Patents

Literature

232 results about "Chloride process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chloride process is used to separate titanium from its ores. In this process, the feedstock is treated at 1000 °C with carbon and chlorine gas, giving titanium tetrachloride. The process is a variant of a carbothermic reaction, which exploits the reducing power of carbon.

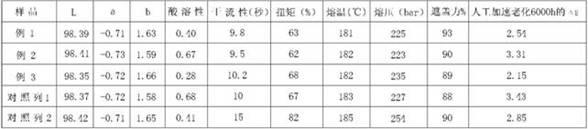

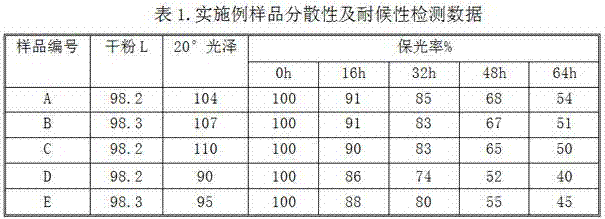

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

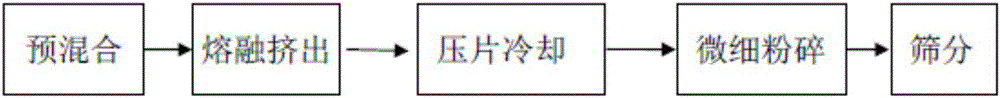

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

Method for preparing multifunctional titanium dioxide pigment with chlorination method

ActiveCN102079885AGood weather resistanceGood light fastnessPigment physical treatmentPhosphatePapermaking

The invention relates to a method for preparing multifunctional titanium dioxide pigment with a chlorination method, which comprises the following steps of: blending a titanium dioxide primary product into titanium dioxide slurry by adopting a chlorination method and adjusting a pH value between 9.0 and 11.0; adding a phosphate dispersing agent and carrying out grinding treatment; removing a grinding medium from the slurry and heating; adding a water-soluble silicate solution for curing; adjusting the pH value of the slurry for forming amorphous silica and curing for forming a first coating layer; cooling the slurry to 50-70 DEG C; adding a sodium metaaluminate solution and curing; adjusting the pH value of the slurry between 8.0 and 9.0, curing and forming an amorphous alumina coating layer on the first coating layer; adding an aluminum salt solution, maintaining the pH of the slurry between 7.0 and 9.0 and curing; adjusting the pH value of the slurry between 6.0 and 7.0 and curing; and washing the slurry with deionized water till the conductivity of a filter cake is larger than 15,000 ohm.cm, and carrying out drying and steaming pulverizing treatment to obtain a finished product. The multifunctional titanium dioxide pigment prepared with the method has higher weather resistance, whiteness, covering capability, opacity and dispersibility and excellent processing performance in the fields of coating, plastics, papermaking, and the like.

Owner:中信钛业股份有限公司

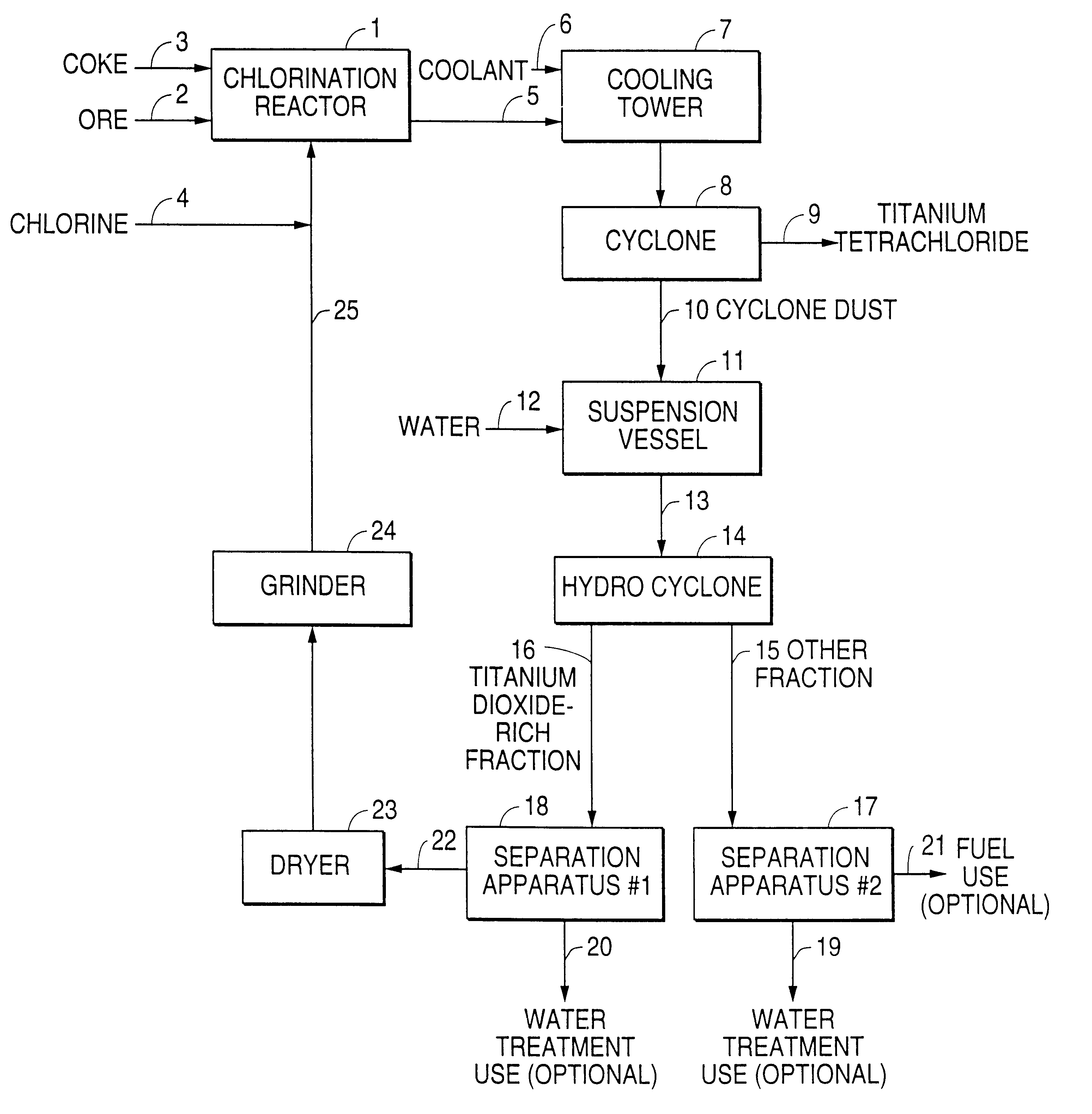

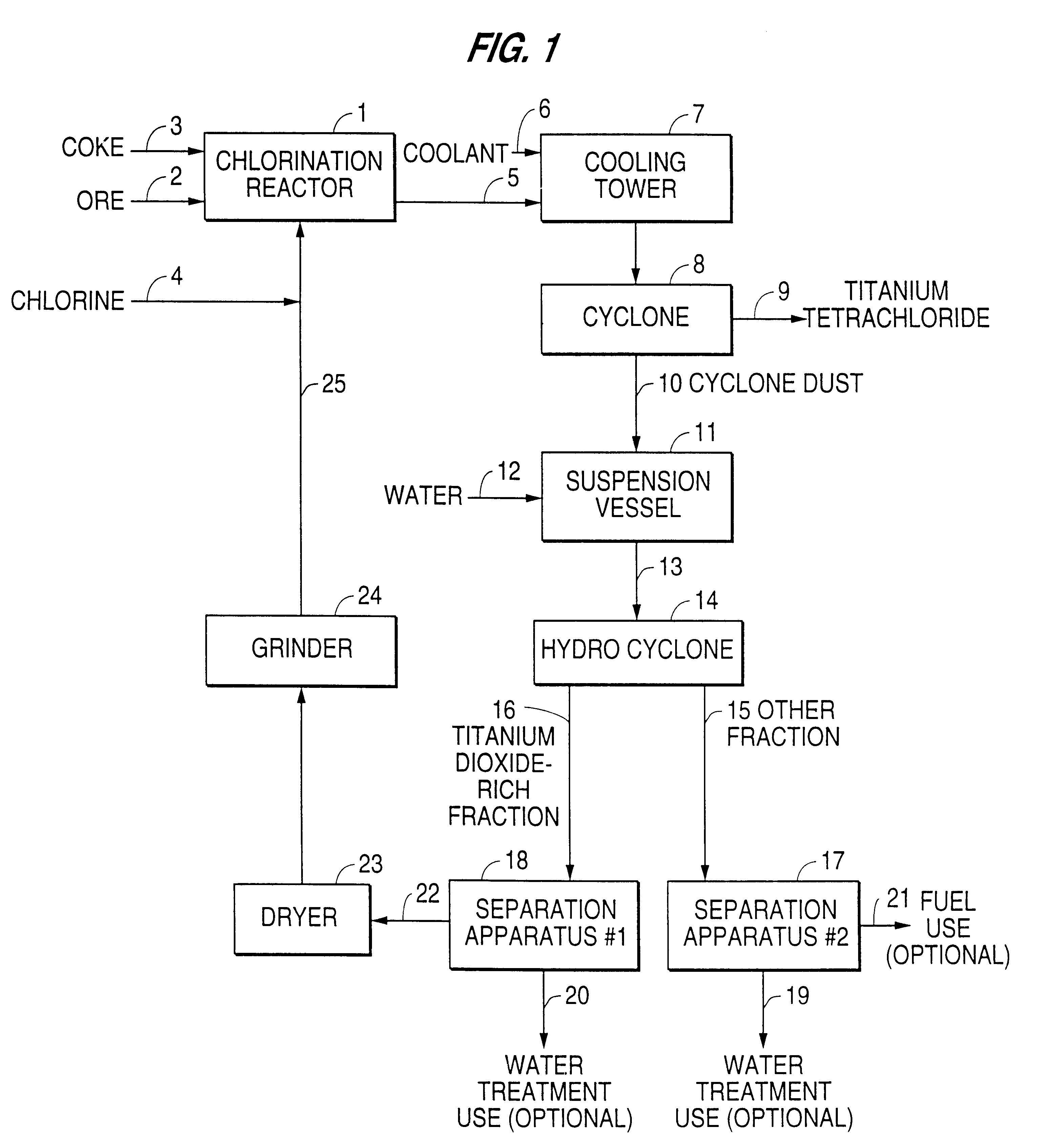

Process for increasing the yield in the manufacture of titanium dioxide by the chloride process

InactiveUS6399033B1Reduce coke contentReduced silica contentZirconium compoundsTitanium dioxideSingle stageFluidized bed

An improvement to the chloride process of making titanium dioxide. By recycling some of the cyclone dust, the yield in the chlorination of titanium-containing raw materials can be increased. In order to prevent silica accumulation in the fluidized bed, the cyclone dust is divided into two fractions. An economic solution is described of a single-stage separation of the cyclone dust in a hydrocyclone, the majority of the titanium dioxide occurring in the hydrocyclone underflow, although the separation is not sharp. By grinding and drying the solids from the hydrocyclone underflow, the titanium dioxide particles returned to the lower region of the fluidized-bed reactor are rapidly chlorinated, while the quartz and coke particles are rapidly discharged again from the fluid bed, so that no silica contamination occurs.

