A method for producing electrolytic manganese dioxide by using manganese tailings and titanium white waste sulfuric acid

A technology of electrolyzing manganese dioxide and manganese tailings, which is applied in the preparation of manganese sulfate and manganese compounds, manganese oxide/manganese hydroxide, etc., which can solve the problems of high impurity content, no recycling value, high recycling cost and complicated process , to achieve the effect of environmental protection and comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

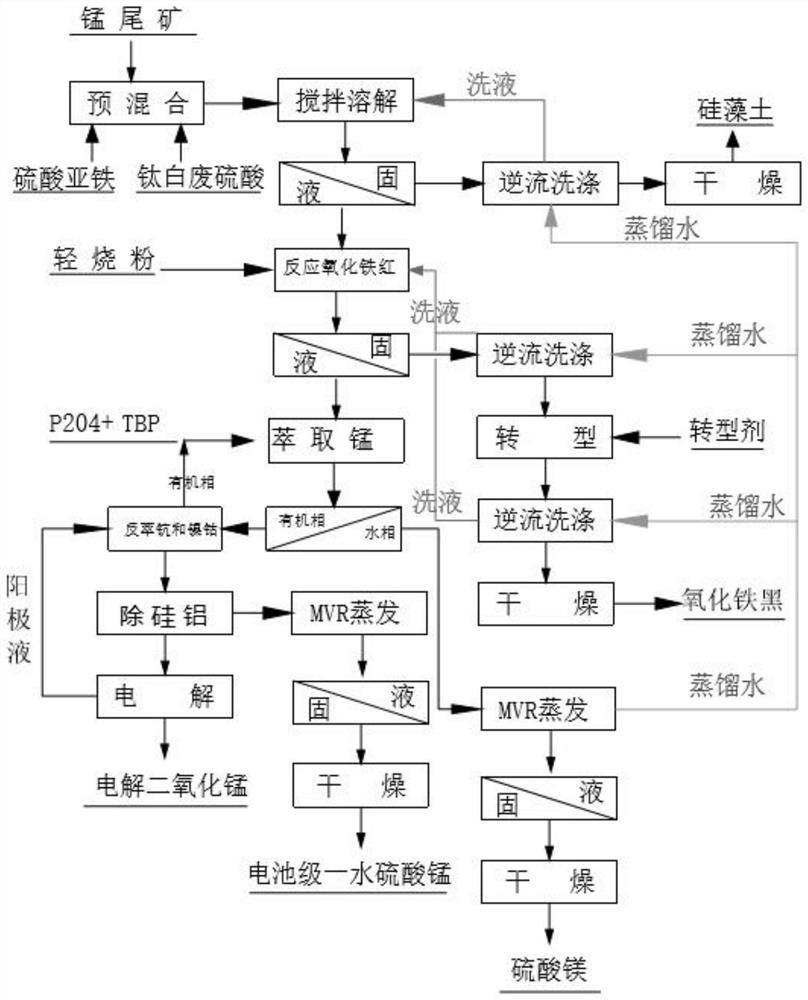

Image

Examples

Embodiment 1

[0030] A method for producing electrolytic manganese dioxide by utilizing manganese tailings and titanium white waste sulfuric acid, comprising the following steps:

[0031] a) placing the manganese tailings in a ball mill for wet grinding with water added, the manganese tailings material after the wet grinding is passed through a 200-mesh sieve, so that the total mass of the material under the sieve is 96% of the total mass of the material;

[0032] Among them, the manganese tailings include the following components in mass percentage: Mn6.0%, Fe7.5%, SiO 2 60.0%, CaO0.3%, Al 2 o 3 4.05%, MgO1.55%;

[0033] b) After pre-mixing the manganese tailings material that has been ball milled with ferrous sulfate and titanium white waste sulfuric acid, add it to a strong mixer for stirring and dissolving for 3 hours, the reaction temperature is 60°C, and the first filtrate and the first filter residue are obtained by solid-liquid separation ; The first filter residue is diatomite a...

Embodiment 2

[0039] A method for producing electrolytic manganese dioxide by utilizing manganese tailings and titanium white waste sulfuric acid, comprising the following steps:

[0040] a) placing the manganese tailings in a ball mill for wet grinding with water added, the manganese tailings material after the wet grinding is passed through a 210 mesh sieve, so that the total mass of the undersize is 97% of the total mass of the material;

[0041] Among them, the manganese tailings include the following components in mass percentage: Mn2.5%, Fe3.0%, SiO 2 35.0%, CaO5.0%, Al 2 o 3 15.05%, MgO0.30%;

[0042] b) After pre-mixing the manganese tailings material that has been ball milled with ferrous sulfate and titanium white waste sulfuric acid, add it to a strong mixer for stirring and dissolving for 1 hour, the reaction temperature is 90°C, and the first filtrate and the first filter residue are obtained by solid-liquid separation ; The first filter residue is diatomite after countercur...

Embodiment 3

[0048] A method for producing electrolytic manganese dioxide by utilizing manganese tailings and titanium white waste sulfuric acid, comprising the following steps:

[0049] a) placing the manganese tailings in a ball mill for wet grinding with water added, the manganese tailings material after the wet grinding is passed through a 200-mesh sieve, so that the total mass of the material under the sieve is 96% of the total mass of the material;

[0050] Among them, the manganese tailings include the following components in mass percentage: Mn22.5%, Fe3.0%, SiO 2 60.0%, CaO0.3%, Al 2 o 3 15.05%, MgO0.3%;

[0051] b) After pre-mixing the manganese tailings material that has been ball milled with ferrous sulfate and titanium white waste sulfuric acid, add it to a strong mixer for stirring and dissolving for 3 hours, the reaction temperature is 60°C, and the first filtrate and the first filter residue are obtained by solid-liquid separation ; The first filter residue is diatomite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com