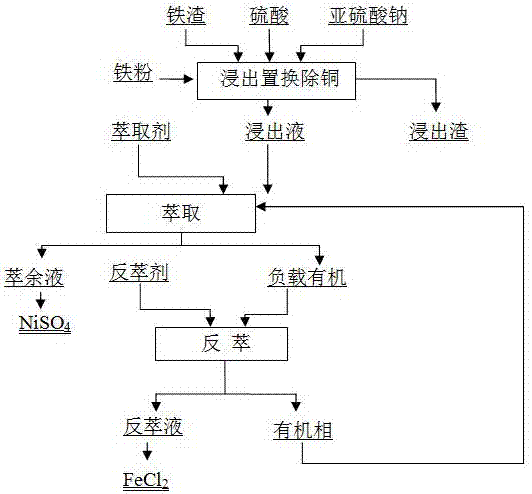

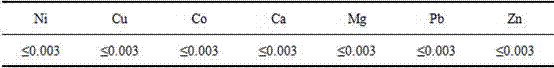

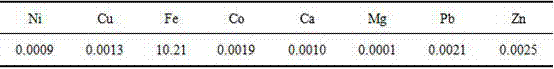

Extraction decontamination method for industrial iron slag sulfuric acid leaching

InactiveCN107200364AHigh removal rateSimple processIron compounds preparationNickel compounds preparationSlagKerosene

The invention discloses an extraction decontamination method for industrial iron slag sulfuric acid leaching. The extraction decontamination method comprises five procedures of sodium saponification, nickel saponification, extraction, washing and back extraction. P507 is adopted as an extraction agent, solvent oil or sulfonated kerosene is adopted as a diluent, on the basis of different combination properties of different metal ion extraction agents and the principle that the combination property of one metal with the extraction agents can be damaged by hydrochloric acid of different concentrations, target metals of Ni and Fe ions can be separated, metal ions such as Co, Cu, Pb, Zn, Ca and Mg in the leaching can be further removed, then the industrial iron slag sulfuric acid leaching can be deeply purified, and a nickel sulfate solution and a ferrous chloride solution with low impurity contents can be prepared. The extraction decontamination method disclosed by the invention is simple and convenient in process procedure and high in impurity removal rate, and the quality of the produced nickel sulfate solution and ferrous chloride solution meets quality requirements for producing nickel sulfate and ferric oxide products.

