Process for preparing vanadium pentoxide from ash composition

A technology for ash content and vanadium compounds is applied in the field of preparing vanadium pentoxide and can solve the problems of co-precipitation of vanadium compounds, low conversion rate of iron ions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

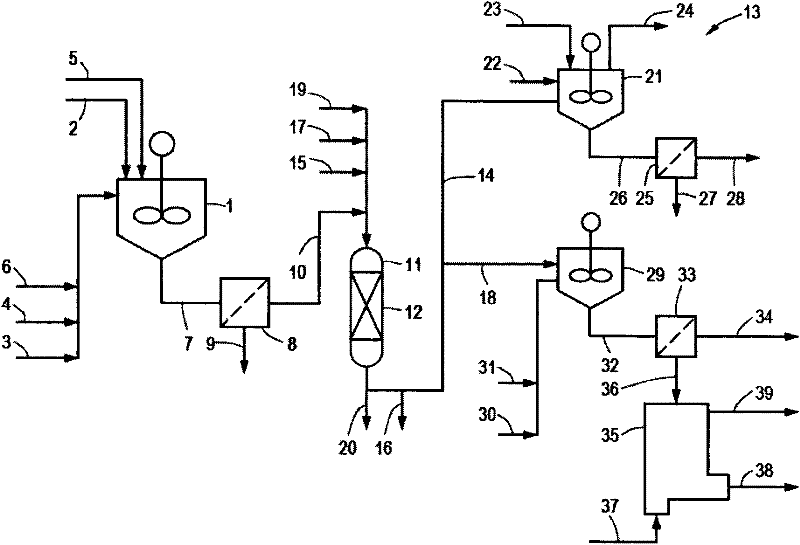

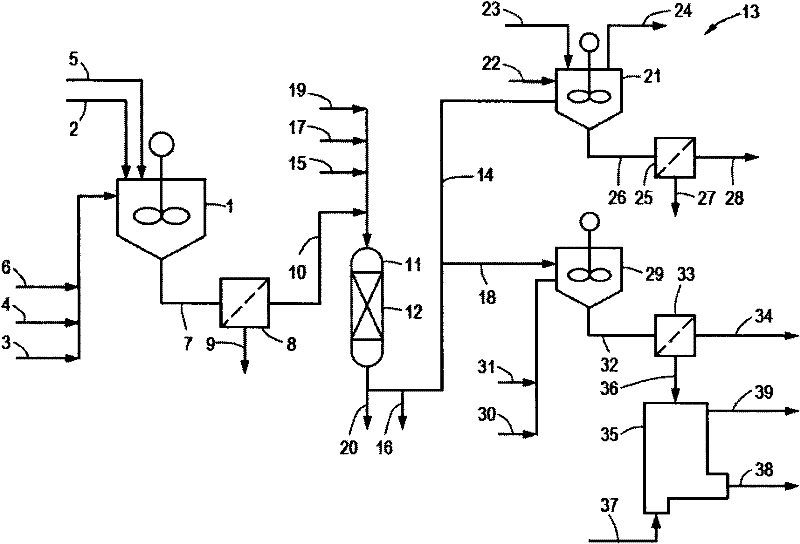

Method used

Image

Examples

Embodiment 1

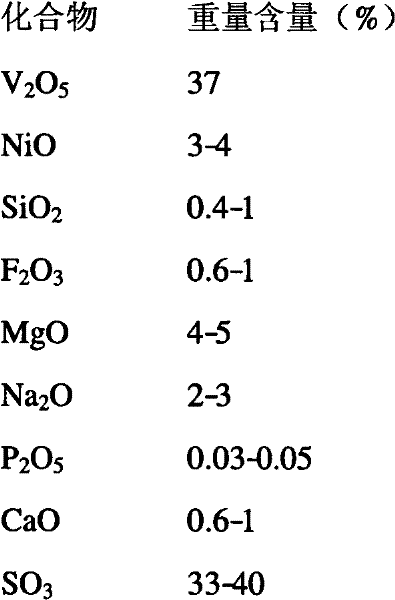

[0038] 100 kg of ash composition having the following characteristics were treated with the method of the present invention. Fluorescence spectroscopy (XRF) was used to analyze, and various elements in the ash were expressed in the form of oxides, as listed in Table 1.

[0039] The material contained in the ash composition of table 1 and its weight ratio

[0040]

[0041] Detailed phase analysis using X-ray diffraction (XRD) can also be applied in fly ash. The analysis found that vanadium mainly exists in the following phases: vanadyl sulfate hydrate (VOSO 4 *3H 2 O), vanadium ocher (V 2 o 5 ), vanadyl sulfate hydrate (VOSO 4 *2H 2 O), magnesium pyrovanadate (Mg 2 V 2 o 7 ), sodium vanadium oxide (NaV 3 o 8 ), magnesium orthovanadate (Mg2VO4) and vanadium oxide (V 4 o 9 ).

[0042] First, the ash composition was treated with a first solution having a pH value of 7 in a stirred tank reactor at a temperature of 80° C. for 2 hours. The solids content in the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com