Owner:KRONOS INCORPORATED

Process for preparing fraction oil hydrogenation treatmnt catalyst

InactiveCN1458232APromote formationModulation of surface propertiesHydrocarbon oils refiningDistillates petroleumActive component

The preparation process of fraction oil hydrogenation treatment catalyst includes assistant adding modification of gamma-alumina precursor and subsequent conventional preparation process. The fraction oil hydrogenation treatment catalyst includes gamma-alumina precursoe prepared through carbonation process, aluminum nitrate process, aluminum sulfate process or aluminum chloride process; F an / or Bas assistant and W and Ni as active component. Compared with available technology, the present invention has the advantages of simple preparation process, low cost, low power consumption, and excellent catalyst performance. The catalyst of the present invention is suitable for hydrogenation treatment of 130-390 deg.c fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing special titanium dioxide pigment for plastic sectional materials by chlorination method

ActiveCN102070921APrevent chalkingGood weather resistancePigment treatment with organosilicon compoundsPigment physical treatmentPhosphateSlurry

The invention provides a method for preparing special titanium dioxide pigment for plastic sectional materials by a chlorination method, which comprises the following steps that: the chlorination method is adopted for preparing titanium dioxide primary products into slurry, and the pH value of the slurry is regulated to 4.0 to 5.0; phosphate dispersing agents are added; grinding treatment is carried out, then, grinding media is removed, and the temperature is raised; water-soluble silicate solution is added, the pH value of the slurry is maintained between 3.5 and 4.5, amorphous silicon oxide is formed, curing is carried out, and a first covering layer is formed; the pH value of the slurry is regulated to 6.0 to 7.0, curing is carried out, and a second covering layer is formed; aluminum salt solution is added, the pH value is controlled between 7.0 and 9.0, curing is carried out, a third covering layer is formed, the pH value of the slurry is regulated to 6.0 to 7.0, and curing is carried out; the slurry is washed by de-ionized water until the conductivity of filter cake is higher than 15000 ohm*cm, and then, drying and air powder treatment are carried out; modified polysiloxane is added in the air powder process, and a fourth organic covering layer is formed; and materials are recovered through a bag filter. The titanium dioxide pigment prepared by the method provided by the invention has the advantages of high weatherability, high shielding capability, high non-transparency and excellent processing performance in the field of plastic sectional materials.

Owner:中信钛业股份有限公司

Preparation method of high-light-resistant titanium dioxide pigment for laminated paper

ActiveCN109705630AImprove retentionGood dispersant effectInorganic compound additionPigment treatment with non-polymer organic compoundsALUMINUM PHOSPHATESlurry

The invention provides a preparation method of a high-light-resistant titanium dioxide pigment for laminated paper. The method comprises the following steps: preparing titanium dioxide slurry from a rutile-type titanium dioxide initial product prepared by adopting a chlorination process method, and adjusting the pH value to 8.5-10.5; adding a citric acid radical-containing organic substance as a dispersing agent, and performing grinding treatment; performing heating to 55-65 DEG C for coating treatment, performing coating by using a dense aluminum phosphate coating layer, performing coating byusing a loose silicon aluminum compound coating layer, and performing coating by using a loose boehmite-type hydrated aluminum oxide coating layer; performing washing by using deionized water until conductivity of a filter cake is greater than 15000 omega*cm, and performing drying; and adding amino-containing organic matter in the steaming powder process, and performing organic coating treatmentto obtain the titanium dioxide pigment for the decorative laminated paper. The method provided by the invention has the advantages that the titanium dioxide pigment prepared by the method has the characteristics of high light performance, good whiteness and a high retention rate in the laminated decorative paper, and the prepared titanium dioxide pigment has a medium color bottom phase and the advantage of easy color matching, and can be widely used in the field of the high-end laminated decorative paper.

Owner:中信钛业股份有限公司

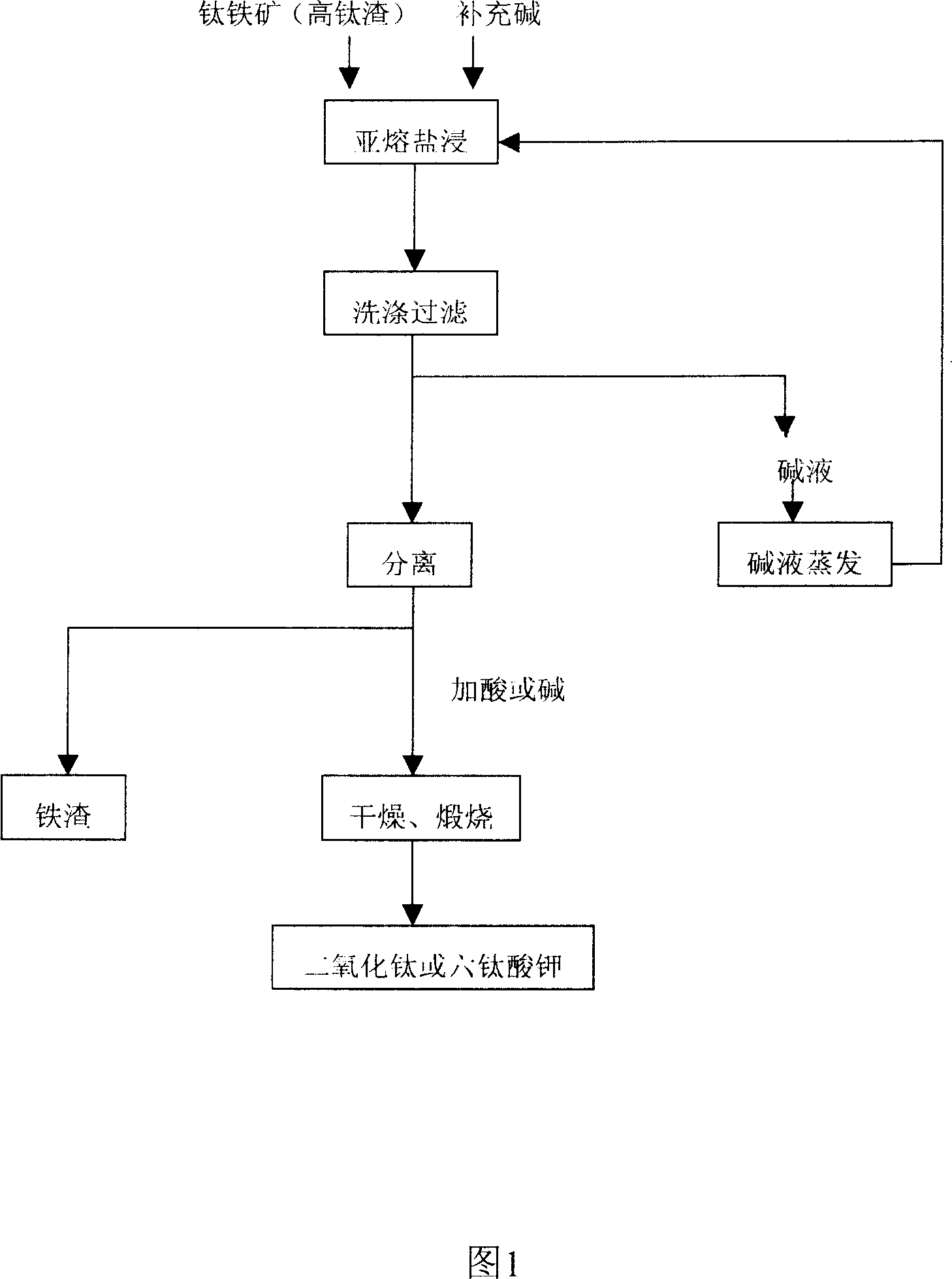

Process for clean producing titanium dioxide and potassium hexatitanate wiskers by titanium iron ore or high-titanium dreg sub-molten salt

The invention relates to a method to produce titanium dioxide and K2Ti6O13 whisker from using ilmenite or high titanium slag as raw material. It includes the following steps: ilmenite or high titanium slag reacting in KOH liquid phase medium, and the weight ratio is 4:1-8:1; gaining the mixture reaction product of alkali liquid, barium titanate and iron enriched slag; taking hydrolysis or acidolysis, burning and purifying to the product to gain purified titanium dioxide and K2Ti6O13 whisker. The reacting temperature is 240-350 degree centigrade and the yield is over 99%. The recycled titanium dioxide could be used as dye, coating, etc; and the K2Ti6O13 whisker could be used as insulating material, refractory material, and friction material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Chlorination residue pulping wastewater comprehensive treatment method

InactiveCN108675499AReduce pollutionReduce pressure on environmental protectionWater contaminantsCalcium/strontium/barium sulfatesMirabiliteSodium sulfate

The invention relates to a chlorination residue pulping wastewater comprehensive treatment method, which comprises the following steps that 1, excessive sodium sulfate is added into calcium chloride wastewater generated during the titanium dioxide preparation by a chlorination process; after the reaction, filtering is performed; white gypsum and crude brine water are obtained; 2, BaCl2 is added into the crude brine water; the SO4<2-> content in the crude brine is regulated to be 3 to 5g / L; according to the contents of Ca<2+>, Ba<2+> and Sr<2+> in the crude brine, the corresponding quantity ofBaCl2 and Na2CO3 is added for reaction; then, precipitates are separated out; finished product brine is obtained; 3, the finished product brine is used as primary brine in chlorine-alkali chemical engineering. The calcium chloride wastewater and the chlorine-alkali plant by-product of mirabilite are comprehensively treated; the environment pollution and the environment protection pressure can be reduced; the treatment cost is low; great economic benefits can be produced.