Owner:甘肃有色冶金职业技术学院

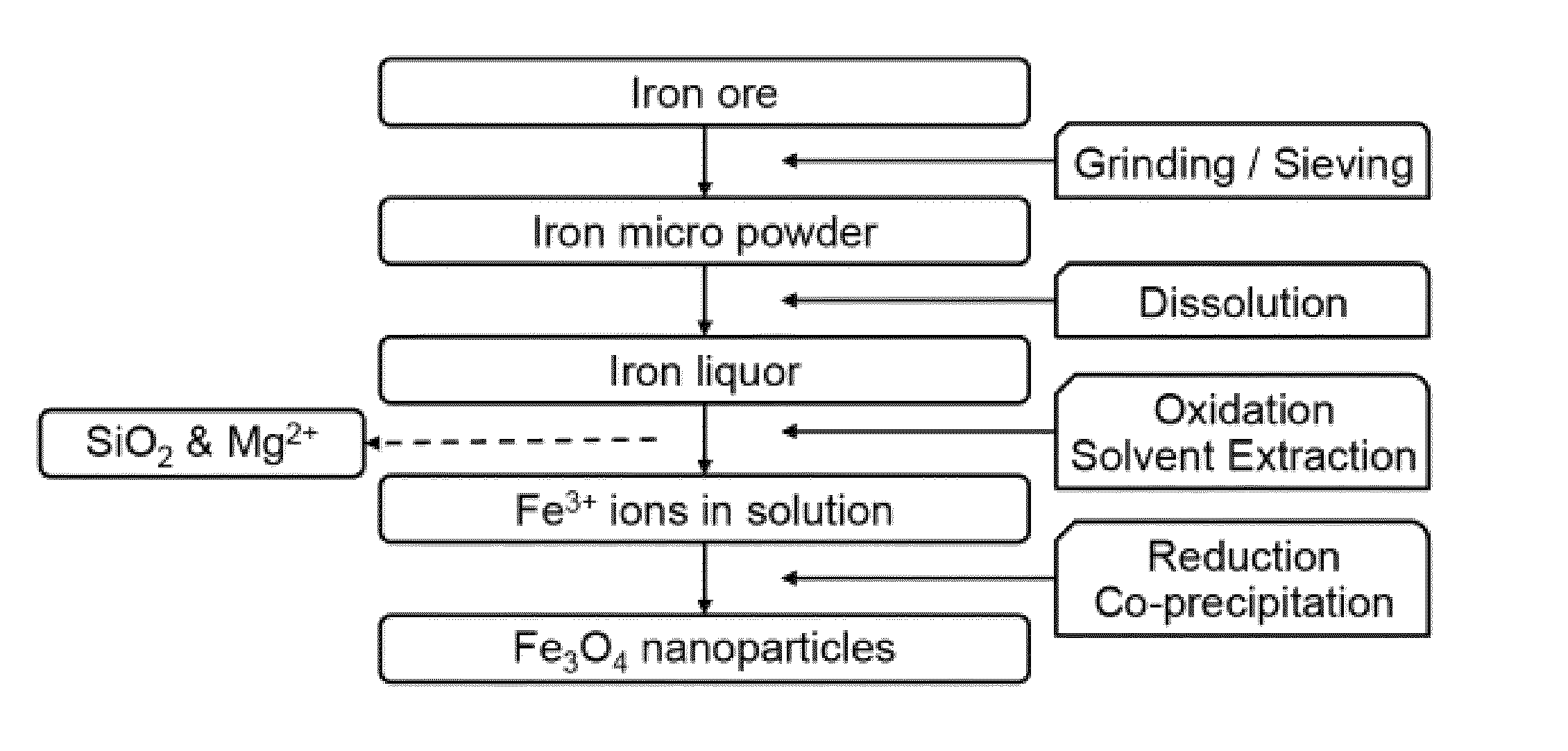

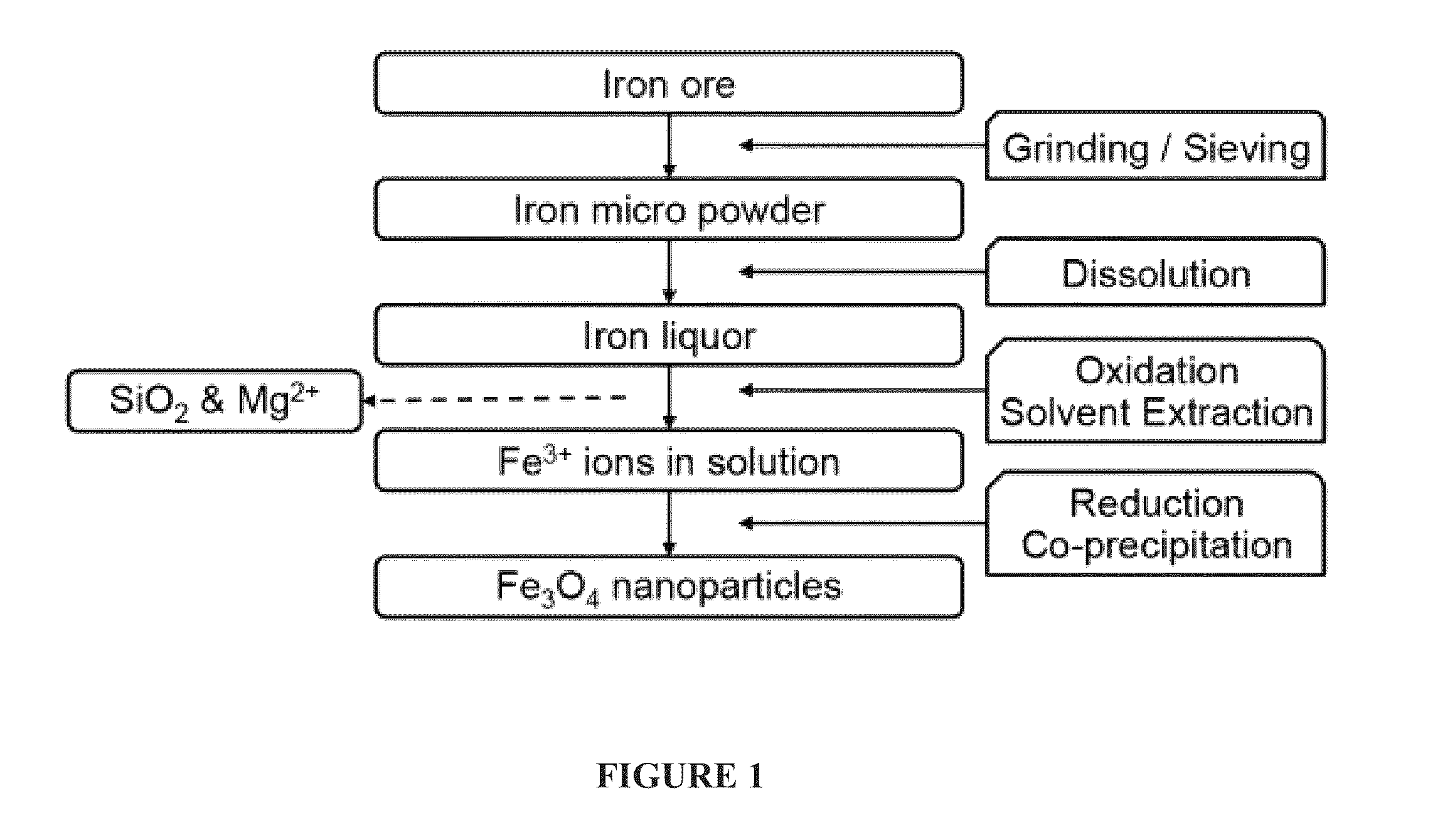

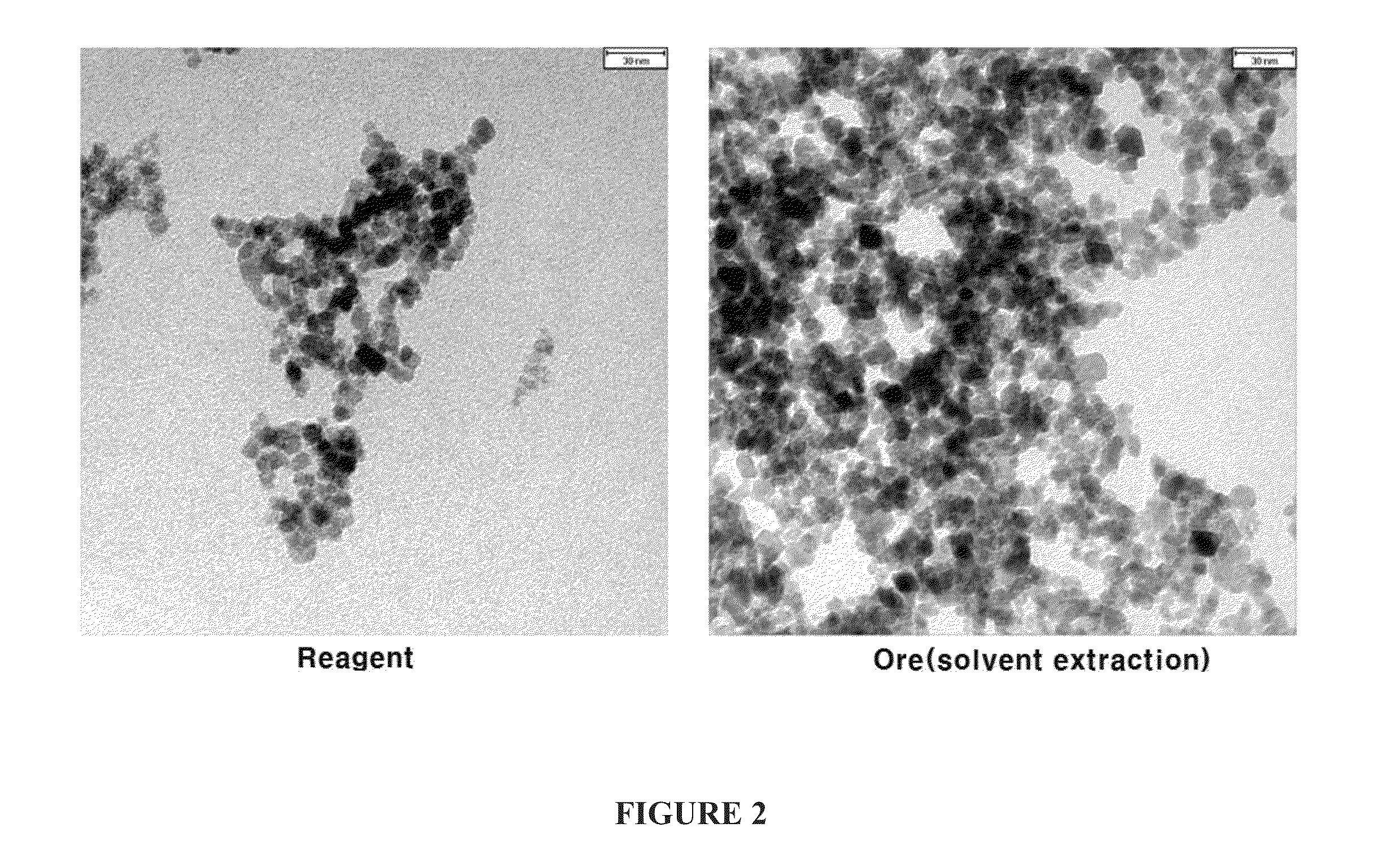

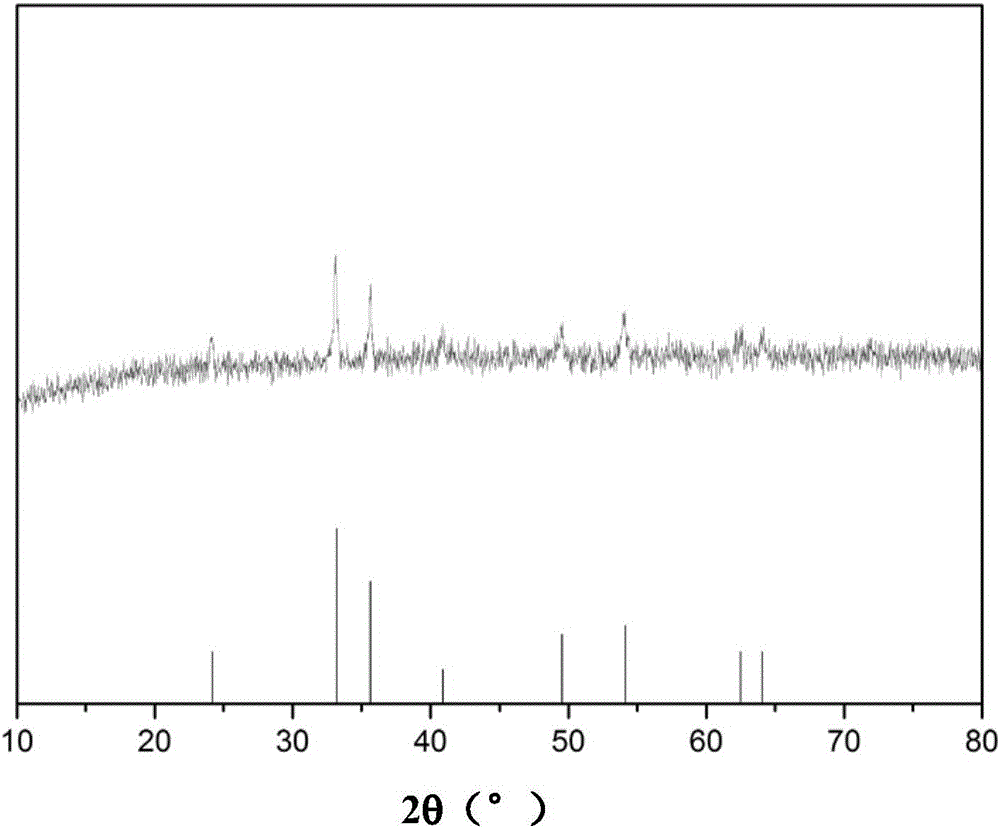

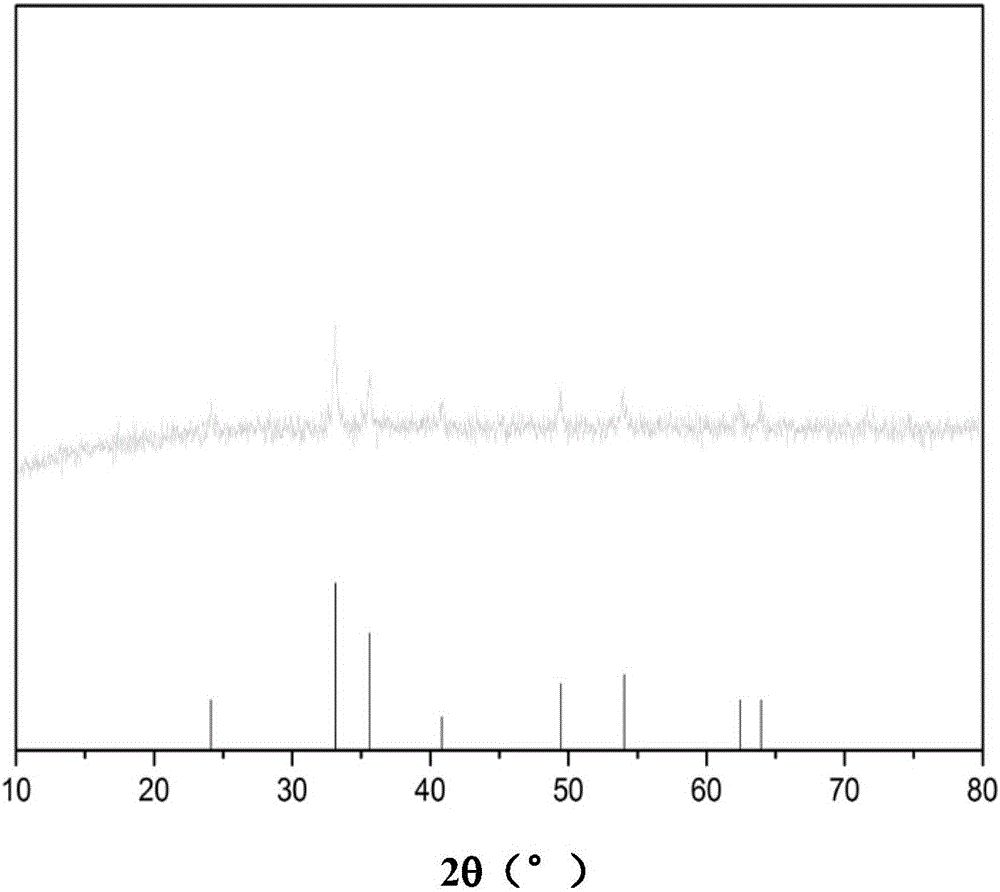

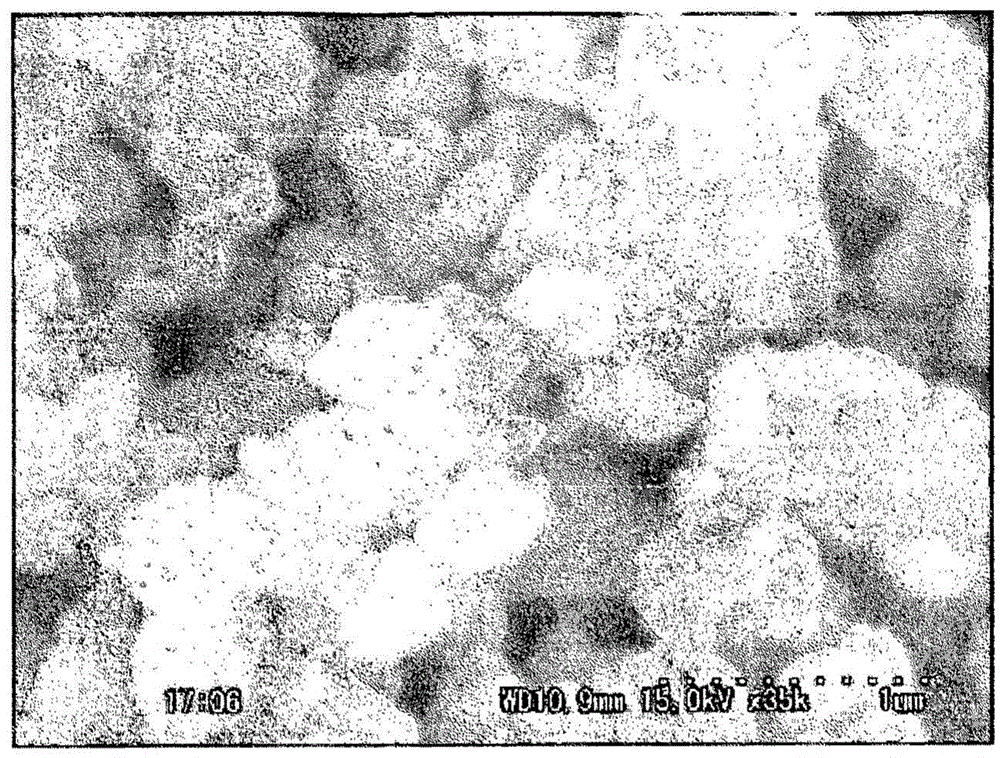

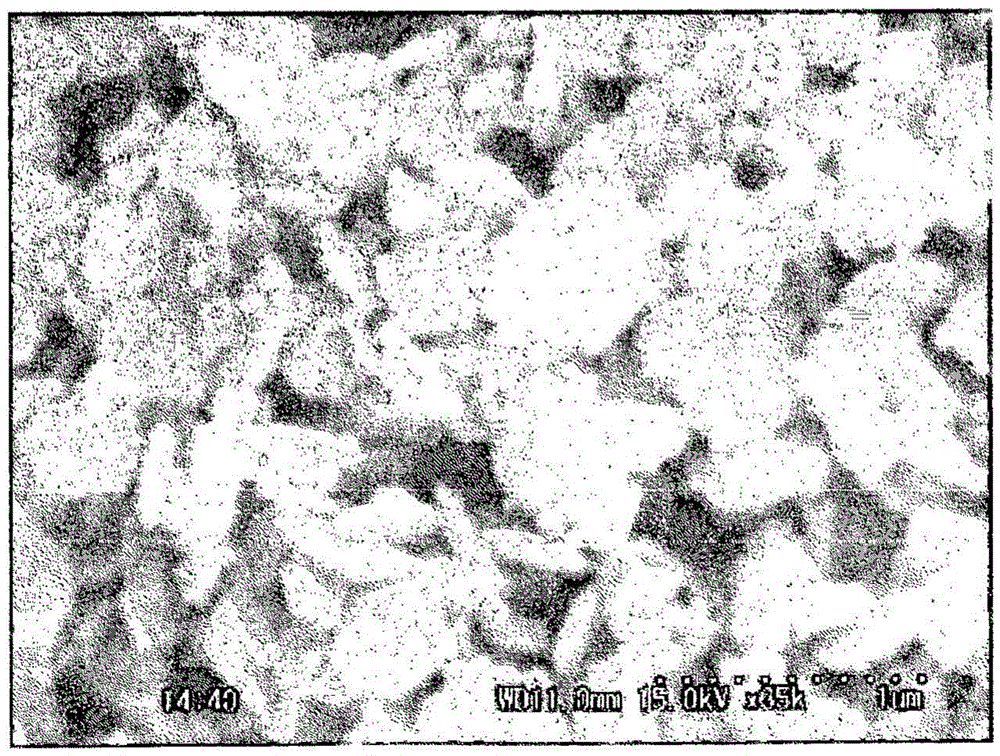

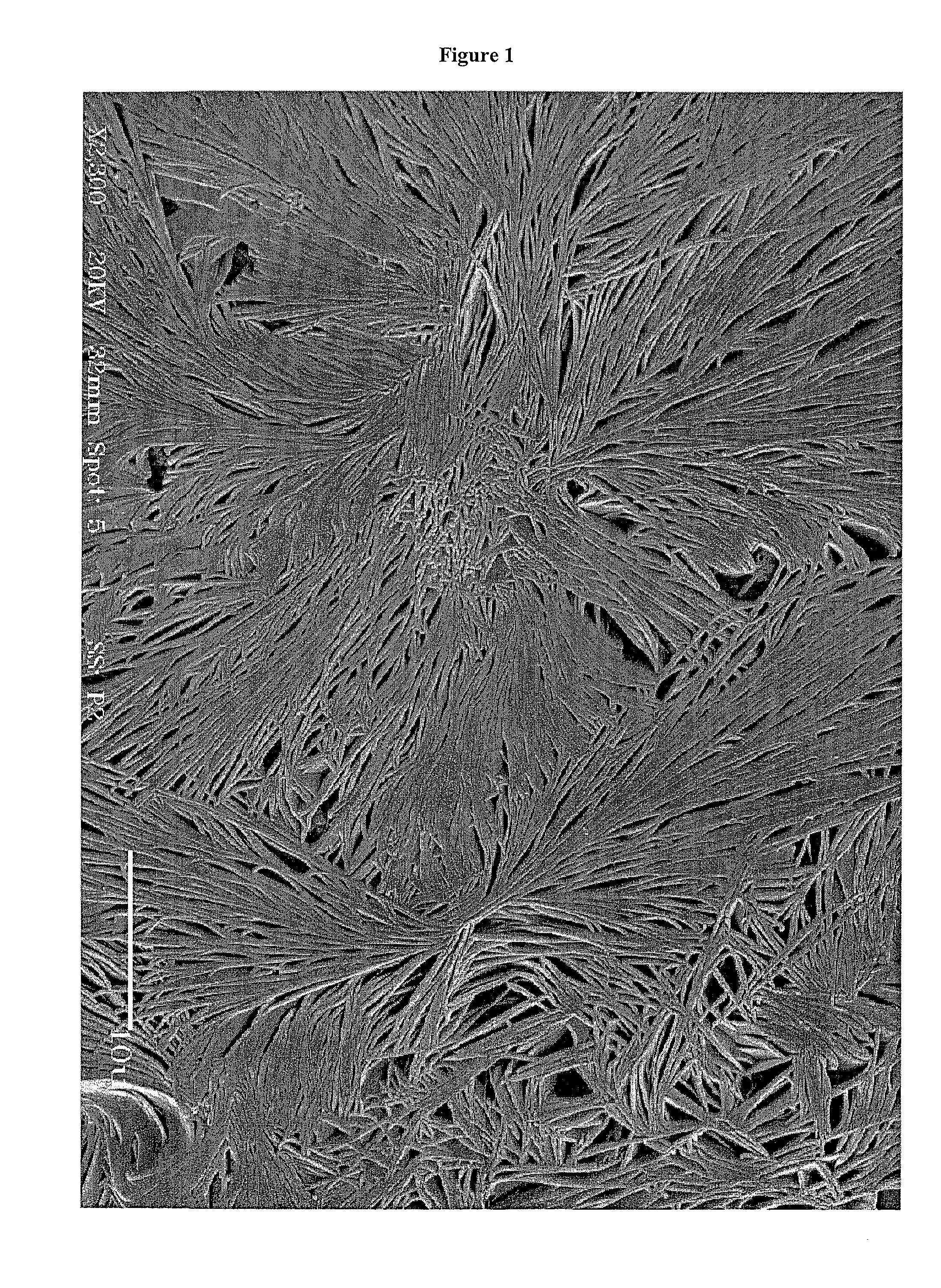

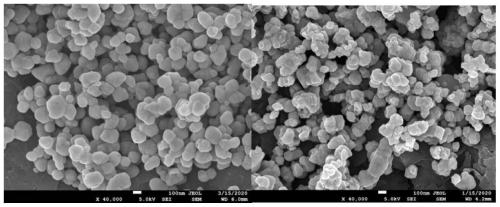

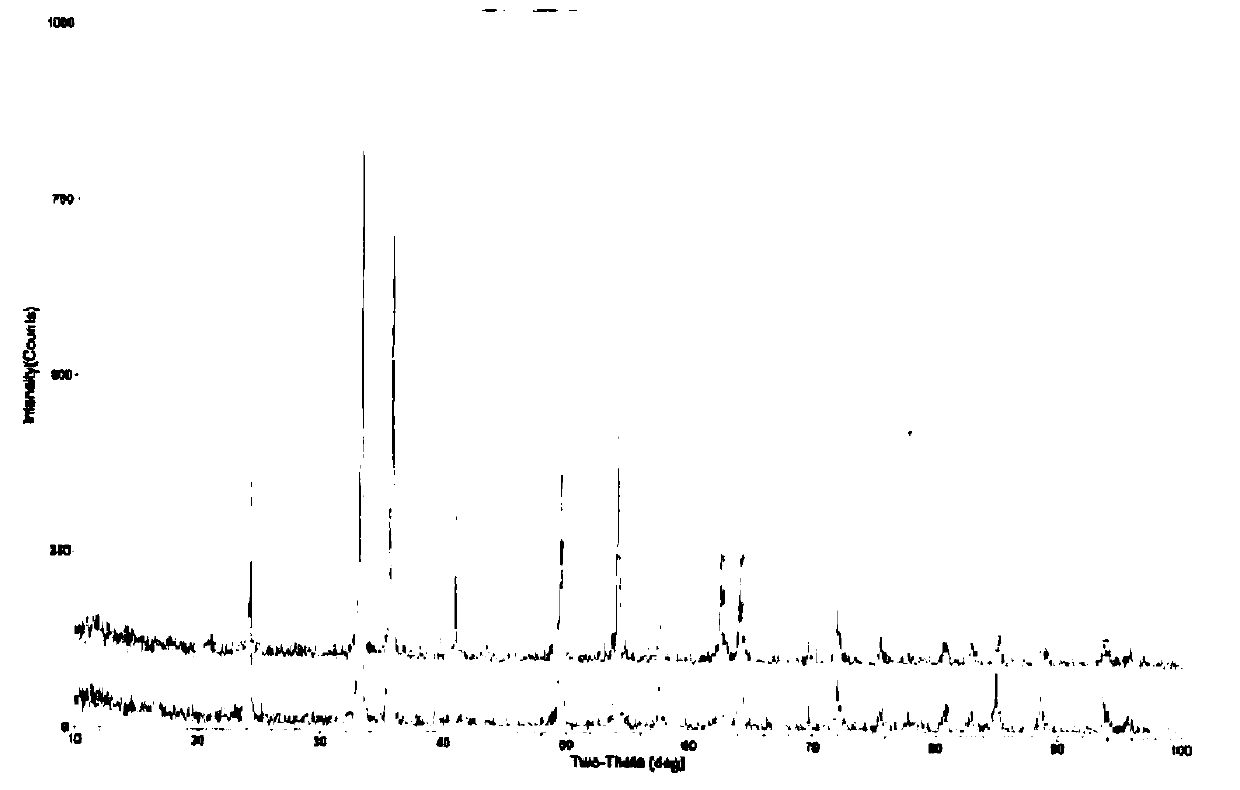

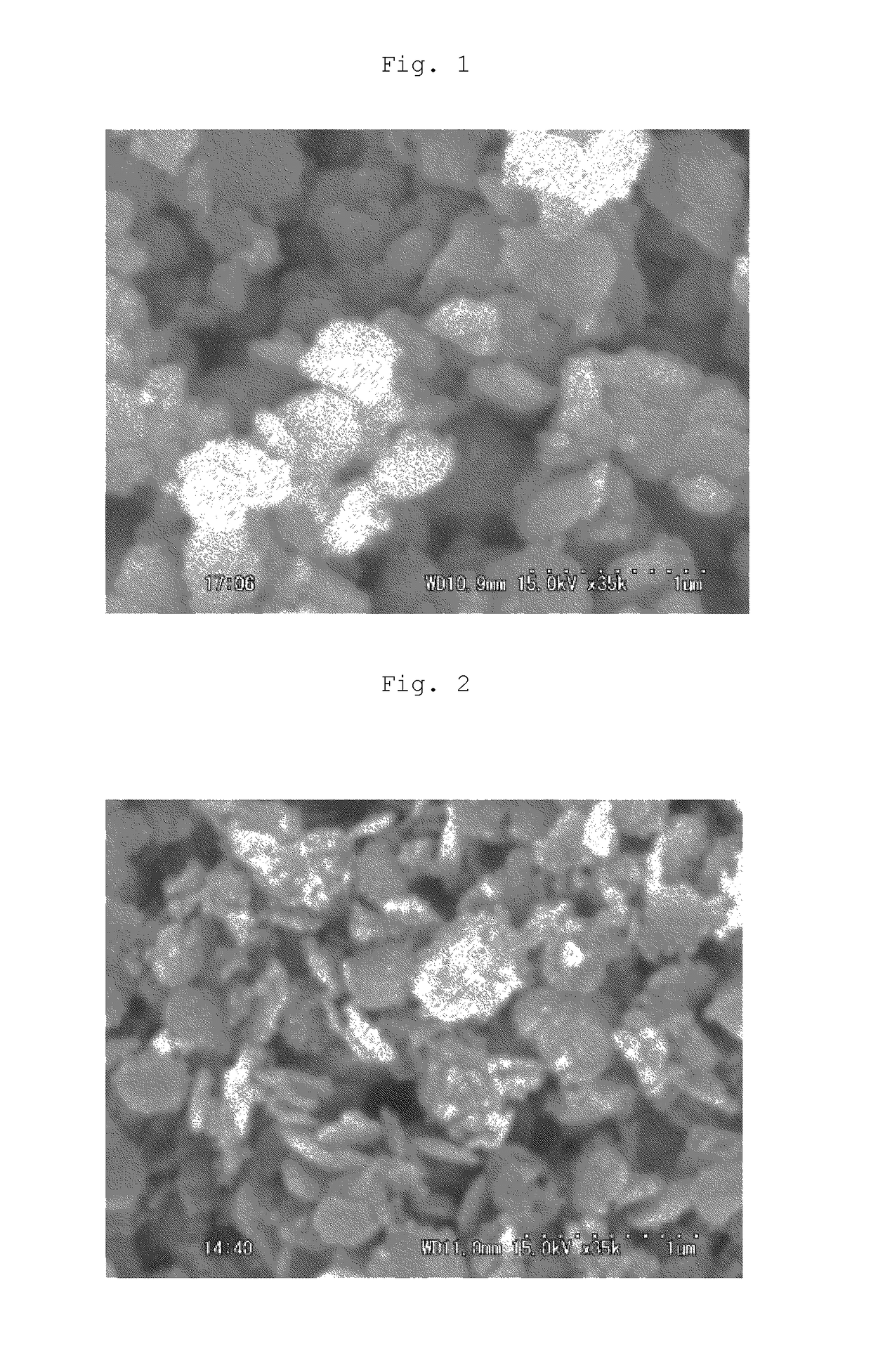

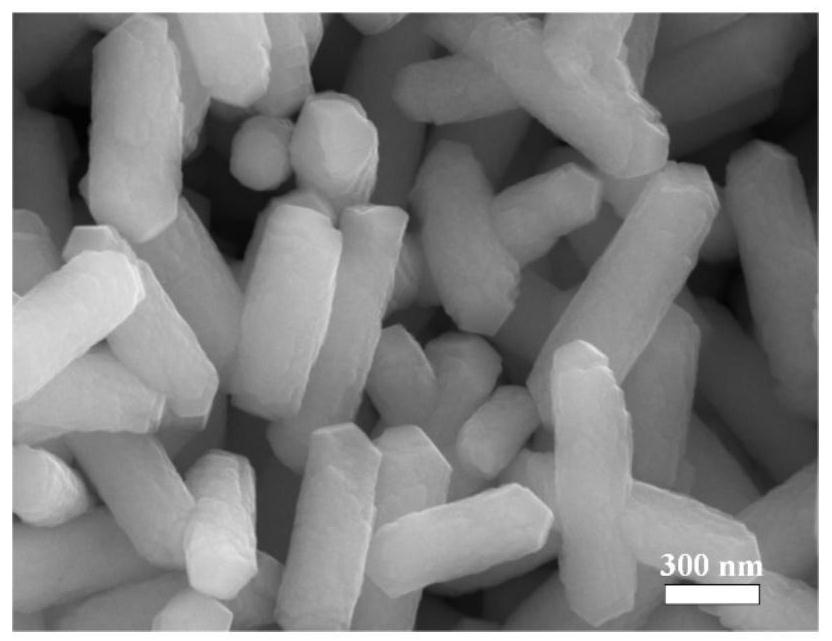

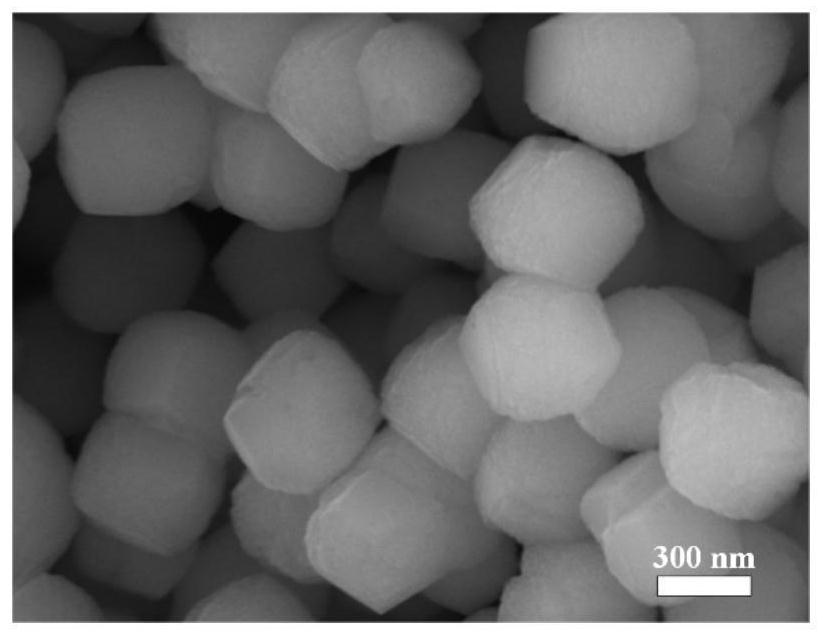

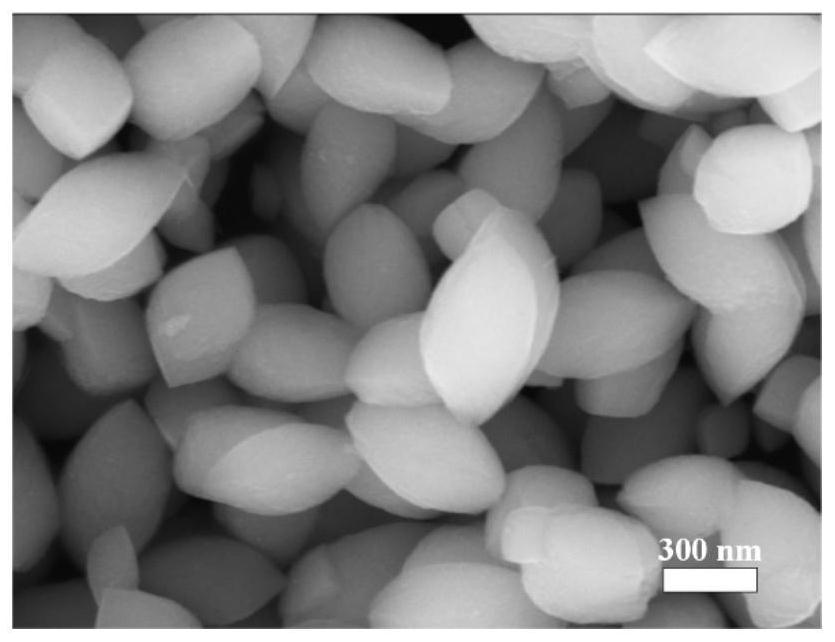

Method for preparing magnetite nanoparticles from low-grade iron ore using solvent extraction and magnetite nanoparticles prepared by the same

InactiveUS8940179B2Exemption stepsPrepare magnetite more economicallyPigmenting treatmentMaterial nanotechnologyIronstoneMRI contrast agent

The present invention relates to a method for preparing magnetite nanoparticles from low-grade iron ore using solvent extraction and magnetite nanoparticles prepared by the same. According to the method for magnetite nanoparticles from low-grade iron ore of the present invention, it is possible to prepare high-purity magnetite nanoparticles having a purity of 99% or higher by solvent extraction using low-grade iron ore as a starting material, and thus it is possible to reduce the processing cost and the amount of energy used, thus supplying a high-efficiency magnetite nanoparticle adsorbent, which can be industrially applied to wastewater treatment or desalination plant, in large quantities at low cost. In particular, it is possible to effectively treat livestock wastewater, heavy metal wastewater, oil discharged into rivers, etc. at low cost, thus significantly contributing to the prevention of environmental pollution. Moreover, the magnetite nanoparticles prepared by the present invention has a purity of 99.5% and thus can be used as raw materials for high-tech products such as nanoparticle catalysts, magnetic fluids, MRI contrast agents, etc.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

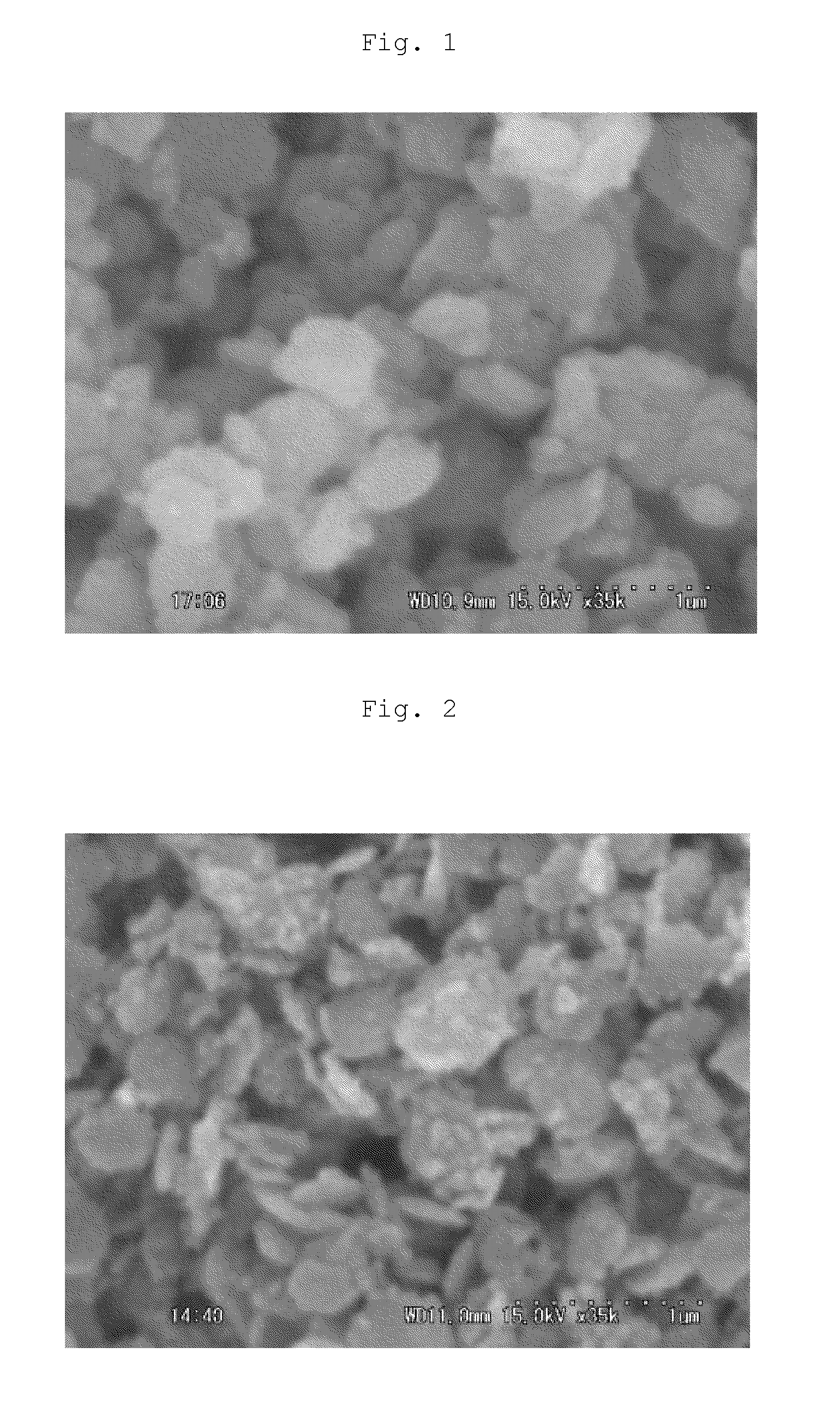

Magnetic hydrotalcite composite and production method thereof

InactiveUS20160203893A1Inhibition of agglomerationIron compounds preparationOther chemical processesUltravioletWastewater

A magnetic hydrotalcite composite which is useful in fields such as wastewater treatment, ultraviolet absorption, electromagnetic wave absorption and acid gas absorption, and a production method thereof.The magnetic hydrotalcite composite comprises an inner layer and an outer layer, in which the inner layer is made of a hydrotalcite compound and the outer layer is made of a ferrite compound.

