Anticorrosive coating composition

An anti-corrosion coating and anti-corrosion pigment technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of insufficient corrosion resistance, poor corrosion resistance, poor chemical resistance, etc., and improve corrosion resistance. performance, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

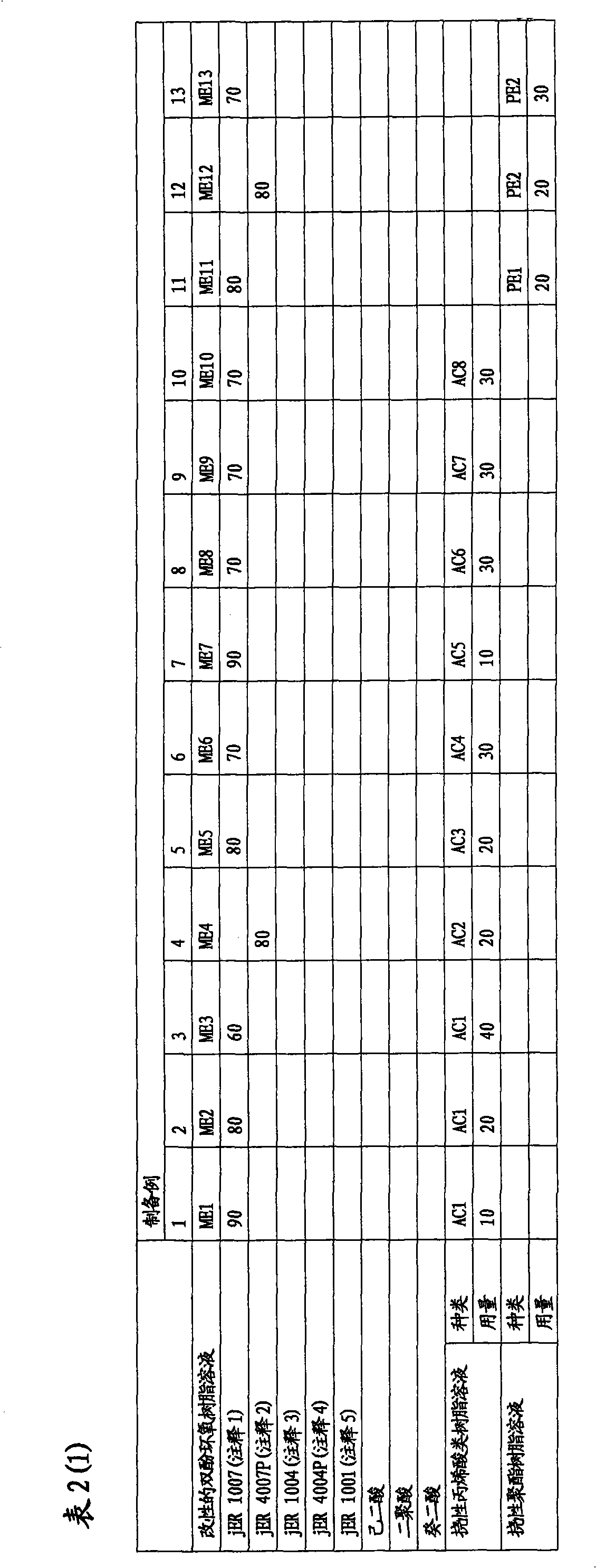

Examples

preparation example Construction

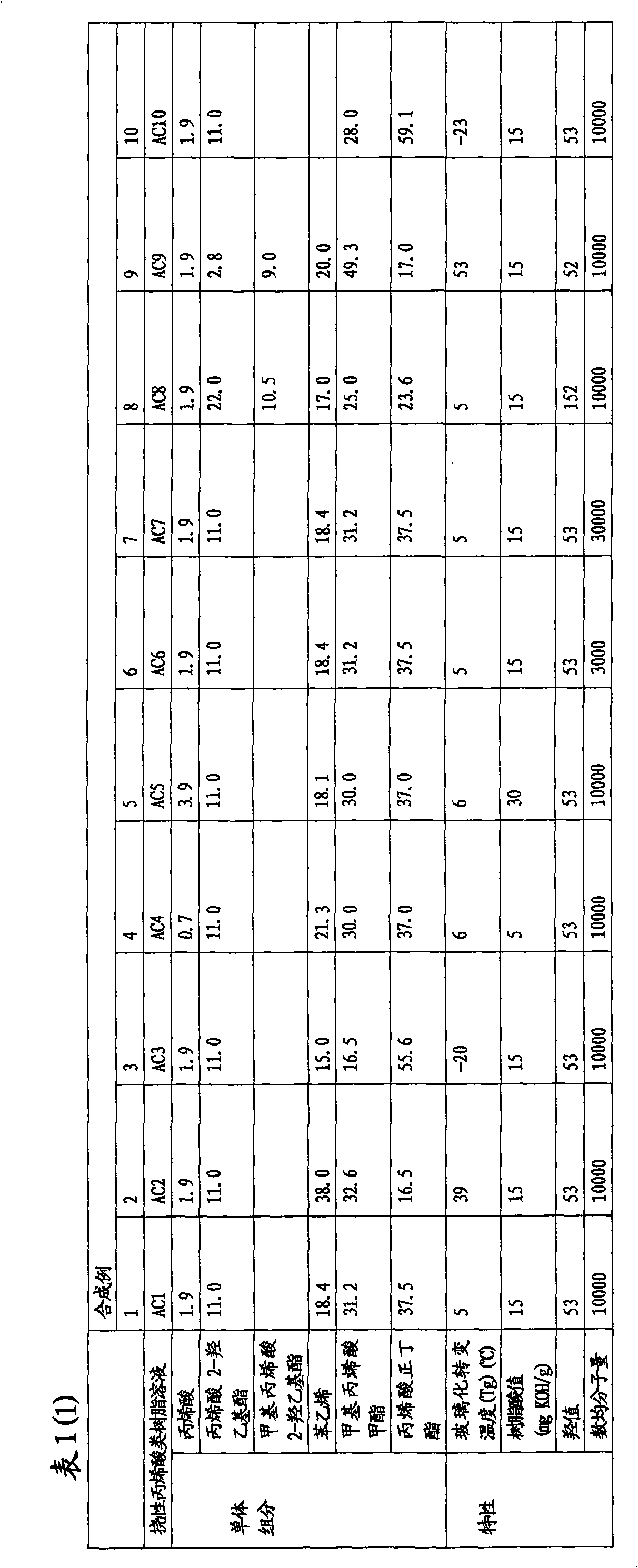

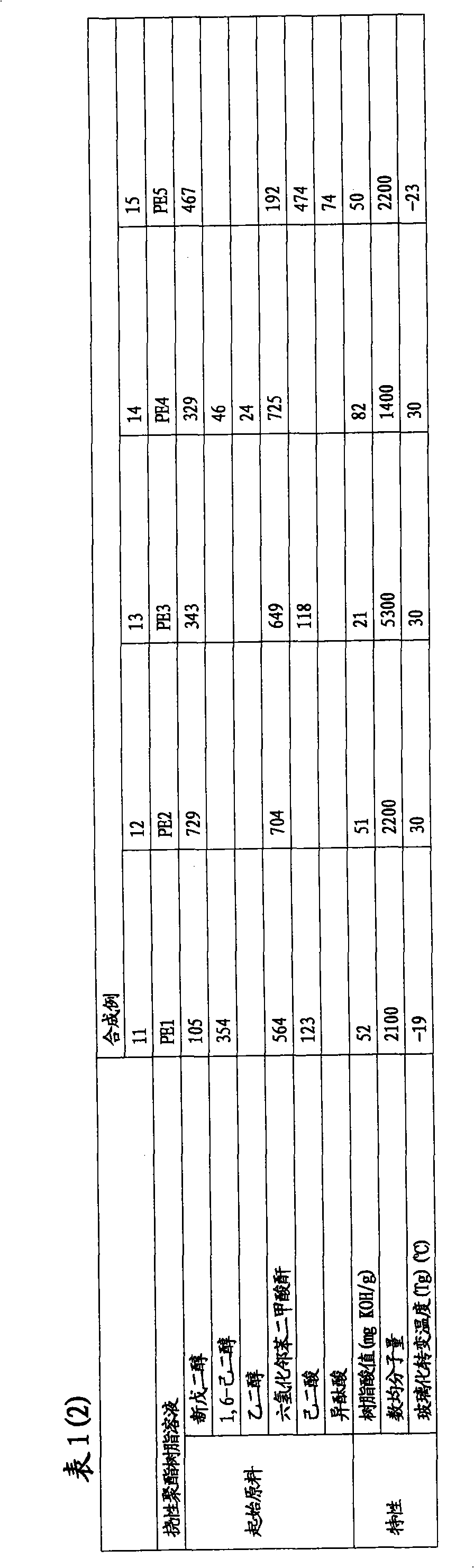

[0037] The acrylic resin used as the flexible organic part in the preparation of the modified resin (A) may include an acrylic resin having a reactive group reactive with a bisphenol epoxy resin. The acrylic resin may include a modified acrylic resin such as, for example, a urethane-modified acrylic resin. The reactive groups may include carboxyl, amino, hydroxyl and the like. Among these, carboxyl group-containing acrylic resins are preferable.

[0038] The carboxyl group-containing acrylic resin may include resins obtained by copolymerizing carboxyl group-containing polymerizable unsaturated monomers with other polymerizable unsaturated monomers according to known processes such as solution polymerization process, suspension The polymerization process, bulk polymerization process, etc. are preferably resins obtained by a solution polymerization process from the viewpoint of ease of control of polymerization conditions. The other polymerizable unsaturated monomers may inclu...