Owner:LOMON BILLIONS GRP CO LTD +1

Process method for producing zirconium tetrachloride through fluidizing chlorination method

ActiveCN104058454AReduce manufacturing costDo not change frequentlyChemical industryZirconium halidesTetrachlorideSilicon tetrachloride

The invention relates to a process method for producing zirconium tetrachloride through a fluidizing chlorination method. The process method comprises the following steps: smashing zircon sand to 300-325 meshes, smashing petroleum coke to 100-200 meshes, smashing chemical heat supplementing agent to 200-400 meshes, firstly fully mixing the zircon sand and the petroleum coke powder, simultaneously adding the mixture and the heat supplementing agent into a fluidizing chlorination furnace, introducing chlorine to carry out chlorination reaction and keeping the temperature of the fluidizing chlorination furnace at 1100 DEG C, wherein the chemical heat supplementing agent is silica powder or silicon carbide or a mixture of the silica powder and the silicon carbide; the reaction formula of the chemical heat supplementing agent is SiC+2Cl2=SiCl4+C or Si+2Cl2=SiCl4; the main reaction formula of producing the zirconium tetrachloride through zircon sand chlorination is ZrSiO4+4C+4Cl2=ZrCl4+SiCl4+4CO. According to the method disclosed by the invention, the heating problem of a zircon sand fluidizing chlorination furnace can be solved, the production cost of the zirconium tetrachloride is reduced and a byproduct: an important chemical raw material silicon tetrachloride can be produced, so that the process method has the advantages of increasing the working efficiency, saving the energy and reducing the production cost.

Owner:内蒙古自治区浩森新材料开发有限公司

Method for preparing high-grade synthetic rutile

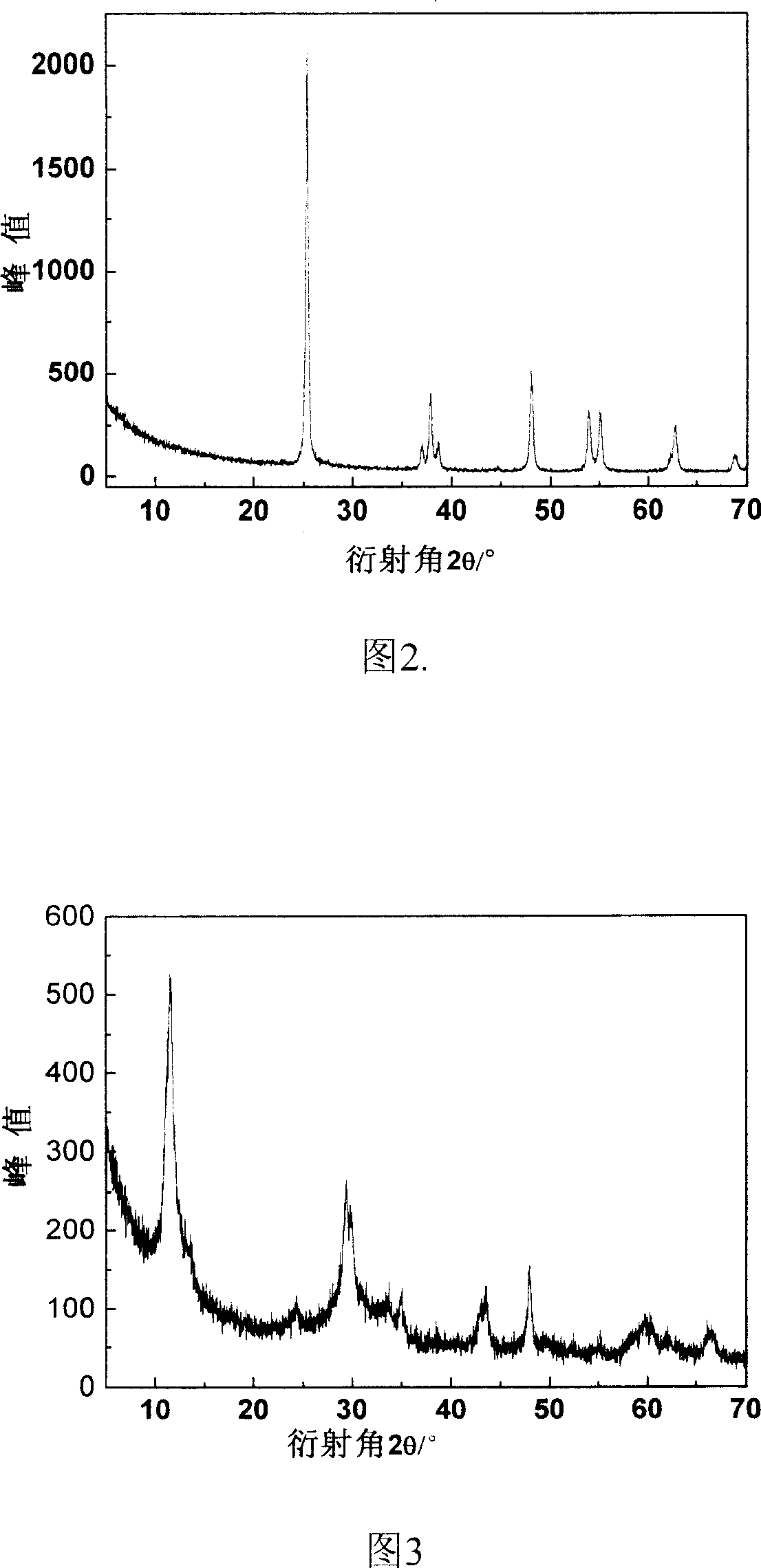

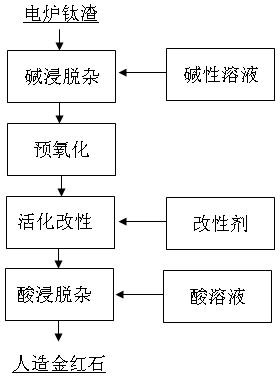

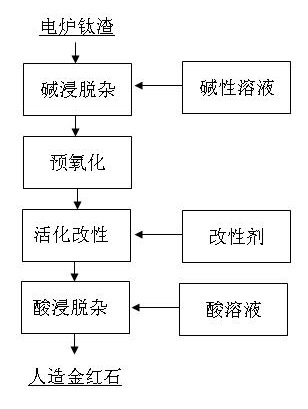

InactiveCN102139918AWide applicabilityExcellent physical and chemical propertiesTitanium dioxidePregnant leach solutionPhysical chemistry

The invention relates to a method for preparing high-grade synthetic rutile; the method comprises the following steps: electro-titanium slag and an alkaline solution are mixed by weight mixture ratio of liquid to solid of 1:1 to 15 for alkali leaching impurity removal reaction; after being reacted for 0.5 to 24 hours, the mixture is filtered and scrubbed to obtain alkali leached slag; modified slag is obtained after pre-oxidation and activated modification are successively carried out on alkali leached slag; the modified slag and the acid solution are mixed by weight mixture ratio of liquid to solid of 1:1 to 15 for acid leaching impurity removal reaction; after the mixture is reacted for 1 to 24 hours, acid leached slag is obtained; the synthetic rutile with the purity of greater than 93% is obtained after the acid leached residue is dried; the method meets the requirement that a chlorination process is used for titanium dioxide production, and has wide applicability to raw materials; the manufactured rutile has excellent physical and chemical properties, high purities and uniform grain fineness distribution; the recovery rate of titanium in the whole process is higher; the needed device has few investment, low energy consumption and has little impact on environment and low cost; leaching solutions generated after each-section reaction is recovered and processed for cyclic utilization.