Owner:KYOWA CHEM IND

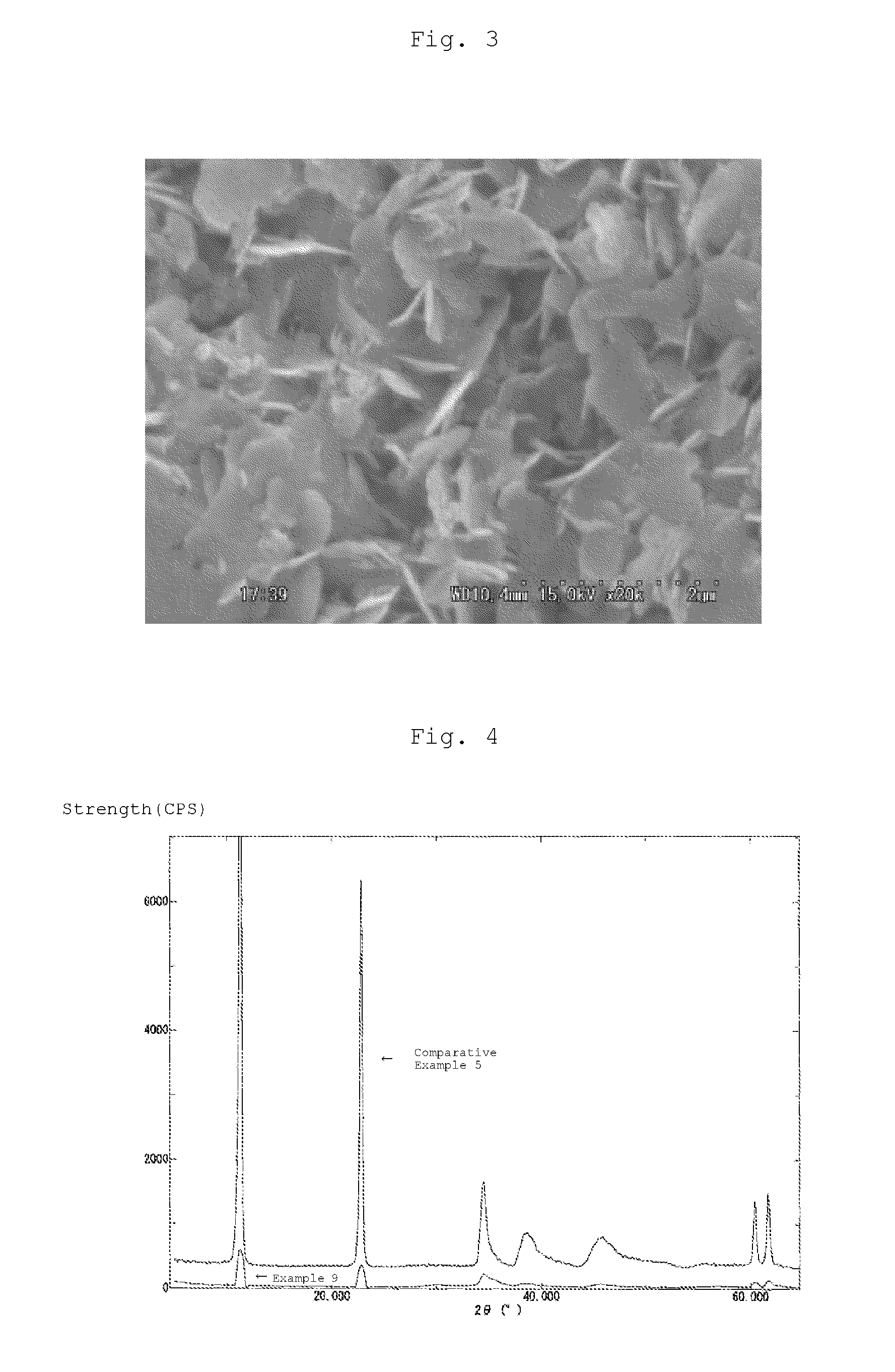

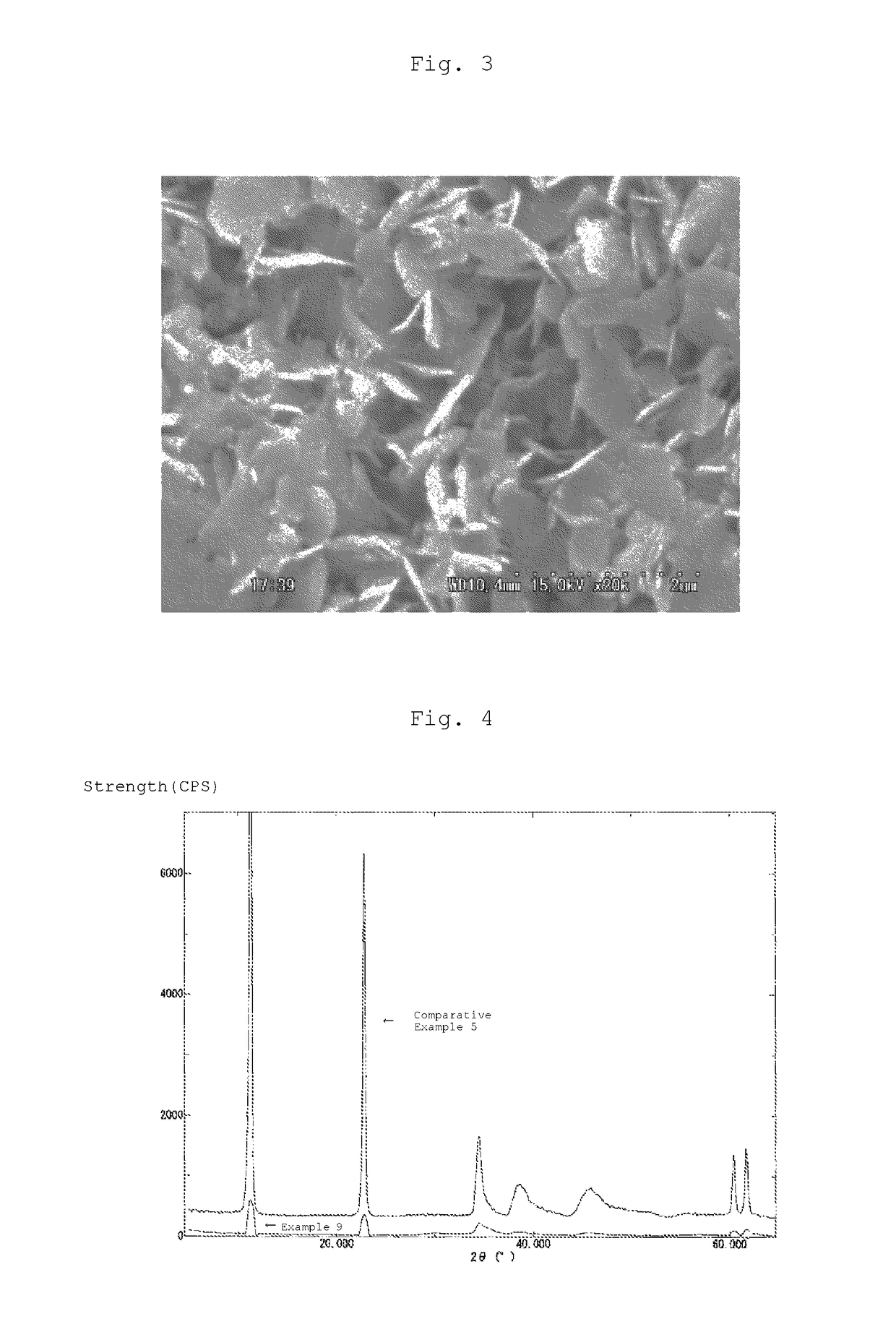

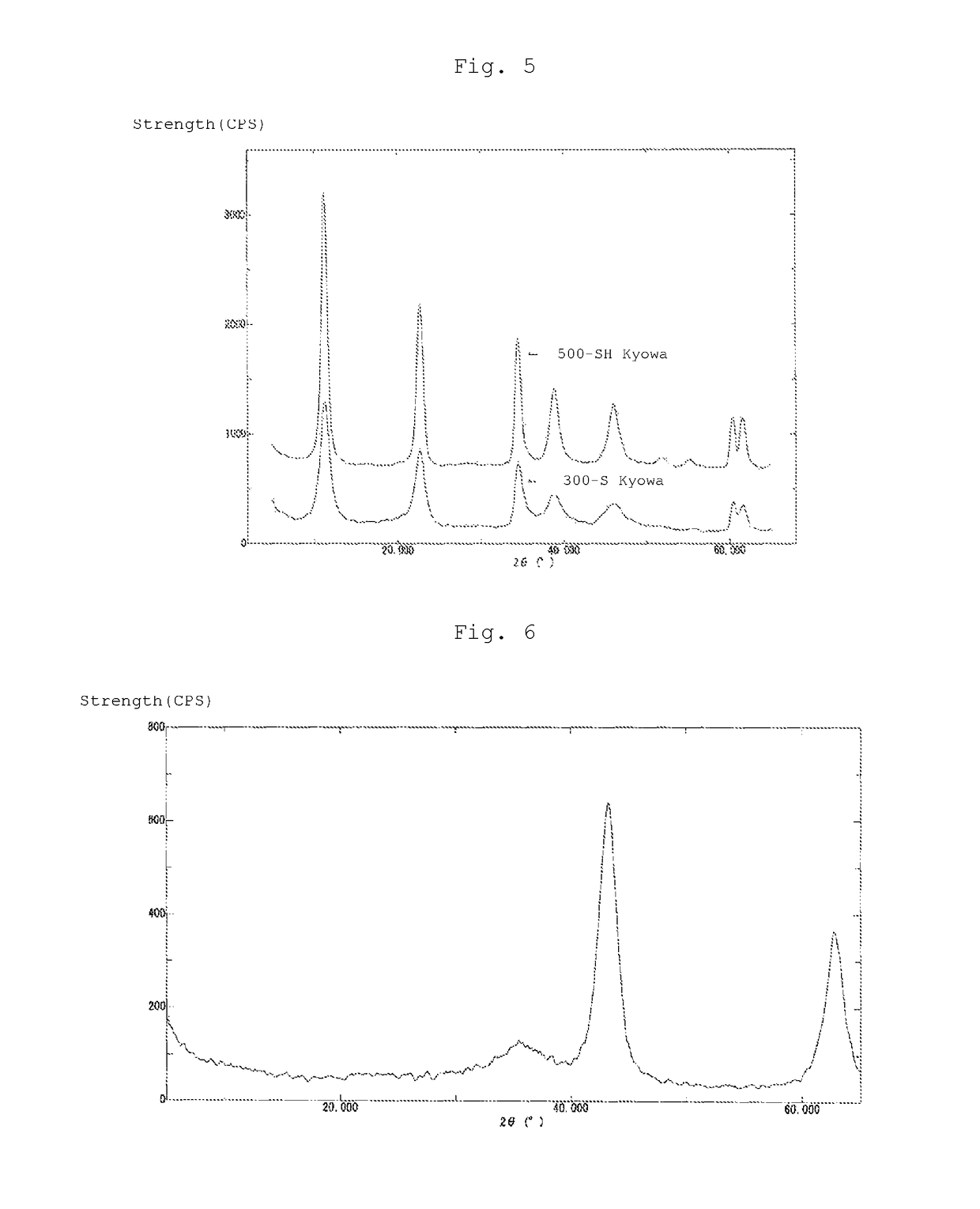

Magnetoplumbite-type hexagonal ferrite

ActiveUS20140291571A1Improve magnetic propertiesImproved high-frequency propertyIron compounds preparationMagnetic/electric field screeningCondensed matter physicsHexagonal ferrite

An object of the present invention is to provide, in order to deal with a high frequency band in which radio waves are expected to be increasingly used hereafter, a magnetoplumbite-type hexagonal ferrite material having significantly improved high-frequency property of magnetic permeability. Specifically, a magnetoplumbite-type hexagonal ferrite is represented by a composition formula: A(1-X)BxCx(D1yD2y)Fe(12-x-2y)O19 (where x: 0.1 to 0.3, y:0.1 to 0.5), wherein A is any one of Ba2+, Sr2+ and Ca2+, B is any one of La3+ and Nd3+, C and D1 are any one or more of Co2+, Mn2+, Mg2+, Zn2+, Cu2+ and Ni2+, and D2 is any one of Ti4+ and Zr4+.

Owner:RIKEN CO LTD

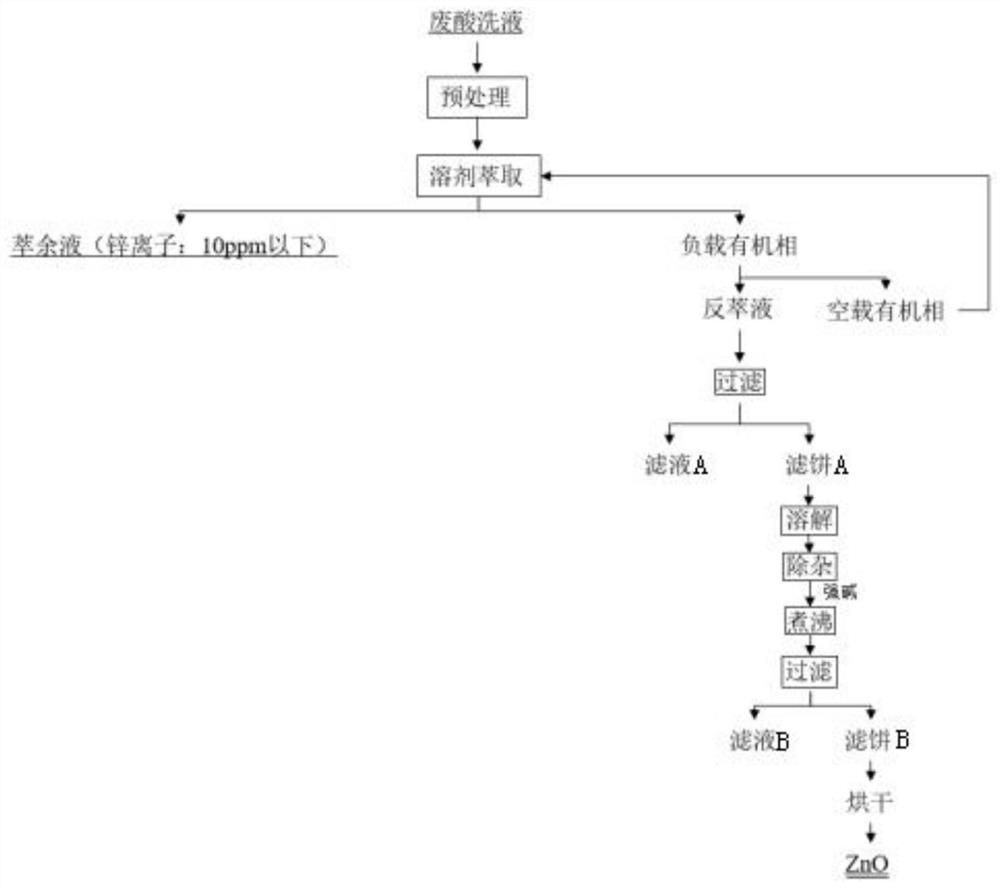

Resourceful treatment method for hot galvanizing pickling waste liquid

PendingCN112408459AHigh purityRealize resource processingIron compounds preparationZinc compounds preparationProcess engineeringSuspended matter

The invention discloses a resourceful treatment method of hot galvanizing pickling waste liquid, which comprises the following steps: filtering the pickling waste liquid to remove suspended matters and insoluble solids, and adding a reducing agent to reduce Fe < 3 + > in the pickling waste liquid into Fe < 2 + >; carrying out multi-stage countercurrent extraction on the pickling waste liquid through an extraction agent, carrying out reverse extraction on an organic phase through a reverse extraction agent, filtering reverse extraction liquid to obtain a filter cake A, dissolving the filter cake A with diluted hydrochloric acid, and adding a small amount of pickling waste liquid to obtain a solution A; adjusting the pH value of the solution A by using ammonia water and ammonium chloride toremove Fe < 3 + > to obtain a solution B; adding strong alkali into the solution B, and heating and boiling until no ammonia smell exists, so as to obtain a solution C containing white precipitate; and filtering the white precipitate to obtain a filter cake B, and drying the filter cake B to obtain zinc oxide. The recovery treatment method for the hot galvanizing pickling waste liquid is simple, low in energy consumption, safe to operate, low in investment cost, capable of achieving maximum resourceful utilization of the hot galvanizing pickling waste liquid, convenient to implement, easy to maintain and manage and worthy of being further popularized in industrial production.

