Process for clean producing titanium dioxide and potassium hexatitanate wiskers by titanium iron ore or high-titanium dreg sub-molten salt

A technology of potassium hexatitanate whisker, titanium dioxide, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of low utilization rate of titanate resources, serious environmental pollution, high energy consumption, etc., Achieve the effect of easy comprehensive utilization, reduce environmental pollution, and reduce production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

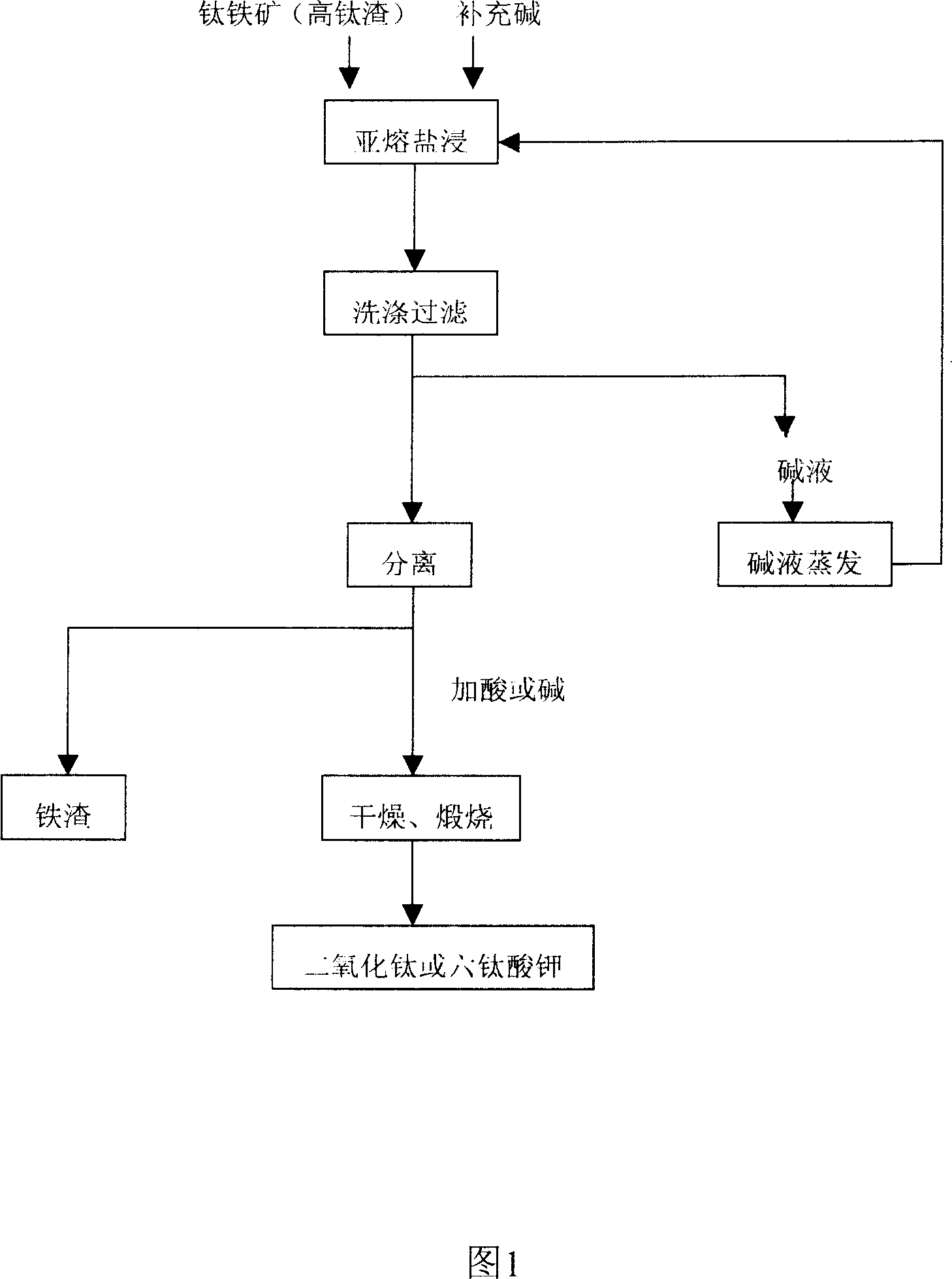

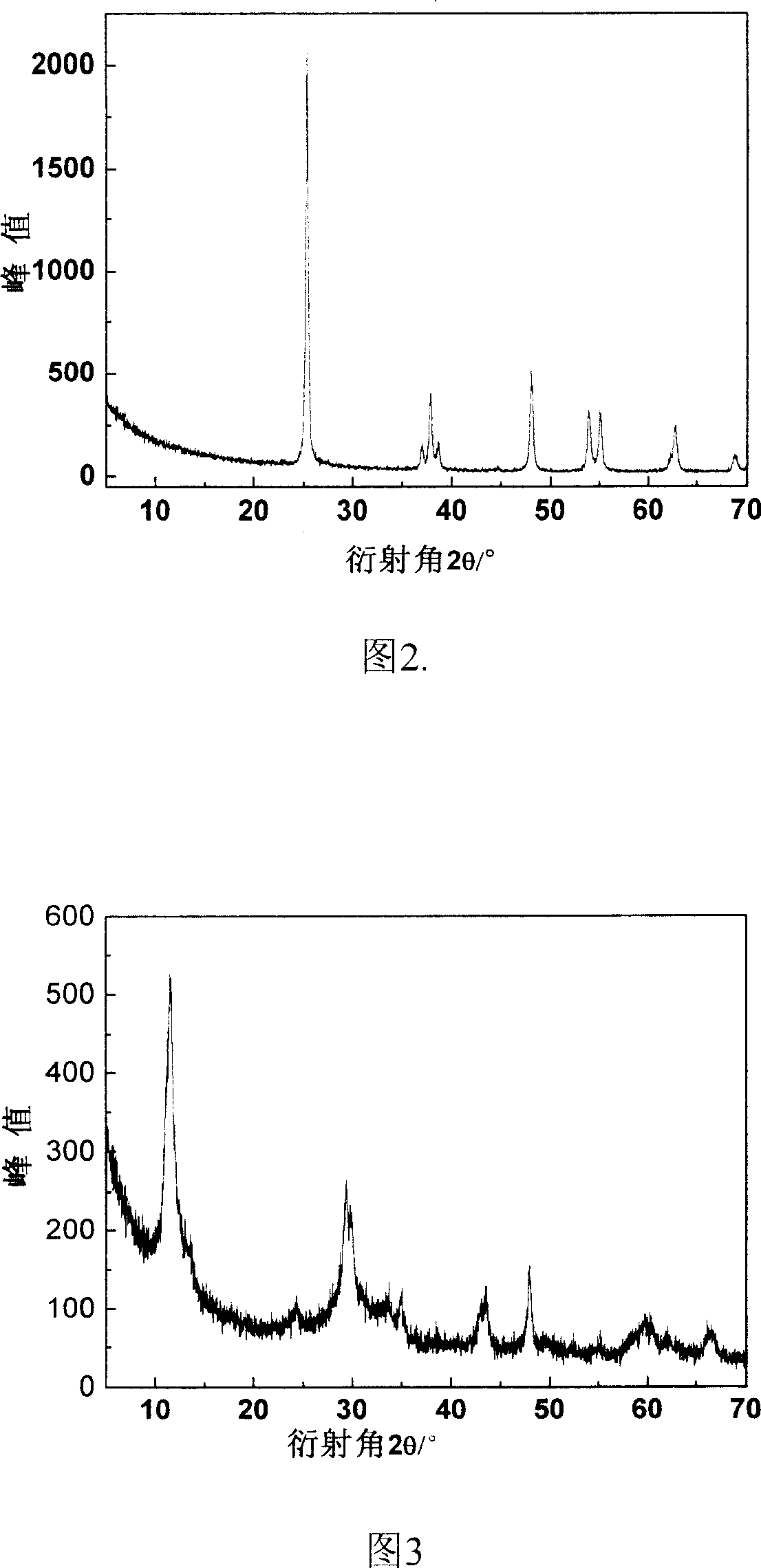

[0027] Please refer to Figures 1 and 2. The KOH solution that is circulated back to the reactor is heated to 240°C after part of the water is removed, and 95% of the ilmenite or high-titanium slag with a particle size of less than 200 mesh is added, and the reaction is carried out for 6 hours under complete mixing conditions, wherein KOH and ilmenite or The weight ratio of the high-titanium slag is 4:1; a mixed reaction product containing lye, titanate and iron-rich slag is obtained; the titanium conversion rate is over 99%. Wash and filter the mixed product. After washing, the temperature is 80°C; the mixed product of titanate and iron-rich slag is subjected to high-gradient magnetic separation, and the obtained titanate is added with water and filled with carbon dioxide gas to adjust the pH of the solution to 6, and keep it warm at 20°C 48 hours, separated, washed the solid with water, dried, and calcined at 500° C. for 10 hours to obtain a titanium dioxide product. The XRD ...

Embodiment 2

