Dechlorination method for chlorination process titanium extracting tailing slag

A technology of extracting titanium tailings and chlorination, which is applied in the field of metallurgy to achieve the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The described method uses the titanium extraction tailings after "high-temperature carbonization-low-temperature chlorination" of Panzhihua Iron and Steel as raw material for processing. The chloride ion content of the titanium extraction tailings is between 2.0% and 4.07%.

[0028] The specific chlorine removal method is:

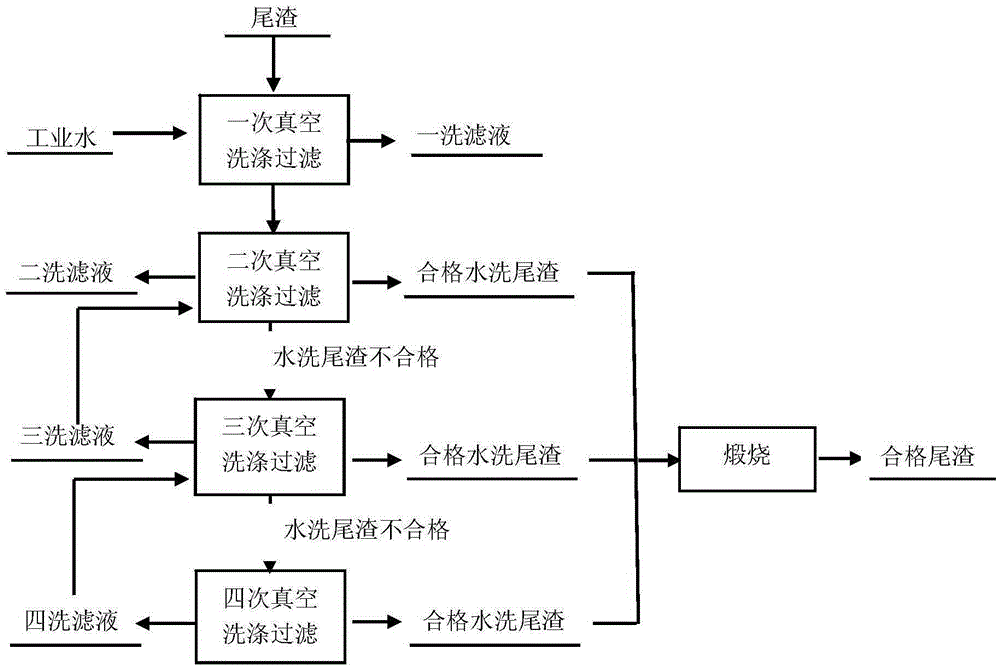

[0029] The tailings and water are mixed in a volume ratio of 1:2 to 4, soaked and stirred for 5 to 10 minutes, and then vacuum filtered. The vacuum is between 0.06 and 0.08 MPa to obtain a wash filtrate;

[0030] Then, in accordance with the ratio of slag water mass of 1:2 to 4, water is added for secondary washing, three washings and four washings in sequence; the ion mass fraction in the obtained preliminary dechlorination tailings can be reduced to less than 0.2%;

[0031] Among them, the four-wash filtrate is used as the third-wash water, the three-wash filtrate is used as the second-wash water, and the second-wash filtrate is used as the first-wash wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com