Radiation refrigeration surface based on fiber array and preparation method and application thereof

A radiation refrigeration and fiber technology, applied in the field of radiation refrigeration surface and its preparation, can solve the problems of complex preparation process of optical thin films and metamaterials, poor adhesion of porous materials, low infrared emissivity, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

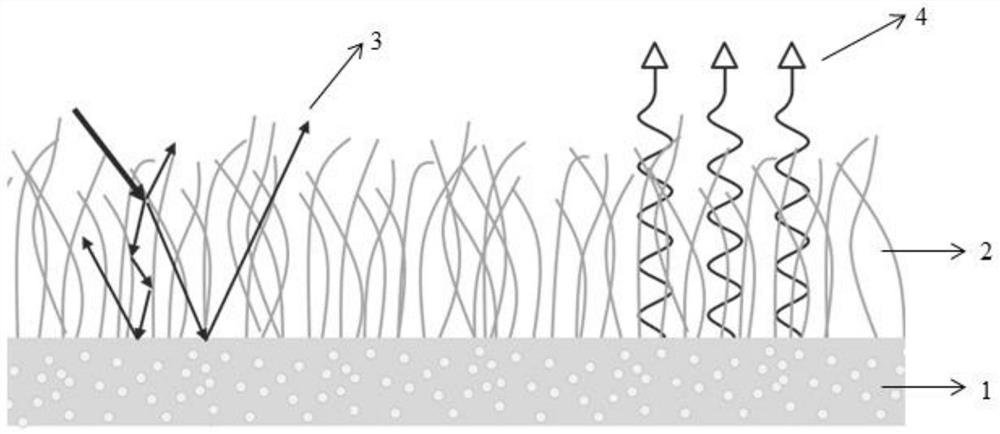

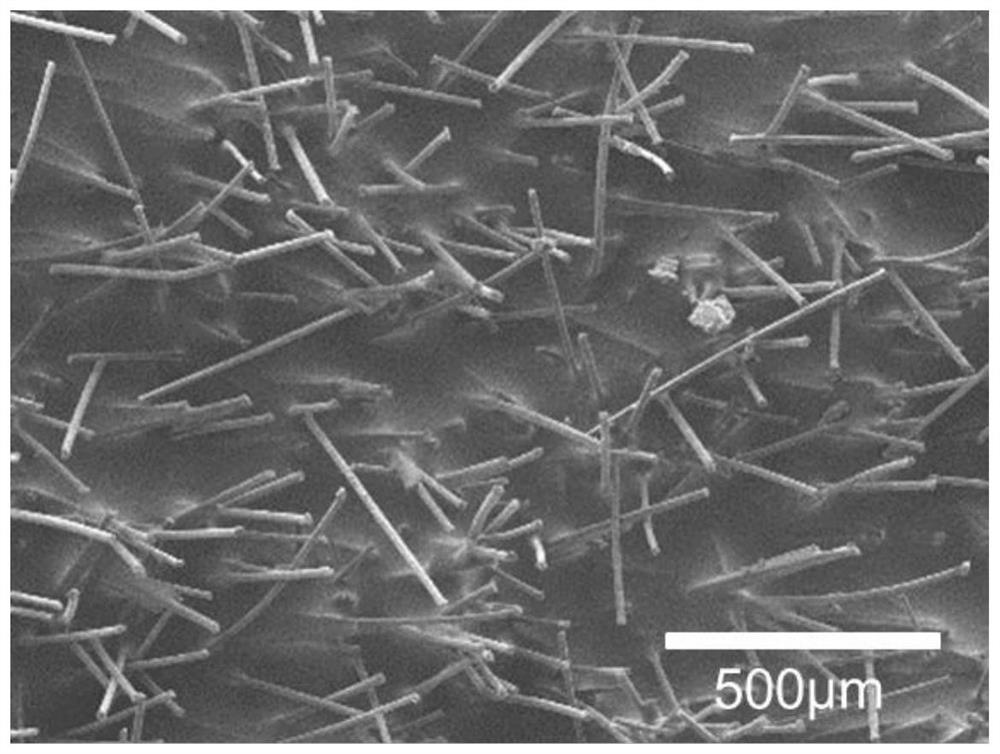

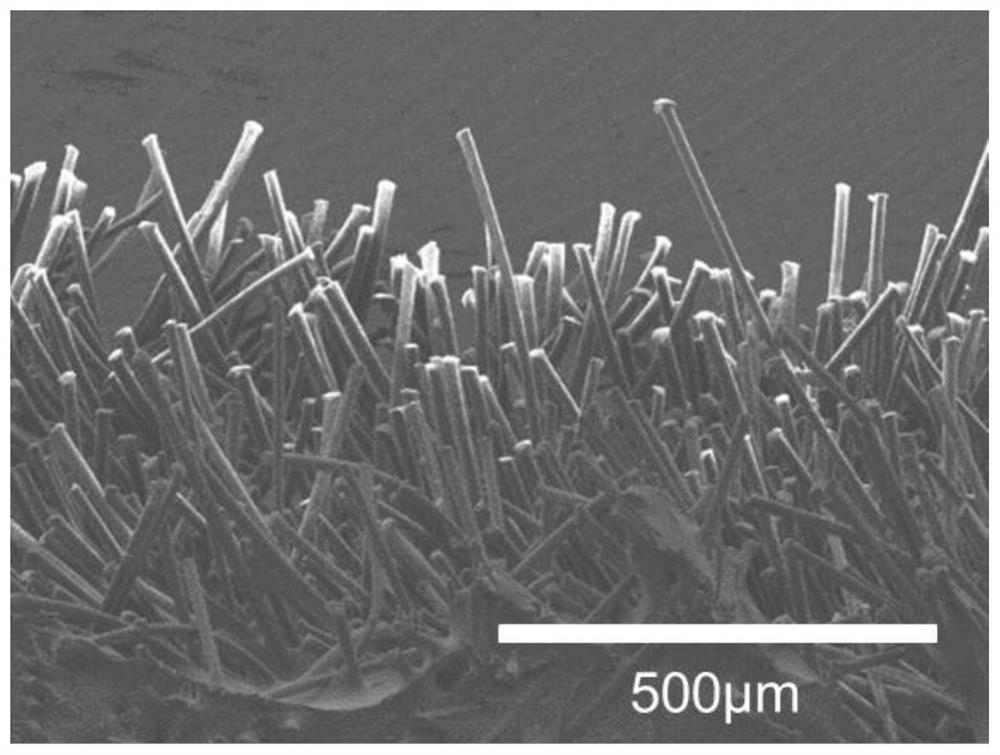

[0074] In this embodiment, a radiative cooling surface based on a fiber array is provided (the schematic diagram is as follows: figure 1 shown), the fiber array-based radiative cooling surface includes a bottom glue layer 1 and a top fiber array structure 2 . Wherein, the preparation raw materials of the bottom adhesive layer include rutile TiO with a mass ratio of 4:10:1 2 Nanoparticles, silicone rubber and silicone rubber curing agent, rutile TiO 2 The diameter of the nanoparticles is 230 nm, the type of silicone rubber and silicone rubber curing agent is Sylgard 184, and the thickness of the bottom adhesive layer is 150 μm; the top fiber array structure is composed of white nylon fibers, the diameter of the white nylon fibers is 14 μm, and the length is 150 μm. 400-600μm, the areal density of the top fiber array structure is 20g / m 2 .

[0075] The fiber array-based radiative cooling surface of this embodiment is prepared by the following method:

[0076] (1) Weigh 2g of...

Embodiment 2

[0090] The only difference between this example and Example 1 is that the rutile TiO 2 The diameter of the nanoparticles is 50 nm.

Embodiment 3

[0092] The only difference between this example and Example 1 is that the rutile TiO 2 The diameter of the nanoparticles is 500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com