Owner:KUNMING UNIV OF SCI & TECH

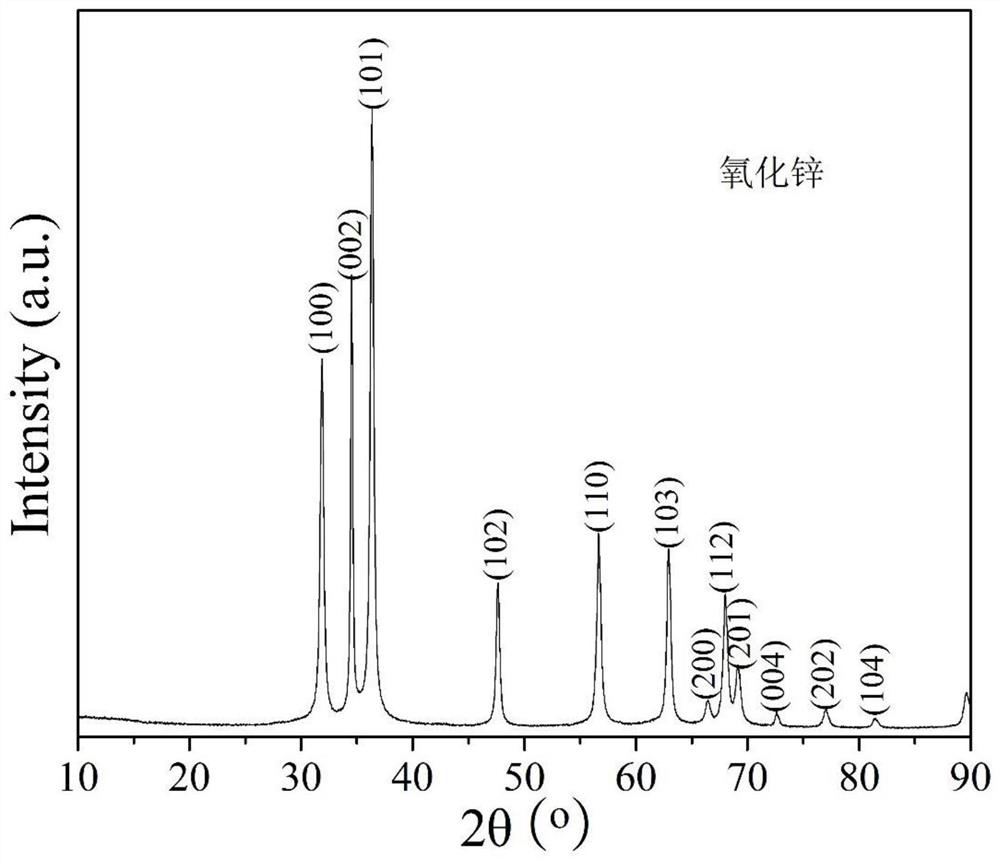

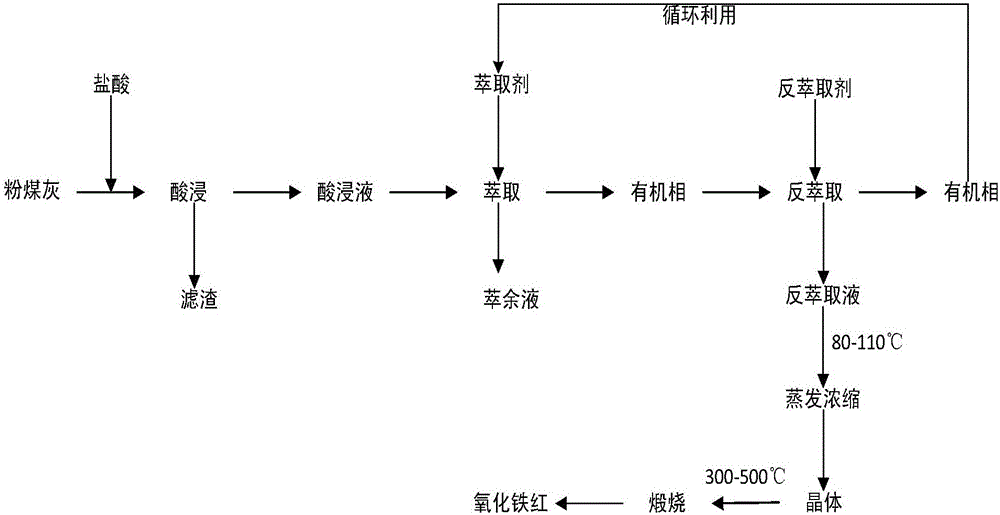

Method for preparing iron oxide red from coal ash

ActiveCN105819517AIncrease profitImprove qualityIron compounds preparationFerric oxidesEvaporationDigestion

The invention belongs to the field of environmental chemistry and discloses a method for preparing iron oxide red from coal ash .The method comprises the steps of 1, acid leaching, wherein digestion is conducted on coal ash with acid solution to obtain acid leaching solution; 2, extraction, wherein the acid leaching solution is extracted with an extracted organic phase to obtain extract liquor; 3, back extraction, wherein back extraction is conducted on the extract liquor with a back extractant to obtain back extraction solution; 4, evaporation and concentration, wherein the back extraction solution is evaporated, concentrated and crystallized; 5, calcination, wherein crystals are calcined to obtain iron oxide red .According to the method, iron oxide red is prepared with coal ash as the raw material, recycling application of coal ash waste is achieved, the utilization rate of valuable metal in coal ash is increased, and the environment problem is solved; an adopted extraction agent can be recycled, so that industrial production cost is reduced; the quality of prepared iron oxide red is high, and purity is 95% or more and meets the GB1863-2008 product technology requirement.

Owner:JINAN UNIVERSITY

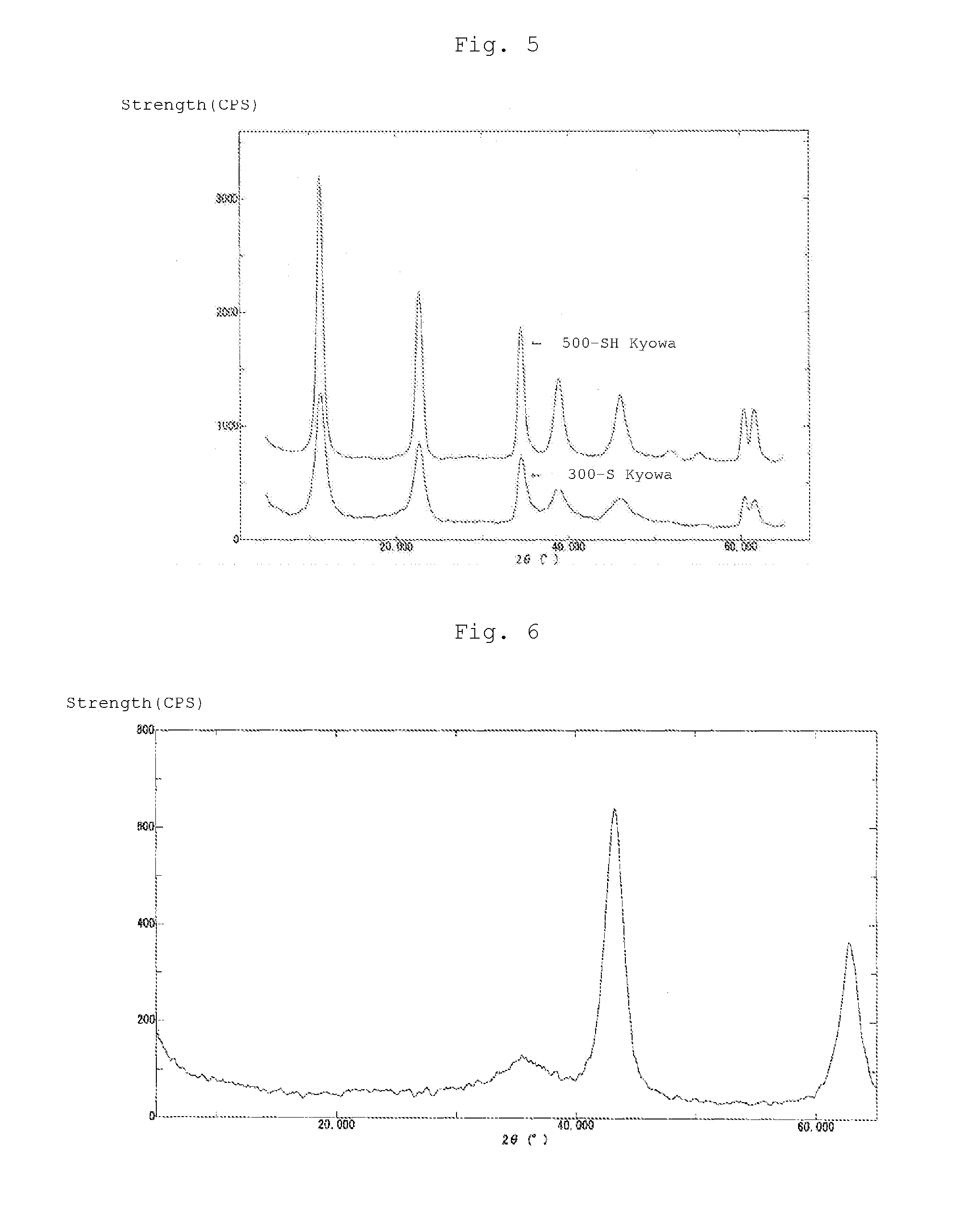

Magnetic hydrotalcite composite and process for manufacturing same

InactiveCN105473503ALess agglutinationGood dispersionIron compounds preparationOther chemical processesUltravioletWastewater

The purpose of the present invention is to provide: a magnetic hydrotalcite composite which is useful in wastewater treatment, ultraviolet absorption, electromagnetic wave absorption, acid gas absorption or other fields; and a process for manufacturing the same. A magnetic hydrotalcite composite which comprises an inner layer and an outer layer and in which the inner layer is made of a hydrotalcite compound and the outer layer is made of a ferrite compound.

Owner:KYOWA CHEM IND

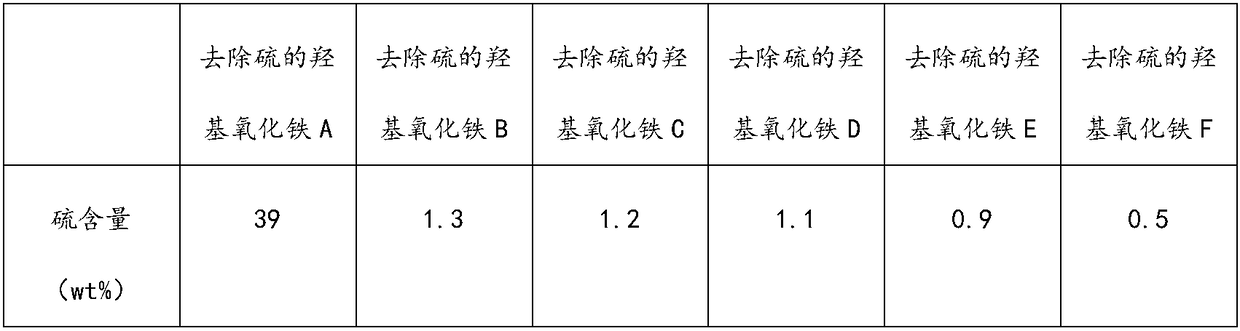

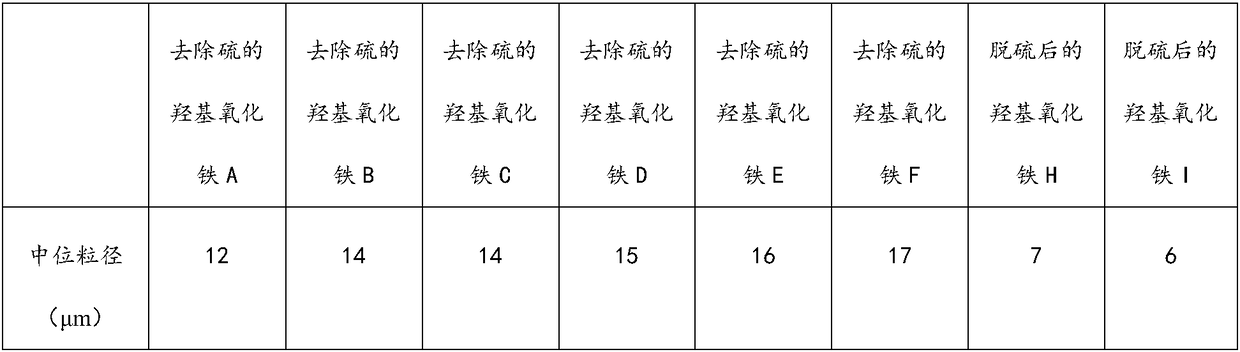

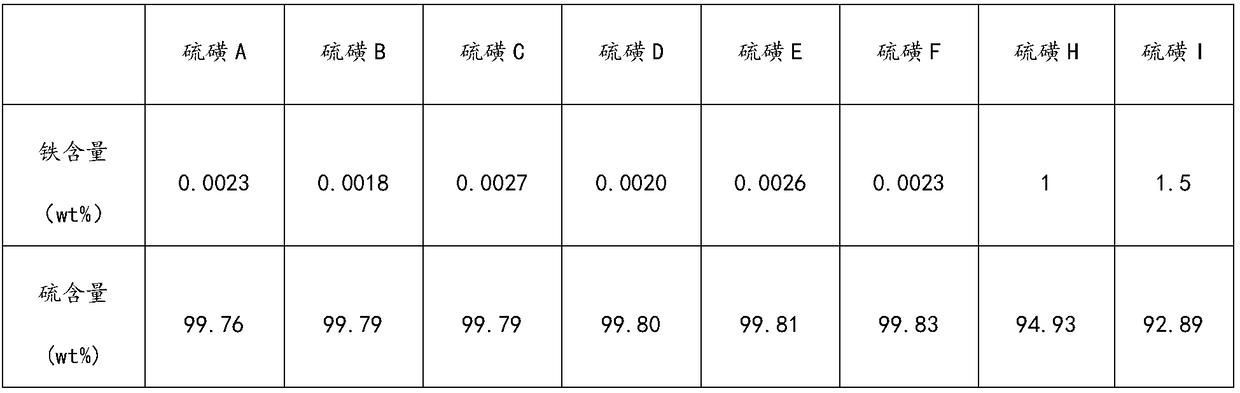

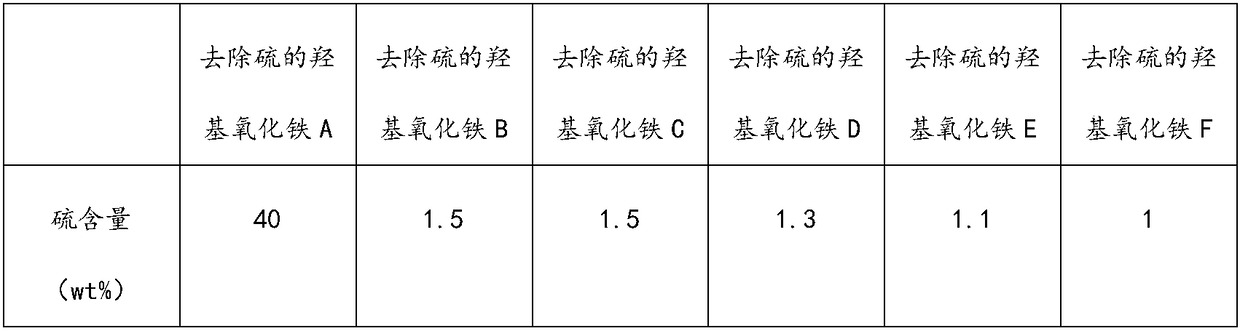

Method for removing sulfur on hydroxyl oxidize iron and application of sulfur-removed hydroxyl oxidize iron

ActiveCN108298592AEnsure desulfurization abilityGuaranteed purityIron compounds preparationIron oxides/hydroxidesOrganic solventSulfur containing

The invention provides a method for removing sulfur on hydroxyl oxidize iron. By strictly controlling the water content of sulfur-containing hydroxyl oxidize iron, the desulfuration capability of hydroxyl oxidize iron and the purity of recycled sulfur are effectively ensured on the premise of efficiently separating sulfur from hydroxyl oxidize iron, which is because when the water content of hydroxyl oxidize iron is too high, the water is dispersed into fine particles in an organic solvent, which not only reduces the desulfurization capability of hydroxyl oxidize iron, but also causes the recycled sulfur to contain a large number of iron.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

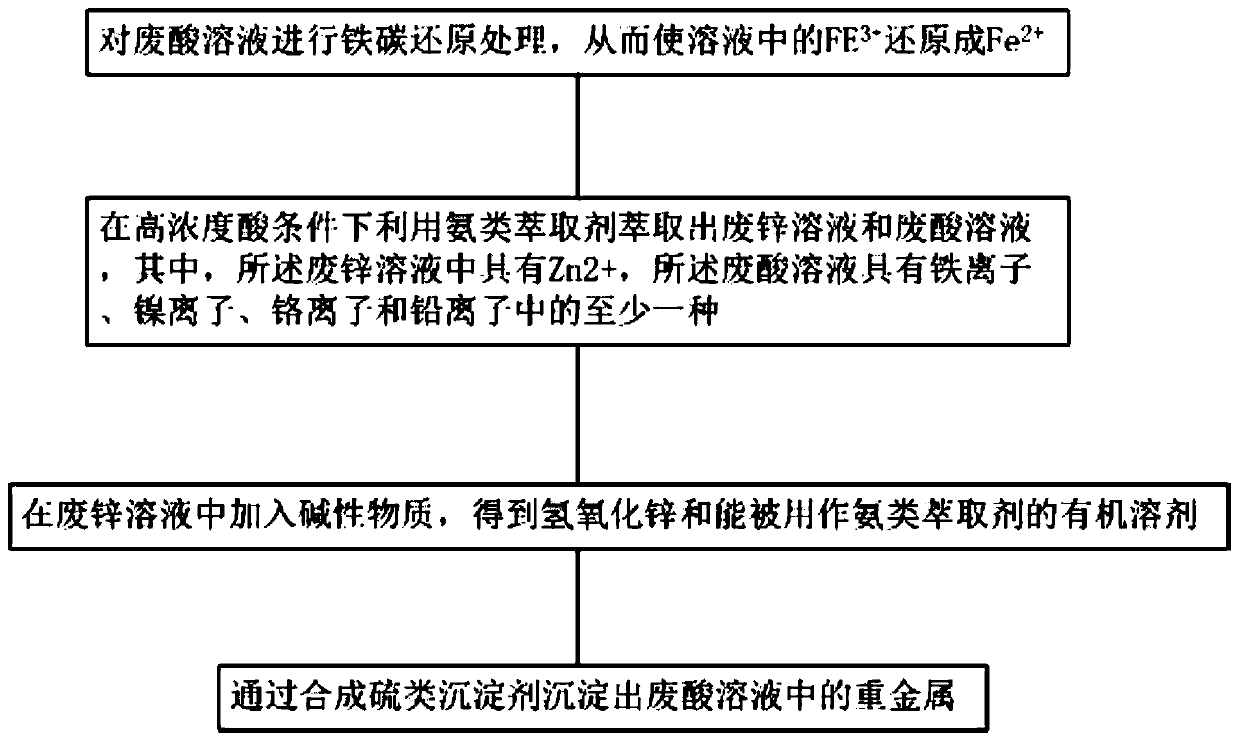

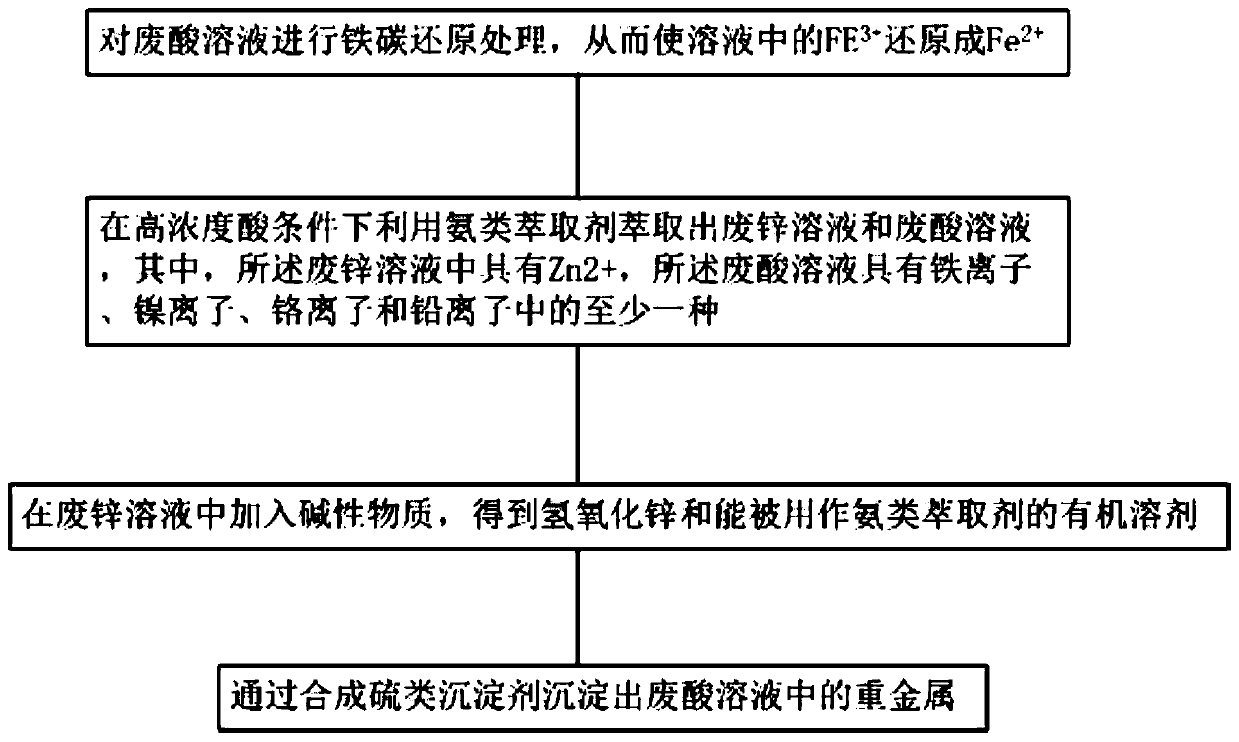

Treatment method of waste acid solution containing heavy metals

InactiveCN111170509ALow free acidLow costIron compounds preparationZinc compounds preparationFree acidEnvironmental chemistry

The invention provides a treatment method of a waste acid solution containing heavy metals, which comprises the following steps: carrying out iron-carbon reduction treatment on the waste acid solutionto reduce Fe< 3 + > in the solution into Fe < 2 + >; under the condition of high-concentration acid, adopting an ammonia extraction agent toextracta waste zinc solution and a waste acid solution, wherein the waste zinc solution contains Zn < 2 + >, and the waste acid solution contains at least one of iron ions, nickel ions, chromium ions and lead ions; adding an alkaline substance into the wastezinc solution to obtain zinc hydroxide and an organic solvent can be used as theammonia extraction agent; and precipitating heavy metals in the waste acid solutionby a synthestic sulfur precipitant. Compared with the prior art, the method has the following advantages that ferric ions are reduced, free acid is reduced and a small amount of heavy metalsarereplaced by utilizing an iron elementary substance while iron-carbon pretreatment is carried out; the zinc separation rate can reach 99.8% or above; the obtained zinc oxide product with the content of 98% or above can be used for selling; one part of an obtained supernatant can be used for circulating water, and the other part can be used for industrial water.

Owner:大康环境技术(苏州)有限公司

Magnetoplumbite-type hexagonal ferrite

ActiveUS9338932B2Improve magnetic propertiesImprove propertiesIron compounds preparationMagnetic/electric field screeningMaterials scienceHexagonal ferrite

An object of the present invention is to provide, in order to deal with a high frequency band in which radio waves are expected to be increasingly used hereafter, a magnetoplumbite-type hexagonal ferrite material having significantly improved high-frequency property of magnetic permeability. Specifically, a magnetoplumbite-type hexagonal ferrite is represented by a composition formula: A(1-X)BxCx(D1yD2y)Fe(12-x-2y)O19 (where x: 0.1 to 0.3, y:0.1 to 0.5), wherein A is any one of Ba2+, Sr2+ and Ca2+, B is any one of La3+ and Nd3+, C and D1 are any one or more of Co2+, Mn2+, Mg2+, Zn2+, Cu2+ and Ni2+, and D2 is any one of Ti4+ and Zr4+.

