Galvanizing steel strip with good conductivity, high corrosion resistance and fingerprint resistance, surface treatment agent and treatment method

A surface treatment agent, galvanized steel strip technology, applied in special surfaces, conductive coatings, pretreated surfaces, etc., can solve the problems of inability to guarantee surface conductivity, only reaching 1mΩ, not enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

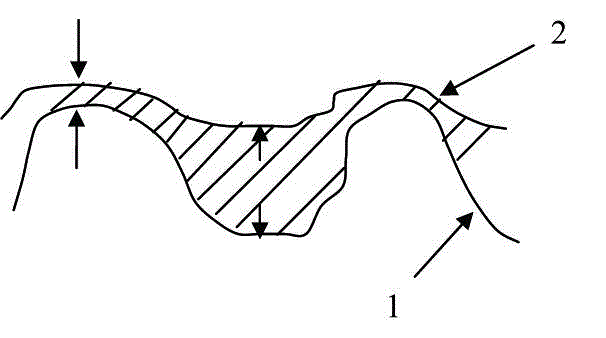

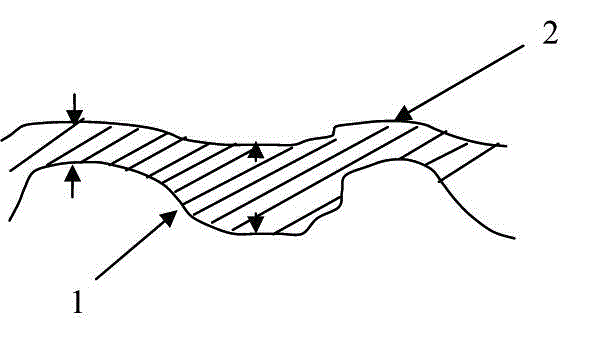

Image

Examples

Embodiment Construction

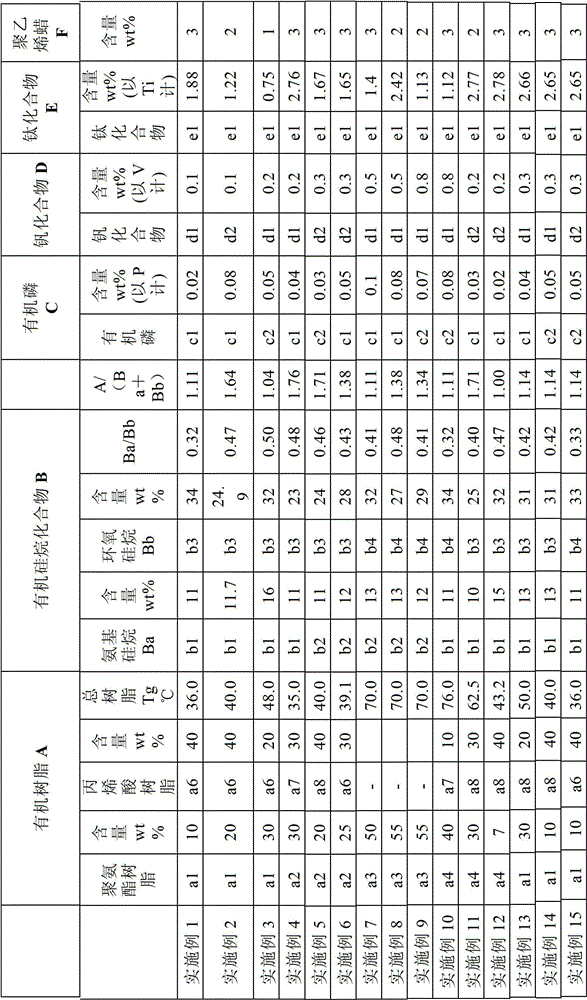

[0052] The present invention will be further described below in conjunction with embodiment.

[0053] The substrates of the embodiments of the present invention are galvanized or hot-dip galvanized steel sheets as examples. Table 1 shows the composition of the embodiment of the present invention. Table 2 shows the performance of the present invention. Table 3, Table 4, and Table 5 are the specific substances corresponding to the embodiments of the present invention.

[0054] Among them, the performance evaluation test is as follows:

[0055] 1. Flat plate corrosion resistance

[0056] According to JIS Z2371 neutral salt spray test (SST) for 120 hours, the sample size is 75×150mm, and the white rust rate of the board surface is observed.

[0057] ◎: White rust rate is less than 5%

[0058] ○: White rust rate is more than 5% but less than 10%

[0059] △: White rust rate is more than 10% but less than 30%

[0060] ×: white rust rate above 30%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com