Extraction decontamination method for industrial iron slag sulfuric acid leaching

An iron slag sulfuric acid and leaching solution technology, applied in the preparation of nickel sulfate, iron compounds, iron halide and other directions, can solve the problems of high consumption of electrolysis, small solution processing capacity, unsuitable for large-scale production, etc., and achieves high impurity removal rate , the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

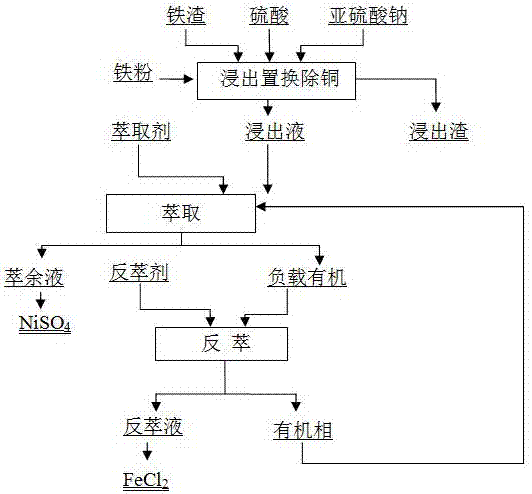

Image

Examples

Embodiment 1

[0032] A method for extracting and removing impurities from industrial iron slag sulfuric acid leaching solution, comprising the following steps:

[0033] Step 1: Preparation of the pre-extraction solution. During the sulfuric acid leaching reaction of industrial iron slag, the iron slag slurry has a liquid-solid ratio of 4:1, the temperature is 76°C, the sulfuric acid concentration is 80.5g / L, and the reaction is 0.5h; then add iron powder, the amount of iron powder added is the leaching solution Cu 2+ 1 times the concentration, react for 0.5h, then add sodium sulfite, the amount added is Fe in the leaching solution 3+ 1.1 times the concentration, and reacted for 2 hours to obtain a sulfuric acid leaching solution of industrial iron slag with higher impurity content. The components of the industrial iron slag leaching solution used are shown in Table 4.

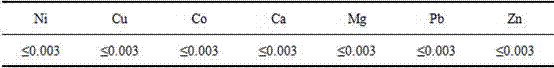

[0034] Table 4 Composition of industrial iron slag sulfuric acid leaching solution g / L

[0035]

[0036] Step 2: Sodi...

Embodiment 2

[0046] A method for extracting and removing impurities from industrial iron slag sulfuric acid leaching solution, comprising the following steps:

[0047] Step 1: Preparation of the pre-extraction solution. During the leaching reaction, the iron slag slurry has a liquid-solid ratio of 4.5:1. The temperature is 80°C, the concentration of sulfuric acid is 83g / L, and the reaction is 0.5h; then add iron powder, and the amount of iron powder added is the leachate Cu 2+ 1.2 times the concentration, react for 0.5h, then add sodium sulfite, the amount added is the leachate Fe 3+ 1 times the concentration, and reacted for 2 hours to obtain a sulfuric acid leaching solution of industrial iron slag with higher impurity content. The components of the industrial iron slag leaching solution used are shown in Table 7.

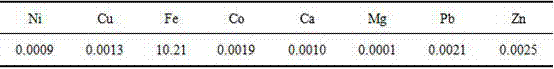

[0048] Table 7 Composition of industrial iron slag sulfuric acid leaching solution g / L

[0049]

[0050] Step 2: Sodium soap, using P 507 As the extractant, the preparat...

Embodiment 3

[0060] A method for extracting and removing impurities from industrial iron slag sulfuric acid leaching solution, comprising the following steps:

[0061] Step 1: Prepare the pre-extraction solution. During the leaching reaction, the iron slag slurry has a liquid-solid ratio of 5:1, the temperature is 85°C, the concentration of sulfuric acid is 85g / L, and the reaction is 0.5h; then add iron powder, the amount of iron powder added is the leaching solution Cu 2+ 1.1 times the concentration, react for 0.5h, then add sodium sulfite, the amount added is the leachate Fe 3+ 1.1 times the concentration, and reacted for 2 hours to obtain a sulfuric acid leaching solution of industrial iron slag with higher impurity content. The components of the industrial iron slag leaching solution used are shown in Table 10.

[0062] Table 10 Composition of industrial iron slag sulfuric acid leaching solution g / L

[0063]

[0064] Step 2: Sodium soap, using P 507 As the extractant, the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com