Owner:KUNMING METALLURGY INST

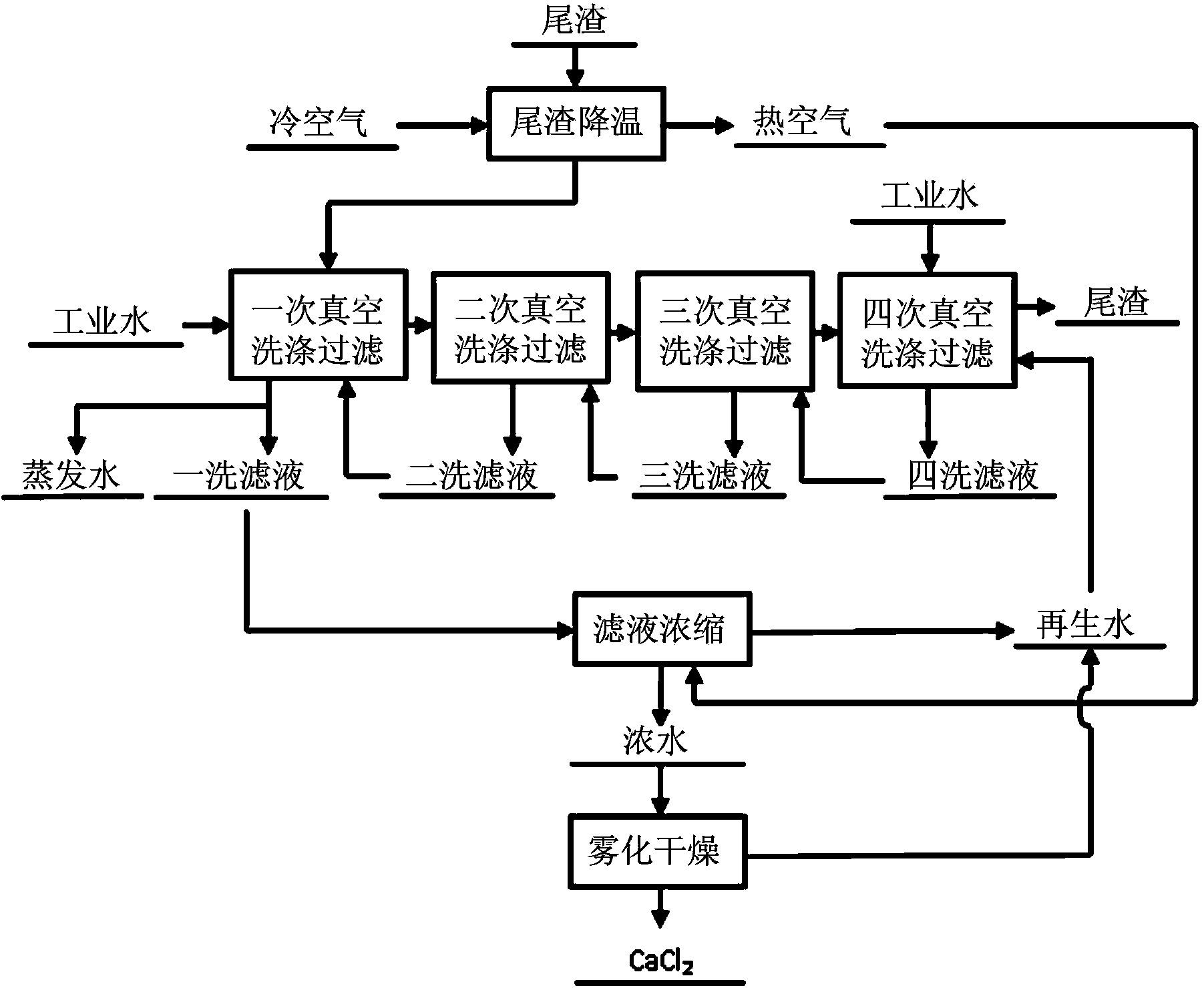

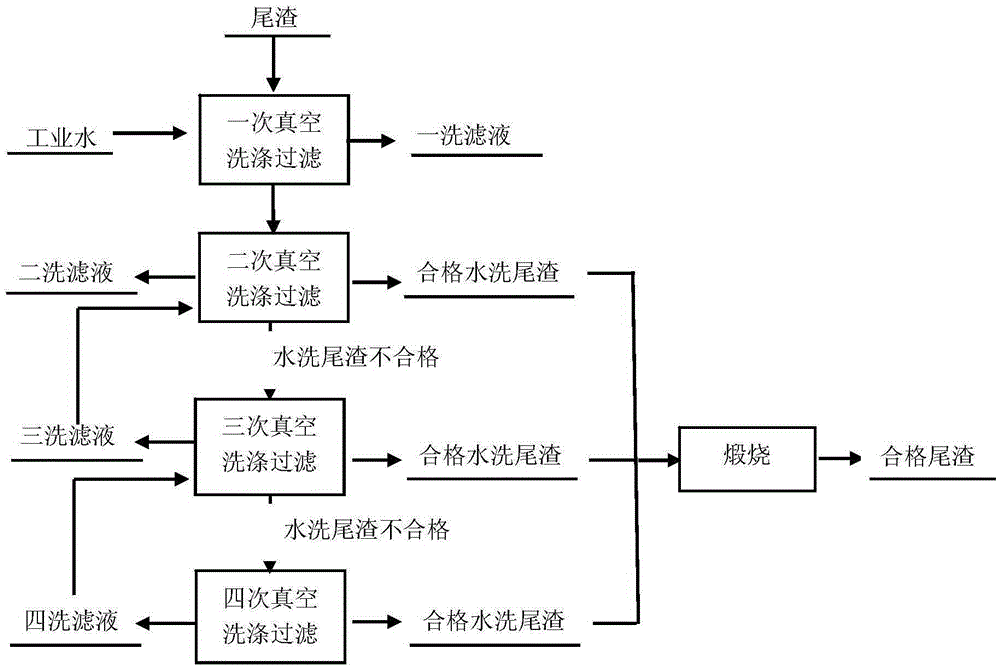

Pollution-free processing method and system for tailings generated by chlorination-process titanium extraction

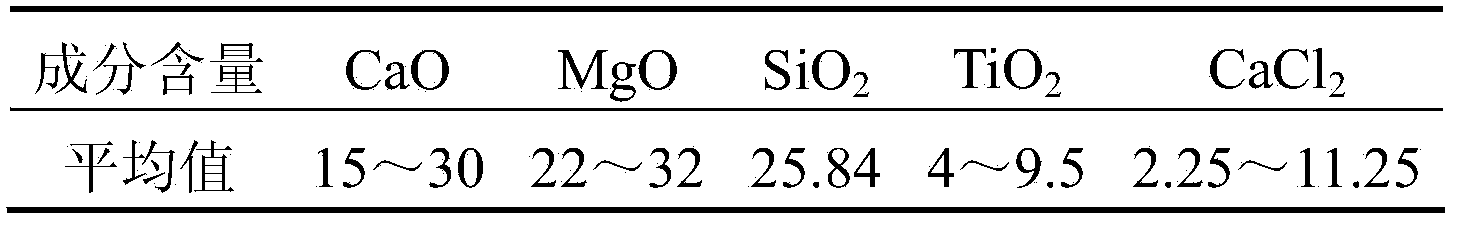

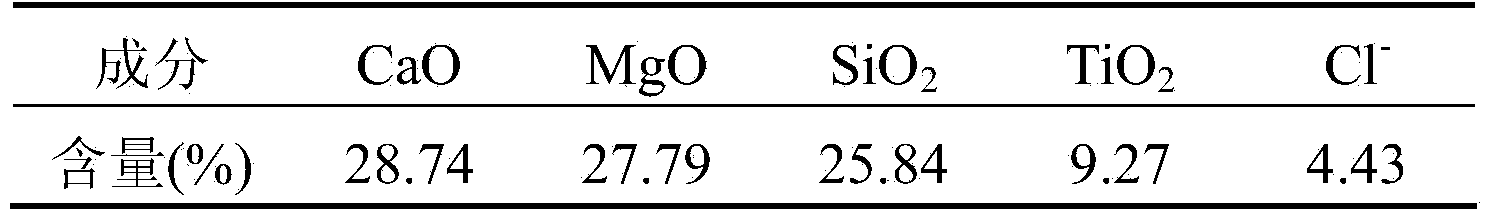

InactiveCN103936050AReduce Chloride ContentAchieve recyclingCalcium/strontium/barium chloridesCold airChloride

The invention provides a pollution-free processing method and system for tailings generated by chlorination-process titanium extraction. The method comprises the following steps: cooling high-temperature tailings generated by chlorination-process titanium extraction by using cold air to obtain hot air and hot tailings with temperature of 120-150 DEG C; orderly carrying out vacuum washing and filtering on the hot tailings for more than twice, wherein every time vacuum washing and filtering is carried out, the tailings are mixed and soaked with a scrubbing solution and then filtrate and washed tailings can be obtained through filtering, and in addition the filtrate in the last vacuum washing and filtering process is used as the scrubbing solution in the previous vacuum washing and filtering process; concentrating the filtrate obtained in the first vacuum washing and filtering process by using hot air, so as to obtain a concentrated solution; and carrying out spray drying on the concentrated solution to obtain calcium chloride. The system comprises a cooling unit, a vacuum washing and filtering unit, a concentrating unit, a spray drying unit and a cold air supply unit. The tailings which can be applied to the industries such as building materials and can meet the pollution-free requirements can be obtained and cyclic utilization of the scrubbing solution can be achieved; moreover, the pollution-free processing method and system can be effectively connected with the process of preparing titanium tetrachloride by the chlorination process.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Scour media for titanium dioxide production

InactiveUS20050249659A1Reduce heat transferCooling problemTitanium dioxideCleaning processes and apparatusRutilePigment

Anatase titanium dioxide pigment calcined to a crush strength and density meeting the requirements for an acceptable scour medium is effectively utilized as a scour medium in the chloride process for producing rutile titanium dioxide. The calcining process converts a portion of the anatase pigment to rutile. This calcined anatase can, consequently, be utilized as a scour medium in the chloride process for producing rutile titanium dioxide. The calcined anatase is not a contaminant to the process for producing rutile titanium dioxide. Thus, relatively inexpensive anatase can be converted into a rutile scour medium that can be processed into pigment.