[0029] Please refer to attached picture 1. The KOH solution that is circulated back to the reactor is heated to 280°C after part of the water is removed, and 95% of the ilmenite or high-titanium slag with a particle size of less than 200 mesh is added, and the reaction is carried out for 4 hours under complete mixing conditions, wherein KOH and ilmenite or The weight ratio of the high-titanium slag is 6:1; a mixed reaction product containing lye, titanate and iron-rich slag is obtained; the titanium conversion rate is above 99%. Wash and filter the mixed product. After washing, the temperature is 140°C; perform high-gradient magnetic separation on the mixed product of titanate and iron-rich slag, add water to the obtained titanate, adjust the pH of the solution to 4 with HCl, and keep it at 60°C for 30 hours , separated, washed with water, dried, and calcined at 500-1000° C. for 0.5-10 hours to obtain a titanium dioxide product.

Embodiment 3

[0031] Please refer to attached picture 1. The KOH solution that is circulated back to the reactor is heated to 350°C after part of the water is removed, and 95% of the ilmenite or high-titanium slag with a particle size of less than 200 mesh is added, and the reaction is carried out for 2 hours under complete mixing conditions, wherein KOH and ilmenite or The weight ratio of the high-titanium slag is 8:1; a mixed reaction product containing lye, titanate and iron-rich slag is obtained; the titanium conversion rate is above 99%. The mixed product was washed and filtered, and the temperature after washing was 180°C; the mixed product of titanate and iron-rich slag was subjected to high-gradient magnetic separation, and the obtained titanate was added to water, and the pH of the solution was adjusted to 3 with HCl, and kept at 100°C for 2 hours, separated, washed the solid with water, dried, and calcined at 500-1000° C. for 0.5-10 hours to obtain a titanium dioxide product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com