Pollution-free processing method and system for tailings generated by chlorination-process titanium extraction

A technology for extracting titanium tailings and processing methods, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve problems such as hindering large-scale utilization, and achieve the effect of reducing the content of chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

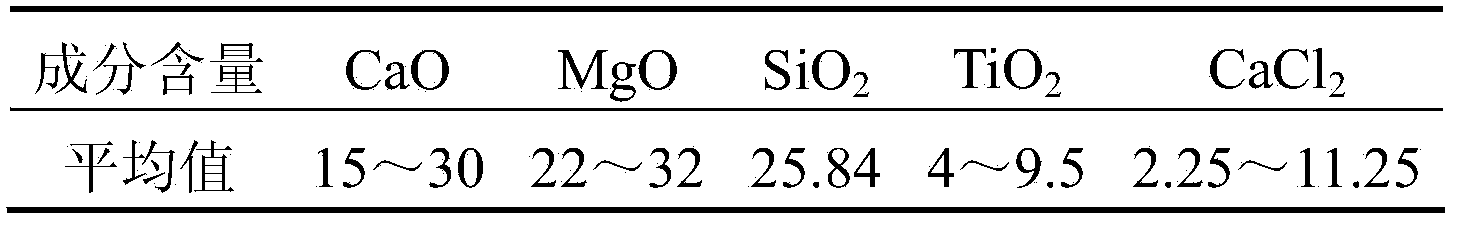

[0038] The tailings treatment capacity of this example is 2 tons.

