Method for preparing titanium-rich material by directly reducing molten slag from vanadium-titanium-ferrum concentrate

A technology of vanadium-titanium iron concentrate and melting slag, which is applied in the direction of improving process efficiency, can solve the problems of long production time, large acid consumption and small dosage of titanium dioxide, and achieve TiO2 grade improvement, improved utilization effect, Effects of low calcium and magnesium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

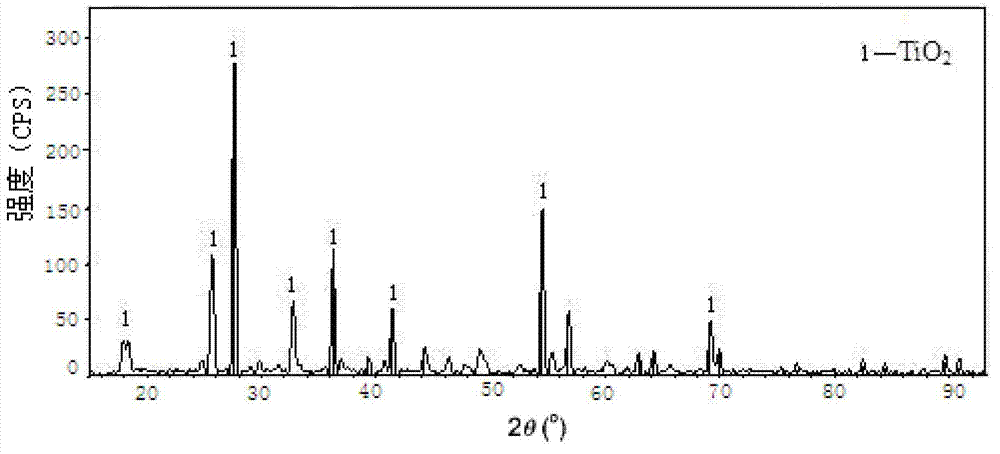

Embodiment 1

[0040] The vanadium-titanium-iron concentrate used in the present embodiment directly reduces slag 500g, wherein TiO 2 The FeO content is 50.5%, the FeO content is 4.5%, the MgO content is 10.3%, and the CaO content is 12.7%. Grinding with a ball mill (the ratio of ball to material is 5:1) and sieving with a set of sieves to obtain the raw material of vanadium-titanium-iron concentrate with a particle size of 75-1000um for direct reduction of slag. The temperature is 800°C, the oxidation time is 35 minutes, and the oxidation atmosphere is 99% oxygen for oxidation modification. Then the acid leaching residue was obtained by acid leaching under the conditions of hydrochloric acid concentration of 10%, acid leaching temperature of 50°C, acid leaching time of 30 minutes, liquid-solid phase mass ratio of 8:1, and stirring speed of 5 rpm. The acid leaching residue is obtained by alkaline leaching under the conditions of sodium hydroxide concentration of 12mol / L, alkali leaching tem...

Embodiment 2

[0042] The vanadium-titanium-iron concentrate used in the present embodiment directly reduces slag 500g, wherein TiO 2 The FeO content is 49.6%, the FeO content is 11.6%, the MgO content is 11.5%, and the CaO content is 13.1%. Grinding with a ball mill (the ball-to-material ratio is 7:1) and sieving with a sieve to obtain the vanadium-titanium-iron concentrate with a particle size of 75-1000um as the raw material for direct reduction of slag. The temperature is 800°C, the oxidation time is 35 minutes, and the oxidation atmosphere is 99% oxygen for oxidation modification, wherein the supplementary oxygen amount is 3 ml / min. After oxidative modification, it is sent to a laboratory tube furnace, and CO with a concentration of 95% is introduced to reduce the oxidation slag for 25 minutes under the condition of 750 ° C and the amount of carbon monoxide added at 5 ml / min to obtain modified slag. The modified slag was acid leached under the conditions of hydrochloric acid concentrat...

Embodiment 3

[0044] The vanadium-titanium-iron concentrate used in the present embodiment directly reduces slag 500g, wherein TiO 2 The FeO content is 51.2%, the FeO content is 3.3%, the MgO content is 10.1%, and the CaO content is 11.3%. Grinding with a ball mill (the ratio of ball to material is 8:1) and sieving with a set of sieves to obtain the raw material of vanadium-titanium-iron concentrate with a particle size of 75-1000um for direct reduction of slag. The temperature is 950°C, the oxidation time is 35 minutes, and the oxidation atmosphere is 99% oxygen for oxidative modification, and the amount of oxygen added during the modification process is 5 ml / min. After oxidative modification, the acid leaching residue was obtained by acid leaching under the conditions of hydrochloric acid concentration of 15%, acid leaching temperature of 50°C, acid leaching time of 50 minutes, liquid-solid phase mass ratio of 12:1, and stirring speed of 10 rpm . The acid leaching residue is obtained by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com