Method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction

A technology of titanium dioxide waste acid and valuable elements, applied in the field of metallurgy, can solve problems such as resource waste and environmental pollution, and achieve the effect of avoiding waste and improving the value of waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

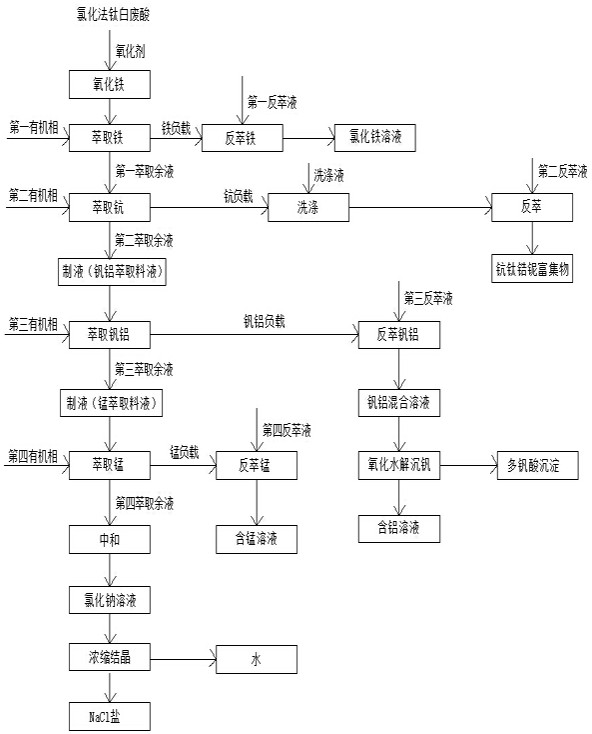

[0033] Embodiment 1, as figure 1 As shown, this embodiment discloses a method for segmental extraction and recovery of valuable elements by chlorination titanium dioxide waste acid, including the following steps:

[0034] S1. Hydrogen peroxide is added to the waste acid of titanium white by the chlorination method, and the iron oxide operation is performed. The oxidation terminal potential is 710mv, and then the iron extraction operation is performed with 50% N235+10% 2-octanol+40% solvent oil, and the extraction is compared to O / A =3:1, the first extraction raffinate and iron load are obtained after phase separation; the iron-loaded organic phase is stripped with 50-degree water, and the stripping ratio O / A=6:1 is obtained to obtain a ferric chloride solution .

[0035] S2. Add 20% P204+5%TBP+75% solvent oil to the first raffinate to extract scandium, titanium, zirconium and niobium. The extraction ratio is O / A=1:10, and the second raffinate is obtained after phase separatio...

Embodiment 2

[0043] Embodiment 2, as figure 1 As shown, this embodiment discloses a method for segmental extraction and recovery of valuable elements by chlorination titanium dioxide waste acid, including the following steps:

[0044] S1. Sodium hypochlorite is added to the waste acid of titanium white by the chlorination method, and the iron oxide operation is performed. The oxidation terminal potential is 800mv, and then the iron extraction operation is performed with 40% N235+12% 2-octanol+48% solvent oil, and the extraction is compared to O / A =2:1, the first extraction raffinate and the iron-loaded organic phase are obtained after phase separation; the iron load is stripped with 60-degree water, and the stripping ratio O / A=4:1 is obtained to obtain a ferric chloride solution ;

[0045]S2. Add 20% P272+5%TBP+75% solvent oil to the first raffinate to extract scandium, titanium, zirconium and niobium. The extraction ratio is O / A=1:40, and the second raffinate is obtained after phase sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com