Treatment method and device for wastewater from production of titanium dioxide

A technology for the production of wastewater and treatment methods, which is applied in natural water treatment, water treatment parameter control, water/sewage multi-stage treatment, etc. It can solve the problems of easy clogging of membrane pores, difficulty in cleaning and regeneration, and membrane fouling, so as to avoid membrane pollution. Pore clogging, avoiding clogging and reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

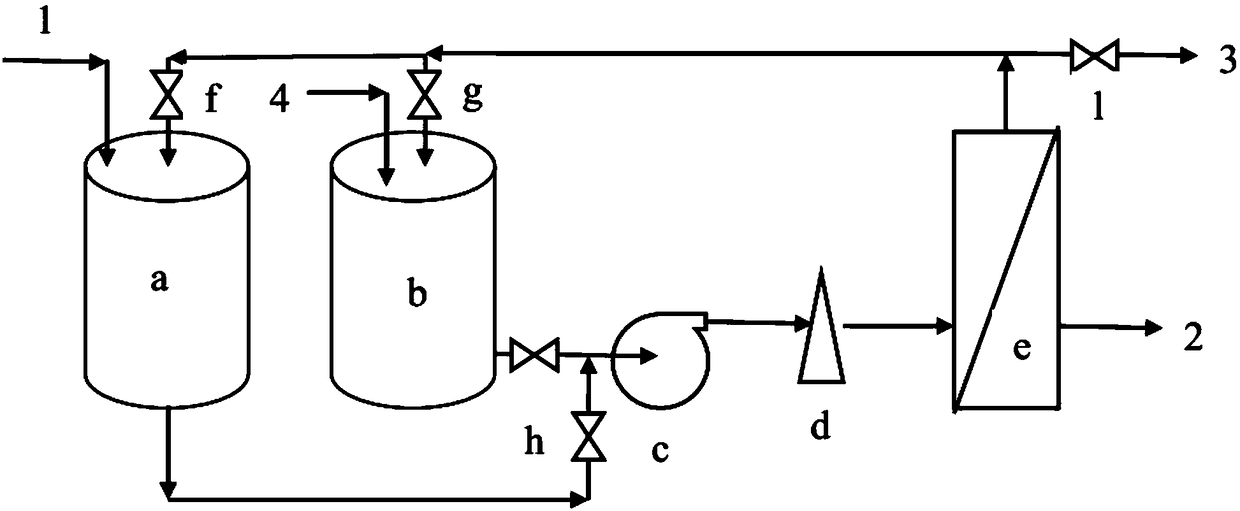

[0075] The same second washing water 1 is treated by the process of the present invention, and enters such as figure 1 Shown in the cross-flow filtration ceramic membrane filtration system. First, the secondary washing water 1 is poured into the ceramic membrane raw material tank a, filtered through the coarse filter d below 1mm through the feed pump c, and then poured into the ceramic membrane filter e for concentrated filtration, and the control pressure is 0.1MPa. The membrane surface velocity is 3m / s, and the temperature is 50°C. The membrane element is an alumina ceramic membrane with a pore size of 50nm. During the filtration process, the product water is used to recoil once every 20 minutes, and the recoil pressure is 0.5MPa. Control the concentration factor to 100. The flux of the membrane is 600~800 L / m 2 h or more. The turbidity of membrane filtration clear liquid 2 reached 0.25 NTU, the amount of metatitanic acid contained was 0, and the solid content of concen...

Embodiment 2

[0079] The same three washing water 1 is processed by the process of the present invention, and enters such as figure 1 Shown in the cross-flow filtration ceramic membrane filtration system. First, the three washing water 1 is pumped into the ceramic membrane raw material tank a, filtered through the coarse filter d below 1mm through the feed pump c, and then pumped into the ceramic membrane filter e for concentrated filtration, and the control pressure is 0.15MPa. The membrane surface velocity is 2.5m / s, and the temperature is 45°C. The membrane element is an alumina ceramic membrane with a pore size of 50nm. During the filtration process, the product water is used to recoil once every 20 minutes, and the recoil pressure is 0.5MPa. The control concentration factor is 150. The flux of the membrane is 550-800 L / m 2 h or more. The turbidity of membrane filtration clear liquid 2 reached 0.25 NTU, the amount of titanium dioxide contained was 0, and the solid content of concen...

Embodiment 3

[0083] The same waste acid 1 is processed by the process of the present invention, and enters such as figure 1 Shown in the cross-flow filtration ceramic membrane filtration system. First, the secondary washing water 1 is poured into the ceramic membrane raw material tank a, filtered through the coarse filter d below 1mm through the feed pump c, and then poured into the ceramic membrane filter e for concentrated filtration, and the control pressure is 0.12MPa. The membrane surface velocity is 3m / s, and the temperature is 50°C. The membrane element is an alumina ceramic membrane with a pore size of 20nm. During the filtration process, the product water is used to recoil once every 10 minutes, and the recoil pressure is 0.5MPa. Control the concentration factor to 100. The flux of the membrane is 200~600 L / m 2 h or more. The turbidity of membrane filtration clear liquid 2 reached 0.25 NTU, the amount of metatitanic acid contained was 0, and the solid content of concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com