Method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin

A technology of acetylene hydrochlorination and rare earth chloride, applied in physical/chemical process catalysts, hydrogen halide addition preparation, chemical instruments and methods, etc., can solve the problems of poor thermal stability, high price, easy sintering, etc. Low cost, simple operation, good catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

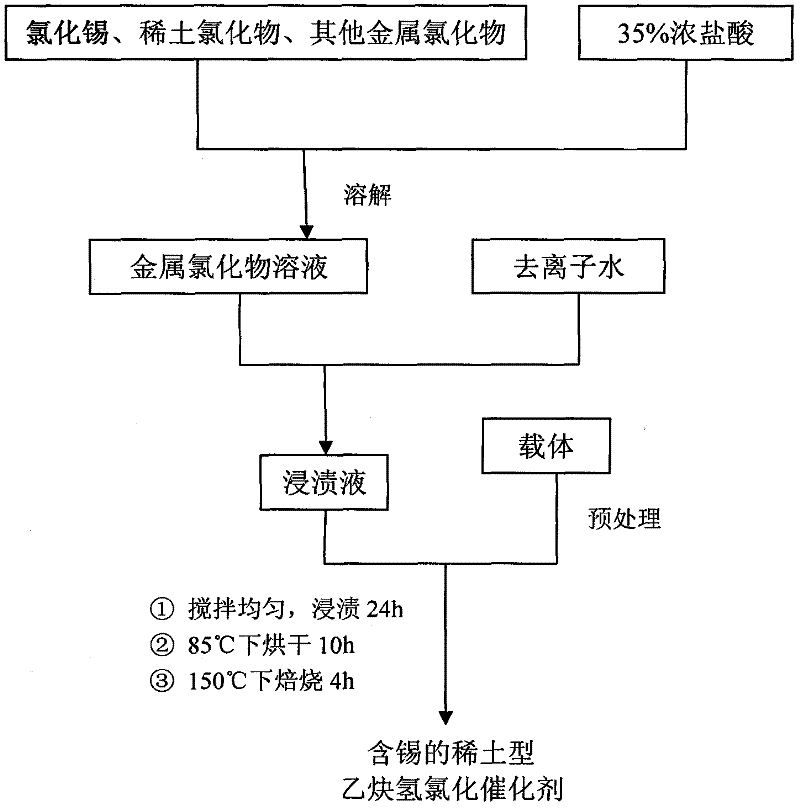

[0026] Example 1: Weigh 1.27gSnCl 2 ·2H 2 O, 0.43gCeCl 3 , 1.04gCuCl and 0.51gBiCl 3 In a beaker, add 4mL of concentrated hydrochloric acid to dissolve, and then add deionized water to make the dipping solution; weigh 10g activated carbon into the dipping solution, stir until evenly dipped, the dipping time is 24h, and then put it in an oven at 85℃ Dry for 10h, calcinate at 150℃ for 4h to obtain a kind of SnCl containing tin 2 -CeCl 2 -CuCl-BiCl 3 / C Acetylene hydrochlorination catalyst.

Embodiment 2

[0027] Example 2: Weigh 1.24g SnCl 2 ·2H 2 O, 0.41gCeCl 3 , 1.22gCuCl and 0.45gBi(NO 3 ) 3 ·5H 2 O in a beaker, add 5mL concentrated hydrochloric acid to dissolve, and then add deionized water to prepare an immersion solution; weigh 10g of cerium-zirconium powder (burned at 400°C for two hours) into the immersion solution, stir until evenly dipped, The immersion time is 24 hours, and then it is put into an oven and dried for 10 hours at 85°C, and baked at 150°C for 4 hours to obtain a tin-containing rare earth SnCl 2 -CeCl 2 -CuCl-BiCl 3 / Cerium-zirconium powder acetylene hydrochlorination catalyst.

Embodiment 3

[0028] Example 3: Weigh 1.42gSnCl 2 ·2H 2 O, 1.45gCuCl and 0.33gBi(NO 3 ) 3 ·5H 2 O in a beaker, add 5mL concentrated hydrochloric acid to dissolve, and then add deionized water to prepare an immersion solution; weigh 10g of cerium oxide (cerium nitrate burned at 400°C for two hours) into the immersion solution, stir until evenly dipped, The immersion time is 24 hours, and then it is put into an oven and dried for 10 hours at 85°C, and baked at 150°C for 4 hours to obtain a tin-containing rare earth SnCl 2 -CuCl-BiCl 3 / CeO acetylene hydrochlorination catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com