Super-weatherable pure-fluorine carbon powder coating for aluminum surface and preparation method and application thereof

A technology for powder coating and aluminum surface, which is applied in the field of super-weather-resistant pure fluorocarbon powder coating for aluminum surface and its preparation field, which can solve the problems of reducing the weather resistance of the coating film, reducing the content of fluororesin, and obvious orange peel on the surface, etc. The effect of improving weather resistance, increasing hardness, and promoting sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

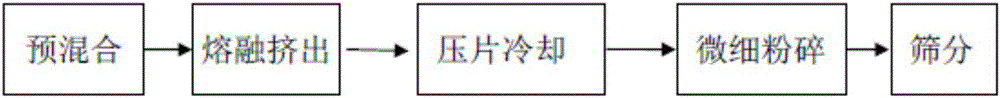

[0031] Prepare the aluminum surface with super strong weather resistance pure fluorocarbon powder coating according to the following steps:

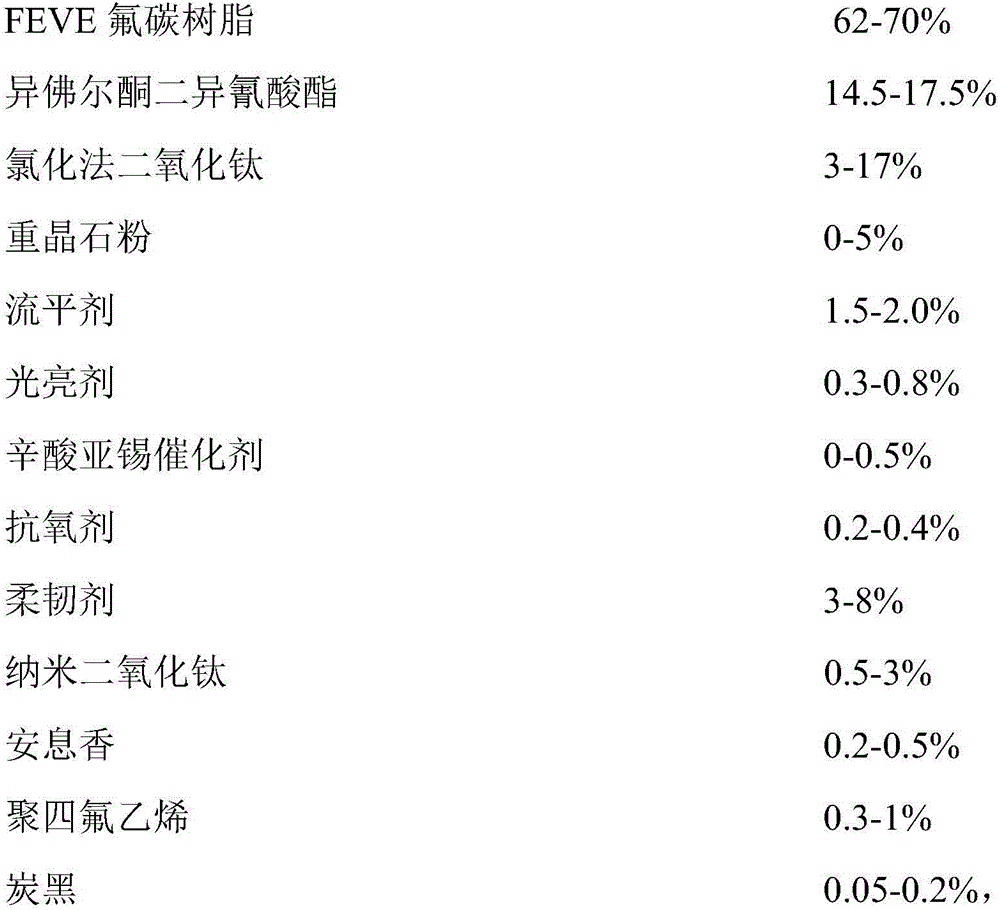

[0032] (1) premix the following raw materials by weight percentage:

[0033]

[0034] Wherein, the hydroxyl value of the FEVE fluorocarbon resin is 46mgKOH / g; the total amount of NCO of the isophorone diisocyanate trimer is 14.8%; the flexible agent has a particle size of 25 μm; the polytetrafluoroethylene The median particle size is 5 μm.

[0035] (2) Melt, knead and evenly disperse the pre-mixed raw materials with a twin-screw extruder, and extrude them. ℃, extrusion screw frequency 30-50Hz; tableting, coarse crushing;

[0036] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40-55Hz, and the frequency of the auxiliary mill is 25-45Hz;

[0037] (4) Pass the finely pulverized material through a 160-180 mesh standard sieve and classify it into a powder coating.

[0038] The powder ...

Embodiment 2

[0042] Prepare the aluminum surface with super strong weather resistance pure fluorocarbon powder coating according to the following steps:

[0043] (1) premix the following raw materials by weight percentage:

[0044]

[0045] Wherein, the hydroxyl value of the FEVE fluorocarbon resin is 47mgKOH / g; the total amount of NCO of the isophorone diisocyanate trimer is 15%; the particle size of the flexible agent is 27 μm; the polytetrafluoroethylene The median particle size is 4.5 μm.

[0046] (2) Melt, knead and evenly disperse the pre-mixed raw materials with a twin-screw extruder, and extrude them. ℃, extrusion screw frequency 30-50Hz; tableting, coarse crushing;

[0047] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40-55Hz, and the frequency of the auxiliary mill is 25-45Hz;

[0048] (4) Pass the finely pulverized material through a 160-180 mesh standard sieve and classify it into a powder coating.

[0049] The powder...

Embodiment 3

[0053] Prepare the aluminum surface with super strong weather resistance pure fluorocarbon powder coating according to the following steps:

[0054] (1) premix the following raw materials by weight percentage:

[0055]

[0056]

[0057] Wherein, the hydroxyl value of the FEVE fluorocarbon resin is 48mgKOH / g; the total amount of NCO of the isophorone diisocyanate trimer is 15.2%; the flexible agent has a particle size of 29 μm; the polytetrafluoroethylene The median particle size is 4.8 μm.

[0058] (2) Melt, knead and evenly disperse the pre-mixed raw materials with a twin-screw extruder, and extrude them. ℃, extrusion screw frequency 30-50Hz; tableting, coarse crushing;

[0059] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40-55Hz, and the frequency of the auxiliary mill is 25-45Hz;

[0060] (4) Pass the finely pulverized material through a 160-180 mesh standard sieve and classify it into a powder coating.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com