Owner:KERR MCGEE CHEM CORP

Dechlorination method for chlorination process titanium extracting tailing slag

InactiveCN105385855AReduce contentReduce adverse effectsProcess efficiency improvementSlagButt joint

The invention relates to a dechlorination process for chlorination process titanium extracting tailing slag, and belongs to the field of metallurgy. A dechlorination method for chlorination process titanium extracting tailing slag includes the steps that the chlorination process titanium extracting tailing slag and water are stirred and mixed to form slurry, wherein the slag to water mass ratio is 1:2-4; and then qualified titanium extracting tailing slag is obtained in a filtering, washing and filtering manner, wherein the qualified titanium extracting tailing slag meets the condition that the chlorine ion content is lower than 0.2%, the water content is 12% by weight to 20% by weight. According to the dechlorination method, the stirring and filtering manner is adopted, the content of chloride ions in the chlorination process titanium extracting tailing slag can be effectively reduced, and the adverse effect of the chlorine ions in tailing slag comprehensive utilization is reduced; in addition, the stirring, filtering and burning manner is further used, free carbon in the tailing slag is removed, the color of the tailing slag is changed from black to grayish yellow, and application of the tailing slag to building materials is facilitated; butt joint of the tailing slag processing process and the Panzhihua steel high temperature carbonization and low temperature chlorination titanium contained blast furnace slag titanium extracting process is achieved; and the blank on the chlorination process titanium extracting tailing slag chlorination technology is filled.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

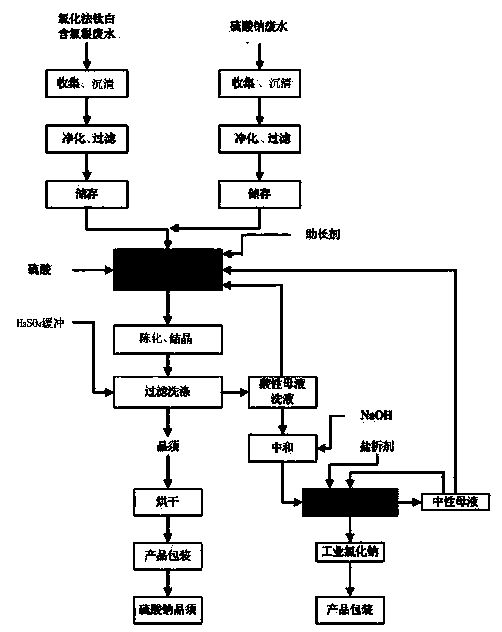

Process of producing calcium sulfate crystal whiskers from chloride-containing wastewater generated in chloride process titanium dioxide production

ActiveCN103834989AImprove the level of cleaner productionSolve processing problemsPolycrystalline material growthFrom normal temperature solutionsFluidized bed dryingAnhydrous Calcium Sulfate

The invention relates to a process of producing calcium sulfate crystal whiskers from chloride-containing wastewater generated in chloride process titanium dioxide production. The process comprises the following steps: respectively colleting, clarifying, purifying and filtering chloride-containing wastewater generated in chloride process titanium dioxide production and sodium sulfate-containing wastewater, mixing for reacting, stirring, heating and adding sulfuric acid to adjust the pH value; meanwhile, adding magnesium chloride as a growth substance; placing in a crystallization tank to age and crystallize to obtain calcium sulfate crystals; filtering, and adding H2SO4 to be buffered and heated to be boiled; thermally filtering and washing by deionized water at the same time to obtain calcium sulfate crystal whiskers; feeding to a fluidized bed dryer to be dried and hydrated, and packaging to obtain anhydrous calcium sulfate crystal whiskers. The process is simple and low in cost, and is suitable for industrialized production, so that wastewater is comprehensively utilized.

Owner:中信钛业股份有限公司

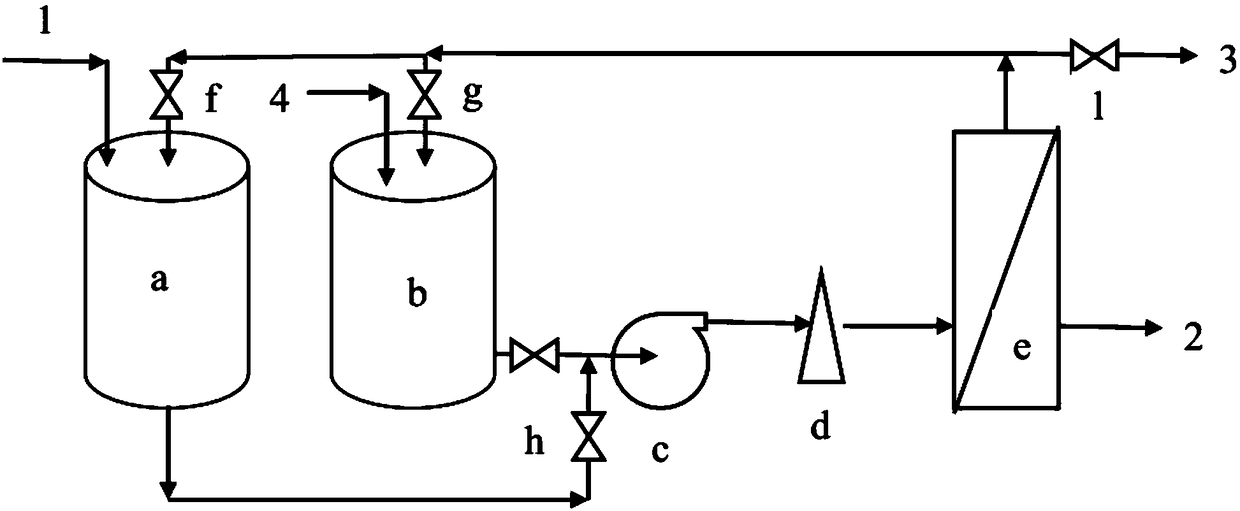

Treatment method and device for wastewater from production of titanium dioxide

PendingCN108658270AReduce adsorptionAvoid cloggingWater treatment parameter controlSemi-permeable membranesCross-flow filtrationCleansing Agents

The invention relates to a process for concentrating and recovering metatitanic acid or titanium dioxide in wastewater from production of titanium dioxide by using a ceramic membrane, and in particular relates to a process for concentrating and recovering the metatitanic acid or the titanium dioxide in waste acids and wastewater of primary washing, secondary washing and tertiary washing in a sulfuric acid method, and in post-treatment wastewater in a chlorination method by adopting cross-flow filtration ceramic membrane filter equipment. According to a pore size screening mechanism of a membrane, the method is started from membrane selection, and a membrane with a suitable pore size and material is searched to avoid clogging of membrane pores; through process optimization of the ceramic membrane, membrane surface pollution formed by easy adsorption of the metatitanic acid or the titanium dioxide in the membrane process is reduced; and finally, a suitable cleaning process and cleaning agent are selected to clean the contaminated membrane, so that a flux of the ceramic membrane is regenerated and restored. Experimental results show that a stable operation period of the ceramic membrane achieves one month or more, and the flux is always maintained at 500 L / m<2>*h (excluding waste acid), and a membrane cleaning regeneration recovery rate reaches 98% or more.

Owner:JIANGSU JIUWU HITECH

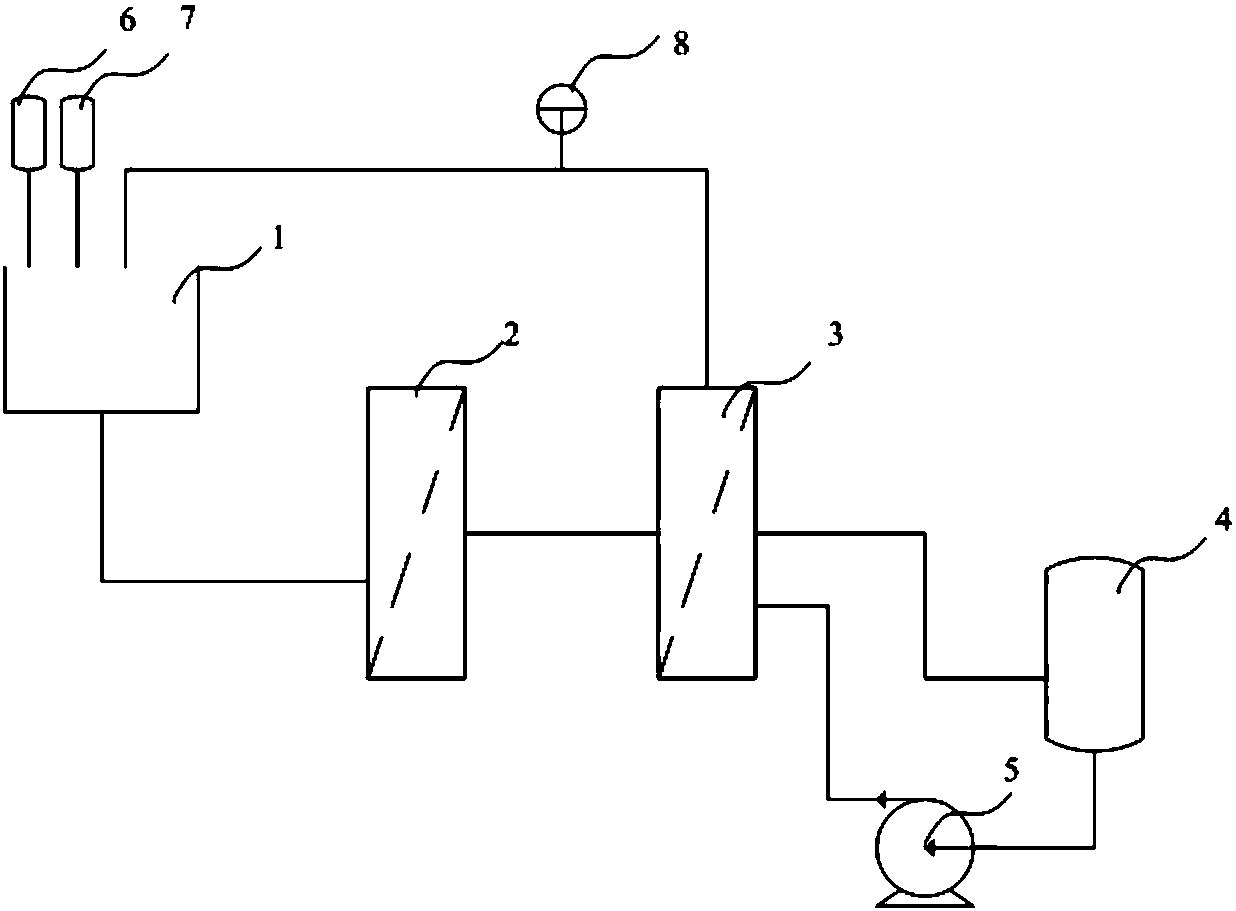

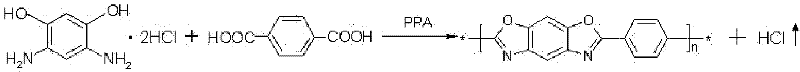

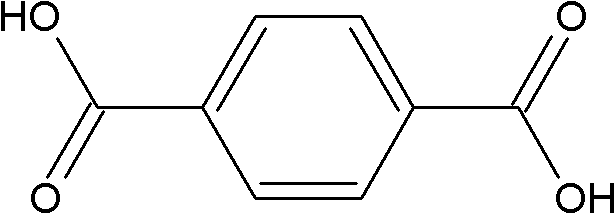

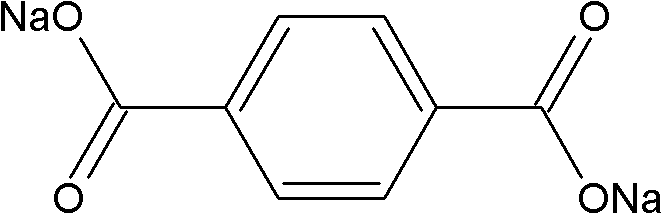

Preparation method of poly-p-phenylene benzobisoxazole fiber

InactiveCN102260932AAchieve removalDoes not affect mechanical propertiesMonocomponent synthetic polymer artificial filamentFiberPolyethylene terephthalate glycol