Owner:RIKEN CO LTD

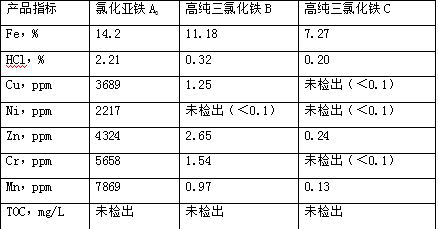

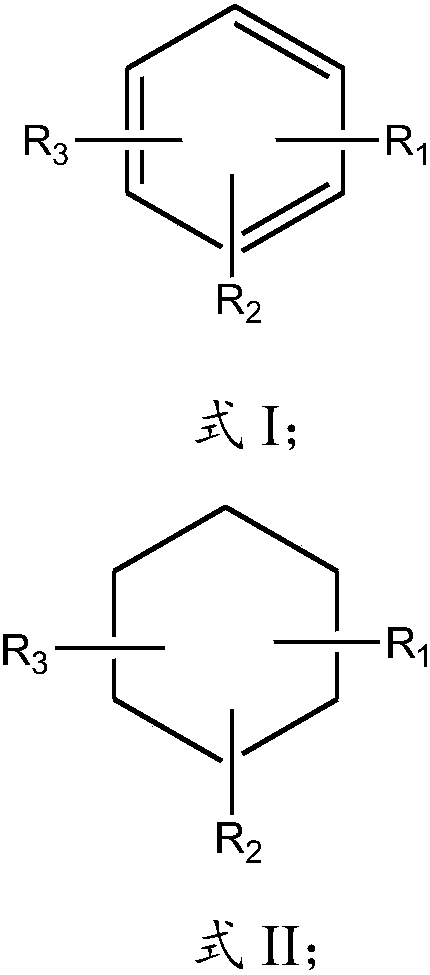

Novel hydrophobic eutectic solvent separation and purification system of weak protonic acid, and method for purifying weak protonic acid

ActiveCN111359258AHigh purityHigh yieldIron compounds preparationHydrogen sulfidesPhysical chemistryNetwork structure

The invention relates to the technical field of biology and chemical engineering, and concretely relates to a novel hydrophobic eutectic solvent separation and purification system of a weak protonic acid, and a method for purifying the weak protonic acid. The novel hydrophobic eutectic solvent separation and purification system of the weak protonic acid consists of a hydrogen bond donor, and a hydrogen bond receptor and an accelerant which are in a eutectic solvent; the weak protonic acid in a raw material solution is used as a hydrogen bond donor; and functional groups existing in the hydrogen bond receptor and the accelerant in the eutectic solvent interact with the weak protonic acid to form the novel hydrophobic eutectic solvent separation and purification system with a linear, planaror multi-dimensional network structure. The system and the method have the advantages of simple process, low energy consumption, high recovery rate, environmental friendliness, less pollution and thelike.

Owner:山东金原德丰科技开发有限责任公司

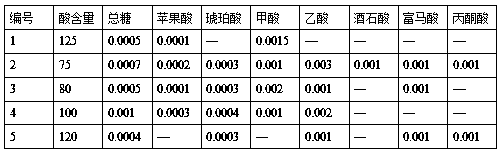

Method for purifying ferric trichloride

PendingCN112661196AHigh purityImprove separation and extraction efficiencyIron compounds preparationIron halidesEtchingIron(III) chloride

The invention discloses a purification method of ferric trichloride, which comprises the following steps: oxidizing iron-containing chloride into ferric trichloride, adding industrial hydrochloric acid and butyl acetate, extracting, standing for layering, taking an organic phase, adding a stripping agent, carrying out reverse extraction to obtain ferric trichloride with ultralow impurity content, evaporating, concentrating, and removing organic matters to obtain high-purity ferric trichloride. Recyclable organic phase. The purification process is not limited by the purity of production raw materials, is simple to operate and low in equipment investment, and does not use toxic extractant. The ferric trichloride product produced by the process disclosed by the invention can be applied to the fields of drinking water treatment, medical intermediates, analytical testing, precision etching and the like.

Owner:3R ENVIRONMENTAL TECH CO LTD +1

Method for separating FeOOH and sulfur and applications of sulfur free FeOOH

ActiveCN108314088AEnsure desulfurization abilityDecreased desulfurization capacityIron compounds preparationIron oxides/hydroxidesOrganic solventSulfur containing

The invention provides a method for separating FeOOH and sulfur and applications of sulfur free FeOOH. According to the method, the water content of sulfur containing FeOOH is strictly controlled, onthe premise that sulfur and FeOOH are separated efficiently, the desulfurization performance of FeOOH is guaranteed, and the purity of recovered sulfur is ensured. If the water content of FeOOH is toohigh, FeOOH is dispersed in an organic solvent to form micro particles, the desulfurization performance of FeOOH is reduced, and recovered sulfur contains a large amount of iron.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

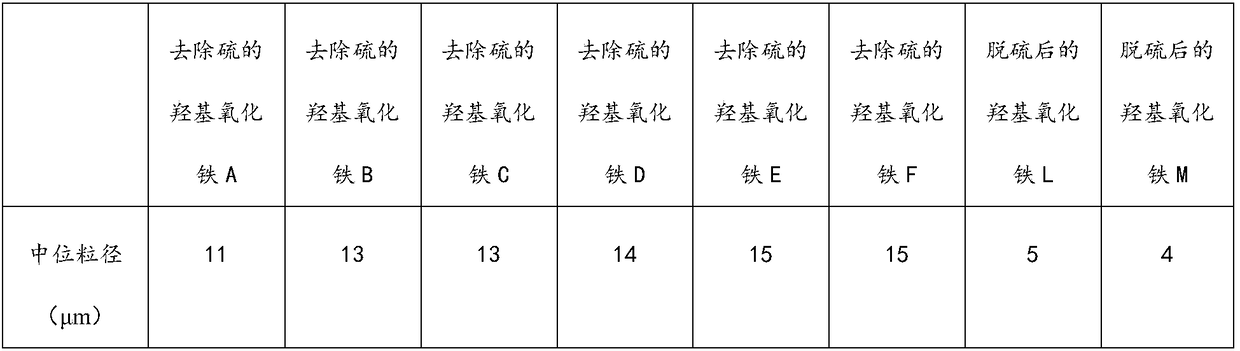

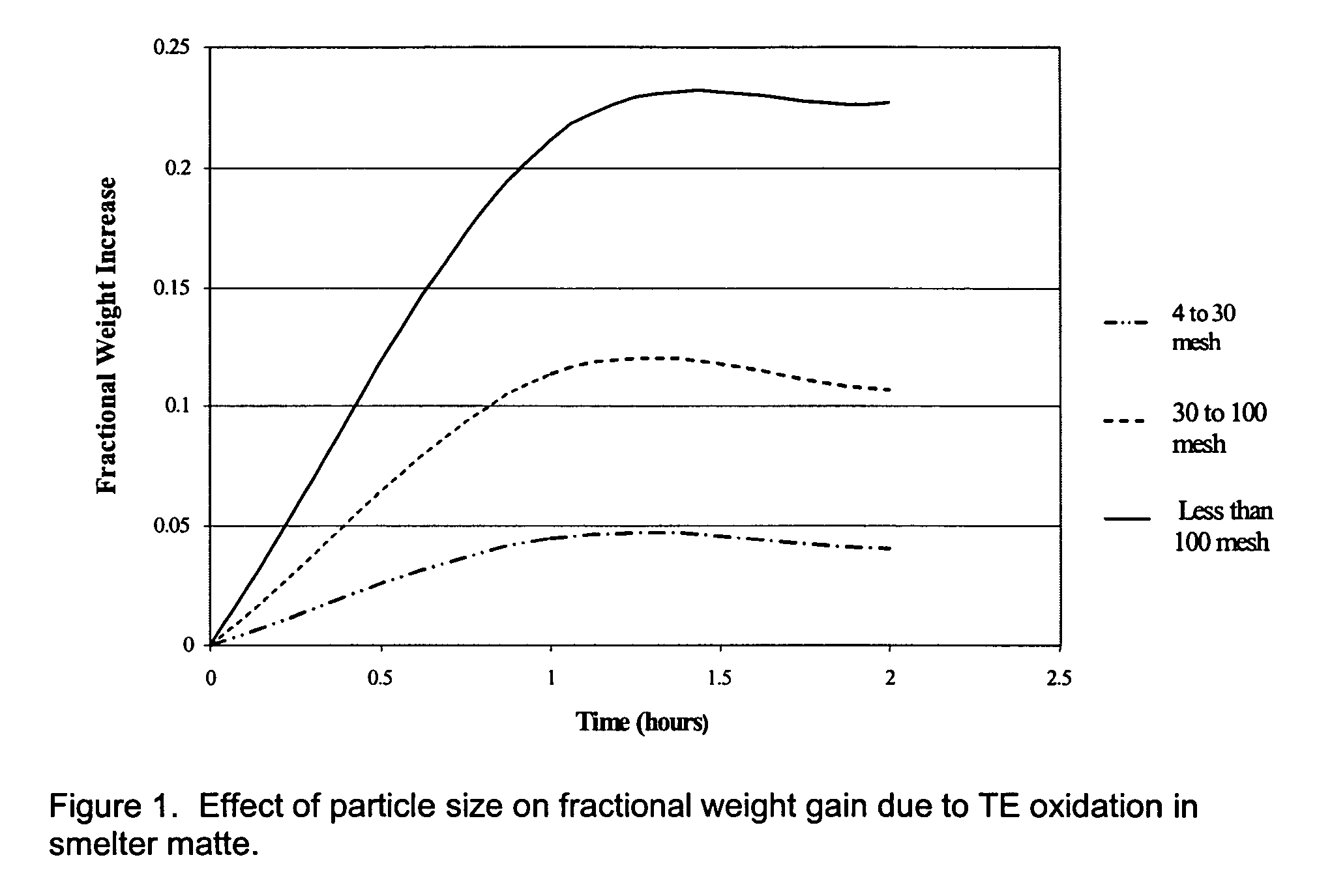

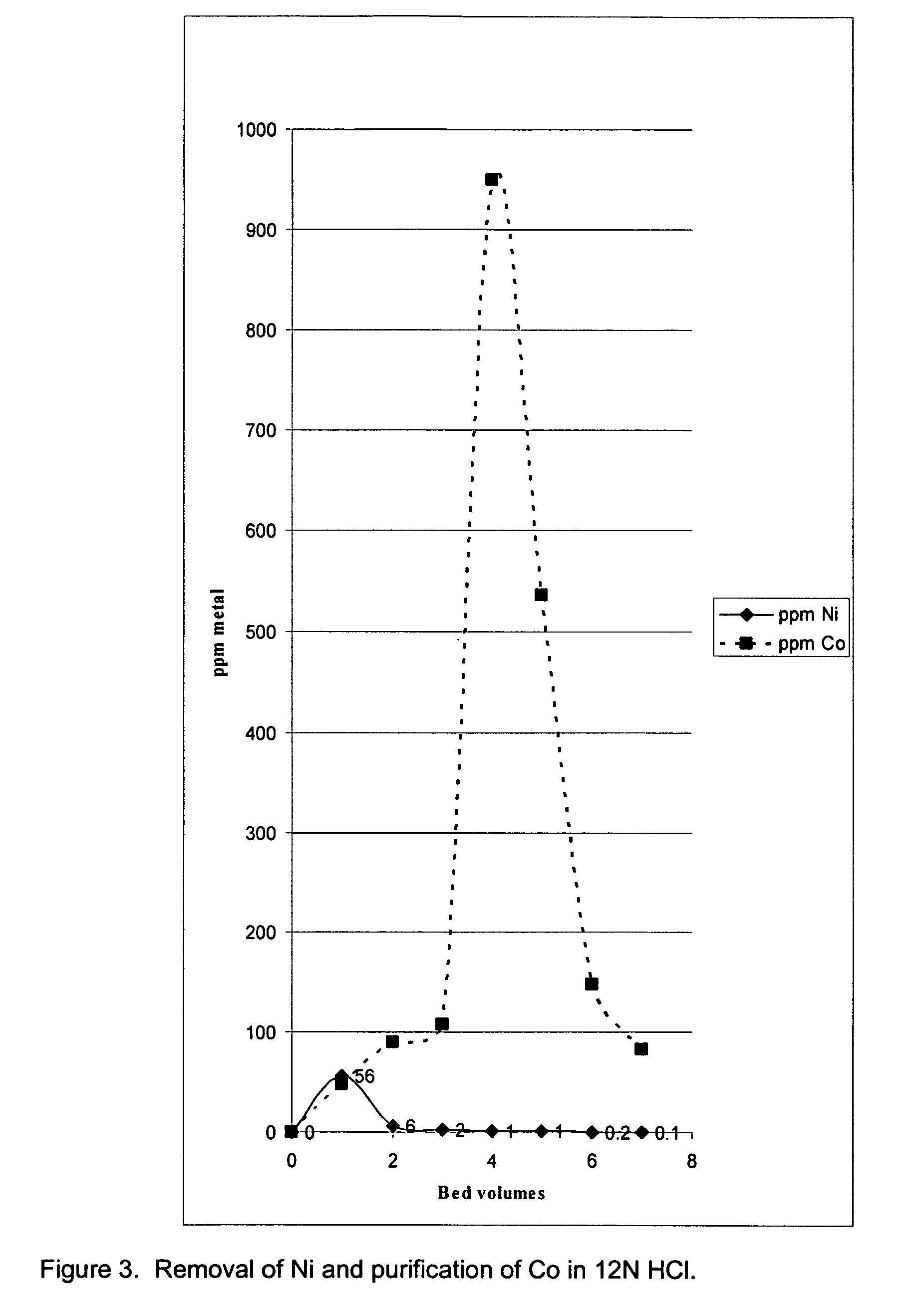

Process for the extraction of specific transition metals with gaseous HCL

A process is disclosed for separation and recovery of vanadium, molybdenum, iron, tungsten, cobalt and nickel from alumina-based materials, mattes, ores, manufacturing by-products and waste. These elements are oxidized. The oxides are reacted with gaseous HCl to form volatile chloride-bearing compounds that subsequently sublimate. The volatile compounds are condensed in a downward-stepped thermal gradient that allows collection of moderate to high purity compounds of individual elements with exception of a nickel-cobalt co-condensate. Nickel is separated from cobalt by precipitation of nickel chloride from concentrated HCl pressurized with gaseous HCl.

Owner:METALS RECOVERY TECH

Procedure for obtaining scorodite with a high arsenic content from acidic solutions with high content of sulfuric acid