Embodiment

[0125] The present invention will be described more specifically with reference to the following Preparations and Examples. The present invention should not be limited to the following examples. Hereinafter, "parts" and "%" represent "parts by weight" and "% by weight", respectively.

Synthetic example 1

[0127] Prepare flexible acrylic resin AC1 solution:

[0128] 65.0 parts of SWASOL 1000 (trade name, sold by Maruzen Petro Chemicals Co., Ltd., a high-boiling aromatic petroleum solvent) was charged into a reactor equipped with a stirrer, a condenser, a thermometer, a nitrogen inlet, and a dropping device, followed by While stirring, the temperature inside the reactor was raised to 110°C, and the following monomer-containing starting material mixture was added dropwise. The dropping process continued for more than 3 hours while maintaining the temperature at 110°C.

[0129] Styrene 18.4 parts

[0130] 31.2 parts of methyl methacrylate

[0131] 37.5 parts of n-butyl acrylate

[0132] 2-hydroxyethyl acrylate 11.0 parts

[0133] Acrylic acid 1.9 parts

[0134] 1.7 parts of 2,2'-azobisisobutyronitrile

[0135] After completion of dropping, 0.5 part of 2,2'-azobisisobutyronitrile was added, followed by reaction at this temperature for 2 hours, and 35.0 parts of cyclohexanone wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com