The invention relates to a preparation method of poly-p-phenylene benzobisoxazole fiber, which is an improvement to the existing salt-forming method. The present invention is that terephthalic acid and 4,6-diaminoresorcinol hydrochloride are neutralized by acid and alkali to directly generate 4,6-diamino-1,3-resorcinol / terephthalic acid composite salt, remove 80-90% of the water in the system by filtration, the compound salt does not need to be further washed and dried, and polyphosphoric acid and phosphorus pentoxide are directly added for polymerization to prepare a poly-p-benzobisoxazole prepolymer. Then the prepolymer is subjected to twin-screw continuous post-polymerization, filtration and defoaming, and directly enters spinning equipment for spinning, water washing, drying and winding to obtain poly-p-phenylene benzobisoxazole fibers. The invention can greatly save time, omit the hydrogen chloride removal process, and increase the continuity of the production process.

Owner:SINOSELEN HI TECH

Preparation method of titanium dioxide pigment special for coating with high weather resistance

ActiveCN109266049AHigh rutile contentGood photochemical spotPigment physical treatmentPigment treatment with non-polymer organic compoundsAluminateSlurry

The invention relates to a preparation method of a titanium dioxide pigment special for a coating with high weather resistance. A chlorination process is adopted for preparing a rutile type titanium dioxide preliminary product, deionized water is used for beating, the preliminary product is prepared into titanium dioxide slurry, and a dispersing agent is added for grinding treatment; a water-soluble silicate solution is added to form a first layer of dense silicon film, a water-soluble alkaline aluminate solution is added to form a second layer of dense aluminum film, and the water-soluble alkaline aluminate solution is added again to form a third layer of loose aluminum film; water washing is conducted to obtain a filter cake, and then drying and steam crushing treatment are conducted toobtain the titanium dioxide pigment special for the coating with high weather resistance. The method has the advantages that the titanium dioxide pigment prepared by means of the method has the advantages of excellent weather resistance, powdering resistance, covering performance and dispersing performance in the coating, and the prepared titanium dioxide pigment has the advantages that the coloris medium, the phase is low, and color blending is easy.