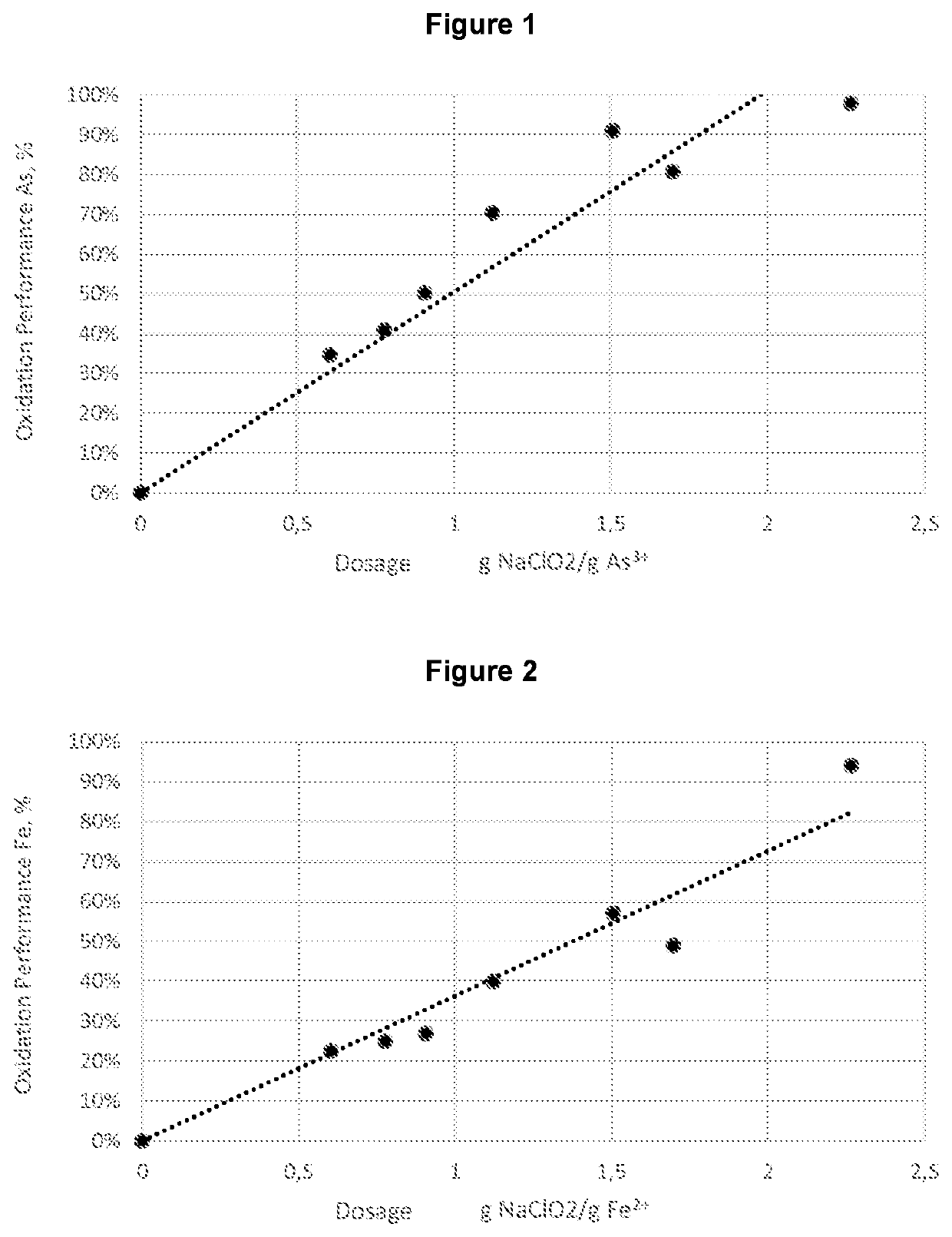

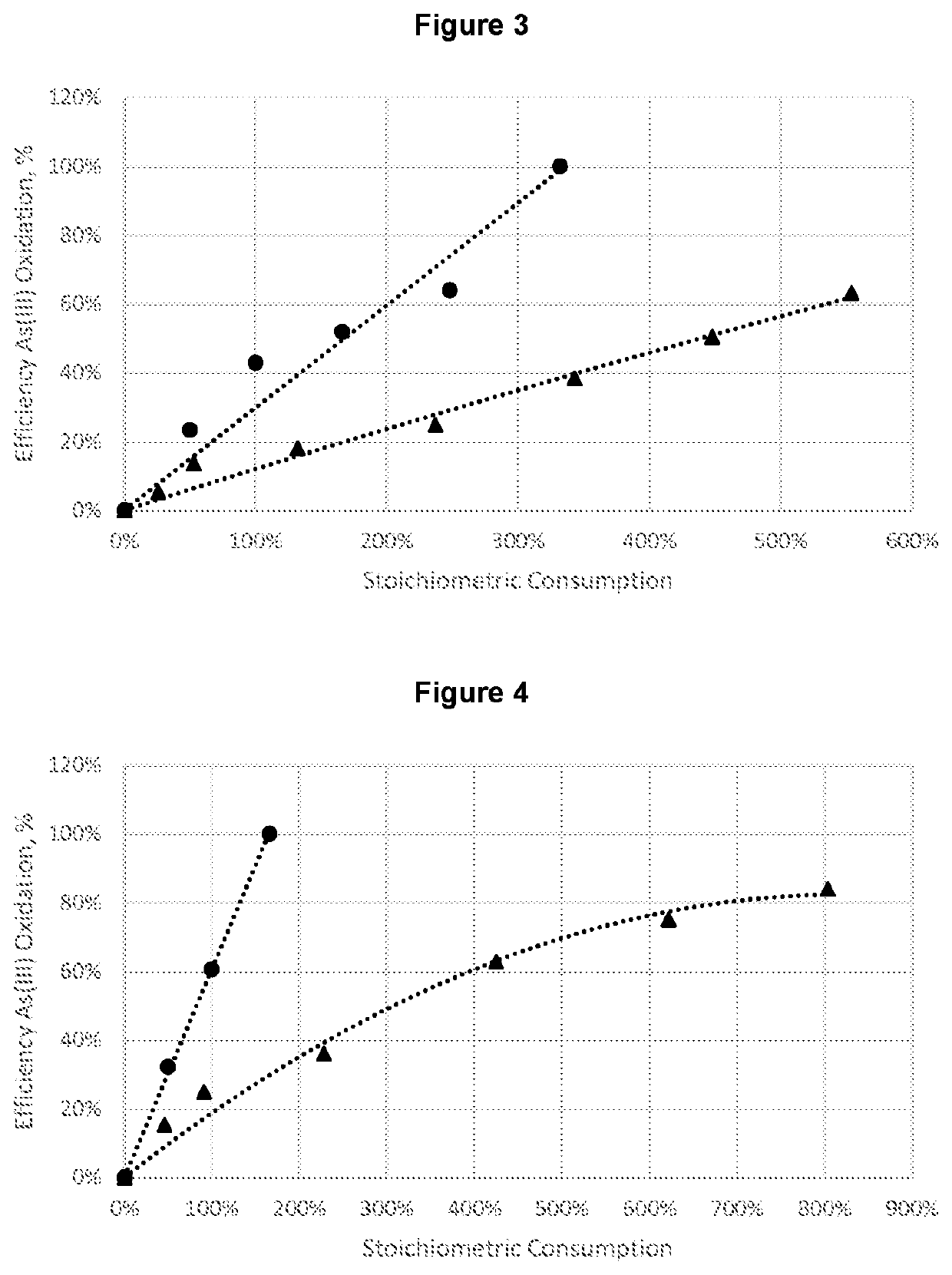

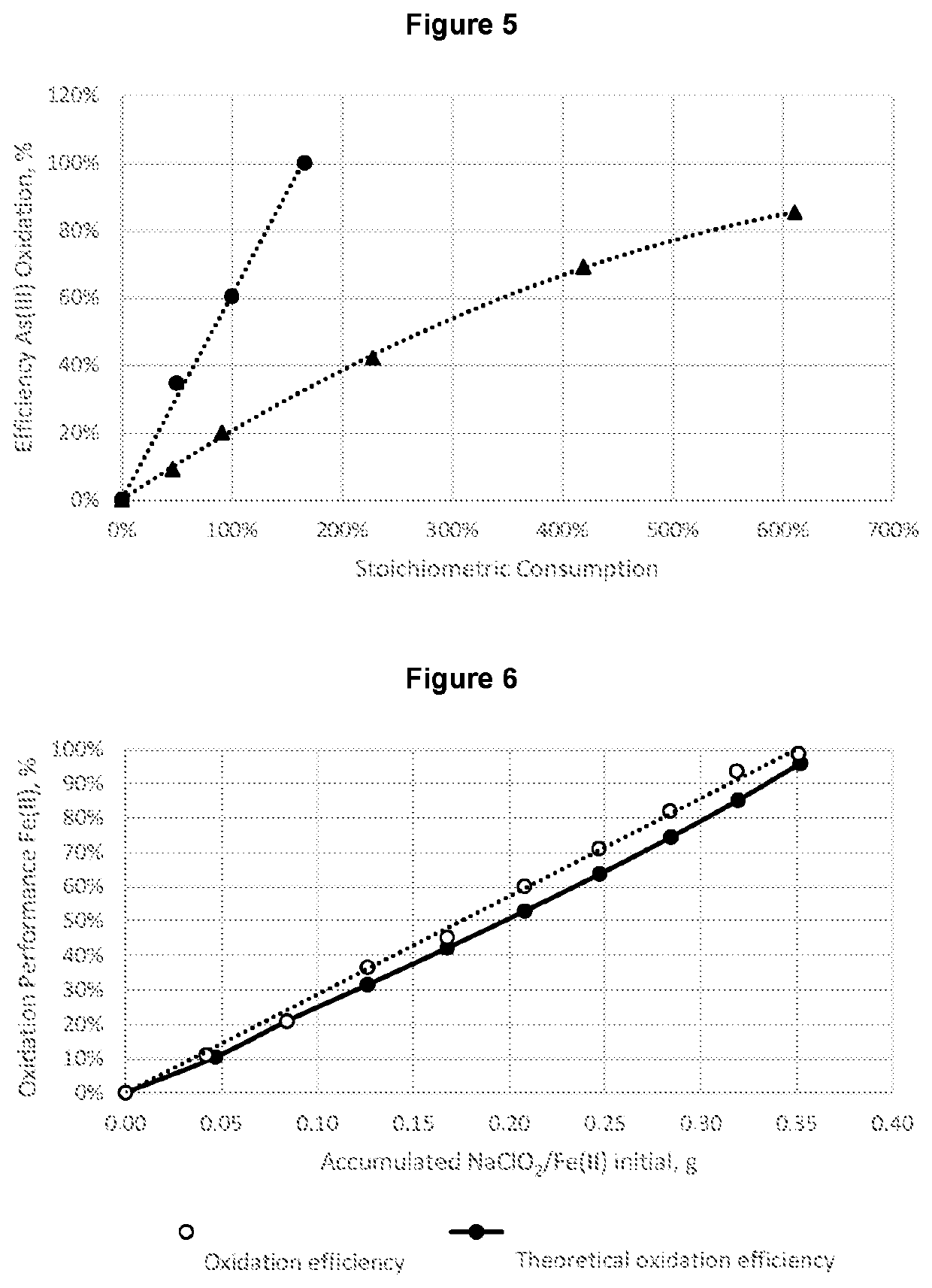

ActiveUS20200198985A1Lower the volumeEfficiently oxidize arsenite ionWaste water treatment from quariesWater treatment parameter controlEnvironmental engineeringScorodite

The present invention provides a process that allows the oxidation of trivalent arsenic and ferrous ion, simultaneous with neutralization of the acid solution to be treated, the precipitation of arsenic and oxidized ferric iron added in a molar ratio Fe:As determined at a defined pH, all of the above with a high efficiency of precipitation of arsenic as ferric arsenate or scorodite, obtaining a final residue stable in the long term, characterized by their higher content of arsenic in a lower volume compared with the procedures described in the state of the prior art.

Owner:ECOMETALES LTD

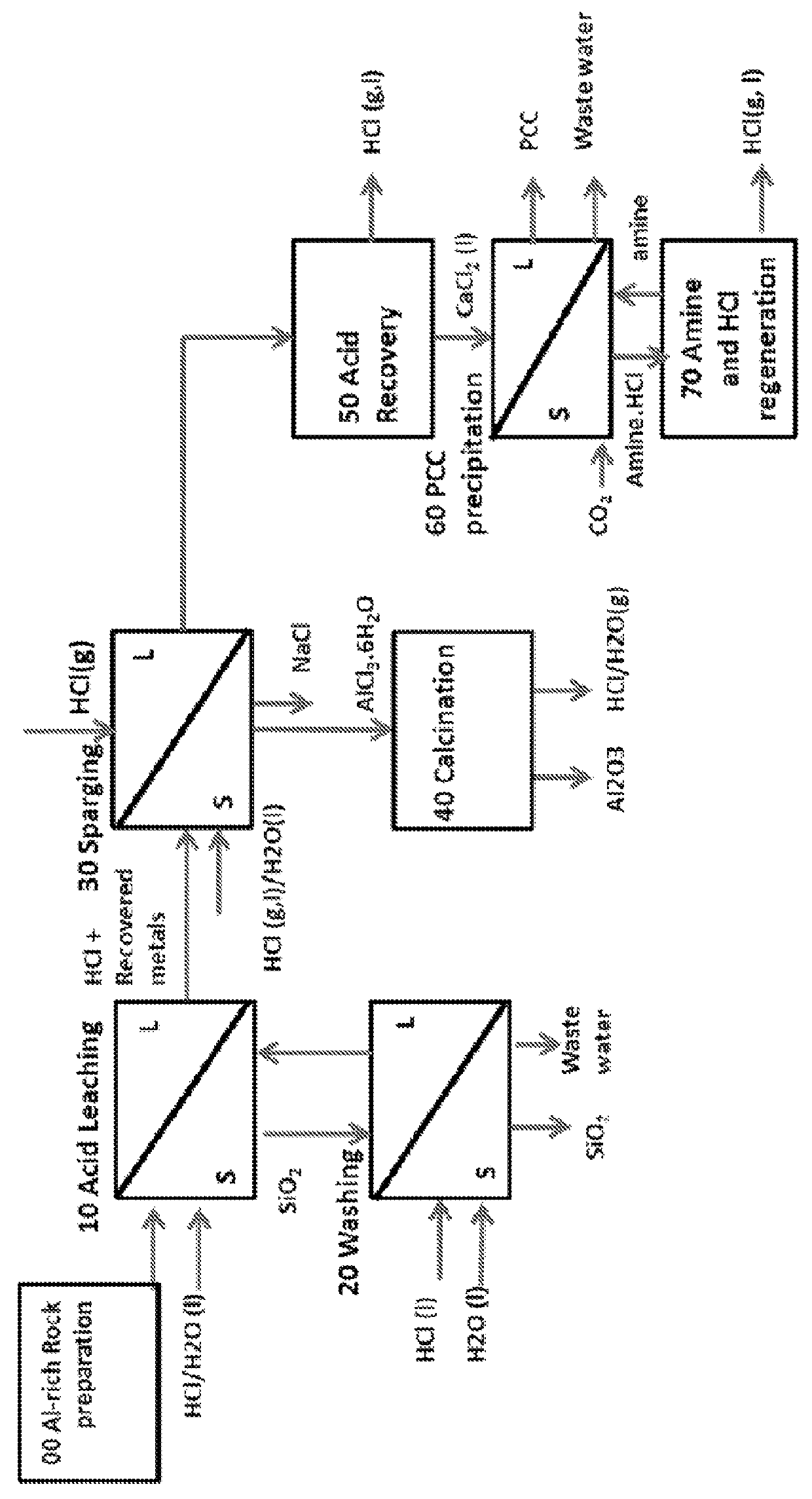

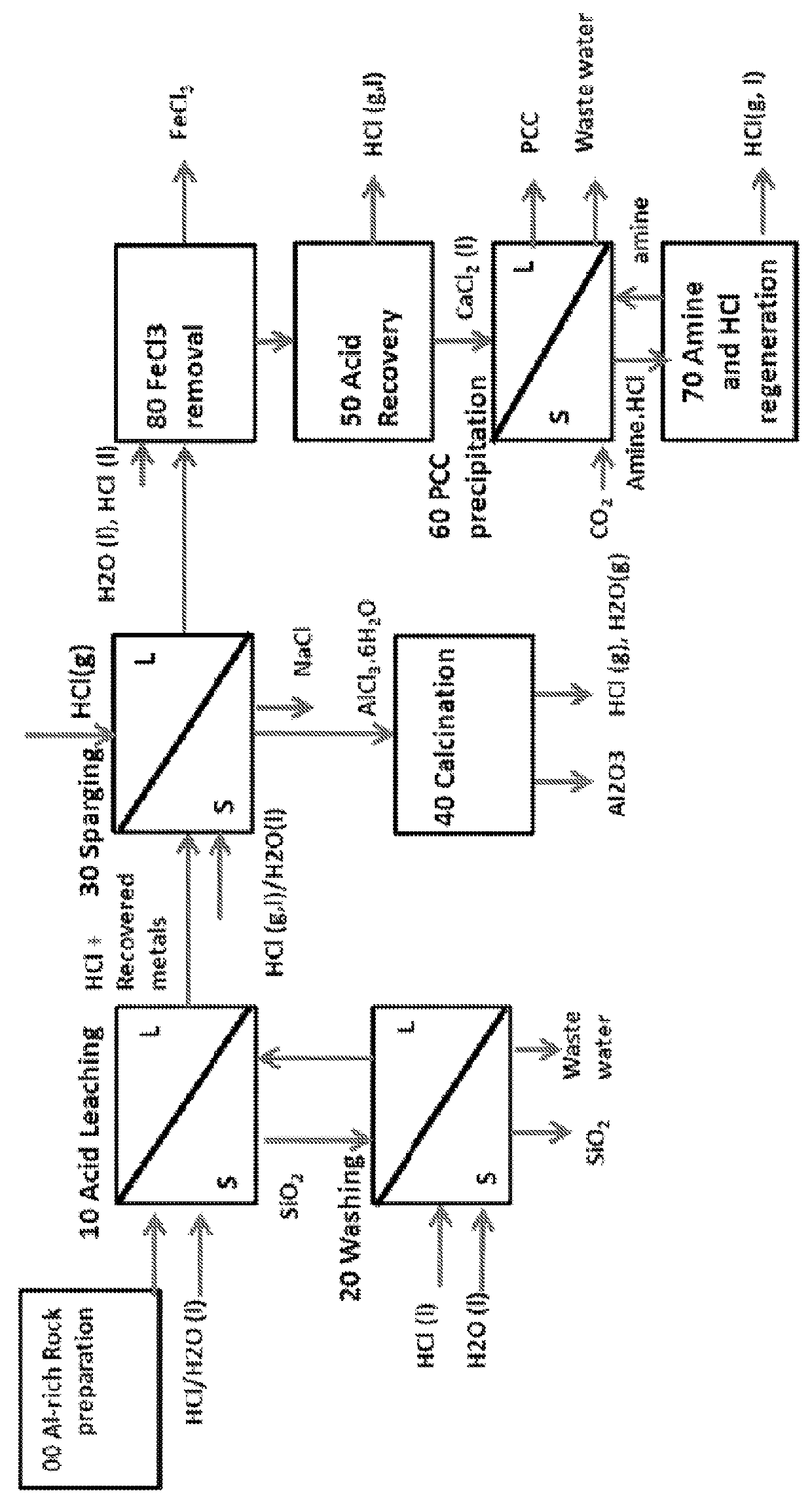

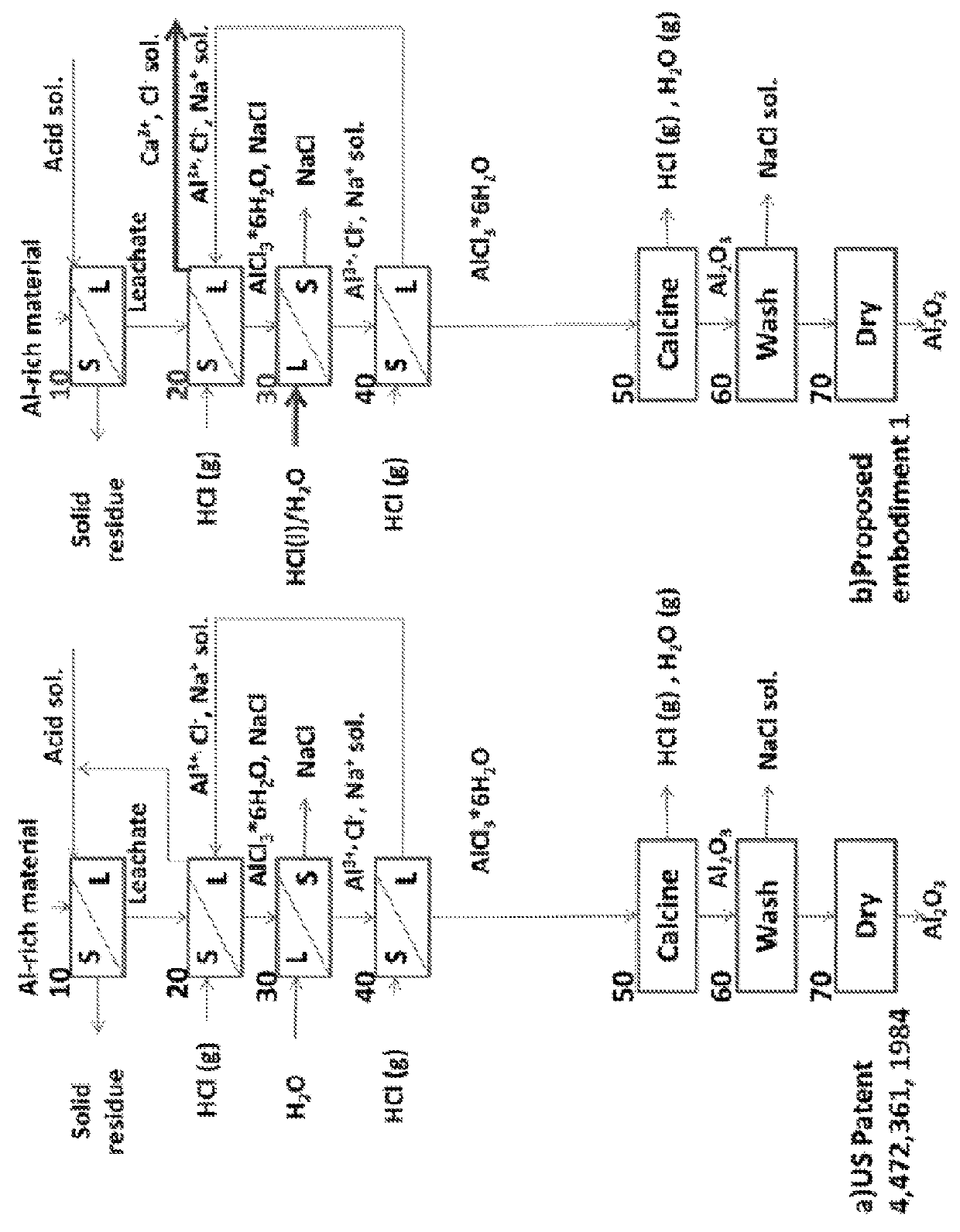

Alumina and carbonate production method from AI-rich materials with integrated CO2 utilization

ActiveUS9963352B2Safely commercializedSafely depositedCalcium/strontium/barium carbonatesProductsChemical treatmentMetal chloride

A process for alumina and carbonate production from aluminium rich materials with integrated CO2 utilization, comprising: comminuting and leaching Al-rich materials in concentrated HCl; separating unreacted material from metal chloride solution; separating Al3+ from solution by crystallization of AlCl3.6H2O; calcination of AlCl3.6H2O with HCl recovery; precipitation of metal carbonates from CO2; regeneration of HCl and extractive amines; the Al3+ separation the facilitated by increasing HCl concentration; the calcination being performed in two steps, one in the range 400 and 600° C. to generate a HCl-rich gas and one above 600° C. to produce Al2O3; for precipitating metal carbonates, mixing the metal chloride solution with an organic solution containing a selected amine and contacting the mixture with a CO2-containing gas, thereby also extracting HCl by formation of an ammonium chloride salt complex; processing thermally or chemically the organic solution to regenerate the amine for recirculation.

Owner:NORDIC MINING +1

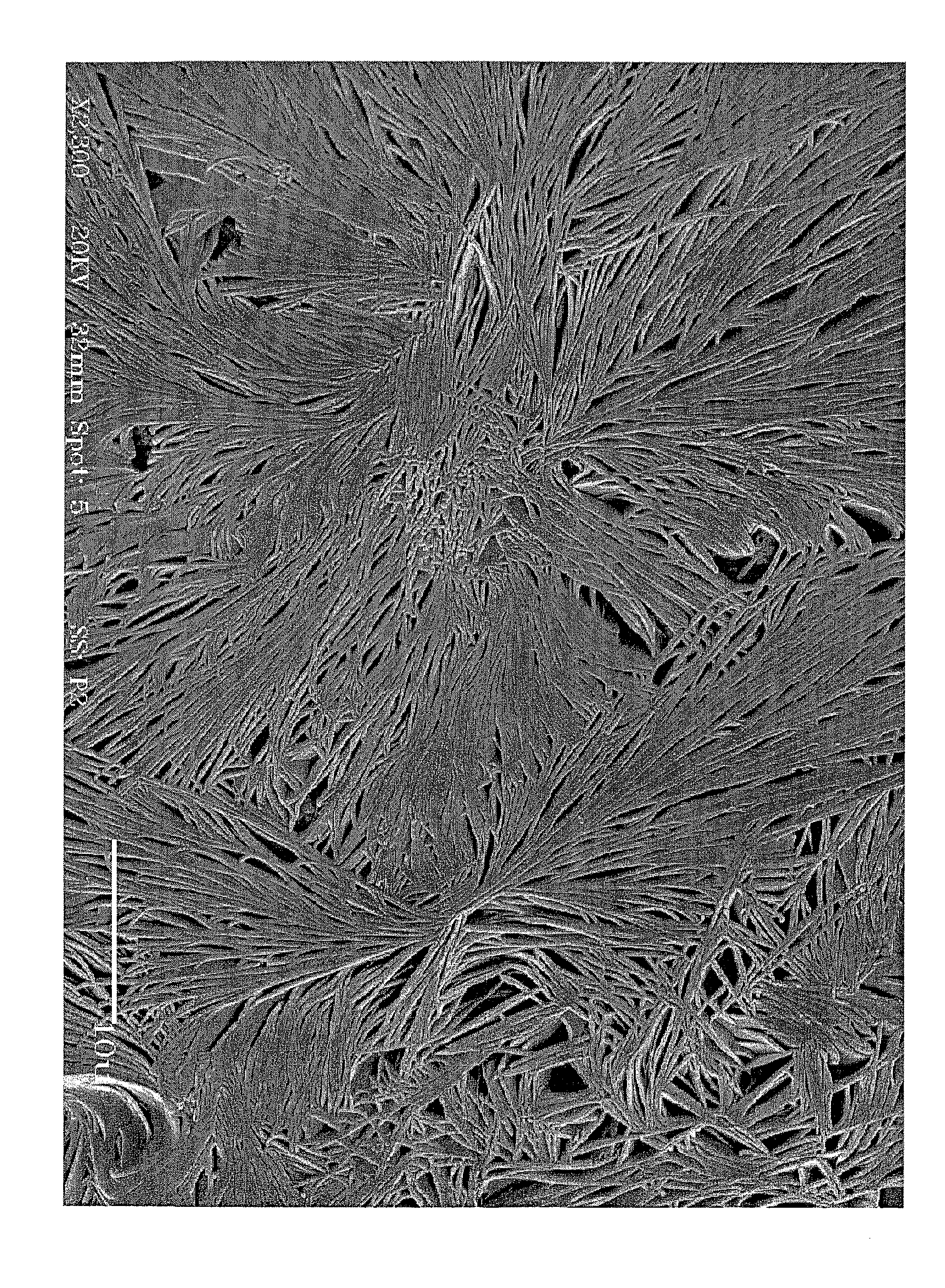

Method of making dendritic magnetic nanostructures

Magnetic nanostructures comprised of an assembly of magnetic nanorods held together by dipole forces in a dendritic pattern and their method of manufacture. The dendritic magnetic nanostructures are prepared at room temperature by applying a magnetic field to a reverse micelle system wherein at least one salt of a magnetic metal is being precipitated within the core of the reverse micelle.