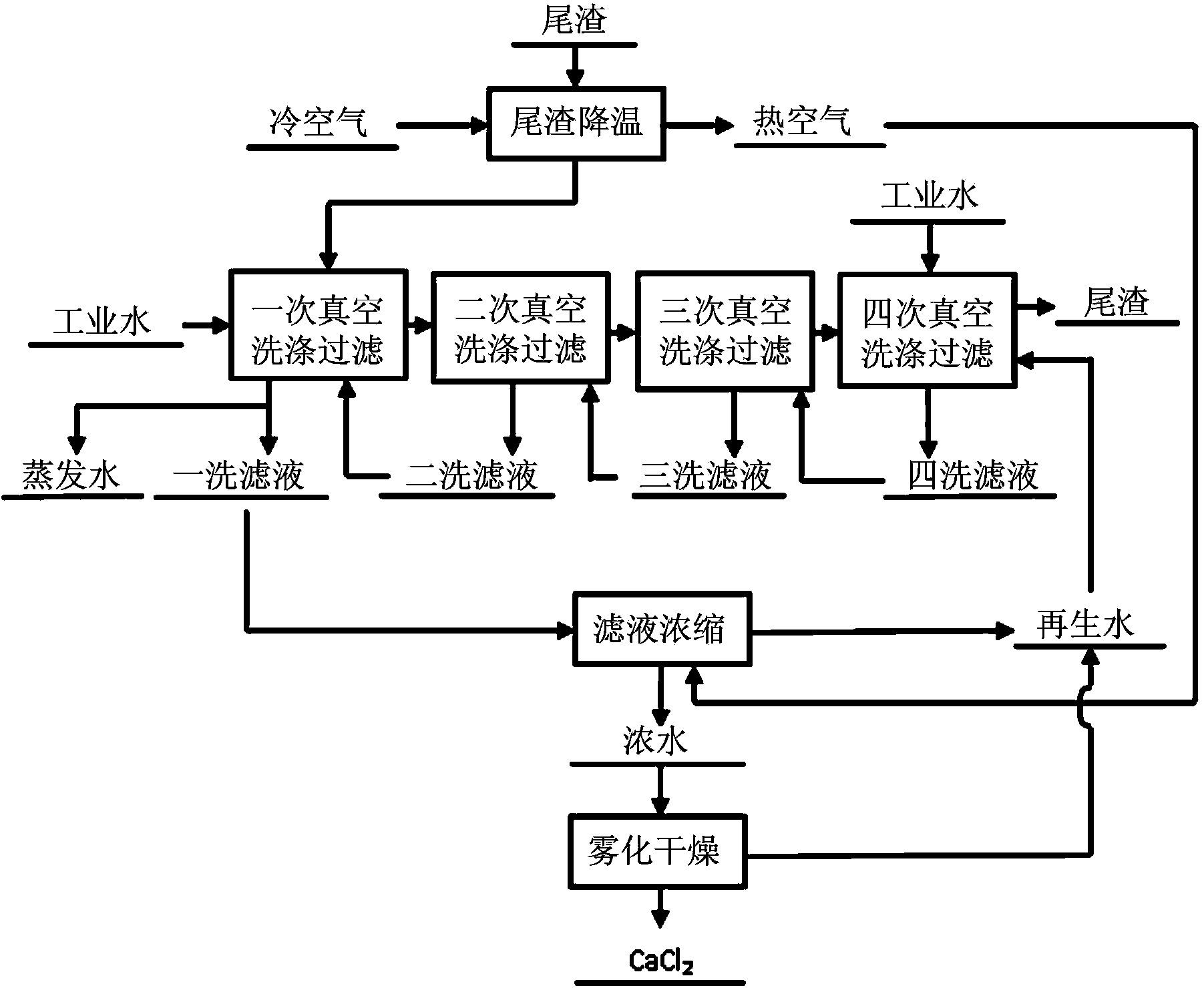

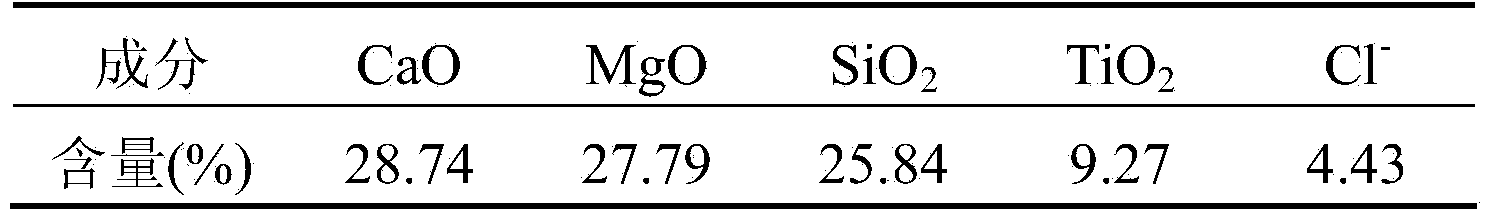

[0039] The temperature of the slag out of the furnace is 500°C, and it is cooled to 150°C by air purging at normal temperature. When the secondary washing liquid is used as the primary washing water, due to the large evaporation, it is necessary to add 0.25t of industrial water, and the tailing slag temperature is reduced to 30°C. After vacuum filtration, the water content in the slag was 15%. After 4 times of vacuum filtration, the chloride ion content in the slag was reduced to 0.12%, and the chloride ion removal rate reached 97.3%.

[0040] The first eluate is enriched with chlorine ions above 80g / L, and after concentration, atomization and drying, 25.6kg of calcium chloride containing water is obtained, and the yield of calcium chloride is about 80%.

example 2

[0042] The temperature of the slag out of the furnace is 400°C, and it is cooled to 125°C by normal temperature air purging. When the secondary washing liquid is used as the primary washing water, due to the large evaporation, it is necessary to supplement industrial water to make the volume ratio of slag water between 1:1~2. During the period, the temperature of the tailings was lowered to 30°C. After each vacuum filtration, the water content in the slag is about 15%. After 4 times of vacuum filtration, the chloride ion content in the slag is reduced to 0.15%, and the chloride ion removal rate reaches 96.6%.

[0043] The chloride ion of the eluent is enriched to more than 70g / L, and after concentration, atomization and drying, 24.3kg of calcium chloride containing water is obtained, and the yield of calcium chloride is about 76%.

[0044] Another aspect of the present invention provides a pollution-free treatment system for titanium tailings extracted by the chlorination meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com