Owner:中信钛业股份有限公司

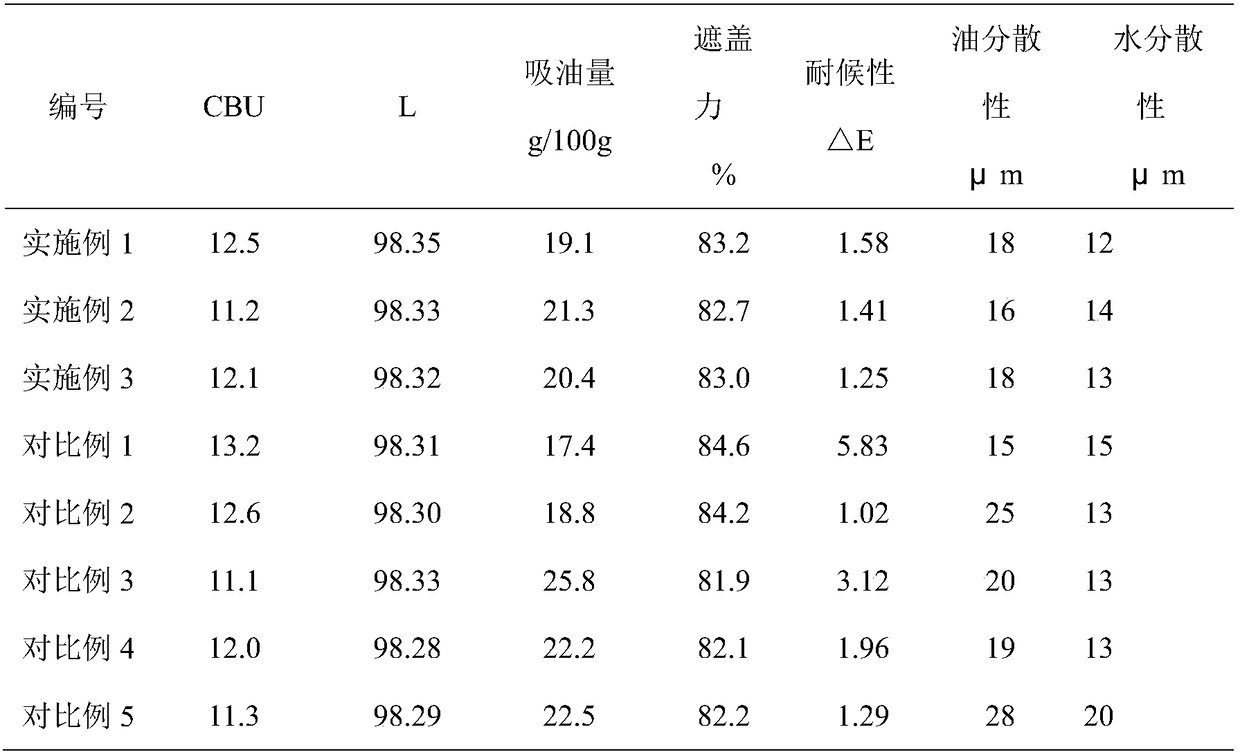

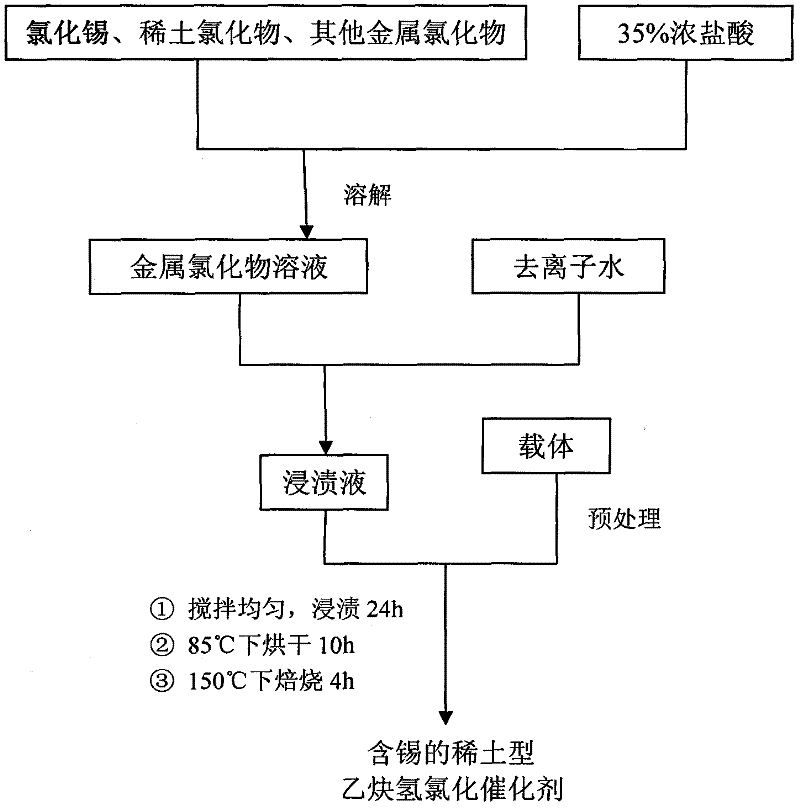

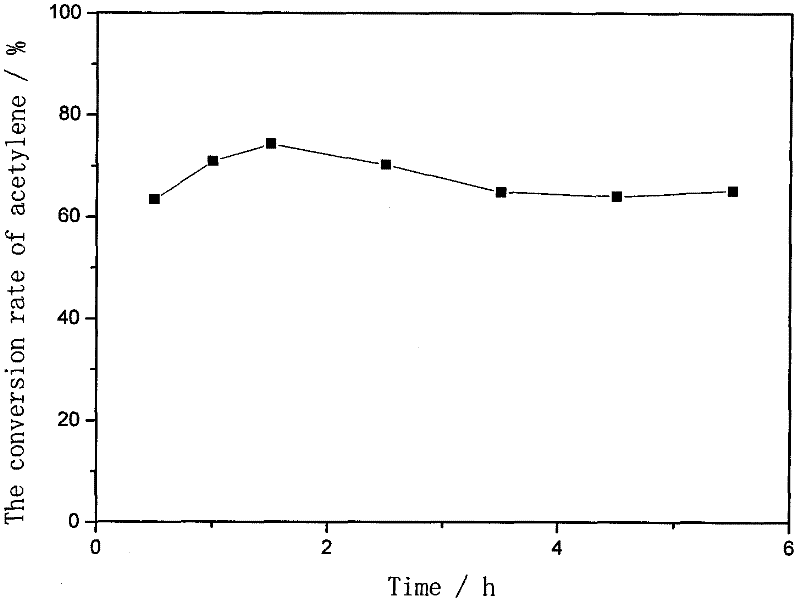

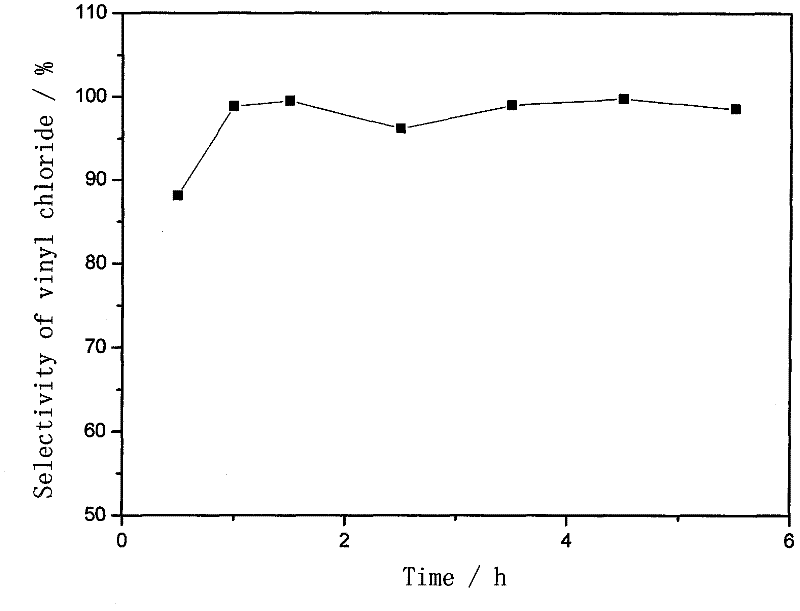

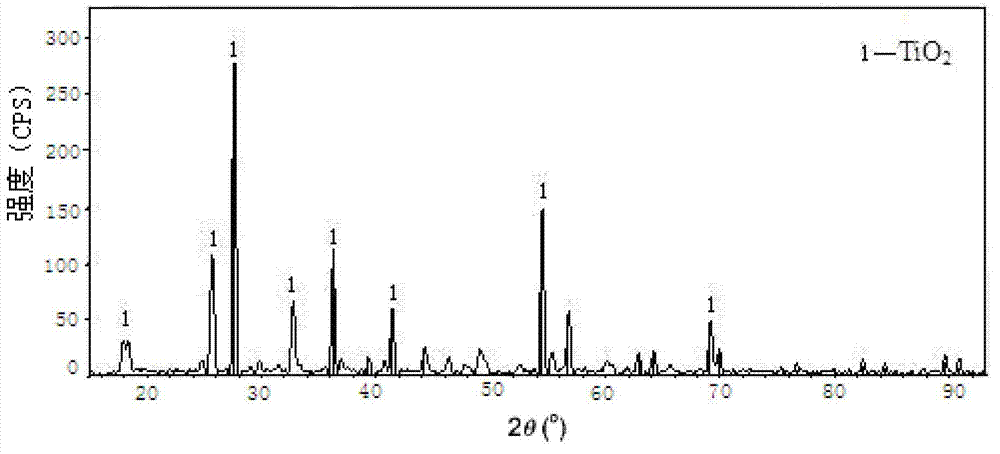

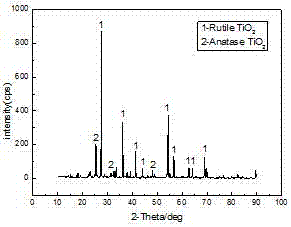

Method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin

InactiveCN102430418AHigh catalytic activitySimple processPhysical/chemical process catalystsPreparation by halogen halide additionMetal chlorideFixed bed

The invention disclose a method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin, which belongs to the field of preparing the hydrochlorination catalyst of acetylene. The catalyst comprises stannic chloride, rare earth chloride, other metal chlorides and carriers, wherein the rare earth chloride is adopted as cerium chloride or lanthanum chloride, and the carriers are cerium-zirconium powder or zirconia. The catalyst is prepared by soaking method, can be applied to fixed-bed reactors, has low cost, has no pollution, and has good catalytic activity and high selection in the process of producing vinyl chloride by hydrochlorination of acetylene.

Owner:INNER MONGOLIA UNIVERSITY

Reduced abrasion of titanium dioxide pigments produced from the chloride process

Disclosed herein are pigments comprising mostly rutile TiO2, wherein the mostly rutile TiO2 consists essentially of low abrasion TiO2 particles produced by introducing a metal halide into the chloride process. Further disclosed are ink, can coatings, fibers, papers, and plastics comprising the pigment. Also disclosed herein are pigments comprising the low abrasion TiO2 pigments comprising TiO2 particles which have been further heat treated at a temperature of at least about 800° C. in an oxidizing atmosphere for a time period of at least about 1 hour.

Owner:EI DU PONT DE NEMOURS & CO

Preparation for water chestnut leather activated char

The invention relates to a method for preparing the activated charcoal of water caltrop peels which comprises the preparation of the powdered activated charcoal of water caltrop peels and the lumpish activated charcoal of water caltrop peels. The preparation method of the invention comprises the steps of drying, pre-oxidation, washing, baking and carbonization. Since the method does not adopt methods such as a potassium hydroxide process and a zinc chloride process, etc., during the preparation process, not only environmental pollution can be avoided, but also the operation becomes simple. The activated charcoal of water caltrop peels prepared by the method of the invention can be applied to a plurality of fields. The powdered activated charcoal can be used as an adsorbent to absorb a plurality of common substances as well as toxic and harmful substances such as dyes and phenol, etc., while the lumpish activated charcoal can be taken as fillers used in fluidized beds, moving beds and certain fixed beds and the fillers have better bio-affinity and hydrophilicity, are beneficial to biofilm culturing and cause no secondary pollution to environment after being disused.

Owner:SHANDONG UNIV

Coating composition, and method for forming coating film

ActiveUS20160200922A1Increase brightnessLow UV transmittanceElectrostatic spraying apparatusCoatingsUltravioletOptical transmittance

The present invention provides a coating composition capable of forming a coating film that is applicable to a variety of industrial products, particularly automobile exterior panels, while exhibiting a high lightness and a low ultraviolet transmittance at a wavelength of 420 to 480 nm. The present invention relates to a coating composition comprising a chloride process titanium oxide pigment, a yellow iron oxide pigment, a carbon black pigment having a primary average particle size of 15 to 80 nm, and a resin composition, which is a vehicle-forming component, wherein when the coating composition is applied to give a cured film having a thickness of 25 μm, the resulting cured coating film has an average light transmittance within the range of 0.1 to 1.0% at a wavelength of 420 nm to 480 nm., and the invention also relates to a method for forming a multilayer coating film, comprising forming a color base coating film on a coating film obtained by applying the coating composition.

Owner:KANSAI PAINT CO LTD

Coating composition, and method for forming coating film

ActiveUS9732237B2Increase brightnessLow UV transmittanceCoatingsSpecial surfacesUltravioletTransmittance

The present invention provides a coating composition capable of forming a coating film that is applicable to a variety of industrial products, particularly automobile exterior panels, while exhibiting a high lightness and a low ultraviolet transmittance at a wavelength of 420 to 480 nm. The present invention relates to a coating composition comprising a chloride process titanium oxide pigment, a yellow iron oxide pigment, a carbon black pigment having a primary average particle size of 15 to 80 nm, and a resin composition, which is a vehicle-forming component.

Owner:KANSAI PAINT CO LTD

Method for preparing titanium-rich material by directly reducing molten slag from vanadium-titanium-ferrum concentrate

ActiveCN102787194AQuality improvementImprove utilizationProcess efficiency improvementMolten saltMolten slag

The invention discloses a method for preparing a titanium-rich material by directly reducing the molten slag from the vanadium-titanium-ferrum concentrate, belonging to the technical field of the comprehensive utilization of the vanadium-titanium-magent ore. The method comprises the following steps: (a) grinding the molten slag directly reduced from the vanadium-titanium-ferrum concentrate, and modifying by oxidizing to prepare the modified slag; (b) adding hydrochloric acid solution into the modified slag prepared in the step (a) for acid leaching, and filtering to obtain the acid-leached slag and the acid-leached liquid; (c) adding sodium hydroxide solution into the acid-leached slag obtain in the step (b) for alkali leaching, and filtering to obtain the alkali-leached slag and the alkali-leached liquid; and (d) washing and calcinating the alkali-leached slag obtained in the step (c) to obtain the titanium-rich material. The invention discloses the novel application of the vanadium-titanium-ferrum concentrate to the direct reduction of the molten slag, and the application effect of the vanadium-titanium-ferrum concentrate is improved greatly. The titanium-rich material prepared by adopting the method has high quality, contains more than 90% of TiO2 and less calcium and magnesium and is suitable for producing chloride process titanium dioxide and titanium sponge.

Owner:盐城捷晶科技有限公司

Method for comprehensively utilizing waste hydrochloric acid produced in chlorination eluting tail gas process in chlorination method titanium white production

InactiveCN103432867AReduce loadAchieve reuseChlorine/hydrogen-chloride purificationCalcium/strontium/barium chloridesResource utilizationEvaporation

The invention discloses a method for comprehensively utilizing waste hydrochloric acid produced in a chlorination eluting tail gas process in chlorination method titanium white production, which comprises the following steps: directly passing acidic tail gas produced in a chlorination method production process through a water washing tower, passing the tail gas subjected to water washing through an alkali washing tower, and then performing up-to-standard discharge; filtering the acidic waste water produced in the water washing process, and precipitating the insoluble substance for recycling; adding an alkaline substance into the filtered solution, regulating the pH value, ensuring that the substance in the solution is hydrolyzed to generate an insoluble substance, then filtering the solution, and recycling the filter residue; performing evaporating concentration on the filtrate to obtain a byproduct chloride; and condensing vapor produced in the evaporation process to obtain high-purity hydrochloric acid. Through treatment and recycling of tail gas eluting wastewater, the discharge amount of the wastewater is reduced, the environmental pollution is decreased, and a large amount of byproducts can be recovered, thus improving the resource utilization efficiency.