Owner:UNIVERSITY OF LOUISIANA AT LAFAYETTE

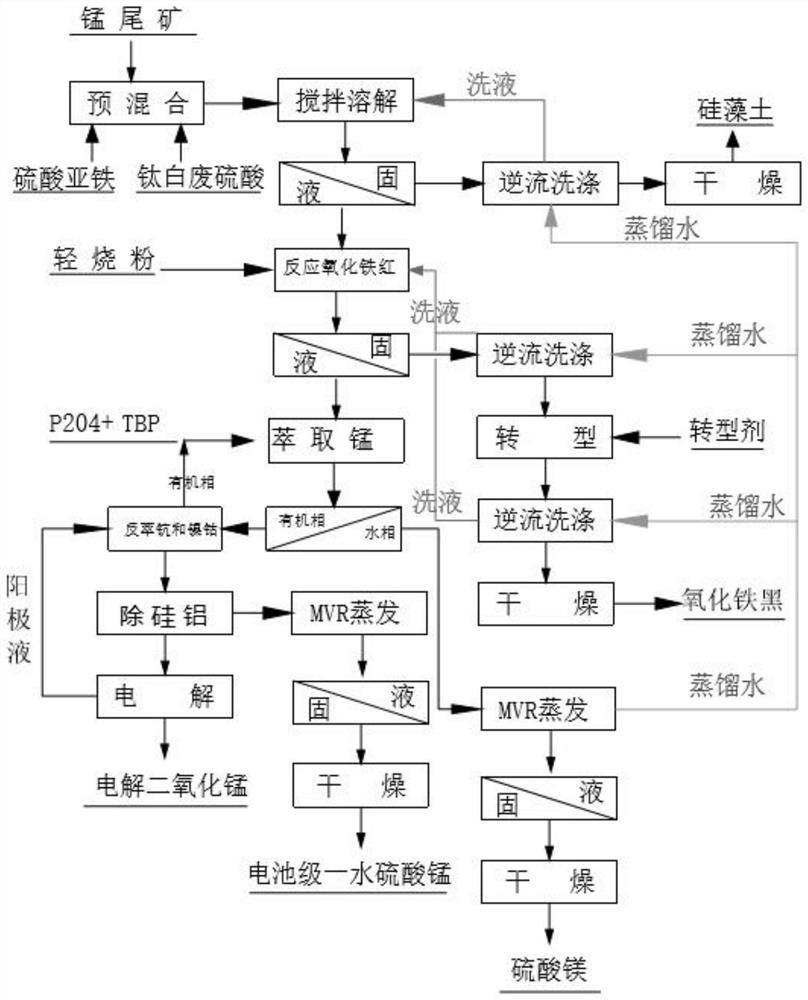

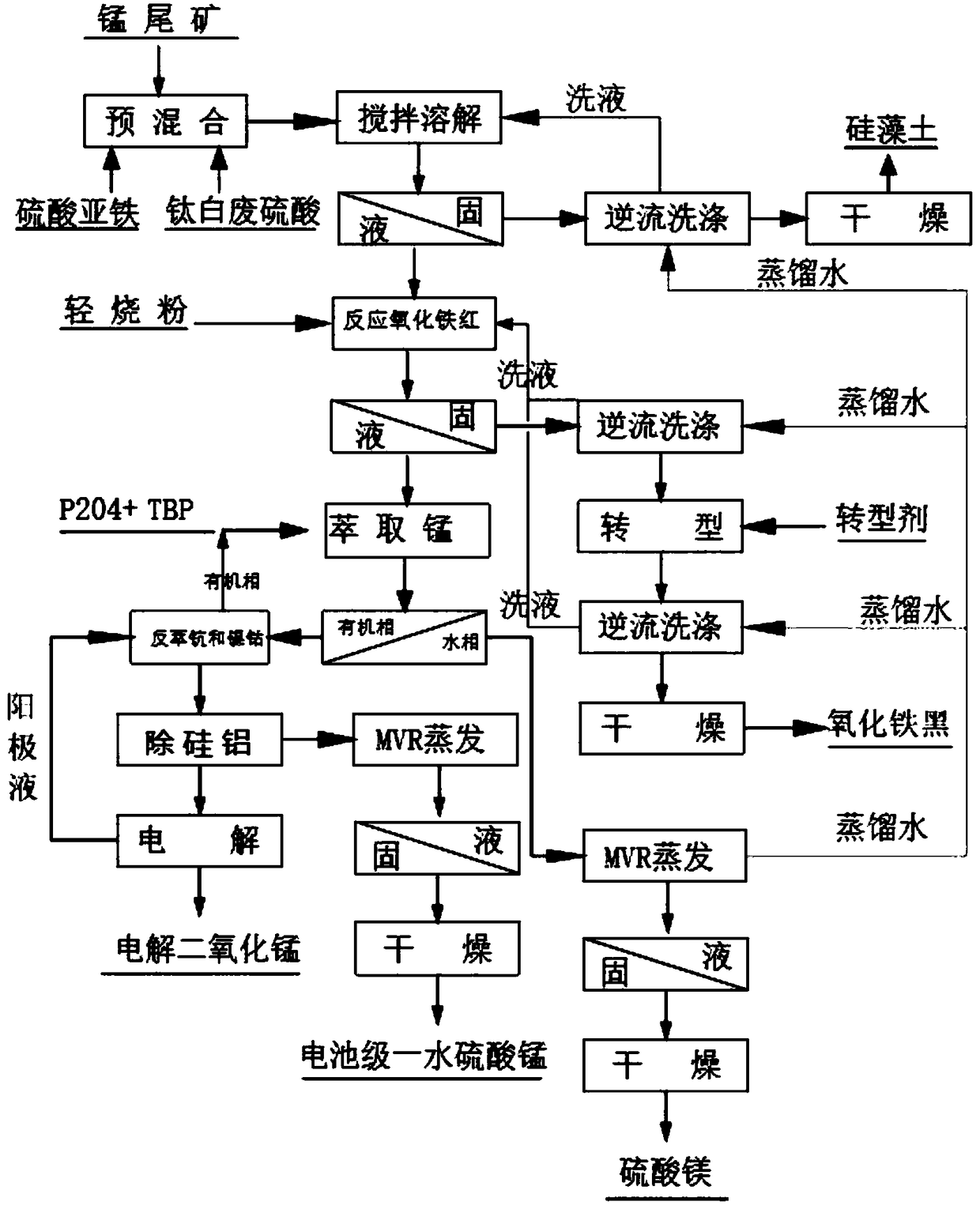

A method for producing electrolytic manganese dioxide by using manganese tailings and titanium white waste sulfuric acid

ActiveCN109399723BReduce consumptionReduce manufacturing costIron compounds preparationFerroso-ferric oxidesPhosphateEcological safety

The invention discloses a method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid. The method particularly includes carrying out reduction leaching and fine grinding on the manganese gangue by the aid of the titanium dioxide waste sulfuric acid; carrying out solid-liquid separation to obtain a white filter residue used as diatomaceous earth; extracting leach liquid by di-(2-ethylhexyl)phosphate extraction agents; carrying out saponification by light burning powder (or magnesium oxide); removing impurities and then carrying out electrolysis to obtain the electrolytic manganese dioxide, iron black and magnesium sulfate. The iron black and the magnesium sulfate are byproducts. The method has the advantages that the manganese gangue and titanium dioxide waste acid can be synergistically disposed by the aid of the method, accordingly, the problems in the aspect of ecological safety due to manganese gangue accumulation can be solvedby the aid of the method, a brand new way can be provided to utilizing the titanium dioxide waste acid, and the comprehensive utilization additional values of the manganese gangue and the titanium dioxide waste acid can be increased; the electrolytic manganese dioxide prepared by the aid of the method is high in quality and low in production cost, processes for the electrolytic manganese dioxide are simple, the manganese gangue and the titanium dioxide waste sulfuric acid can be completely recycled, secondary pollution can be prevented, wastewater is free of discharge, and the method is favorable for protecting environments and comprehensively utilizing resources.

Owner:宣城市安工大工业技术研究院有限公司

Method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid

ActiveCN109399723AReduce consumptionReduce manufacturing costIron compounds preparationFerroso-ferric oxidesElectrolysisPhosphate

The invention discloses a method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid. The method particularly includes carrying out reduction leaching and fine grinding on the manganese gangue by the aid of the titanium dioxide waste sulfuric acid; carrying out solid-liquid separation to obtain a white filter residue used as diatomaceous earth; extracting leach liquid by di-(2-ethylhexyl)phosphate extraction agents; carrying out saponification by light burning powder (or magnesium oxide); removing impurities and then carrying out electrolysis to obtain the electrolytic manganese dioxide, iron black and magnesium sulfate. The iron black and the magnesium sulfate are byproducts. The method has the advantages that the manganese gangue and titanium dioxide waste acid can be synergistically disposed by the aid of the method, accordingly, the problems in the aspect of ecological safety due to manganese gangue accumulation can be solvedby the aid of the method, a brand new way can be provided to utilizing the titanium dioxide waste acid, and the comprehensive utilization additional values of the manganese gangue and the titanium dioxide waste acid can be increased; the electrolytic manganese dioxide prepared by the aid of the method is high in quality and low in production cost, processes for the electrolytic manganese dioxide are simple, the manganese gangue and the titanium dioxide waste sulfuric acid can be completely recycled, secondary pollution can be prevented, wastewater is free of discharge, and the method is favorable for protecting environments and comprehensively utilizing resources.

Owner:宣城市安工大工业技术研究院有限公司

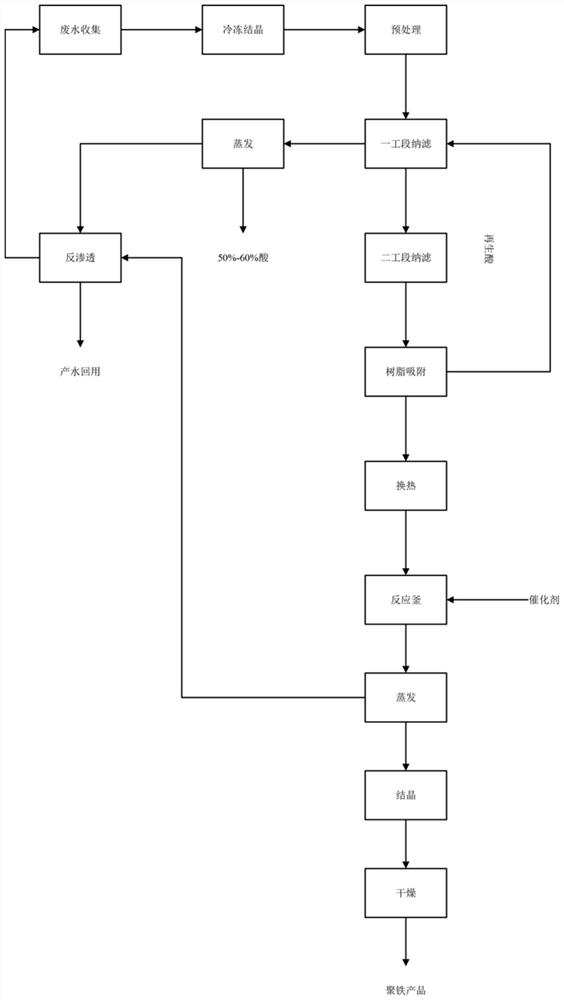

Titanium dioxide hydrolysis waste acid recycling treatment process

PendingCN111661966AEffective resource utilization and treatment of hydrolyzed waste acidEasy to handleWater treatment parameter controlIron compounds preparationReverse osmosisWastewater

The invention provides a titanium dioxide hydrolysis waste acid recycling treatment process. The process comprises the following steps: (1) collecting generated wastewater, freezing for crystallizing,carrying out heat exchange, and then carrying out pretreatment; (2) enabling pretreated produced water to enter a first-section nanofiltration unit; (3) enabling the concentrated solution of the first-section nanofiltration unit to enter a second-section nanofiltration unit, returning the water produced by the second-section nanofiltration unit to the first-section nanofiltration unit for water feeding; (4) enabling water produced by the first-section nanofiltration unit to enter an evaporation unit, performing evaporative concentration, and enabling condensed water of the evaporation unit toenter a reverse osmosis unit; and (5) enabling concentrated water of the second-section nanofiltration unit to enter a resin adsorption unit, enabling effluent of the resin adsorption unit to enter aheat exchange unit, enabling the wastewater subjected to heat exchange to enter a reaction kettle, using the wastewater subjected to reaction as inlet water of the evaporation unit, and then crystallizing and drying to obtain a polyferric product. The process provided by the invention can effectively treat the titanium dioxide hydrolysis waste acid, realizes zero-discharge recycling of the wasteacid, and realizes waste-to-treasure.

Owner:SUNUP ENVIRONMENTAL TECH CO LTD

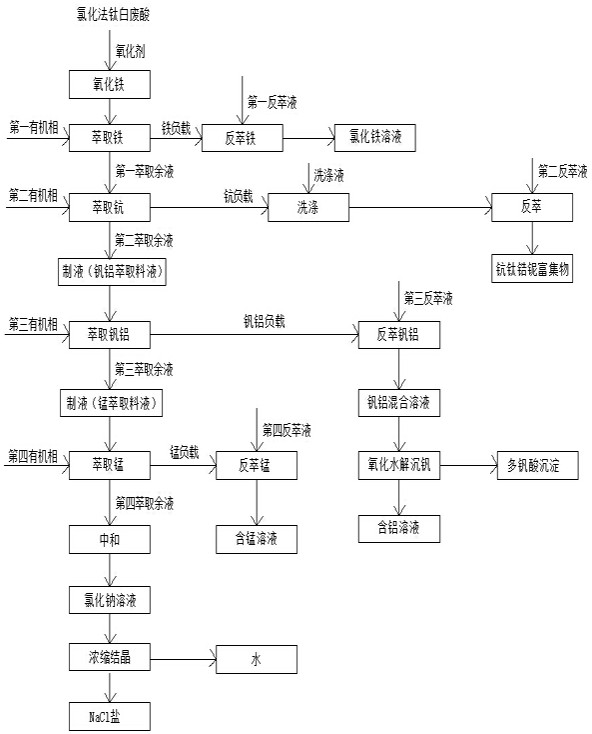

Method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction

ActiveCN112429780AAchieve recyclingIncrease valueTreatment involving filtrationWater/sewage treatment by neutralisationTitanium zirconiumNiobium

The invention discloses a method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction. The method comprises the following steps: S1, adding a first organic phase into the chlorination-process titanium dioxide waste acid to obtain a first extraction raffinate and an iron load, and carrying out back extraction on the iron load to obtaina ferric chloride solution; S2, adding a second organic phase into the first extraction raffinate to obtain second extraction raffinate and a scandium-titanium-zirconium-niobium load; S3, carrying outback extraction on the scandium load to obtain a scandium-titanium-zirconium-niobium enriched product; S4, adjusting the pH value of the second extraction raffinate to prepare a liquid; S5, adding athird organic phase after liquid preparation to obtain a vanadium-aluminum load and a third extraction raffinate; S6, carrying out back extraction on the vanadium-aluminum load to obtain a vanadium-aluminum mixed solution; S7, adjusting the pH value of the third extraction raffinate to prepare a liquid; S8, after liquid preparation, adding a fourth organic phase into manganese extraction feed liquid to obtain a manganese load and a fourth extraction raffinate, and carrying out back extraction on the manganese load to obtain a manganese-containing solution; and S9, neutralizing the fourth extraction raffinate, carrying out filtering, then performing concentrating and crystallizing to obtain NaCl edible salt and water, and recycling the NaCl edible salt and water.

Owner:河南荣佳钪钒科技有限公司

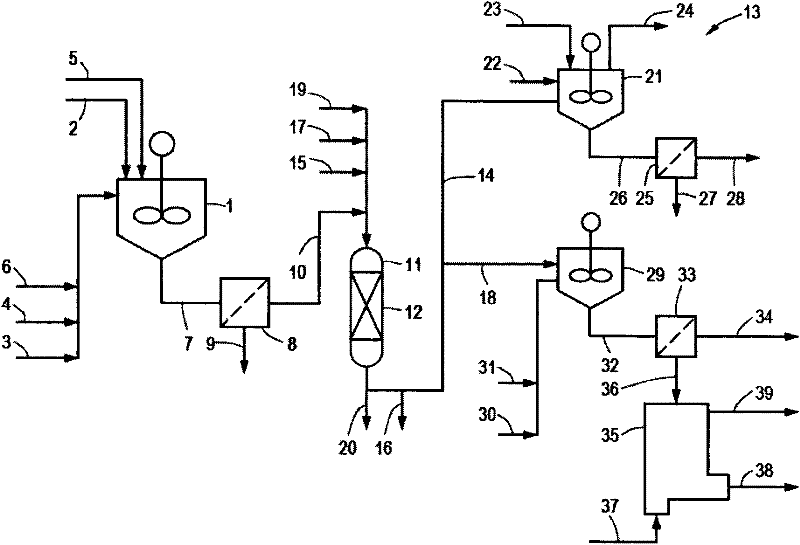

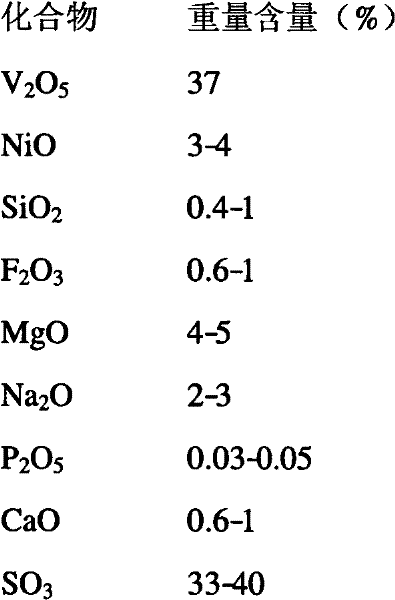

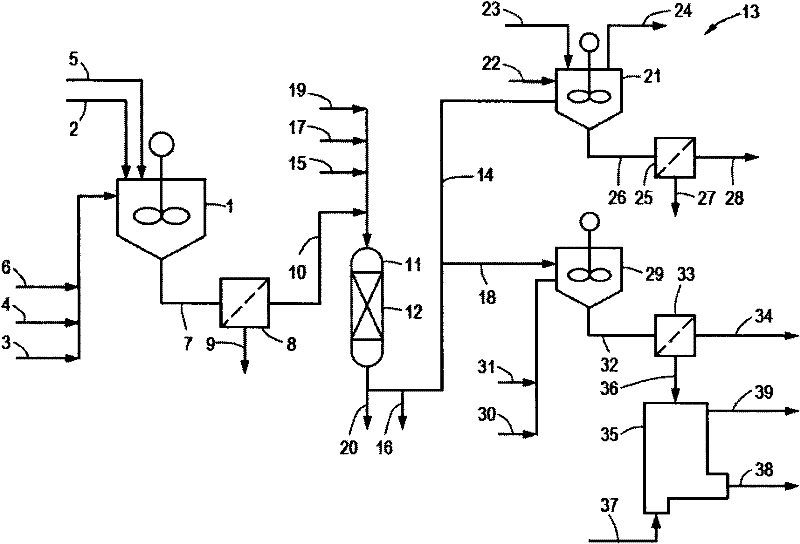

Process for preparing vanadium pentoxide from ash composition

The present invention is directed to a process for preparing vanadium pentoxide from an ash composition comprising solid ash particles, vanadium, iron and nickel compounds optionally present in an aqueous solution. The process comprises the following steps: (i) leaching the ash composition by contacting the ash composition with an acid aqueous solution at a pH of below 1, (ii) adding a reducing agent to the aqueous solution, (iii) contacting the aqueous solution obtained in step (ii) with an ion exchange resin in its H + ionic form, (iv) desorption of the vanadium compounds from the ion exchange resin rich in vanadium compounds by contacting the ion exchange resin with an aqueous solution of H 2 SO 4 to obtain an aqueous solution rich in vanadium compounds, and (v) converting and isolating the vanadium compounds as present in the aqueous solution to vanadium pentoxide.

