Method for recovering copper and iron from etching waste liquid

A technology for etching waste liquid and recovering copper, which is applied to the preparation of iron compounds, iron halides, and the improvement of process efficiency. It can solve the problems of low economic value of copper and iron recovery, achieve less impurity ions, reduce the possibility, and be economical. high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

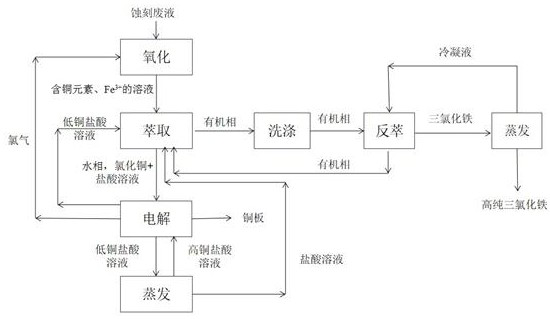

Method used

Image

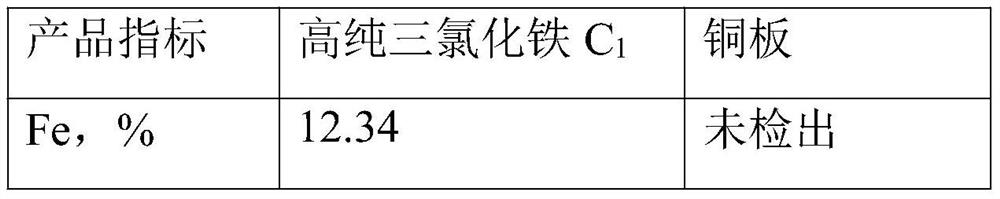

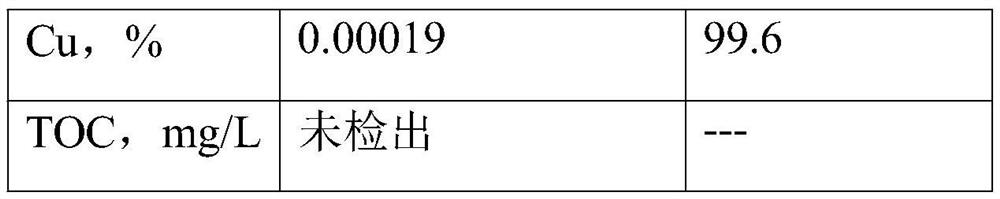

Examples

Embodiment 1

[0032] A method for recovering copper and iron in etching waste liquid, comprising the following steps:

[0033] S1. 1kg copper-containing and iron-containing waste hydrochloric acid A 0 Chlorine gas was introduced to make the Fe in the solution 2+ Oxidation is complete, and the iron trichloride solution containing copper element is obtained;

[0034] S2 Add 4.5kg of industrial hydrochloric acid and 2kg of butyl acetate to the ferric chloride solution, oscillate and let it stand until the water phase and the organic phase are separated completely, and take the organic phase;

[0035] S3. Use 5 kg of 2% ferric chloride 9mol / L hydrochloric acid solution as a washing solution for the organic phase in S2, shake it, and let it stand until the water phase and the organic phase are separated completely, and then take the organic phase;

[0036]Add 1 kg of pure water to the S4 organic phase for back extraction, the water phase is ferric chloride with ultra-low impurity content, evap...

Embodiment 2

[0043] A method for recovering copper and iron in etching waste liquid, comprising the following steps:

[0044] S1. 2kg copper-containing and iron-containing waste hydrochloric acid sample A 0 Add appropriate amount of industrial hydrochloric acid, add oxygen and catalyst to make Fe in the solution 2+ Oxidation is complete, and the iron trichloride solution containing copper element is obtained;

[0045] S2 Get 1 kg of copper-containing ferric chloride solution and add 3 kg of the condensate in Step S7 of Example 1, 2 kg of butyl acetate, shake, leave standstill until the water phase and the organic phase are completely separated, and take the organic phase;

[0046] S3 takes the organic phase of S2 and adds 1 kg of copper-containing ferric chloride solution solution, adds 5 kg of industrial hydrochloric acid, shakes and stands until the water phase and the organic phase are completely separated, and then takes the organic phase;

[0047] The S4 organic phase is washed with...

Embodiment 3

[0055] A method for recovering copper and iron in etching waste liquid, comprising the following steps:

[0056] S1. 1kg copper-containing and iron-containing waste hydrochloric acid A 0 Pass into the chlorine gas that electrolysis produces in embodiment 1 and embodiment 2, make Fe in the solution 2+ Oxidation is complete, and the iron trichloride solution containing copper element is obtained;

[0057] S2 adds 6kg industrial hydrochloric acid, 2.5kg embodiment 2 step S6 butyl acetate with the iron trichloride solution solution containing copper element, shakes, leaves standstill until aqueous phase and organic phase delamination are complete, get organic phase;

[0058] The S3 organic phase was washed with 5 kg of the washing solution in step S4 of Example 2, shaken, and left to stand until the water phase and the organic phase were separated completely, and the organic phase was taken;

[0059] S4. Add 0.5kg condensate (the condensate produced by evaporating and concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com