Owner:LUOHE XINGMAO TITANIUM IND

Method for preparing artificial rutile from high titanium slag

The invention relates to a method for preparing artificial rutile from high titanium slag. The method comprises the following steps: crushing high titanium slag, performing alkaline leaching decontamination, performing modification roasting, performing acid decontamination, calcining and the like. According to the method, microwaves are adopted as a heat source, so that the heating velocity is increased, the heating effect is improved, and meanwhile the reaction energy consumption is reduced when being compared with that of conventional roasting; the roasting temperature of the high titanium slag is reduced, a roasting process is simple, the grade of titanium dioxide is ensured, furthermore the obtained artificial rutile meets a chlorination process for producing titanium dioxide, the production cycle is greatly shortened, and the production cost is lowered; and meanwhile, due to acid-alkali combined leaching, impurities such as calcium oxide, aluminum oxide and silicon dioxide in the high titanium slag are effectively removed, and the grade of the rutile is greatly increased.

Owner:YUNNAN MINZU UNIV

Preparation method of high-gloss rutile titanium dioxide

ActiveCN104119703AGood dispersionHigh glossPigment physical treatmentWater chlorinationPhysical chemistry

The invention discloses a preparation method of high-gloss rutile titanium dioxide. The preparation method comprises the following steps: grinding titanium dioxide slurry obtained by adopting a sulfuric acid process or a chlorination process through a sanding process, and performing heating, zirconium coating, aluminum coating, subsequent water washing, organic treatment and jet milling in sequence to obtain finished high-gloss rutile titanium dioxide, wherein the slurry is cooled in an indirect heat exchange way, ground for more than 5 minutes, heated to 45-55 DEG C and subjected to the aluminum coating after the zirconium coating. According to the method, titanium dioxide aggregates formed due to the pH change are depolymerized, so that the dispersity of titanium dioxide particles can be improved, the subsequent aluminum coating can be carried out in a state that the titanium dioxide particles are fully dispersed, the titanium dioxide particles are fully subjected to the aluminum coating, the dispersity of titanium dioxide is improved, the glossiness of titanium dioxide is also improved, and the high-gloss rutile titanium dioxide is obtained.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Vanadium-titanium iron ore utilization method

InactiveCN107083466AImprove product qualityReduce difficultyFluidised-bed furnacesTitanium chlorideCarbonization

The invention provides a vanadium-titanium iron ore utilization method. The vanadium-titanium iron ore utilization method comprises the following steps of conducting oxidizing roasting pretreatment on vanadium-titanium iron ore, so that a pretreatment product is obtained; mixing the pretreatment product with a carbonaceous reducing agent and a binding agent, so that a mixed material is obtained; conducting agglomeration and drying on the mixed material, so that carbon-containing pellets are obtained; conducting reductive carbonization on the carbon-containing pellets, so that a metalized material is obtained; and conducting physical separation on the metalized material, so that an iron-enriched material and a titanium-enriched material are obtained. According to the vanadium-titanium iron ore utilization method, oxidizing roasting pretreatment is conducted on the vanadium-titanium iron ore, the ore phase structure of the vanadium-titanium iron ore is changed, and the difficulty of reduction and carbonization of titanic oxide is lowered; and meanwhile, most of the element sulfur in the vanadium-titanium iron ore is removed, quality of vanadium-titanium iron ore preparation products is improved, and the application scope of the vanadium-titanium iron ore is widened. It is indicated through experimental results that the removal rate of sulfur is 79% or above; titanium in the titanium-enriched material exists in the form of titanium carbide, the mass content of the titanium reaches 24% or above, and the titanium can serve as a raw material for producing titanium tetrachloride through a chlorination process; and the mass content of total ferrum (TFe) in the iron-enriched material reaches 88% or above.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Production method using chlorination process by-product for inorganic coating of titanium dioxide

The invention relates to a production method using a chlorination process by-product for inorganic coating of titanium dioxide. The method comprises the following steps that 1, a kiln product of titanium dioxide by a sulfuric acid method which is qualified after calcination is subjected to sanding, then sanding slurry with qualified sanding grain sizes is introduced into a coating pot, the sandingslurry concentration is controlled at 250-350 g / L by TiO2, and meanwhile the temperature is elevated to 40 DEG C; 2, TiCl4 is added, and meanwhile, NaH2PO4 and Na3PO4 are added; 3, heating is conducted to elevate the temperature to 80 DEG C, an aluminium salt solution is added to adjust the pH to 6.8-7.0, then H3PO4 and an aluminium salt solution are added in a parallel-flow mode, and it is maintained that pH=6.0-7.5; 4, an aluminium salt solution and H2SO4 are added in a parallel-flow mode, and it is maintained that pH=6.0-7.5; 5, dilute H2SO4 is used for adjusting the slurry pH value to 5.3-5.5; 6, after third-washing, flash evaporation and fluid energy milling, a finished product is obtained. By means of the method, the titanium dioxide by the sulfuric acid method with the light resistance close to that of a cerium salt coated finished product can be obtained, and the cost is very low.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

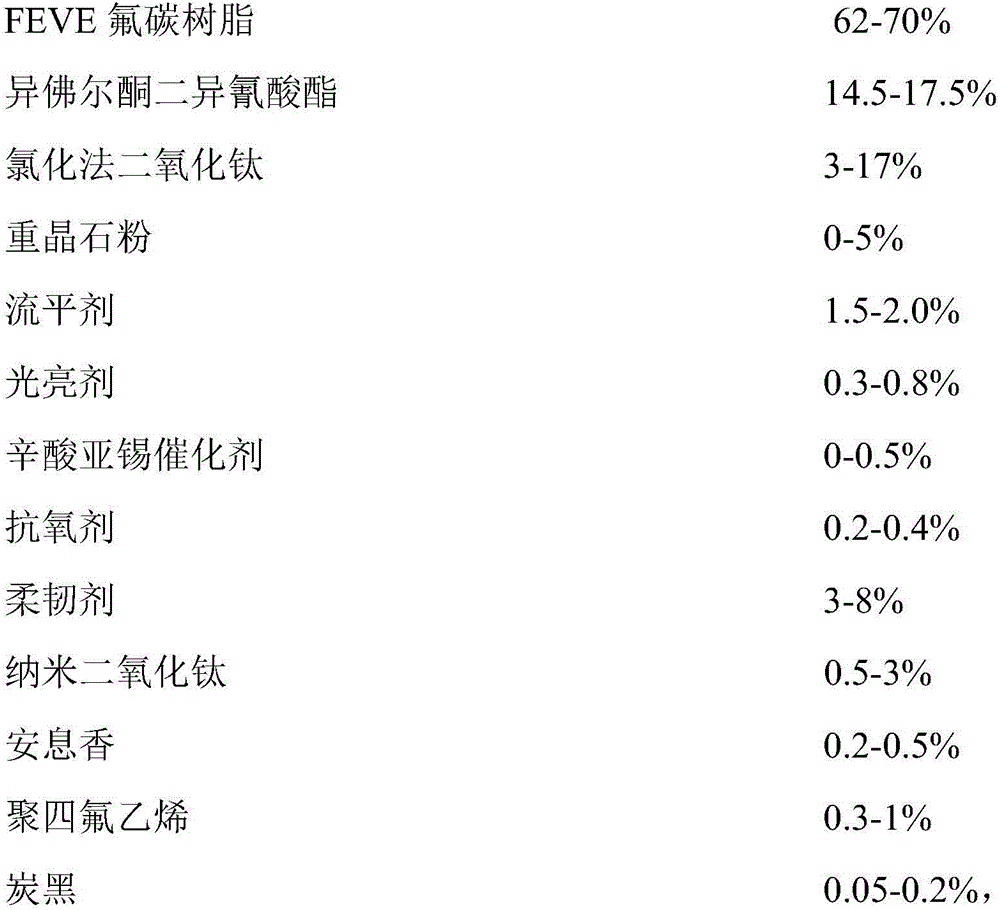

Super-weatherable pure-fluorine carbon powder coating for aluminum surface and preparation method and application thereof

InactiveCN106833165AOvercome adhesionOvercoming impact resistancePowdery paintsVinyl etherAntioxidant

The invention discloses super-weatherable pure-fluorine carbon powder coating for aluminum surface and a preparation method and application thereof. The super-weatherable pure-fluorine carbon powder coating for aluminum surface is prepared from, by weight, 62-70% of FEVE (fluoroethylene vinyl ether) fluorocarbon resin, 14.5-17.5% of isophorone diisocyanate, 3-17% of chloride process titanium dioxide, 0-5% of barite powder, 1.5-2.0% of a leveling agent, 0.3-0.8% of a brightener, 0-0.5% of stannous octoate catalyst, 0.2-0.4% of an antioxidant, 3-8% of a softener, 0.5-3% of nano titanium dioxide, 0.2-0.5% of benzoin, 0.3-1% of polytetrafluoroethylene, and 0.05-0.2% of carbon black. The super-weatherable pure-fluorine carbon powder coating for aluminum surface is brand-new pure-fluorine carbon powder coating employing fluorocarbon resin as base material with no other resin doped, weatherability of a coating film is improved significantly, and the problem that domestic existing fluorocarbon powder coatings are poor in adhesion, impact resistance and yellowing resistance and have apparent cedrate can be solved.

Owner:山东千江粉末科技有限公司

Agglomeration of titania

InactiveUS7931886B2Conducive to agglomerationImprove bindingPigmenting treatmentIron oxides/hydroxidesChloride process

According to the present invention there is provided a process for the agglomeration of titania slag particles comprising providing titania slag at a d50 particle size of below 106 μm; mixing the slag particles with an organic binder; and agglomerating the mixture of the slag particles and organic binder into agglomerated particles with a d50 particle size in the range from 106 μm to 1000 μm. The agglomerated particles have a (TiO2 and FeO) / C mass ratio of more than 3.4. The invention also relates to such agglomated slag particles and a chloride process for the production of TiO2 wherein such agglomerated titania slag particles are used.

Owner:EXXARO TSA SANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com