Owner:GREENSHORES PATENT

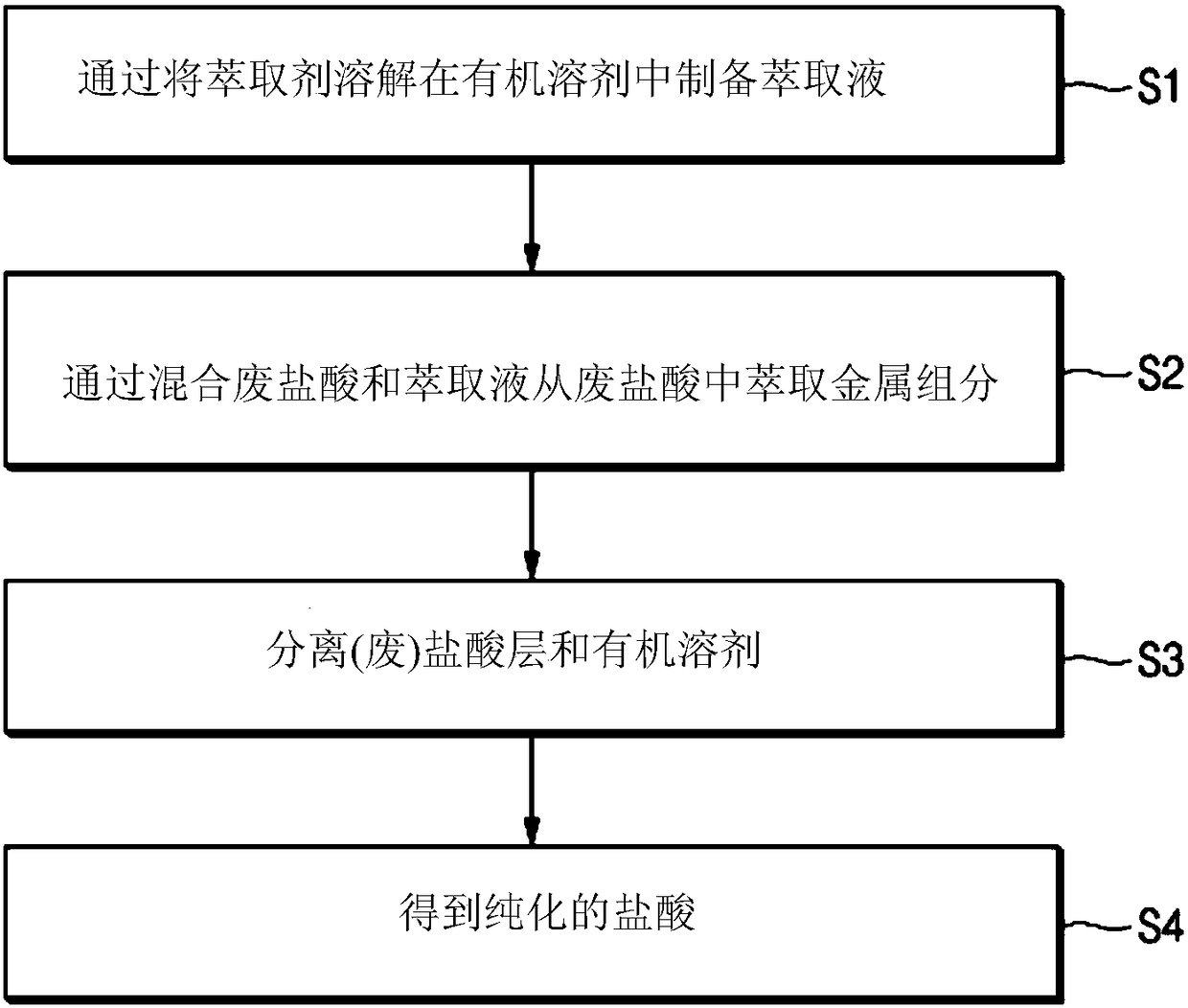

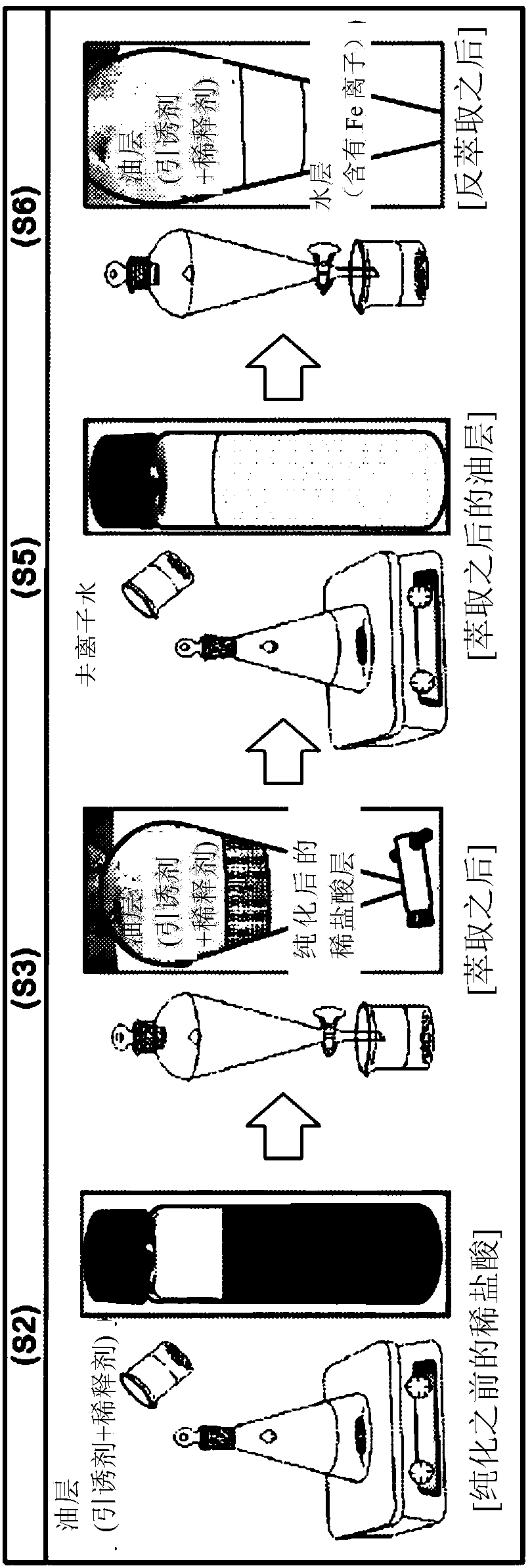

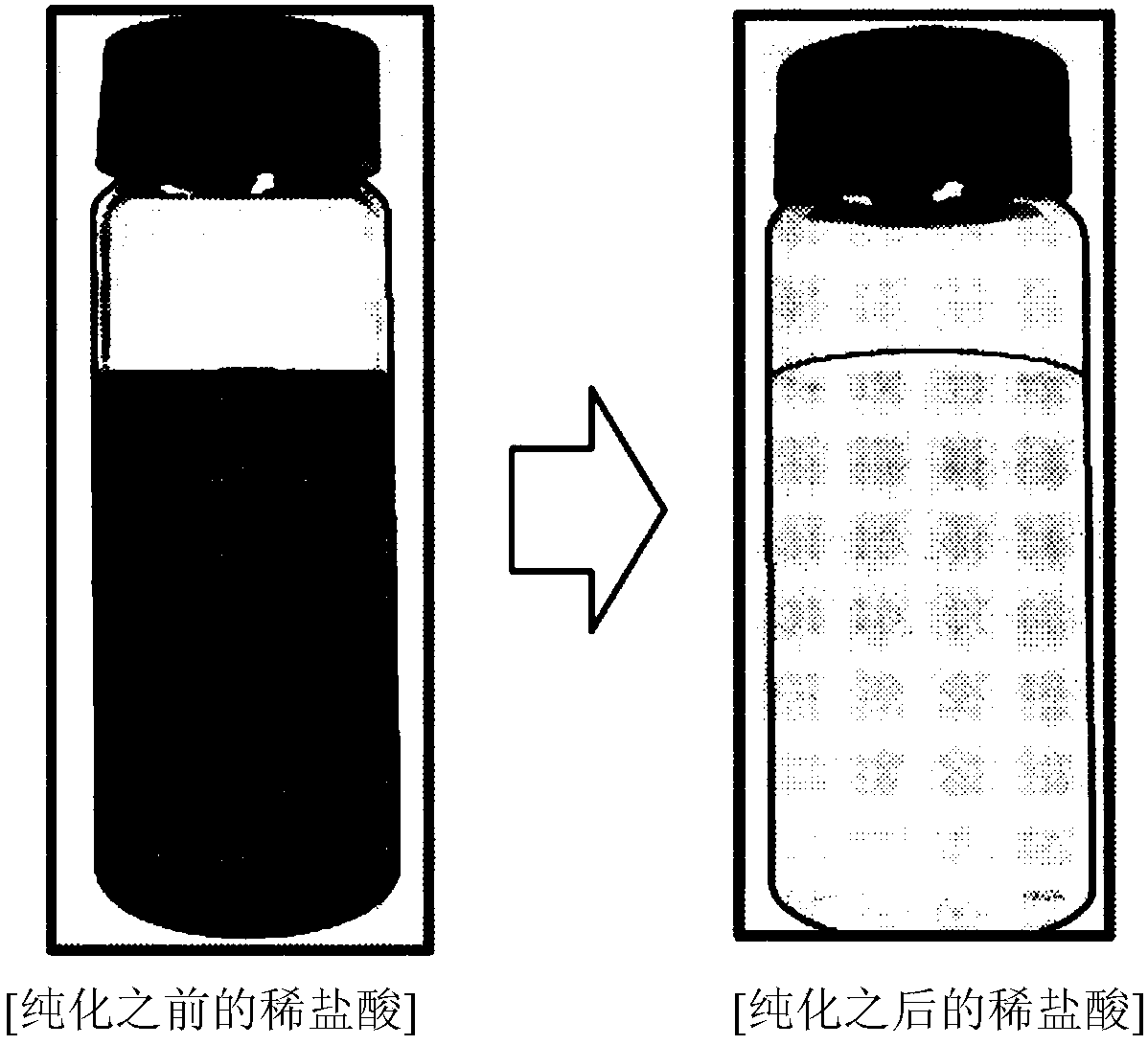

Method for purifying waste hydrochloric acid

ActiveCN108290083AImprove cycle efficiencyEfficient removalChlorine/hydrogen-chlorideGas treatmentOrganic solventMetal

The present invention relates to a method for purifying waste hydrochloric acid and, specifically, to a method for purifying waste hydrochloric acid, comprising the steps of: (S1) preparing an extraction solution by dissolving an extractant in an organic solvent; (S2) extracting a metal component with an organic solvent by injecting the extraction solution into waste hydrochloric acid; (S3) phaseseparating a water hydrochloric acid layer and the organic solvent containing the metal component; and (S4) obtaining purified hydrochloric acid by recovering the phase separated (fractionated) waterhydrochloric acid layer, wherein at least 40 mol of the extractant is used on the basis of 1 mol of Fe contained in the waste hydrochloric acid, and the waste hydrochloric acid and the extraction solution are mixed in a volume ratio of waste hydrochloric acid : extraction solution of 1 to 0.1-1.

Owner:LG CHEM LTD

Method for recycling iron-containing zinc-containing sludge to prepare zinc hydroxide and dye-grade iron oxide yellow

InactiveCN106745192AEliminate secondary pollutionHigh purityIron compounds preparationZinc compounds preparationZinc hydroxideSludge

The invention relates to a method for recycling iron-containing zinc-containing sludge to prepare zinc hydroxide and dye-grade iron oxide yellow and belongs to the field of waste resourceful treatment. The method comprises the steps of adding hydrochloric acid into iron-containing zinc-containing sludge to adjusting a pH value, then adding steel scrap, stirring, extracting in an extraction agent, classifying and deoiling; performing back extraction on zinc-containing load organic phase to prepare zinc hydroxide; adding alkaline substance into ferrous chloride solution with the zinc content smaller than or equal to 1g / L to adjust a pH value as 3.0 to 7.5 in 12 to 32 DEG C, introducing oxidizing gas, performing low-temperature oxidization with oxidization time of 60 to 1200min, warming to 50 to 90 DEG C, adding alkaline substance to adjust a pH value to be 2.8 to 3.6, introducing oxidizing gas, oxidizing for 30 to 115h, guaranteeing the pH value of liquid to be 2.8 to 3.6 in an oxidizing process, finishing oxidization, filtering and drying to obtain the dye-grade iron oxide yellow. The method is a recycling technology of iron-containing zinc-containing sludge in a hot galvanizing factory and has the advantages of small equipment invest, low energy consumption and high purity of a prepared product.

Owner:NORTHEASTERN UNIV

Preparation method and application of iron oxide red

PendingCN111453775AImprove qualitySimple preparation processIron compounds preparationFerric oxidesPrinting inkAqueous solution

The invention discloses a preparation method and application of iron oxide red. The preparation method of the iron oxide red comprises the following steps of: transferring iron ions from an aqueous solution containing the iron ions into an oil phase by adopting an extracting agent, adding a precipitant into the separated oil phase to form iron precipitate, and then treating the iron precipitate toobtain the iron oxide red. The synthesized iron oxide red is used in the fields of paint, printing ink, plastic, leather coloring, wallpaper, powder coating, cosmetics, food and the like.

Owner:福建富仕新材料有限责任公司

Magnetic hydrotalcite composite and production method thereof

InactiveUS10037839B2Inhibition of agglomerationIron compounds preparationOther chemical processesHydrotalciteUltraviolet

A magnetic hydrotalcite composite which is useful in fields such as wastewater treatment, ultraviolet absorption, electromagnetic wave absorption and acid gas absorption, and a production method thereof. The magnetic hydrotalcite composite comprises an inner layer and an outer layer, in which the inner layer is made of a hydrotalcite compound and the outer layer is made of a ferrite compound.

Owner:KYOWA CHEM IND

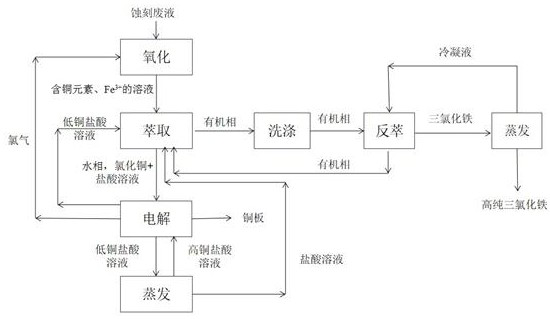

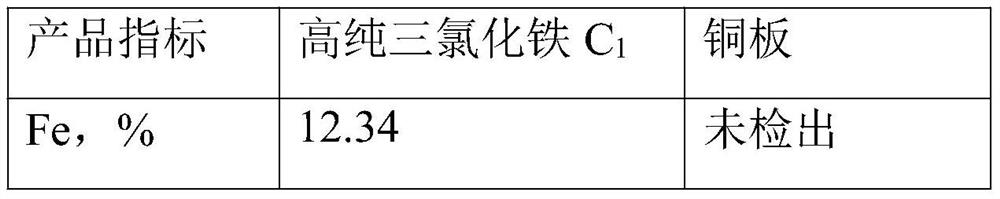

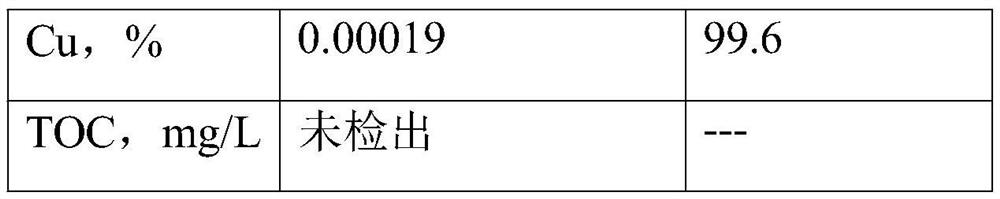

Method for recovering copper and iron from etching waste liquid

PendingCN113213547AEasy to separateHigh recovery ratePhotography auxillary processesIron compounds preparationElectrolytic agentEtching

The invention discloses a method for recovering copper and iron from etching waste liquid. The method comprises the following steps: oxidizing the etching waste liquid containing copper and iron elements into a ferric trichloride solution containing the copper element, adding industrial hydrochloric acid and butyl acetate for extraction, standing for layering, taking an organic phase, adding an iron-containing and acid-containing washing solution for washing the organic phase, and adding a stripping agent into the organic phase for stripping, to obtain ultralow-impurity ferric trichloride, and evaporating and concentrating to remove organic matters to obtain the high-purity ferric trichloride. The organic phase can be recycled, a water phase is extracted for multiple times until no ferric trichloride exists, a high-purity copper plate can be obtained through an electrolytic copper extraction process, and a low-copper electrolyte can be electrolyzed again through evaporation and concentration or can be used as hydrochloric acid required by extraction. The copper content of the high-purity ferric trichloride product produced by the process is lower than 5 ppm, and the high-purity ferric trichloride product can be applied to the fields of drinking water treatment, medical intermediates, analysis and testing, precise etching and the like; and the copper plate obtained by electrolysis has high purity and high value.

Owner:3R ENVIRONMENTAL TECH CO LTD

Doped sensitive material for improving performance of hydrogen sensor, and preparation method and application thereof

ActiveCN113933360AEvenly Mix the SlurryImprove adsorption capacityIron compounds preparationFerric oxidesActive agentPhysical chemistry

The invention discloses a preparation method of a doped sensitive material for improving the performance of a hydrogen sensor. The preparation method comprises the following steps: S1, adding a precipitant into deionized water, and fully and uniformly mixing to obtain a colorless and transparent mixed solution A; S2, adding ferric trichloride and transition metal salt into the mixed solution A obtained in the step S1, and fully and uniformly mixing to obtain a clear and transparent precursor solution B; S3, putting the precursor solution B obtained in the step S2 into a high-temperature stirring reaction kettle with a polytetrafluoroethylene lining, and performing stirring and heat preservation at 120 DEG C for 12-24 hours; and S4, centrifuging, washing and drying the material obtained in the step S3 to obtain the doped alpha-Fe2O3-based sensitive material. The preparation method is simple in synthesis process, high in repeatability and low in cost, and high-temperature calcination and use of a surfactant are not needed. The sensitivity, the stability and the selectivity of the hydrogen sensor made of the sensitive material are remarkably improved.

Owner:GUANGZHOU MARITIME INST

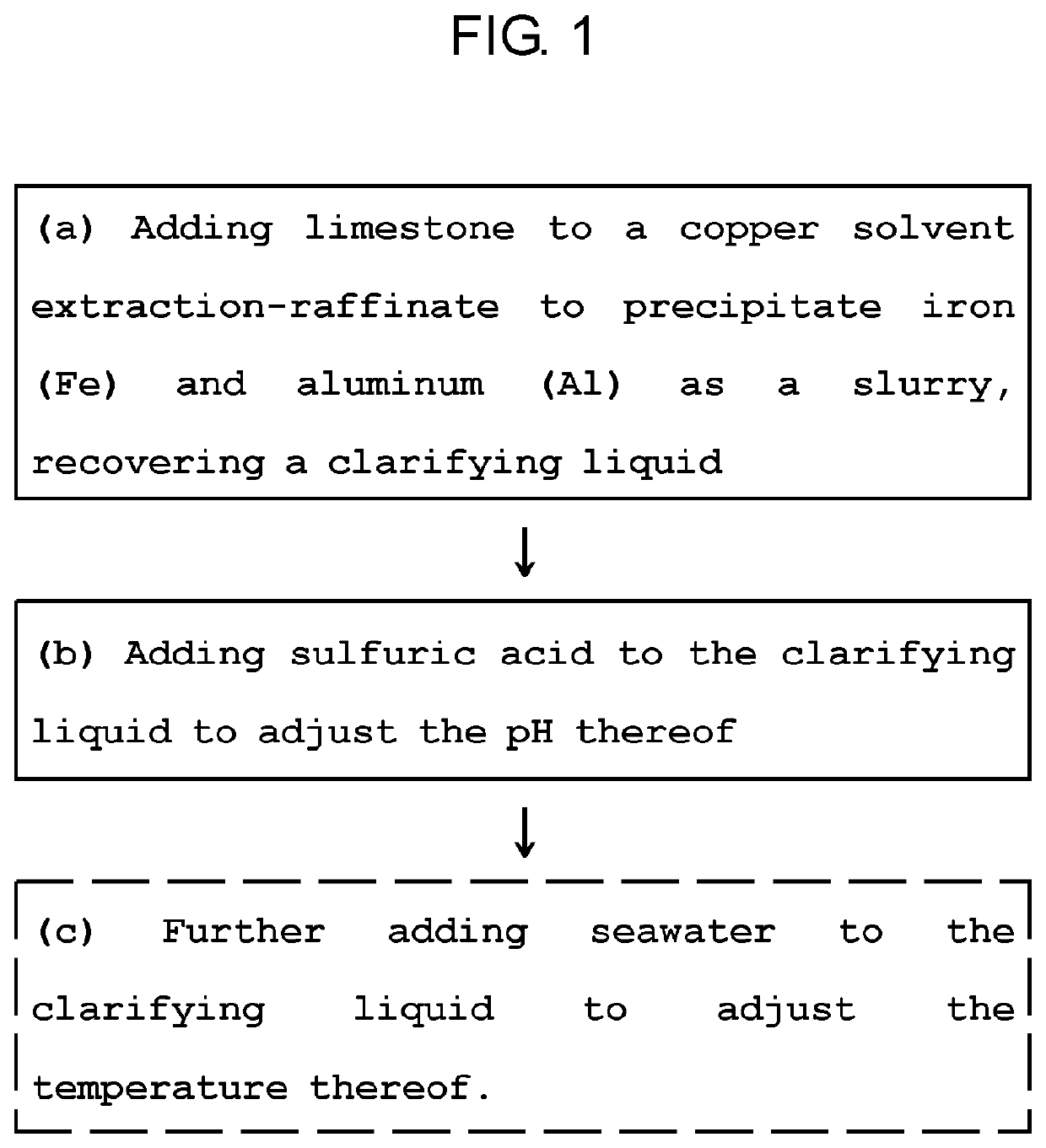

Method for inhibiting extractant degradation of dsx process through metal extraction control

ActiveUS20210024367A1Minimizing extractionPrevent degradationIron compounds preparationZinc compounds preparationPhysical chemistrySlurry

Provided is a method for inhibiting extractant degradation in the DSX process through the metal extraction control, the method comprising steps of: (a) adding limestone to a copper solvent extraction-raffinate to precipitate iron (Fe) and aluminum (Al) as a slurry, recovering a clarifying liquid; and (b) adding sulfuric acid to the recovered clarifying liquid to adjust the pH thereof.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

Popular searches

Calcium/strontium/barium chlorides Dispersed particle separation Waste water treatment from metallurgical process Multistage water/sewage treatment Water/sewage treatment by heating Water/sewage treatment by oxidation Nickel sulfates Transportation and packaging Individual molecule manipulation Metal-working apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com