Doped sensitive material for improving performance of hydrogen sensor, and preparation method and application thereof

A sensitive material and doping technology, which is applied in the field of semiconductor metal oxide gas sensors, can solve the problems of low gas sensitivity and hinder development, and achieve the effects of no need for high-temperature calcination, good stability, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

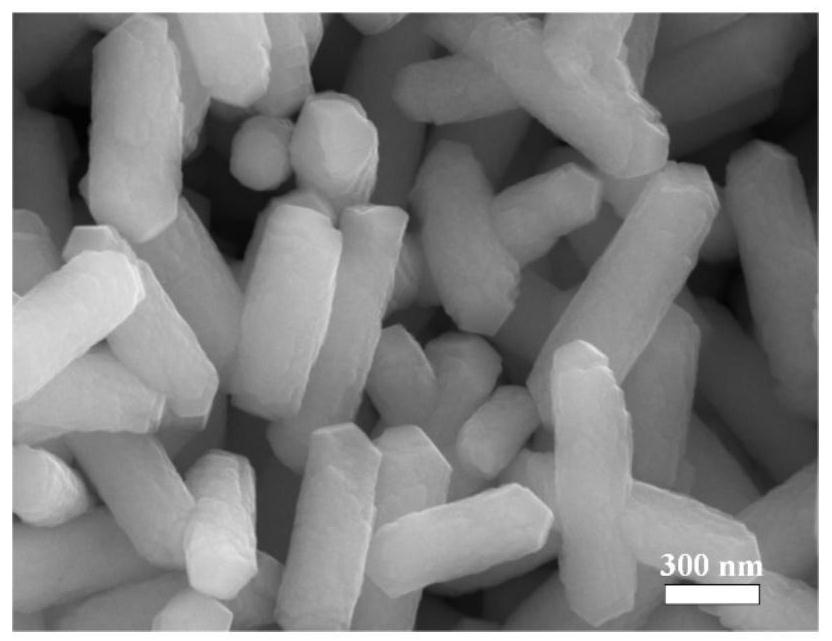

[0045] Prepare Mn / α-Fe as follows 2 o 3 Sensitive materials and Mn / α-Fe 2 o 3 Hydrogen sensor:

[0046] Add 4.4g of ferric chloride, 0.6g of manganese chloride and 20mL of N,N-dimethylformamide into 160mL of deionized water in sequence, stir for 20min under a magnetic stirrer to obtain a uniformly mixed solution, and then mix them The formed mixed solution was put into a 250mL high-temperature stirred reactor with a polytetrafluoroethylene liner (rotating speed: 600rmp / min), and kept at 120°C for 18h. After the reaction kettle is cooled to room temperature, the obtained material is centrifuged (5000rpm / min), washed with a mixed solution of ethanol and deionized water (ethanol / deionized water=1:3), and then dried at 80°C , to get Mn / α-Fe 2 o 3 sensitive material. The resulting Mn / α-Fe 2 o 3 The sensitive material and the binder are mixed and stirred in the mortar to obtain a uniform mixed slurry and then evenly coated on the Al 2 o 3 plate surface until the mixed slu...

Embodiment 2

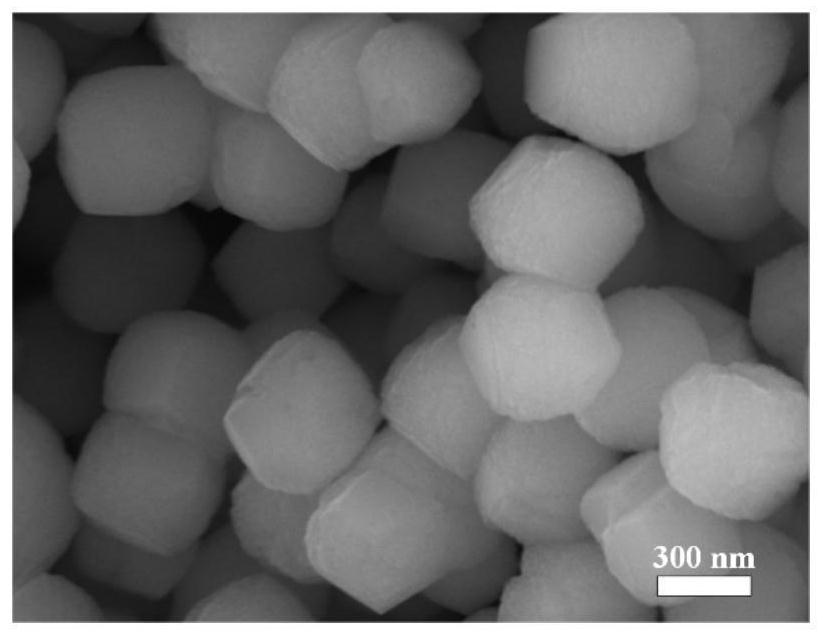

[0048] Prepare Ni / α-Fe as follows 2 o 3 Sensitive materials and Ni / α-Fe 2 o 3 Hydrogen sensor:

[0049] Add 4.4g of ferric chloride, 0.15g of nickel chloride and 20mL of N,N-dimethylformamide into 160mL of deionized water in sequence, stir for 20min under a magnetic stirrer to obtain a uniformly mixed solution, and then mix them The formed mixed solution was put into a 250mL high-temperature stirred reactor with a polytetrafluoroethylene liner (rotating speed: 600rmp / min), and kept at 120°C for 18h. After the reaction kettle is cooled to room temperature, the obtained material is centrifuged (5000rpm / min), washed with a mixed solution of ethanol and deionized water (ethanol / deionized water=1:3), and then dried at 80°C , to get Ni / α-Fe 2 o 3 sensitive material. The resulting Ni / α-Fe 2 o 3 The sensitive material and the binder are mixed and stirred in the mortar to obtain a uniform mixed slurry and then evenly coated on the Al 2 o 3 plate surface until the mixed slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com