Method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid

A technology of electrolytic manganese dioxide and manganese tailings, which is applied in the preparation of manganese sulfate and manganese compounds, manganese oxide/manganese hydroxide, etc., which can solve the problems of high recycling cost, high impurity content, no recycling value, low recovery rate, etc. problems, to achieve the effect of no secondary pollution, environmental protection and comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

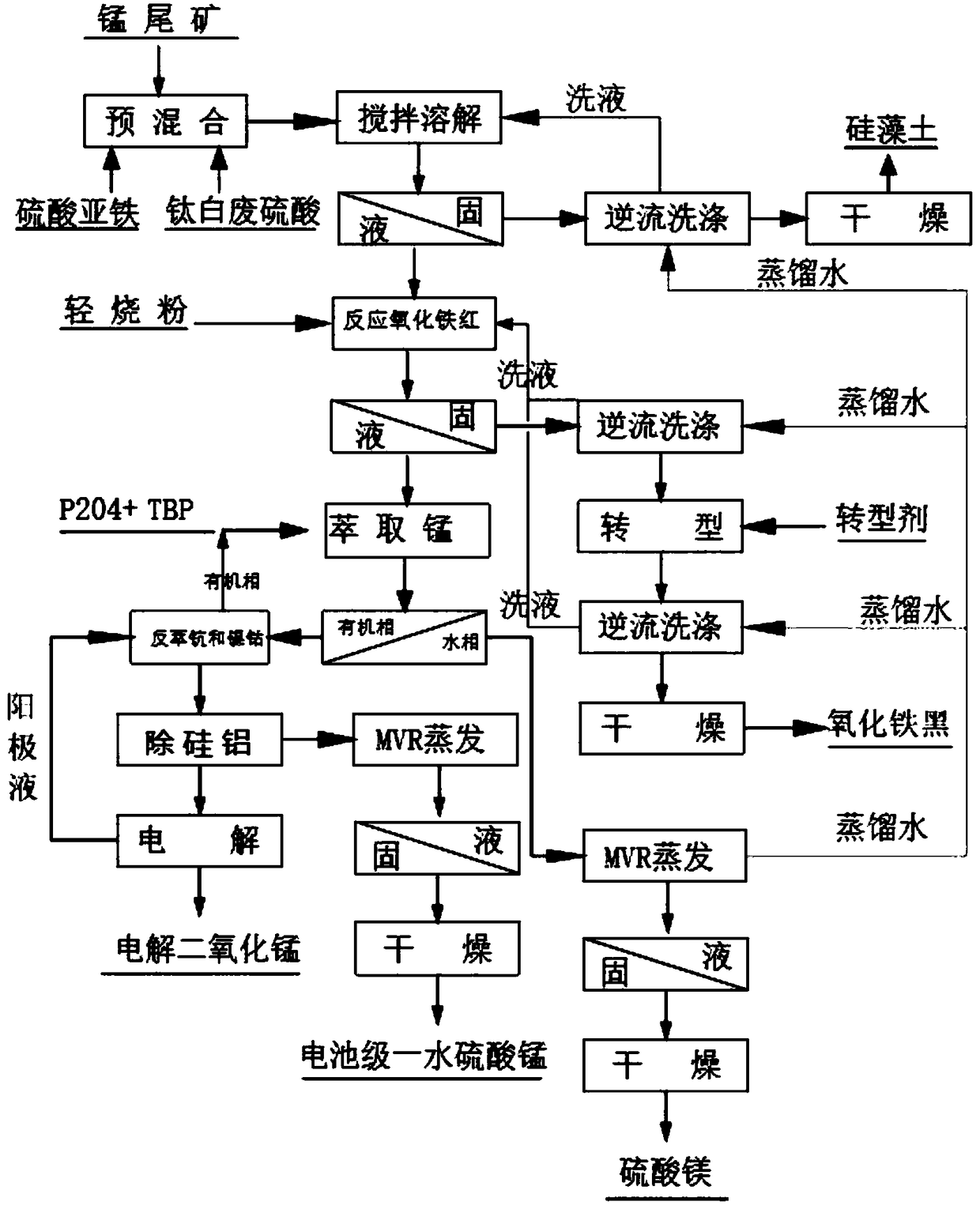

Image

Examples

Embodiment 1

[0030] A method for producing electrolytic manganese dioxide by utilizing manganese tailings and titanium white waste sulfuric acid, comprising the following steps:

[0031] a) placing the manganese tailings in a ball mill for wet grinding with water added, the manganese tailings material after the wet grinding is passed through a 200-mesh sieve, so that the total mass of the material under the sieve is 96% of the total mass of the material;

[0032] Among them, the manganese tailings include the following components in mass percentage: Mn6.0%, Fe7.5%, SiO 2 60.0%, CaO0.3%, Al 2 o 3 4.05%, MgO1.55%;

[0033] b) After pre-mixing the manganese tailings material that has been ball milled with ferrous sulfate and titanium white waste sulfuric acid, add it to a strong mixer for stirring and dissolving for 3 hours, the reaction temperature is 60°C, and the first filtrate and the first filter residue are obtained by solid-liquid separation ; The first filter residue is diatomite a...

Embodiment 2

[0039] A method for producing electrolytic manganese dioxide by utilizing manganese tailings and titanium white waste sulfuric acid, comprising the following steps:

[0040] a) placing the manganese tailings in a ball mill for wet grinding with water added, the manganese tailings material after the wet grinding is passed through a 210 mesh sieve, so that the total mass of the undersize is 97% of the total mass of the material;

[0041] Among them, the manganese tailings include the following components in mass percentage: Mn2.5%, Fe3.0%, SiO 2 35.0%, CaO5.0%, Al 2 o 3 15.05%, MgO0.30%;

[0042] b) After pre-mixing the manganese tailings material that has been ball milled with ferrous sulfate and titanium white waste sulfuric acid, add it to a strong mixer for stirring and dissolving for 1 hour, the reaction temperature is 90°C, and the first filtrate and the first filter residue are obtained by solid-liquid separation ; The first filter residue is diatomite after countercur...

Embodiment 3

[0048] A method for producing electrolytic manganese dioxide by utilizing manganese tailings and titanium white waste sulfuric acid, comprising the following steps:

[0049] a) placing the manganese tailings in a ball mill for wet grinding with water added, the manganese tailings material after the wet grinding is passed through a 200-mesh sieve, so that the total mass of the material under the sieve is 96% of the total mass of the material;

[0050] Among them, the manganese tailings include the following components in mass percentage: Mn22.5%, Fe3.0%, SiO 2 60.0%, CaO0.3%, Al 2 o 3 15.05%, MgO0.3%;

[0051] b) After pre-mixing the manganese tailings material that has been ball milled with ferrous sulfate and titanium white waste sulfuric acid, add it to a strong mixer for stirring and dissolving for 3 hours, the reaction temperature is 60°C, and the first filtrate and the first filter residue are obtained by solid-liquid separation ; The first filter residue is diatomite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com